Sandy sound absorbing plate and preparation method thereof

A technology of sound-absorbing panels and sand, which is applied in chemical instruments and methods, ceramic products, and other household appliances. It can solve the problems of complicated production process and poor decoration of porous sound-absorbing materials, and achieve high purity without impurities. Excellent light stability and weather resistance, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

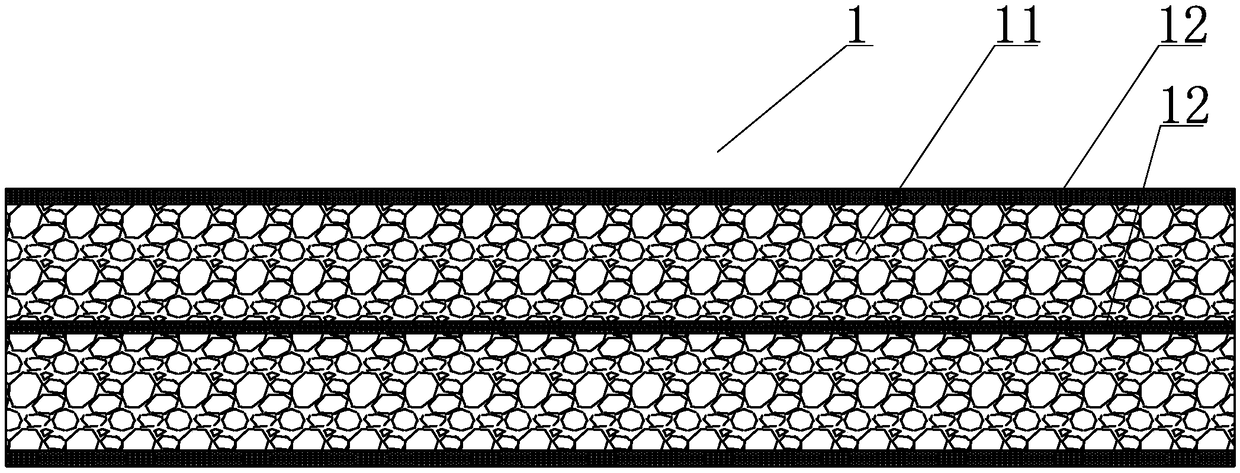

[0015] Below in conjunction with accompanying drawing, invention is described in further detail.

[0016] Such as figure 1 As shown, a sandy sound-absorbing panel is mainly composed of at least two sound-absorbing material bodies 1 that are combined and integrally formed. The sound-absorbing material body 1 is formed by pressing natural round quartz sand 11 and resin glue after mixing. Adhesive covering layers 12 coated on the surfaces of the two sound-absorbing bodies are arranged between the two sound-absorbing bodies. The integrally formed sound-absorbing material passes through the resin glue and the adhesive covering layer 12, and the gaps between the natural round-grained quartz sand 11 particles form sound-absorbing pores. Resin glue is a polymer synthetic resin. It is a kind of hydrocarbon whose main chain does not contain unsaturated structure synthesized by various resin materials. It can be used to make acrylate coatings, or it can be polymer resins such as epoxy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com