Fluorescent latex particles and preparation method thereof

A latex particle and fluorescence technology, applied in the field of fluorescent latex particles and their preparation, can solve the problems of uneven distribution of fluorescent molecules, poor monodispersity, and easy leakage, and achieves clean and clean surface, mild process conditions, and good monodispersity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing fluorescent latex particles, comprising a) mixing acrylate monomers, fluorescent dyes and ultrapure water at a weight ratio of 1-15:0.004-0.4:100, stirring, heating, and Soap-free emulsion polymerization occurs under the action of an initiator to obtain a first reaction product;

[0033] b) filtering and centrifuging the reaction product obtained in step a) to remove the supernatant, and washing the residue after removing the supernatant to obtain fluorescent latex particles.

[0034]What the present invention uses is soap-free emulsion polymerization, and so-called soap-free emulsion polymerization refers to the emulsion polymerization process that does not add emulsifier at all or only adds trace emulsifier (its concentration is less than the critical micelle concentration CMC) in the reaction process, also known as Emulsifier-free emulsion polymerization, the present invention does not add any emulsifier, when preparing f...

Embodiment 1

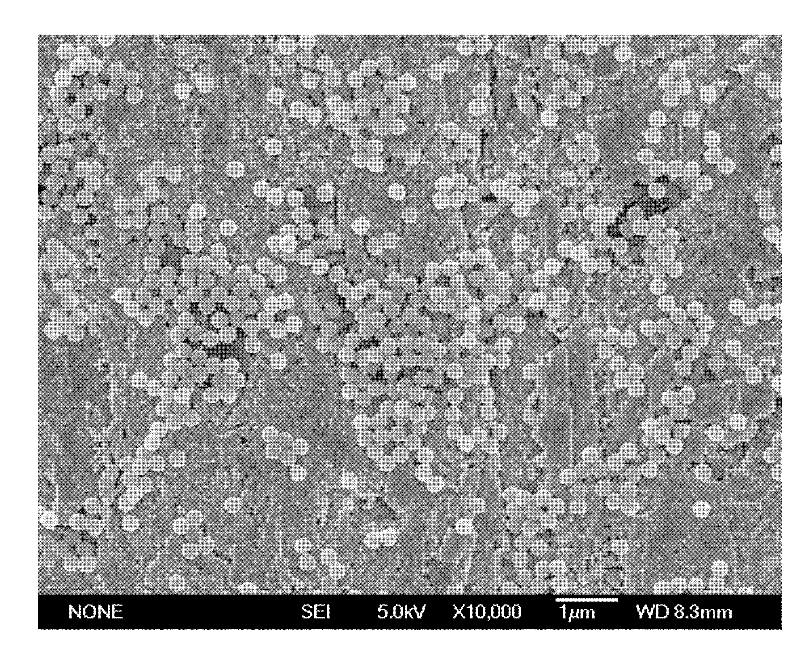

[0048] Example 1: Carboxyl fluorescent latex particles with a size of about 250nm

[0049] Add 570ml of ultra-pure water, 10ml of MMA, 0.02g of Rhodamine B, and 18mg of sodium styrene sulfonate into the reaction kettle, mix and heat together with stirring at a stirring speed of 150rpm, and pass nitrogen gas for 30min to 60min to exhaust the dissolved oxygen in the reaction system as much as possible. When the temperature was raised to 70°C, 20ml of potassium persulfate was added to start timing. After 90 minutes of reaction, MAA and MMA were added. The ratio between them was 1:1, and the reaction stopped after 2 hours. After cooling, the particles were filtered, and then the particles were centrifuged in a 50ml centrifuge tube, washed 3 times to obtain fluorescent latex particles.

Embodiment 2

[0050] Example 2: Carboxyl fluorescent latex particles with a size of about 300nm

[0051] Add 565ml of ultra-pure water, 15ml of MMA, 0.02g of rhodamine 6G, and 18mg of sodium styrene sulfonate into the reaction kettle, mix and stir together and heat at a stirring speed of 180rpm, and pass nitrogen gas for 30min to 60min to exhaust the dissolved oxygen in the reaction system as much as possible. do. When the temperature was raised to 70° C., 20 ml of potassium persulfate was added to start timing. After 120 minutes of reaction, MAA and MMA were added, and the ratio between them was 1: 1. The reaction stopped after continuing for 2 hours. After cooling, the particles were filtered, and then the particles were centrifuged in a 50ml centrifuge tube, washed 3 times to obtain fluorescent latex particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com