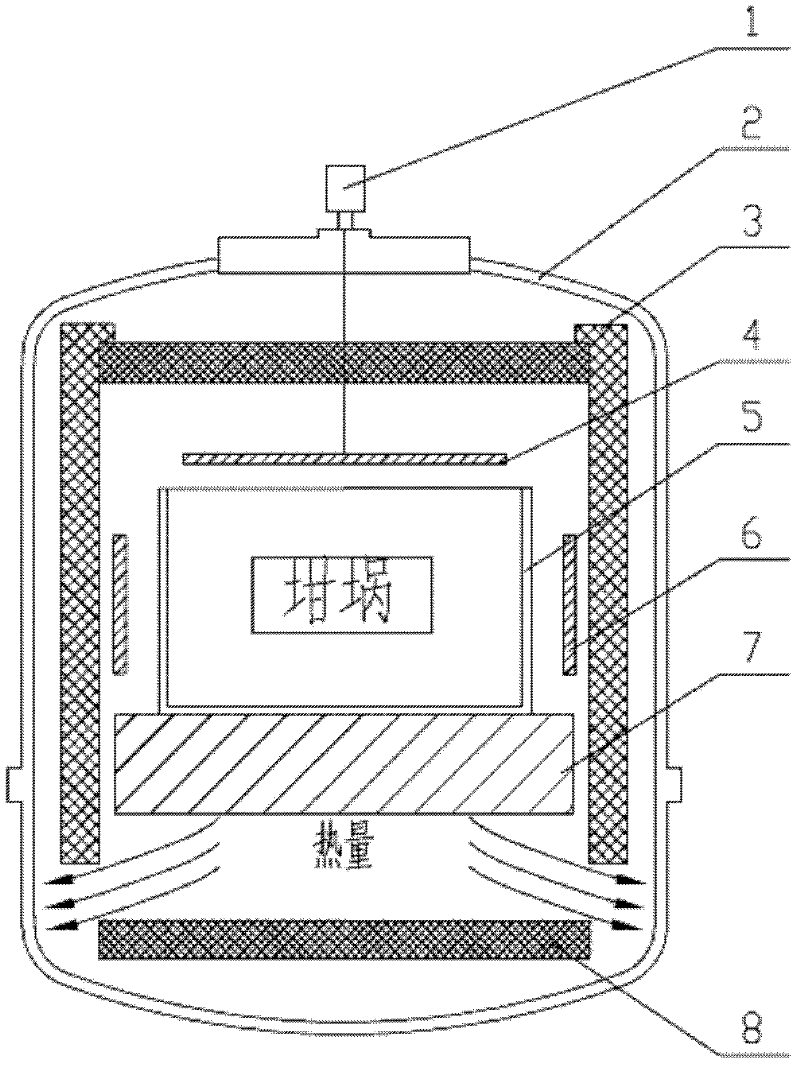

Closed cooling system of gas cooled polysilicon ingot furnace

A polycrystalline silicon ingot furnace and cooling system technology, applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve problems such as failure to make breakthroughs in technological improvement, and achieve stability, convenient operation, and accurate temperature control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

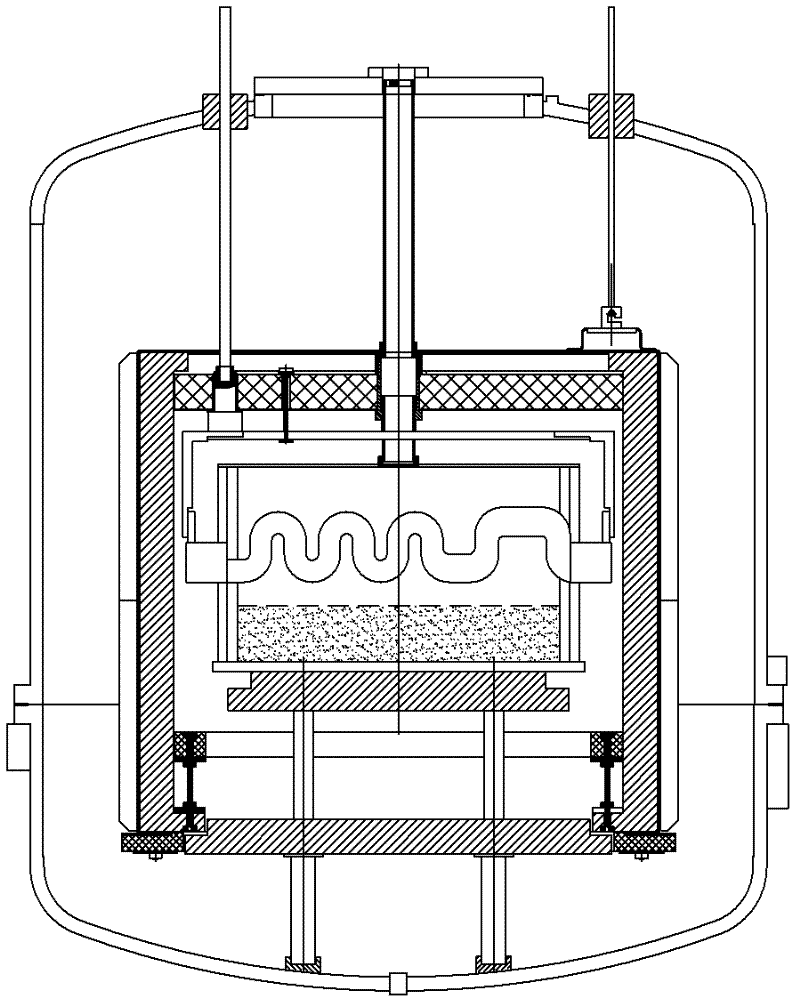

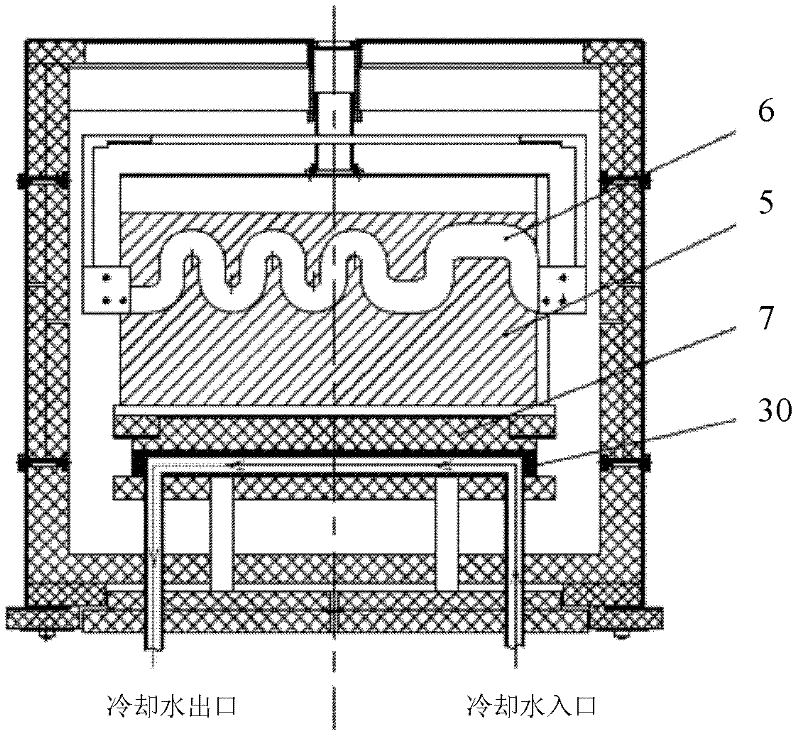

[0067] The present invention will be further described below in conjunction with accompanying drawing.

[0068] The improved structure heat exchange table for polysilicon ingot furnace is used to place the crucible of polysilicon ingot furnace and realize heat exchange, usually made of graphite. The heat exchange platform is provided with a gas inlet and a gas outlet, and a cooling air channel is arranged inside the heat exchange platform, and is connected with the aforementioned gas inlet and gas outlet.

[0069] Usually, based on the processing method, graphite material cannot be processed into internal channels with changing shapes without cutting. Therefore, the commonly used method is to divide it into a layered structure, slot the two layers according to the designed channel shape, and then put the two layered structures together to obtain heat exchange table products with various shapes and structures.

[0070] As a special case, the heat exchange platform does not rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com