Dual-beam laser rapid forming and manufacturing method based on laser ultrasound

A laser rapid prototyping and manufacturing method technology, applied in the direction of improvement of process efficiency, improvement of energy efficiency, additive processing, etc., can solve problems such as insufficient absorption of laser energy, achieve improved heterogeneous nucleation rate, and increase crystal nucleation The effect of enhancing the rate and action effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

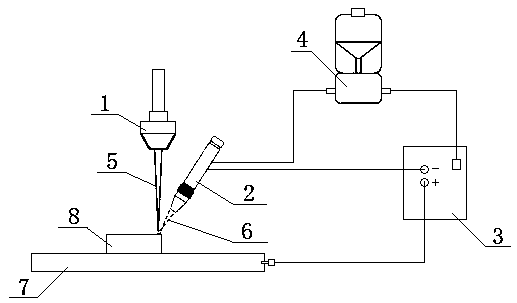

[0031] Embodiment 1, a double-beam laser rapid prototyping manufacturing method based on laser ultrasound, which includes the following steps:

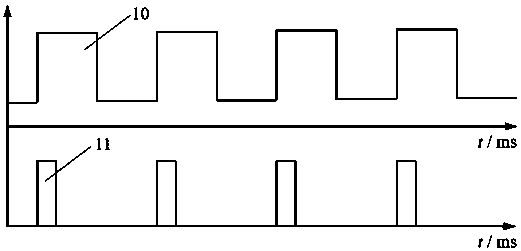

[0032] 1. The substrate 7 is made of 6061 aluminum alloy plate with a thickness of 4mm, and the particle size of the powder material in the powder feeder 4 is 200~300 mesh aluminum alloy powder; the substrate 7 is horizontally fixed on the rapid prototyping platform, and the substrate 7 is connected to the positive electrode of the power supply 3 , The main heat source laser 2 is connected to the negative pole of the power supply 3 . Adjust the relative position of the pulse oscillation laser 1 and the main heat source laser 2, so that the main heat source laser beam 6 emitted by the main heat source laser 2 and the pulse oscillation laser beam 5 emitted by the pulse oscillation laser 1 are located on the same plane, and the forward direction of the workbench is used as a reference , the action point of the pulse oscillating laser bea...

Embodiment 2

[0037] Embodiment 2, a double-beam laser rapid prototyping manufacturing method based on laser ultrasound, which includes the following steps:

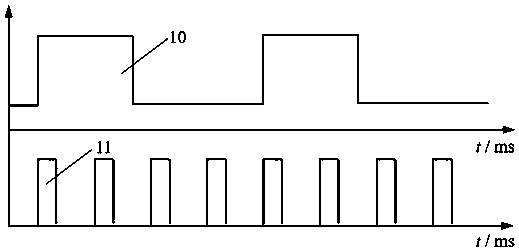

[0038] 1. The substrate 7 is made of 304 stainless steel plate with a thickness of 4mm, and the particle size of the powder material in the powder feeder 4 is 200~300 mesh austenitic stainless steel powder; the substrate 7 is horizontally fixed on the rapid prototyping platform, and the substrate 7 is connected to the power supply 3 Positive electrode, main heat source laser 2 connected to power supply 3 negative electrode. Adjust the relative position of the pulse oscillation laser 1 and the main heat source laser 2, so that the main heat source laser beam 6 emitted by the main heat source laser 2 and the pulse oscillation laser beam 5 emitted by the pulse oscillation laser 1 are located on the same plane, and the forward direction of the workbench is used as a reference , the action point of the pulse oscillating laser beam is behin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com