Composite lithium metal negative electrode based on MXene nanoribbon and general synthesis method of composite lithium metal negative electrode

A technology of metal anode and synthesis method, applied in battery electrodes, electrode manufacturing, lithium batteries, etc., can solve the problems of irreversible loss of battery capacity, battery short-circuit failure, uneven current density, etc., so as to reduce local current density and avoid lithium dendrites. The formation of , the effect of inhibiting volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

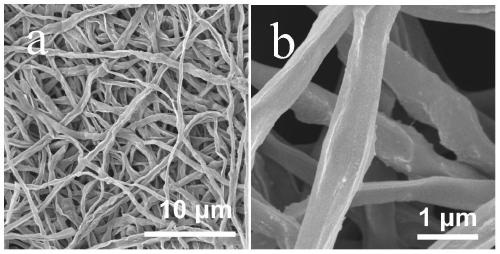

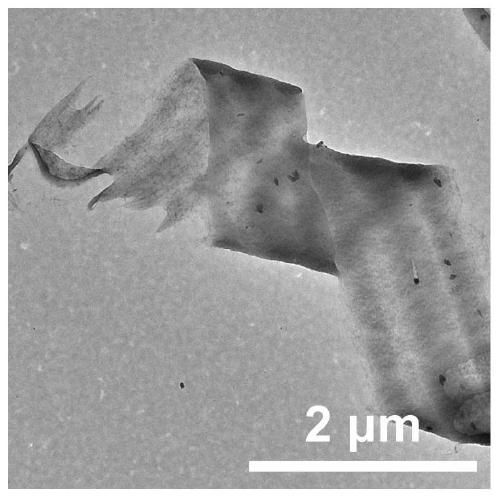

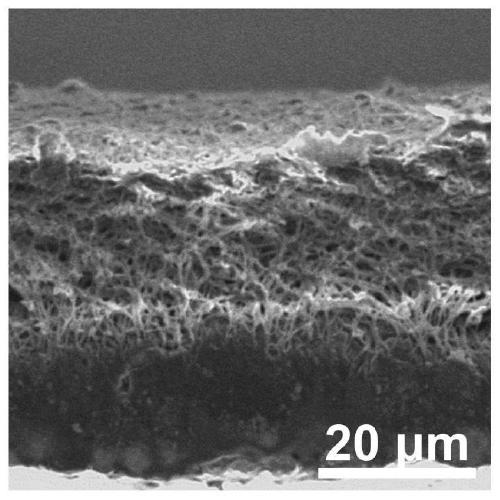

[0035] (1) Disperse MXene in N,N-dimethylformamide under normal temperature and pressure conditions to prepare a dispersion, the concentration of the dispersion is 10 mg mL -1 .

[0036] (2) Dissolve polyacrylonitrile in the MXene dispersion prepared in step (1) at 50°C and mix evenly, wherein the concentration of polyacrylonitrile in the mixed solution is 100 mg mL -1 .

[0037] (3) Dissolve the swelling agent in N,N-dimethylformamide at 60°C to form a homogeneous solution, the concentration of the swelling agent solution is 200mg mL -1 . The swelling agent is one or more mixtures of polyvinylpyrrolidone and polyvinyl alcohol.

[0038] (4) Put the mixed solution described in step (2) into syringe A, put the solution in step (3) into syringe B, and use an electrospinning machine to carry out coaxial electrospinning, and the mixed solution described in step (2) For the outer layer solution, the advancing speed is 1.0ml h -1 , the solution described in step (3) is the inner l...

Embodiment 2

[0043] (1) Disperse MXene in N,N-dimethylformamide under normal temperature and pressure conditions to prepare a dispersion, the concentration of the dispersion is 50 mg mL -1 .

[0044] (2) Dissolve polyacrylonitrile in the MXene dispersion prepared in step 1) at 55°C and mix evenly, wherein the concentration of polyacrylonitrile in the mixed solution is 110 mg mL -1 .

[0045] (3) Dissolve the swelling agent in N,N-dimethylformamide at 70°C to form a homogeneous solution, and the concentration of the swelling agent solution is 220mg mL -1 . The swelling agent is one or more mixtures of polyvinylpyrrolidone and polyvinyl alcohol.

[0046] (4) Put the mixed solution described in step (2) into syringe A, put the solution in step (3) into syringe B, and use an electrospinning machine to carry out coaxial electrospinning, and the mixed solution described in step (2) For the outer layer solution, the advancing speed is 1.2ml h -1 , the solution described in step (3) is the in...

Embodiment 3

[0051] (1) Disperse MXene in N,N-dimethylformamide under normal temperature and pressure conditions to prepare a dispersion, the concentration of the dispersion is 80mg mL -1 .

[0052] (2) Dissolve polyacrylonitrile in the MXene dispersion prepared in step 1) at 60°C and mix evenly, wherein the concentration of polyacrylonitrile in the mixed solution is 120 mg mL -1 .

[0053] (3) Dissolve the swelling agent in N,N-dimethylformamide at 75°C to form a homogeneous solution, the concentration of the swelling agent solution is 250mg mL -1 . The swelling agent is one or more mixtures of polyvinylpyrrolidone and polyvinyl alcohol.

[0054] (4) Put the mixed solution described in step (2) into syringe A, put the solution in step (3) into syringe B, and use an electrospinning machine to carry out coaxial electrospinning, and the mixed solution described in step (2) For the outer layer solution, the advancing speed is 1.2ml h -1 , the solution described in step (3) is the inner l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com