Patents

Literature

58results about How to "High Mohs hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

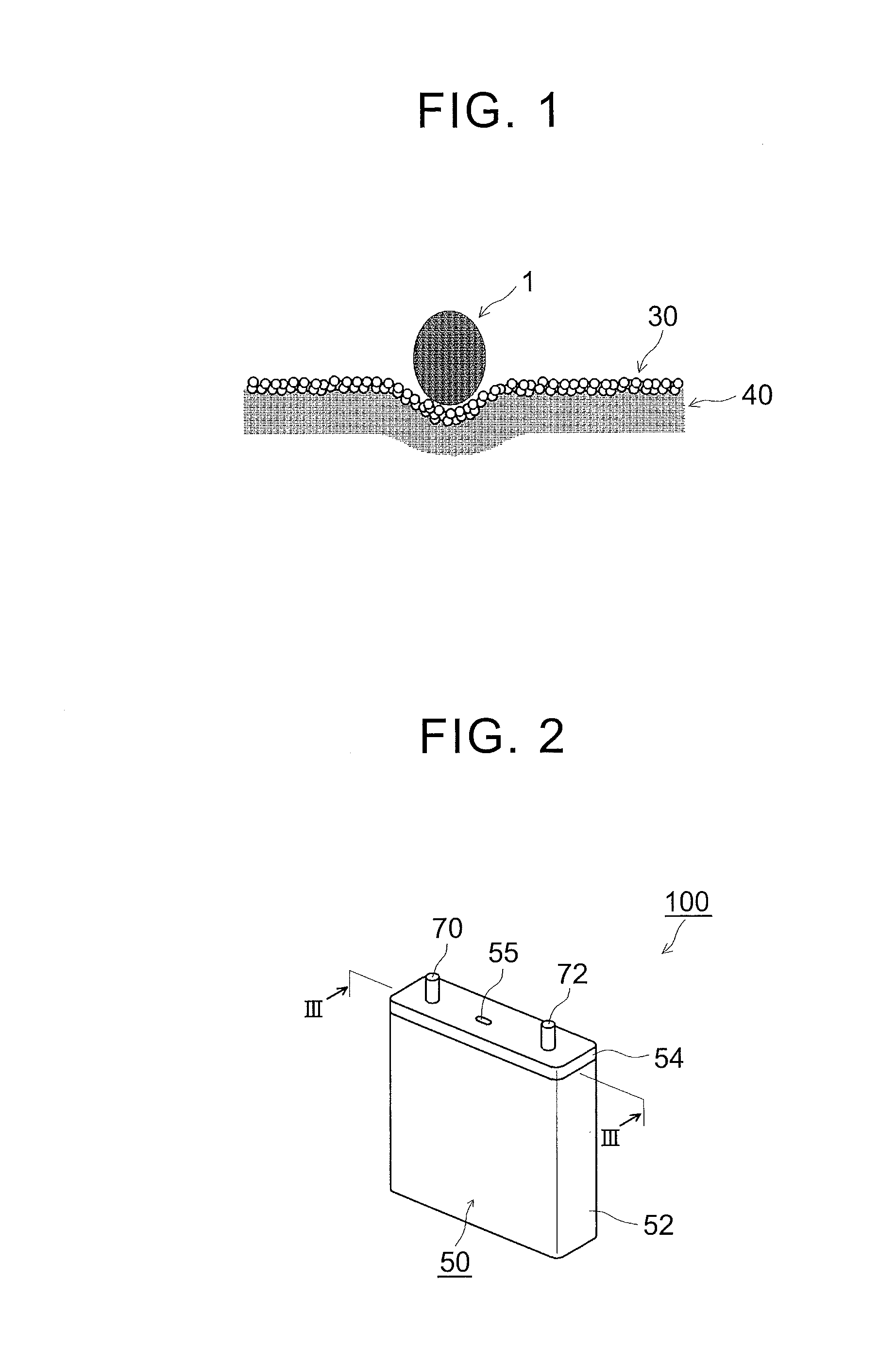

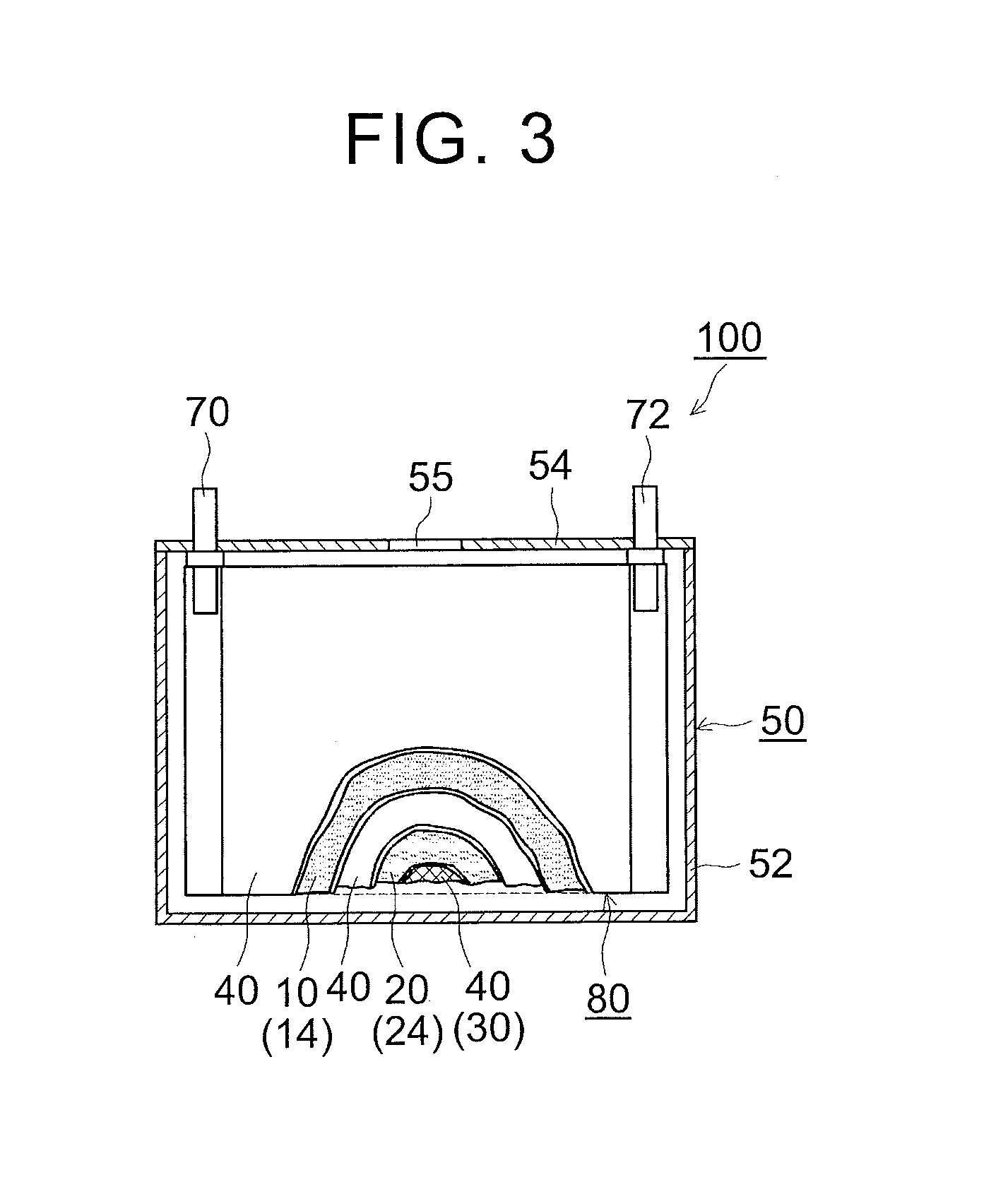

Nonaqueous electrolyte secondary battery

ActiveUS20140170464A1Improve reliabilityLower resistanceFinal product manufactureCell component detailsPorosityHeat resistance

Owner:TOYOTA JIDOSHA KK

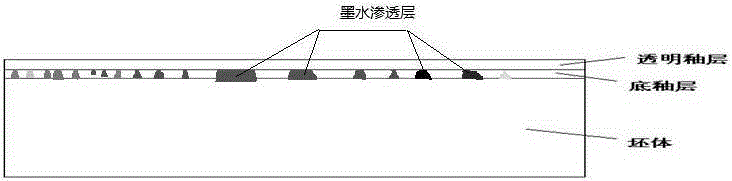

Inkjet infiltrating glazed porcelain tile and preparation method thereof

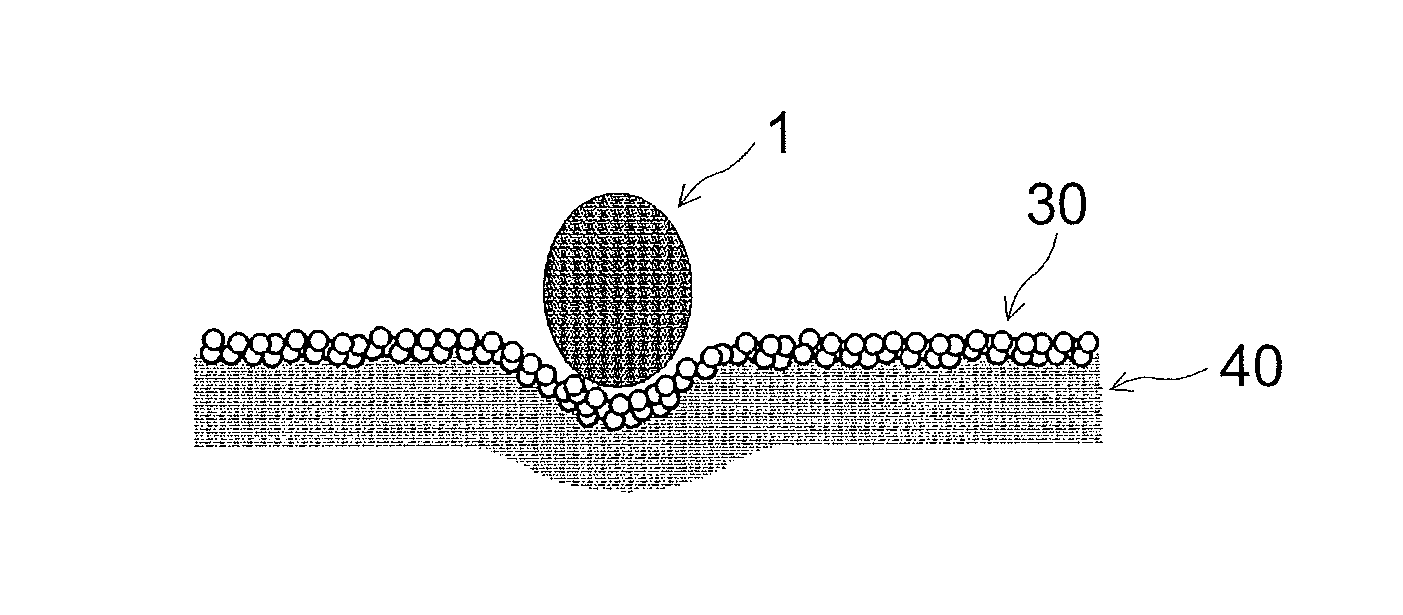

The invention relates to an inkjet infiltrating glazed porcelain tile and a preparation method thereof. The preparation method comprises the following steps: 1) preparing ground glaze slurry and transparent glaze slurry; 2) spraying the ground glaze slurry onto a blank, performing drying, coating a ground glaze layer with infiltrating ink and an infiltrating aid, and standing for more than 5 minutes to guarantee an infiltrating effect; 3) performing biscuit firing on the blank prepared in the step 2) at the temperature of 800 to 950 DEG C; 4) spraying the transparent glaze slurry onto the biscuit-fired blank in the step 3); 5) firing the blank, onto which the transparent glaze slurry is sprayed, prepared in the step 4) at the temperature of 1,150 to 1,230 DEG C, and then performing polishing to obtain the inkjet infiltrating glazed porcelain tile. Due to the fact that the ink infiltrates into the ground glaze layer after firing, the whole layer of transparent glaze is polished by a non-elastic module and then is polished to a ground glaze upper middle layer, so that local exposure can be avoided.

Owner:MONALISA GRP CO LTD

Ceramics with added jade powder

The present invention relates to a kind of ceramics to which the jade powder is added, which is characterized by that it uses clay, feldspar and quartz as base material or uses talcum, feldspar, kaolin, magnesium oxide and silicon oxide as base material or uses kaolin, quartzite, feldspar and phosphate as base material and adds the jade powder to said base material, and its composition comprises (wt%) 70-90% of base material and 10-30% of jade powder. The whiteness of the product made up by said method is increased, and its Mohs' hardness, compression strength and tensile strength are greatlyraised.

Owner:白石

Stone slab with patterns

The invention discloses a formula of a stone slab with artificial patterns. The formula comprises raw materials as follows: unsaturated polyester resin, a curing agent, quartz, glass fiber, color paste, an accelerant, a coupling agent, alloy powder, composite powder and water serving as a hydraulic bonding agent. The stone slab is energy-saving and environment-friendly due to the fact that the quartz and the glass fiber which are low in price and easy to obtain are taken as the raw materials of the formula and belongs to a novel environment-friendly building material, and various resources can be sufficiently used; the stone slab replaces natural quartz stone to serve as a high-grade decoration, over-exploitation of the natural quartz stone is effectively restrained, and environment protection and development of recycling economy and low-carbon economy are promoted; the stone slab has the advantages of non-toxic, tastelessness, non-radiation, no microcellular structure, dirt resistance, easiness in maintenance and high processability and can has a good lighting effect by the aid of projection of common light.

Owner:ZHUHAI SESALI HEALTH STONE CO LTD

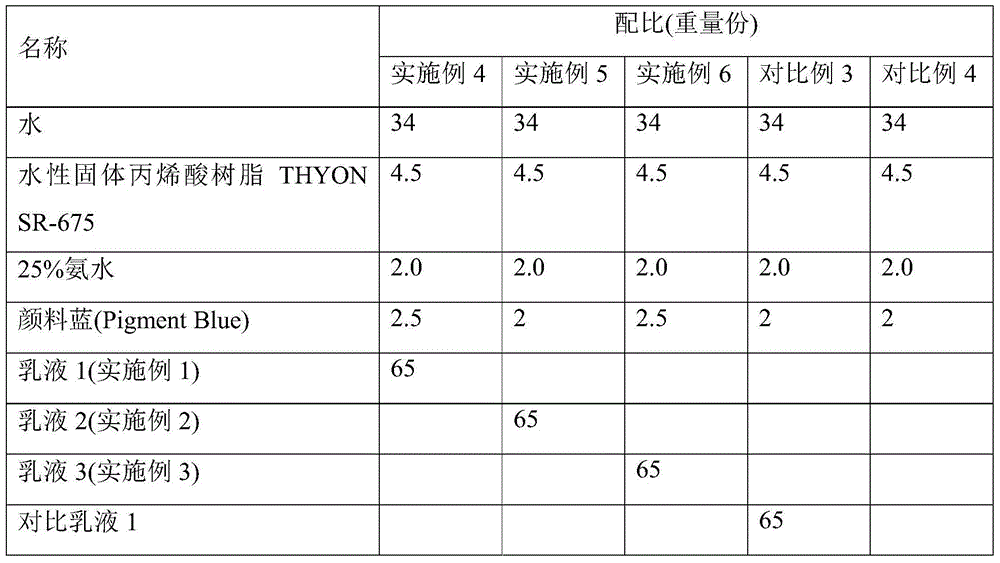

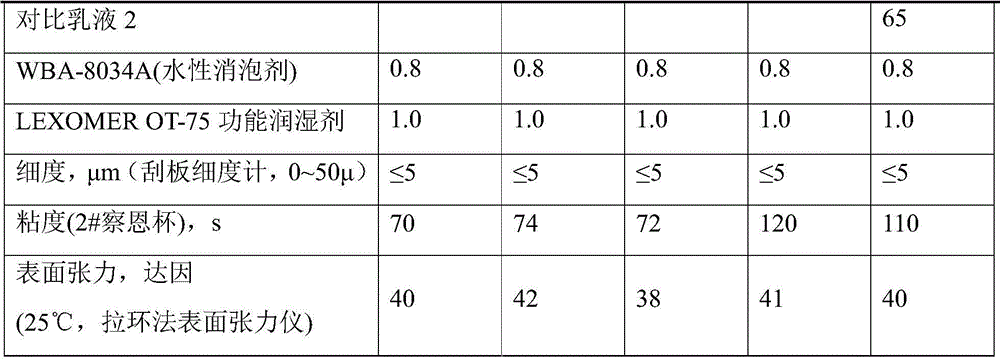

Paint composition containing modified tung oil and preparation method thereof

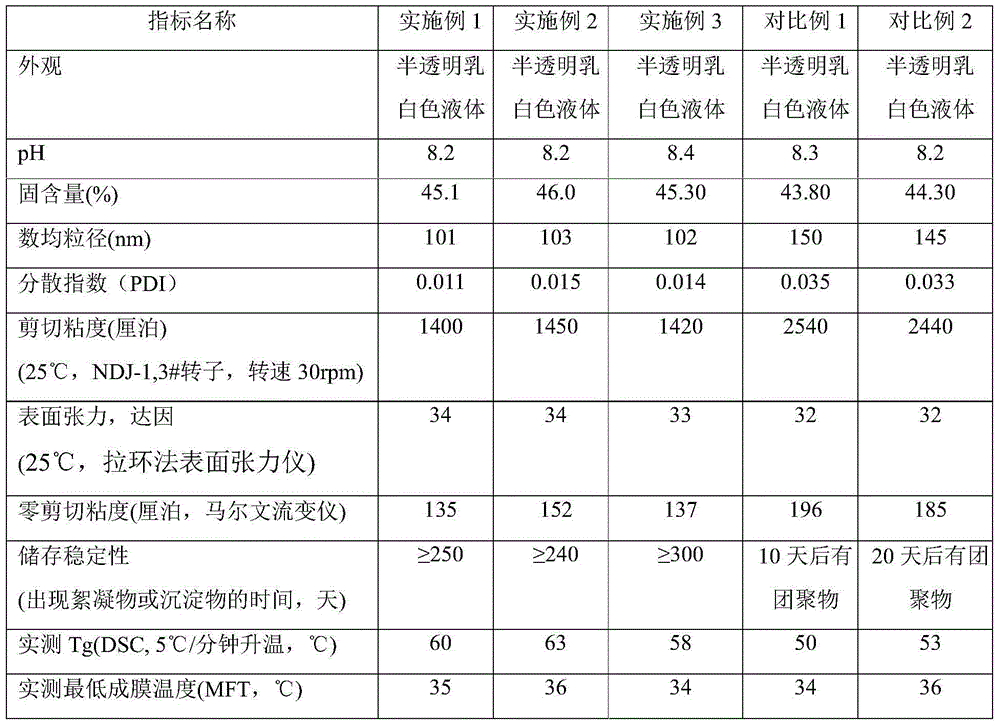

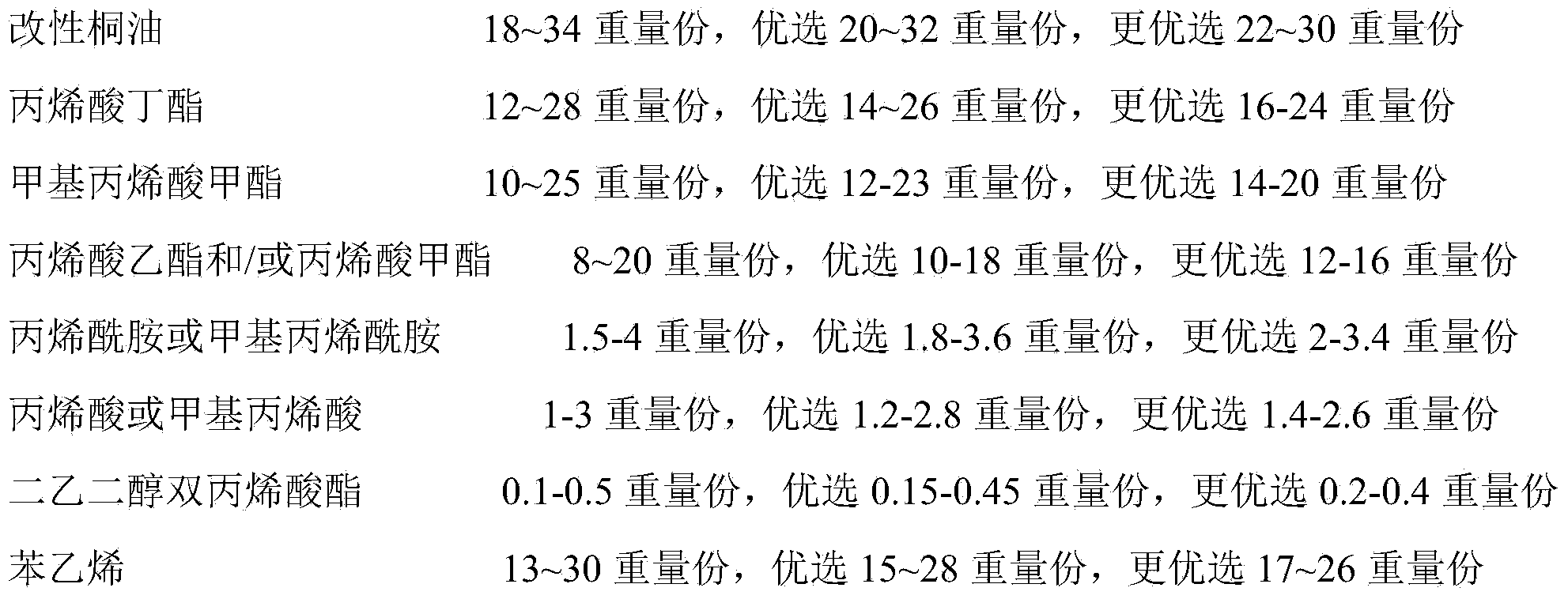

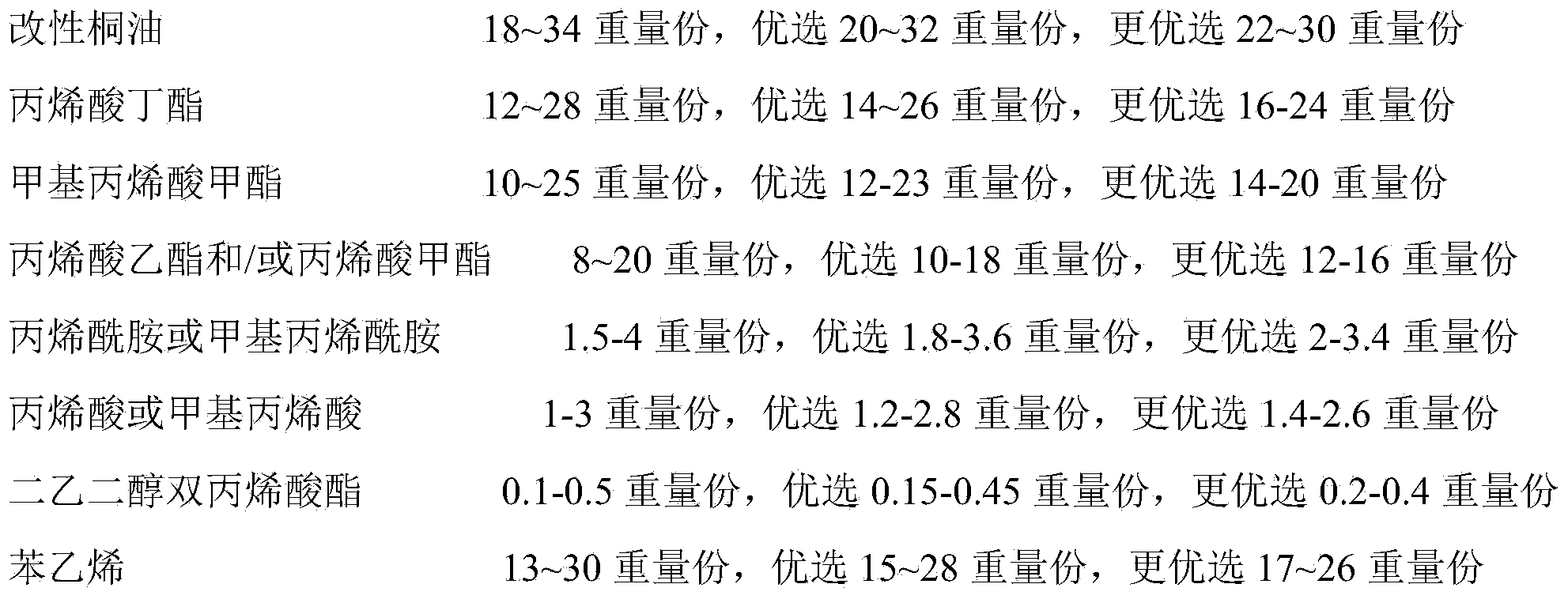

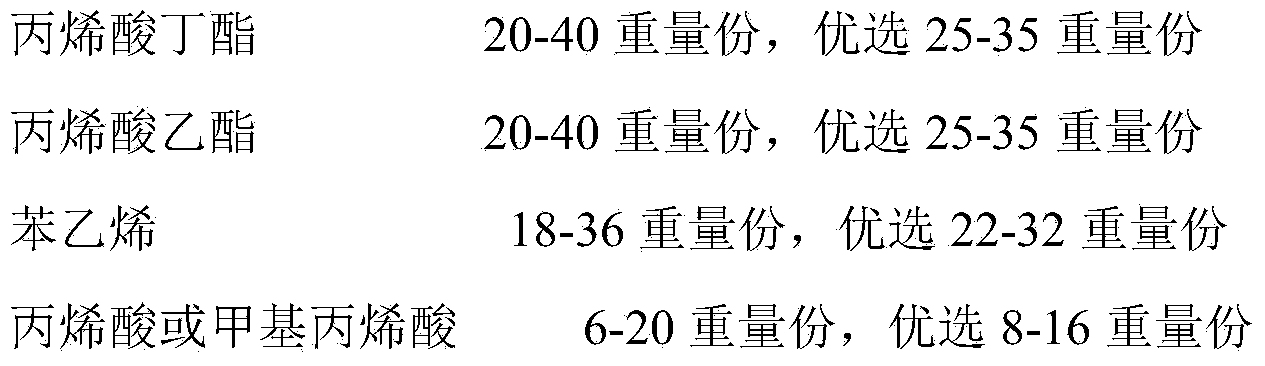

The invention discloses a modified tung oil-acrylate copolymer emulsion which is prepared by carrying out free radical emulsion polymerization reaction on modified tung oil, acrylate monomer, styrene and crosslinking monomer as monomer components and adding a diamidohydrazine or polyhydrazide crosslinking agent, wherein the modified tung oil is an addition reaction product prepared from tung oil and an alkene unsaturated surfactant with the molecular weight of 100-500 in a weight ratio of 100:(50-150). The invention also discloses a paint composition using the emulsion. The paint composition can be used for coating metals and plastics.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Aqueous coating composition and preparation method thereof

The invention discloses a modified tung oil-acrylic ester copolymer emulsion which contains a small quantity of acrylamide and acrylic monomer units. A preparation method of the emulsion comprises the following steps: carrying out free radical emulsion polymerization by taking modified tung oil, acrylic ester monomers, acrylamide, acrylic acid, styrene and cross-linking monomer as components of monomers, and then adding hydrazide or polyhydrazide cross-linking agents to prepare the emulsion, wherein the modified tung oil is a product of addition reaction between the tung oil and an olefinic unsaturated surfactant with molecular weight being 100-500 according to a weight ratio of 100 to (50-150). The invention also discloses an aqueous coating composition which uses the emulsion and aqueous acrylic resin containing acrylamide. Compared with the pigment, the coating composition has improved dispersion, is excellent in storage stability and can be used for coating metals and plastics.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Preparation method for artificial quartz plate with ice-crack grains

The invention discloses a preparation method for an artificial quartz plate with ice-crack grains. The quartz plate is prepared from quartz sand, quartz powder, inorganic pigments, a coupling agent, unsaturated resin, a curing agent and dry powder. The preparation method includes the steps of material preparation, stirring, material arrangement, pressing, thermal curing and fixed-thickness polishing. According to the provided preparation method for the artificial quartz plate with ice cracks, through adjustment of the matching ratio of the components and cooperation of the dry powder in use, amold is used for material arrangement, the prepared quartz plate has naturally distributed ice-crack grains, the hardness of the artificial quartz plate is large, the surface compactness is good, andthe artificial quartz plate is relatively excellent in stain repellent effect.

Owner:肇庆爱博新材料科技有限公司

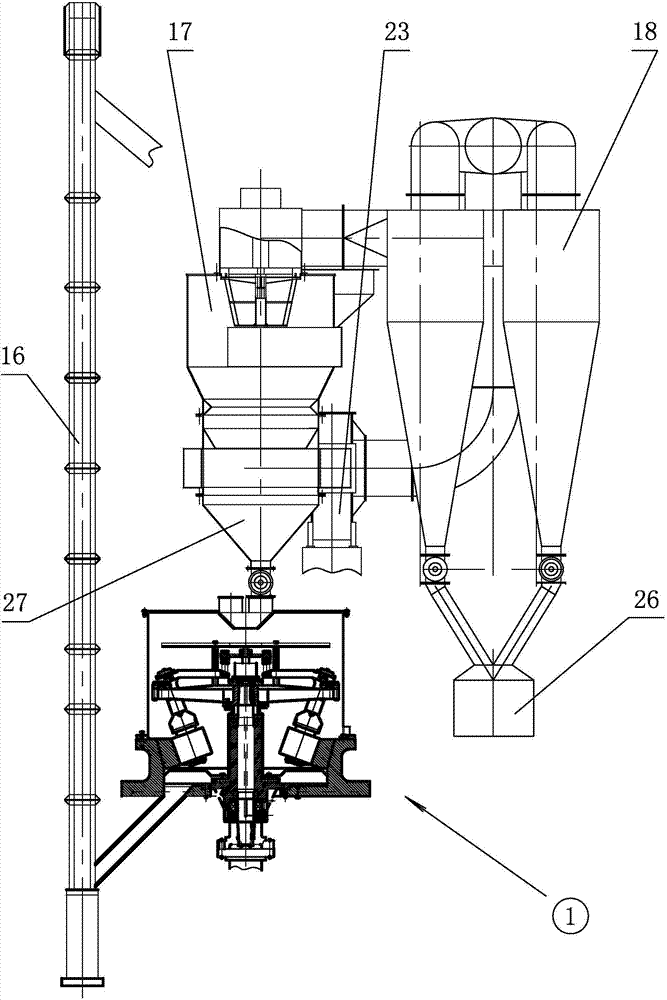

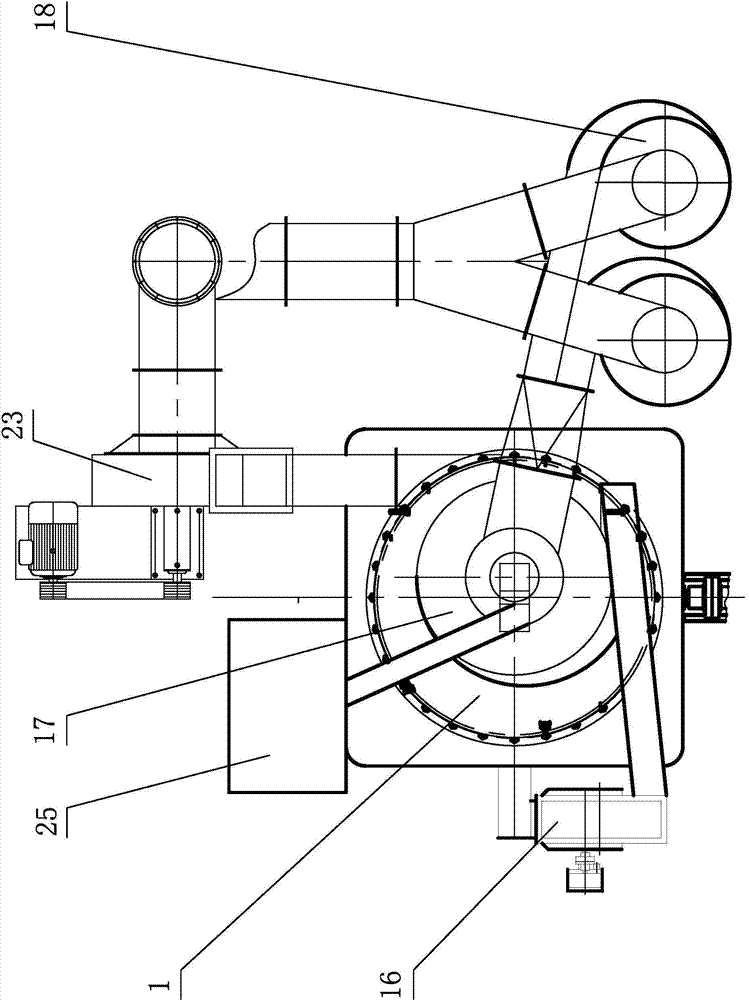

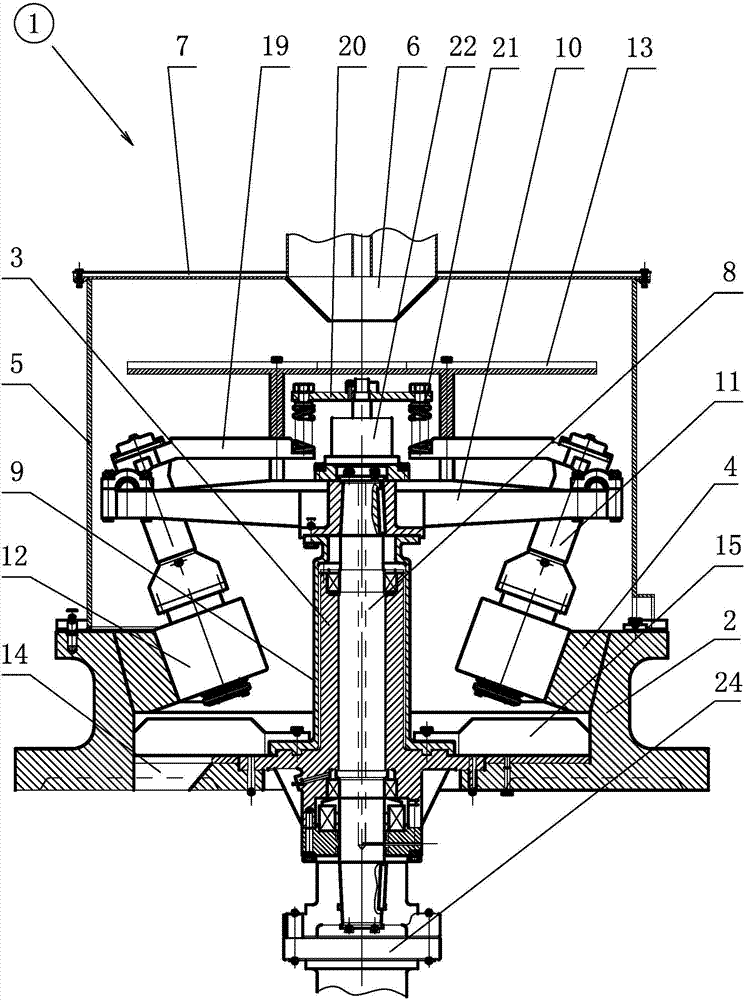

Oblique swing pressurization external circulation mill

The invention discloses an oblique swing pressurization external circulation mill. A central shaft frame is mounted at the bottom of a base of a milling main engine; milling rings are mounted at an upper part of the base; a cover barrel is mounted on the end surface of the base; a main engine feeding hole is formed in an upper cover of the cover barrel; a main engine discharging hole is formed in the bottom of the base near the central shaft frame and communicated with an external grading system through a pipeline; a lower part of a main-engine main shaft is arranged on the central shaft frame; a fixed roller frame connected with a material scraping frame is mounted at an upper end of the main-engine main shaft; the central shaft frame is sleeved with the material scraping frame; material scraping plates are mounted on the material scraping frame; milling roller devices are uniformly distributed around the circumference of the main-engine main shaft; each milling roller device comprises a milling roller sleeve, a milling roller and a milling roller shaft; the milling roller sleeves are obliquely hung on the fixed roller frame; the milling rollers obliquely lean on the milling rings; a material equalizing plate synchronously rotating and provided with a baffle edge is arranged above the fixed roller frame; a pressurization mechanism acting on the milling roller devices is arranged on the fixed roller frame. According to the mill, a finished product is separated by adopting external circulation, so that equipment is convenient to repair; a shovel blade mechanism is not arranged, so that the power consumption is reduced and the total power loss of the milling main engine is reduced.

Owner:吴斌

Optical glass polishing disk and manufacturing method thereof

InactiveCN108068025AReduce dosageTough and durableFlexible-parts wheelsGrinding devicesCross-linkManufacturing cost reduction

The invention discloses an optical glass polishing disk and a manufacturing method thereof. A polishing disc raw material comprises the following components in percentage by weight: 30-45% of polishing powder, 6-18% of resin, 10-22% a pore forming substance, 0.2-20% of aminolipin, 8-18% of a curing agent and 8-18% of a catalyst. By improving the formula of the polishing disc, the dosage of the polishing powder is reduced directly, the manufacturing cost is lowered, the environmental pollution is reduced, and damage on human body can be also reduced. The added aminolipin organic high-molecularpolymer in cross-linking reaction with resin is high in adhesive force and good in toughness. The polishing powder after coordinated bonding is high in Moh's hardness, and the grinding force of the optical glass polishing disk is enhanced; finally, the polishing disc is high in light out-coupling efficiency, good in polishing effect and durable. 300-400 tons of rare earth polishing powder can be saved by only one county of Pujiang every year.

Owner:王佳佳

Heat-conduction anti-abrasion fireproof material

InactiveCN106588055AImprove thermal conductivityImprove high temperature resistanceMohs scale of mineral hardnessPorosity

The invention provides a heat-conduction anti-abrasion fireproof material. With magnesium oxide micro powder being a main raw material, a dispersing agent and an organic binding agent are added, and by the utilization of slip casting production forming, the heat-conduction anti-abrasion fireproof material is formed through sintering at the temperature of 1750 DEG C. The product is composed of raw materials with good heat conduction, the crystal-phase magnesium oxide has the porosity larger than or equal to 2%, is even and compact and has good heat conduction, the heat-conduction coefficient can reach about 30-35 W / (m.k) at the temperature of 1000 DEG C, moh's hardness is slightly higher than corundum hardness, high anti-abrasion performance is achieved, high temperature resistance is good, and refractoriness under load can reach 1680 DEG C or above.

Owner:ZHENGZHOU ANLIANKAI IND CO LTD

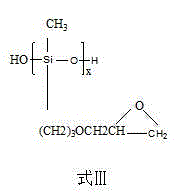

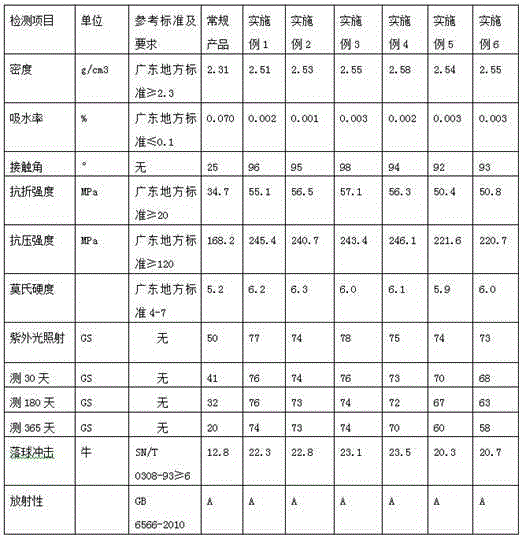

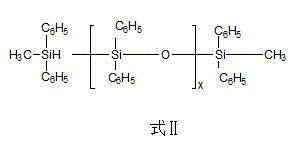

Artificial quartz sheet for ground pavement, and its preparation method

The invention discloses an artificial quartz sheet for ground pavement, and its preparation method, and belongs to the field of artificial quartz production. The artificial quartz sheet is obtained through vibration and curing molding of main materials comprising an organic silicon resin prepolymer and an inorganic silicon filler. Compared with artificial quartz sheets in the prior art, the artificial quartz sheet for ground pavement has the advantages of no warping in the curing or use process, good ageing resistance, good chemical medicine resistance, high rupture strength, high compressive strength and very good popularization application value.

Owner:SHANDONG YUANGEN CHEM TECH RES & DEV CO LTD

Far-infrared high-temperature anti-abrasion energy-saving coating and preparation method thereof

InactiveCN106278293AImprove barrier propertiesImprove high temperature resistanceAluminium hydroxidePhosphoric acid

The invention relates to a fireproof material and a preparation method thereof, in particular to a far-infrared high-temperature anti-abrasion energy-saving coating and a preparation method thereof. The far-infrared high-temperature anti-abrasion energy-saving coating consists of a main material and an auxiliary material, wherein the main material is composed of fused alumina zirconia fine powder, zirconium oxide, pure calcium aluminate cement, yttrium oxide, high-purity sintered magnesia-zirconia powder, silica micro powder, aluminum oxide micro powder, sodium tripolyphosphate, silicon nitride and hydrotalcite; and the auxiliary material is composed of phosphoric acid, aluminum hydroxide for ink, aluminum sulfate, calcium borate, borax and a sintering agent. The far-infrared high-temperature anti-abrasion energy-saving coating has high pressure resisting strength, relatively high hardness, high Moh's hardness and high compactness, has good heat preservation property, abrasion resistance, erosion resistance and washing resistance and has heat shock stability and high viscosity.

Owner:YIXING GUOQIANG FURNACE IND

Zirconium gem processing technology and zirconium gem

ActiveCN105671490AStrong scratch resistanceHigh Mohs hardnessVacuum evaporation coatingSputtering coatingMaterials preparationEvaporation

The invention relates to a zirconium gem processing technology and a zirconium gem. The zirconium gem processing technology and the zirconium gem solve the problem that design is unreasonable in prior art. The zirconium gem processing technology includes the following steps that A, material preparation is carried out, wherein a zirconium gem body, a ZrO2 material, a SiO2 material and an AF material are prepared; B, vacuumizing is carried out, wherein the zirconium gem body is placed into a coating cavity umbrella stand, a door is closed, vacuumizing is carried out, then a workpiece disc is rotated, a coating cavity is vacuumized at the normal temperature, and the vacuum degree in the coating cavity ranges from 8.0E to 4Pa after the coating cavity is vacuumized; C, coating is carried out, wherein the ZrO2 material, the SiO2 material and the AF material are placed into corresponding evaporator sources, the evaporator sources are communicated with the coating cavity, the ZrO2 material, the SiO2 material and the AF material are sequentially coated to the zirconium gem body by means of the corresponding evaporator sources through an evaporation technology; and D, material taking is carried out, air is led in, the door is opened, and the finished zirconium gem is taken out. The zirconium gem processing technology and the zirconium gem have the beneficial effect that the practicability is high.

Owner:WENLING MODERN CRYSTAL

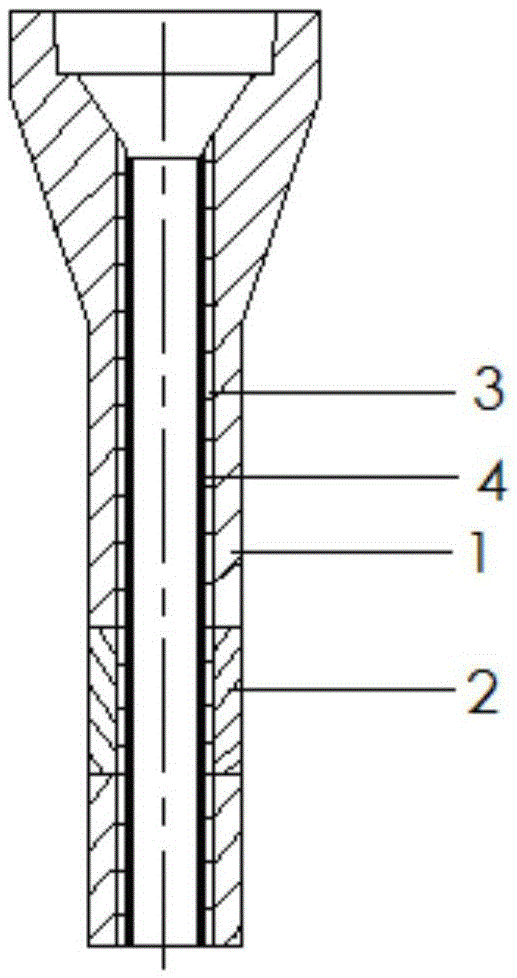

High-strength composite submersed nozzle combined with silicon carbide crystal whiskers and manufacturing method

The invention relates to a high-strength composite submersed nozzle combined with silicon carbide crystal whiskers. The high-strength composite submersed nozzle comprises an outer layer body, an outer layer slag line segment, an inner layer and a boundary layer; the boundary layer is composed of, by weight, 40-60% of one or two kinds of white corundum and tabular corundum, 3-10% of calcined alumina, 15-40% of one or more kinds of SIALON, ALON and silicon nitride and boundary sols accounting for 8-10% of raw materials of the boundary layer in weight; the boundary sols are formed by mixing 60-80% of metasilicic acid ethyl esters and 20-40% of cane sugar uniformly and then treating the mixtures at 40-60 DEG C for 12-24 hours. The sols in the boundary layer react for generating the bamboo-like and reed-like beta-silicon carbide crystal whiskers with the end faces pointed at high temperature, the beta-silicon carbide crystal whiskers of the structure are embedded into the outer layer and the inner layer of the nozzle, and therefore the two composite layers can be combined closely.

Owner:鞍山市和丰耐火材料有限公司

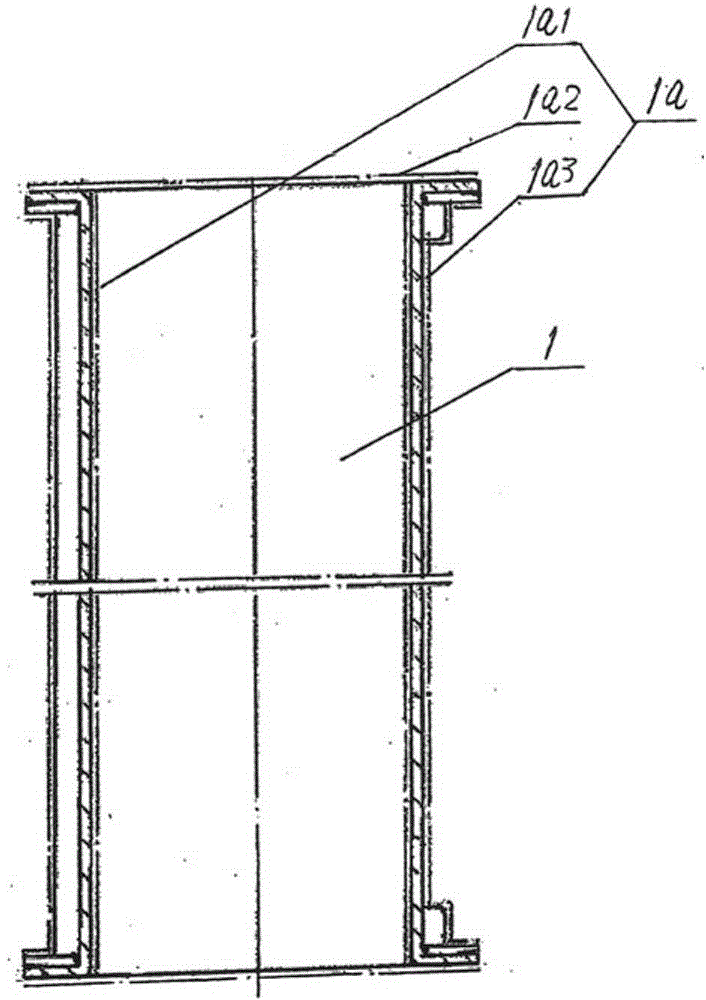

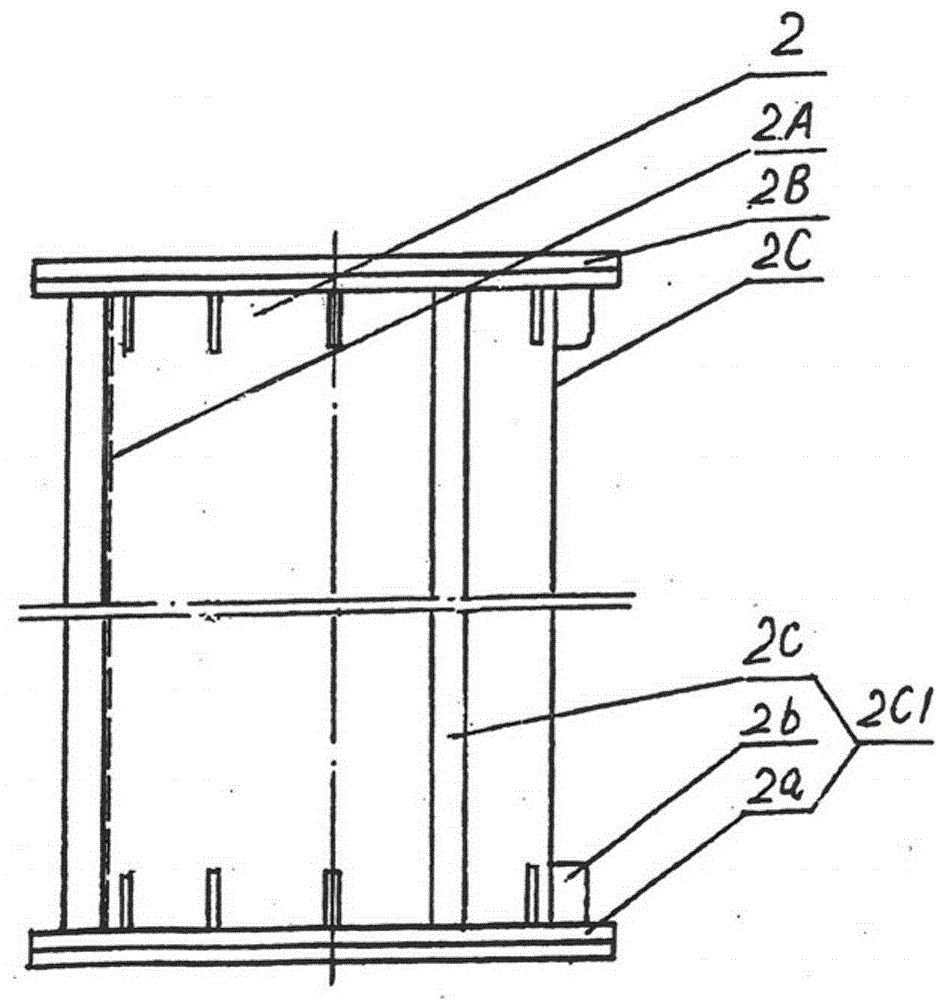

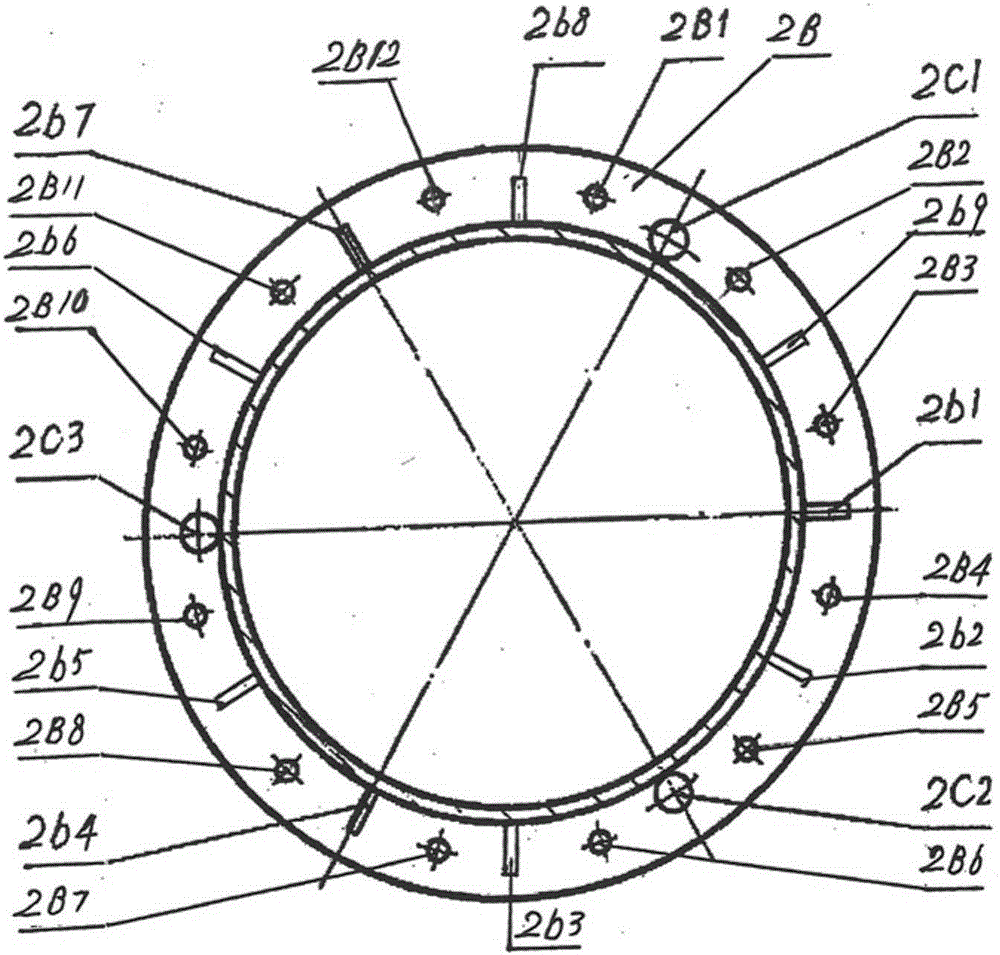

Large microcrystalline glass-lined pipeline and manufacturing method thereof

InactiveCN105196054AImprove corrosion resistanceStrong abrasion resistanceFlanged jointsCharge composition/stateWear resistantEngineering

The invention relates to a pipeline for conveying petroleum, natural gas and the like and a manufacturing method thereof, and belongs to the field of special pipelines for conveying oil and gas. The oil and gas pipeline provided by the invention has three scientific and technological innovations; two groups of strengthening annular bodies are welded on the large flanges at the two ends of the pipeline; a plurality of groups of strengthening steel bar plates and overall strengthening steel circular pipe fittings are combined and welded symmetrically, and the non-deformable mechanical strength of the overall pipeline is increased. The microcrystalline glass lining has the advantage of 8-level Mohs strength, and the highest quality index can be performed comprehensively and creatively by adjusting the formula and the ratio of the microcrystalline and amorphous glass lining enamel according to the requirements on the specific physicochemical performances of different structural parts of each oil and gas pipeline engineering and each pipeline. By applying an openable and closeable extra long horizontal electric heating furnace and an intelligent temperature control instrument, and combining a new process of rotating while heating, the extra large and extra long integrated large microcrystalline glass-lined pipeline which has high glass-lined layer quality, and is smooth in circulation, durable, non-corrosive, wear-resistant, high in seismic resistance, and safe in operation is developed. The large microcrystalline glass-lined pipeline can comprehensively replace various current pipelines by virtue of comprehensive strong advantages.

Owner:朱文华

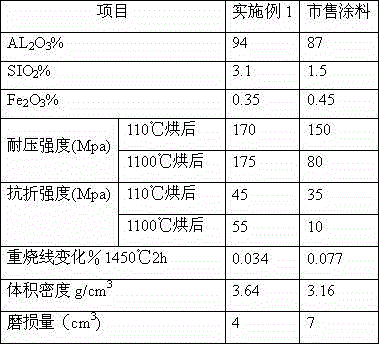

Multielement high-strength wear-resistant composite paint and preparation method thereof

InactiveCN104628403AImprove high temperature resistanceImprove stabilityWear resistantBound property

The invention relates to a refractory material and a preparation method thereof, particularly a multielement high-strength wear-resistant composite paint and a preparation method thereof. The multielement high-strength wear-resistant composite paint is composed of a main material and an auxiliary material, wherein the main material is composed of fused alumina zirconia fine powder, kyanite, pure calcium aluminate cement, aluminium titanate, magnesium zircon sand, silicon micropowder, aluminum oxide micropowder, sodium tripolyphosphate, calcium chromate and gahnite; and the auxiliary material is composed of phosphoric acid, aluminum hydroxide for inks, aluminum chloride, boron-iron-molybdenum alloy, borax and agglutinant. The multielement high-strength wear-resistant composite paint provided by the invention has the advantages of high compressive strength, higher hardness, high Mohs hardness, high density, favorable wear resistance, favorable erosion resistance, favorable scour resistance, high thermal shock stability and high binding property. When being used for a circulating fluid bed boiler, the multielement high-strength wear-resistant composite paint prolongs the service life of the paint coat, reduces the repair frequency and lowers the maintenance cost.

Owner:YIXING GUOQIANG FURNACE IND

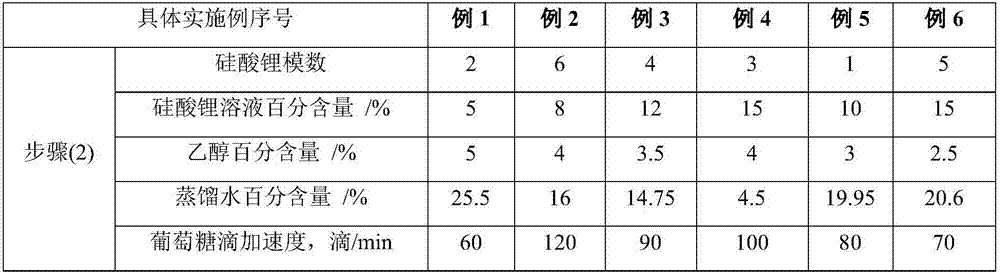

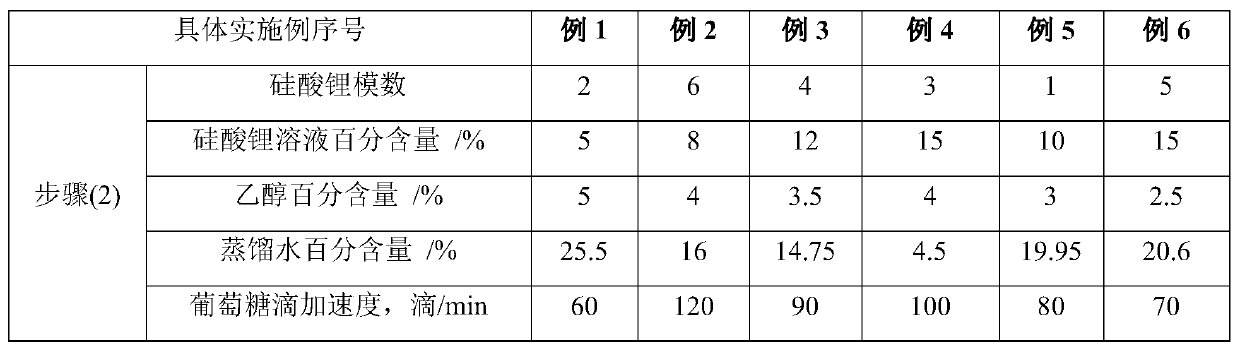

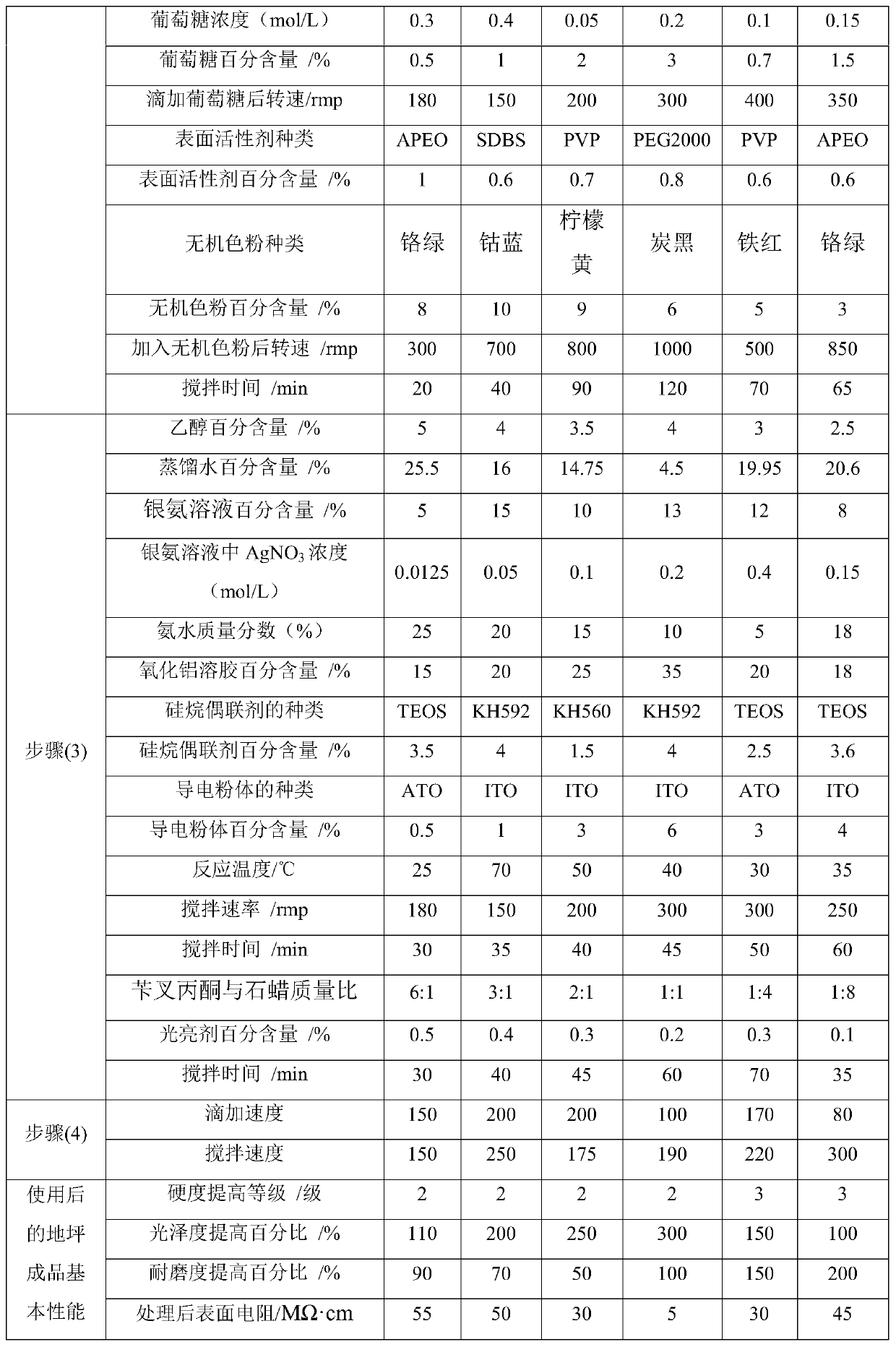

Colored antistatic and anticorrosive paint and using method thereof

ActiveCN107987566AMeet anti-static requirementsStrengthen and hardenAlkali metal silicate coatingsAnti-corrosive paintsWater basedMaterials science

The invention relates to the field of building materials, aiming at providing colored antistatic and anticorrosive paint and a using method thereof. The paint is prepared from the following componentsby mass percent: 5-15% of a lithium silicate solution, 0.5-3% of a glucose solution, 3-10% of inorganic toner, 0.6-1% of a surfactant, 5-10% of ethanol, 15-35% of alumina sol, 5-12% of a silver ammonia solution, 0.5-6% of conductive powder, 0.1-0.5% of a brightener, 1.5-4% of a silane coupling agent and the balance of distilled water. The colored antistatic and anticorrosive paint is prepared from water-based materials, is simple and convenient to construct, and can be directly applied to the surface of a terrace in a way of roller coating or spraying for construction; the terrace treated byusing the colored antistatic and anticorrosive paint has the characteristics of being high in hardness, wear resistance and gloss, antistatic, and the like, and is especially excellent in antistatic property; furthermore, a variety of colors are available for adjustment and selection. The surface gloss of the terrace becomes more durable after the terrace is used for a longer time, and the terraceshows waxing luster.

Owner:ZIGONG GELING NEW MATERIAL TECH CO LTD

Lithium-based flooring curing agent and preparation method thereof

The invention discloses a lithium-based flooring curing agent and a preparation method thereof. The curing agent is prepared from substances in parts by weight as follows: 50-100 parts of lithium silicate sol, 5-15 parts of N,N-methylene bisacrylamide, 1-3 parts of quartz powder, 0.5-1.5 parts of silicone oil, 1-5 parts of a stabilizer, 0.5-2 parts of calcium sulfoaluminate, 2-6 parts of an anionic surfactant and 3-5 parts of sulfonated acetone-formaldehyde (based superplasticizer). The curing agent can remarkably improve the strength, the Moh's hardness, wear resistance and acid resistance of flooring, has high product permeability, is quick to dry, easy to use, clean and maintain, long in service life, odorless, non-toxic, safe and environment-friendly and has a wide application range.

Owner:XIAMEN SINO CHEM CO LTD

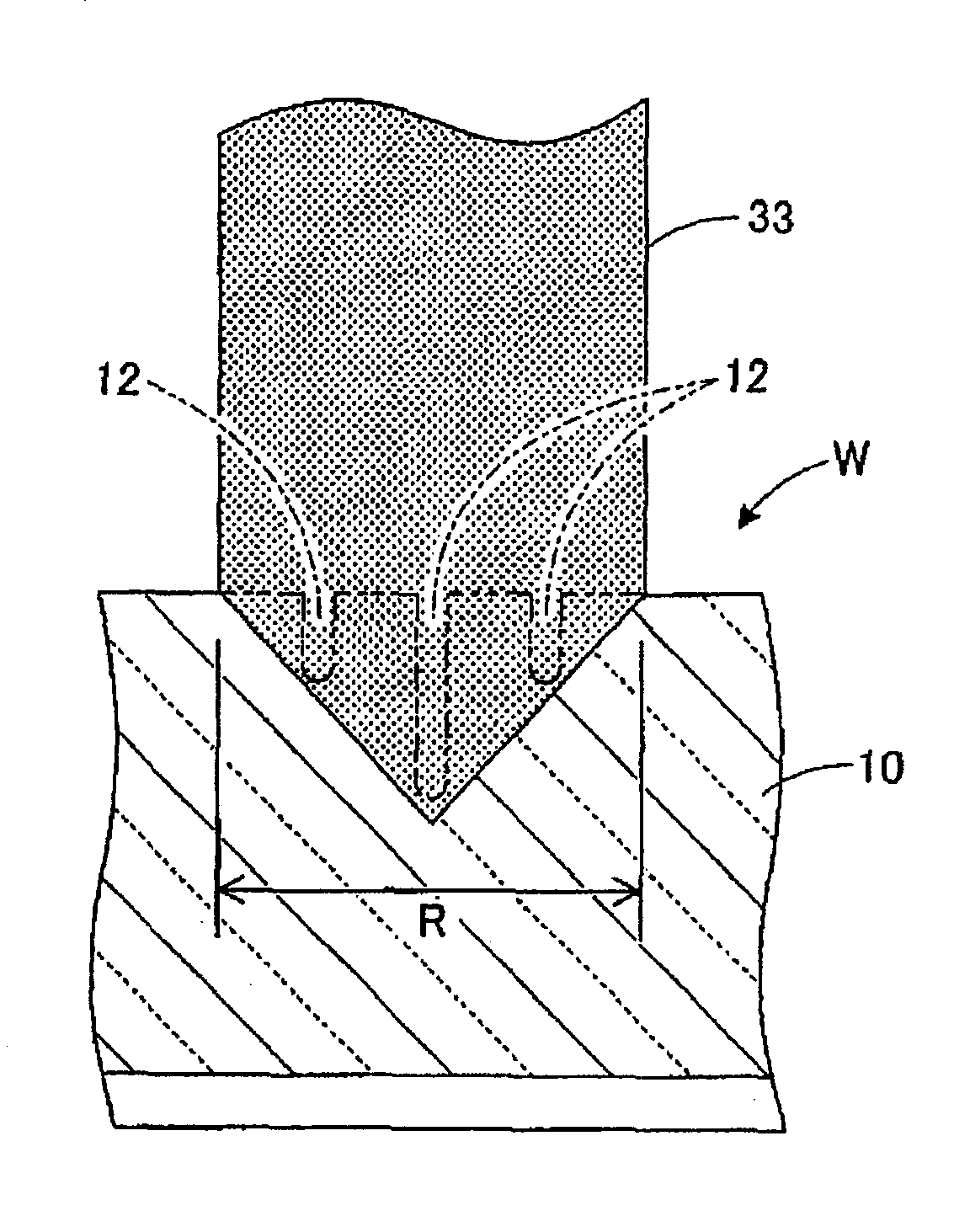

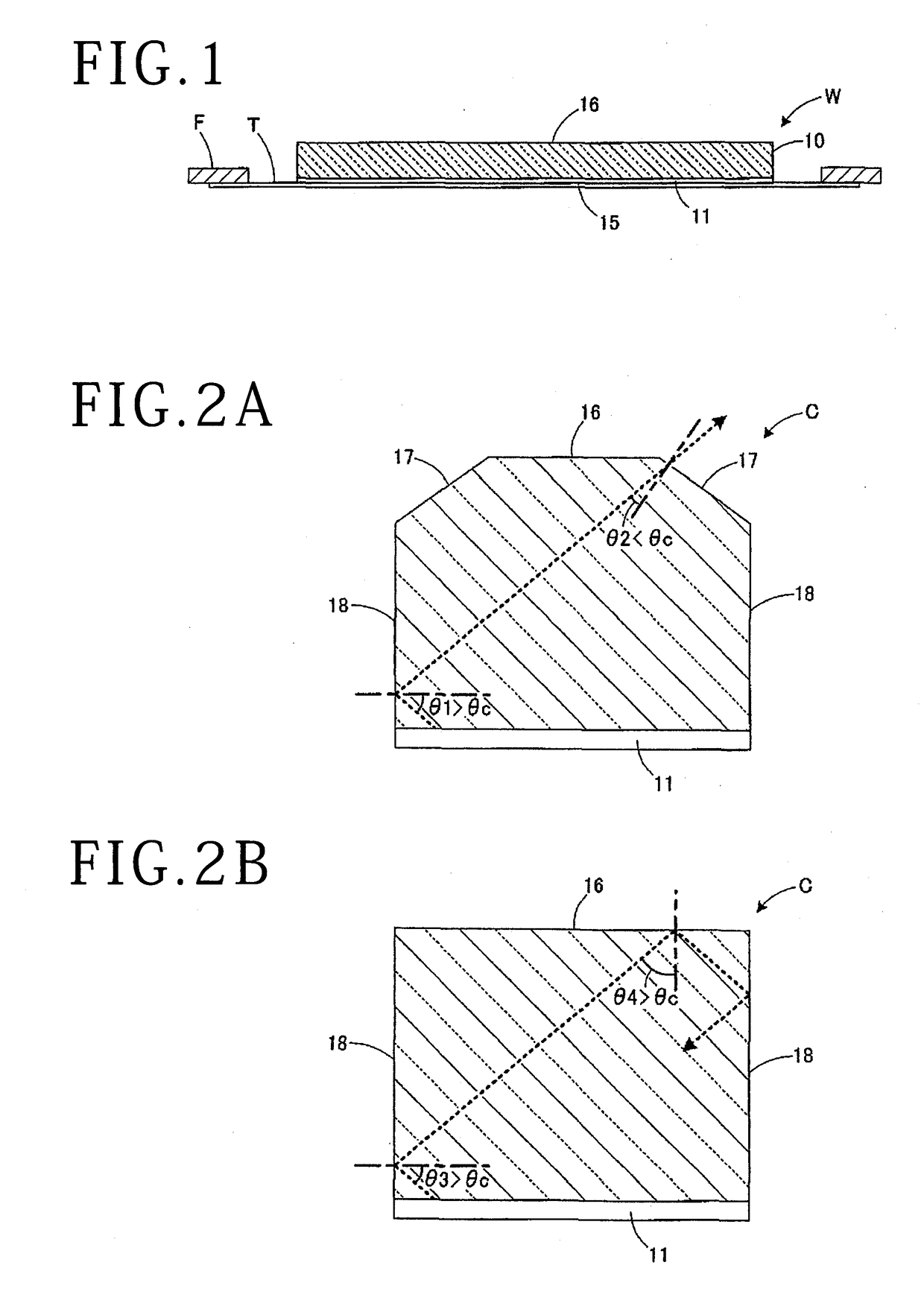

Optical device wafer processing method

ActiveUS20180212098A1Reduced strengthIncrease the amount of lightSemiconductor/solid-state device manufacturingFine working devicesSplit linesEngineering

An optical device wafer processing method for dividing an optical device wafer along a plurality of division lines to obtain a plurality of individual device chips includes applying a laser beam to a wafer substrate along each division line to thereby form a laser processed groove along each division line, and next forming a V groove along each laser processed groove on the optical device wafer by using a cutting blade having a V-shaped tip in the condition where each laser processed groove is removed by the cutting blade. A crack is formed so as to extend from the bottom of each laser processed groove due to a load applied from the cutting blade, thereby dividing the optical device wafer into the individual device chips. The depth of each laser processed groove is set smaller than the depth of cut by the cutting blade.

Owner:DISCO CORP

Satin glaze as well as preparation method and application thereof

The invention discloses satin glaze as well as a preparation method and application thereof. The satin glaze is prepared from the following formula components in parts by mass: 5-10 parts of barium carbonate, 5-10 parts of zirconium silicate, 40-50 parts of albite, 5-10 parts of burnt talc, 10-20 parts of calcium carbonate, 5-15 parts of aluminum hydroxide, 5-10 parts of kaolin, 5-15 parts of titanium dioxide and 0.1-5 parts of additives. By adding the materials such as the titanium dioxide, a great deal of high hardness crystals are precipitated out from the chemical components of the satin glaze after high-temperature firing, and the mohs hardness of the formed overglazed surface is increased to grade 5; furthermore, the satin glaze is enabled to have glaze effects of being smooth, flatand fine, and the problems that in the prior art, the satin glaze is softer in texture and low in surface hardness are solved.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

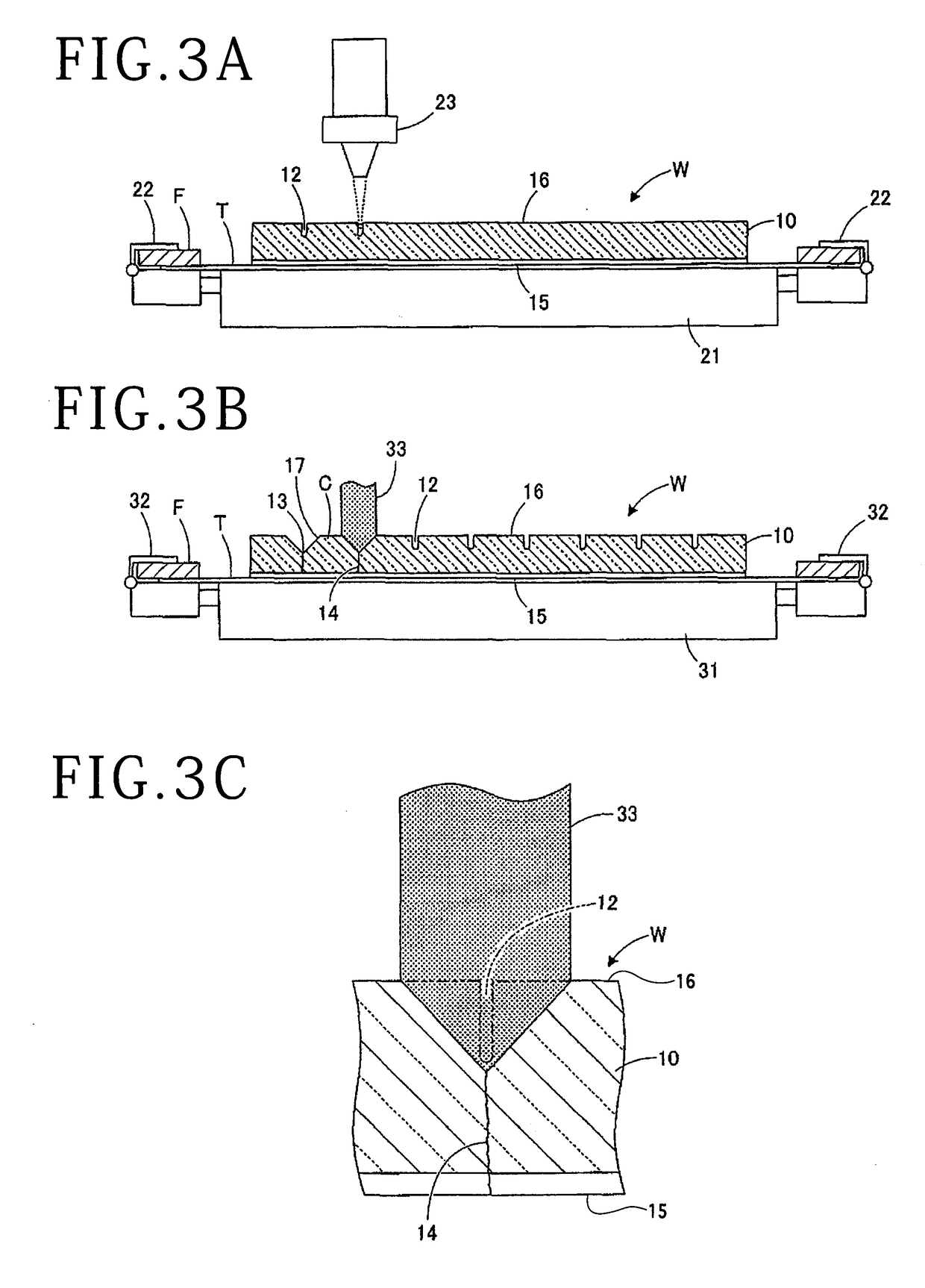

Portable emergency evacuation tool in motor vehicle

ActiveCN104260687AShort force distanceIncrease buffer distancePedestrian/occupant safety arrangementEngineeringScrew thread

Disclosed is a portable emergency evacuation tool in a motor vehicle. The portable emergency evacuation tool is high in starting speed, high in window breaking success rate, small in size, convenient to carry and safe and stable. The portable emergency evacuation tool is formed by a ball handle, a cylinder cover, a safety pin, a screw, a screw spike, a cylinder, a pressure spring, a spring support and a rivet and is characterized in that the ball handle is connected with the upper end of the screw through threads; the screw penetrates the cylinder cover and the pressure spring; the cylinder cover and the cylinder are fixed through the screw spike; the lower end of the screw and the spring support are fixed; the river is embedded at the bottom of the screw; the bottom of the cylinder is provided with a circular hole; a nail point of the rivet extends out of the circular hole; the safety pin penetrates the cylinder cover and the screw.

Owner:SHENZHEN GREENWHEEL ELECTRIC VEHICLE CO LTD

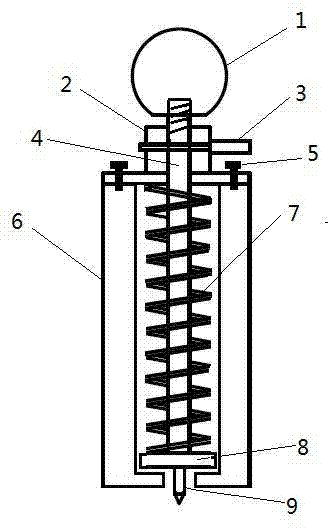

Sandy sound absorbing plate and preparation method thereof

PendingCN108529928AGood sound absorptionHigh purity without impuritiesLamination ancillary operationsLaminationEngineeringQuartz

The invention discloses a sandy sound absorbing plate and a preparation method thereof. The plate is mainly composed of at least two sound absorbing material bodies integrally formed; the sound absorbing material bodies are made from natural round grain quartz sand and resin glue through mixing and pressing; the two sound absorbing material bodies are provided with an adhesive covering layer respectively applied on the surfaces of the two sound absorbing material bodies; after the integrally formed sound absorbing material bodies are covered with the resin glue and the adhesive covering layer,sound absorbing holes are formed in gaps among the natural round grain quartz sand particles. The method has the advantage of obtaining a better sound absorbing effect.

Owner:刘志徽

Preparation method of synthetic quartz plate with imitated rosy cloud patterns

The invention discloses a preparation method of a synthetic quartz plate with imitated rosy cloud patterns. The preparation method comprises a material A, a material B, and a dry powder; the weight ratio of the material A to the material B is 1:0.7-1.1. The preparation method comprises following steps: material preparation, stirring, material distribution, pressing, thermal curing, and thickness determination and polishing. According to the preparation method, the ratio of the components is adjusted, and cooperation of a plurality of pigments is adopted, and at the same time, the dry powder isadopted for embellishing, so that the obtained quartz plate possesses a plurality of randomly changeable colors and natural patterns with high layering sense.

Owner:肇庆爱博新材料科技有限公司

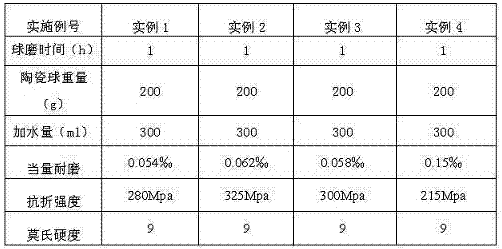

A kind of forming method of super wear-resistant alumina ceramic ball

ActiveCN103252823BEasy to operateImprove reliabilityCeramic shaping apparatusTemperature controlInjection pressure

The invention provides a forming method for a super wear-resistant alumina ceramic ball. The forming method includes a first step of providing pug with 17-25% of moisture content through working procedures of material proportioning, ball grinding, filtering, iron removing, mud squeezing, vacuum pugging and the like, a second step of sending the pug into an injection molding machine, a third step of enabling the pug to be injected into a metal mold cavity at high speed within 1 / 5-1 / 2 second, and opening a mold and forming the super wear-resistant alumina ceramic ball, wherein injection pressure in the injection process is 1-3MPa, and temperature of the metal mold in the forming process is controlled within 130-200 DEG C, and a fourth step of carrying out high-temperature sintering on formed semi-finished products at 1450 DEG C, carrying out heat preservation for two hours and obtaining the products. Equivalent abrasion of the products reaches 0.054 %., rupture strength of the products reaches 320MPa, and degree of sphericity is bigger than 95%. The forming method enables main performance index of the products to be remarkably improved, and expands application scope of the products.

Owner:JINGDEZHEN BETTERWEAR NEW MATERIALS

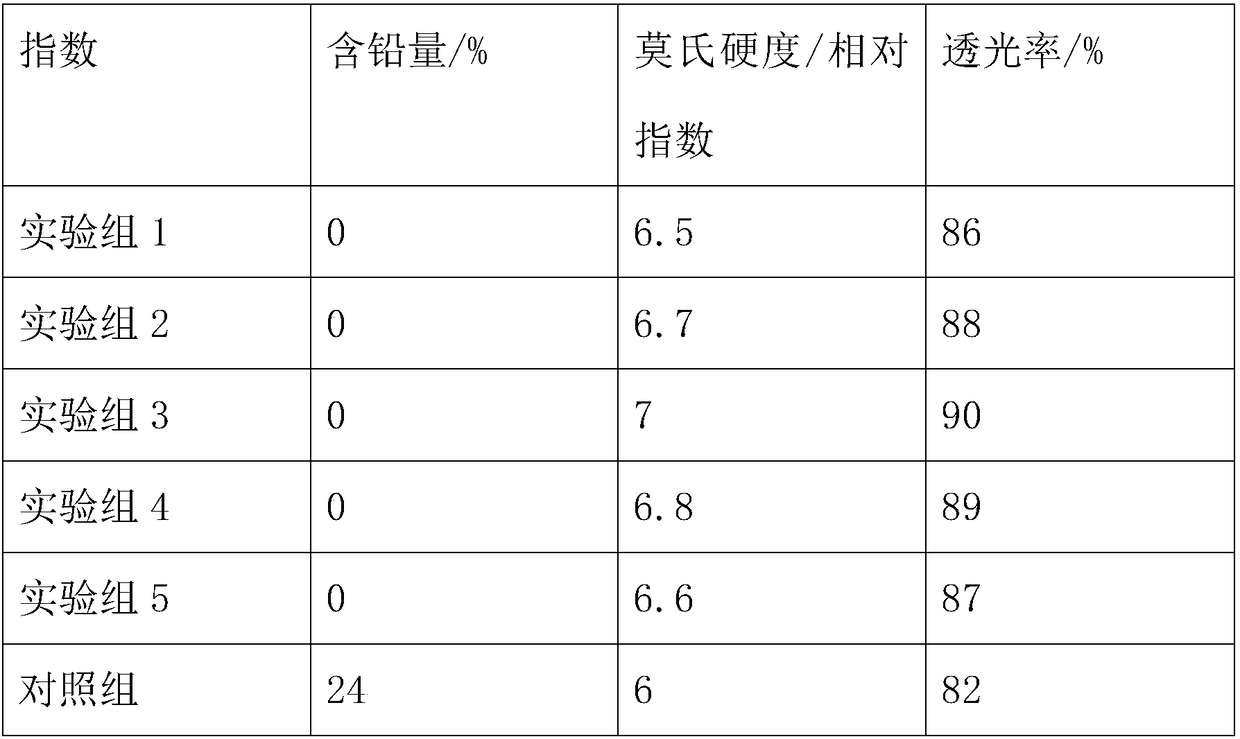

Preparation method of lead-free electronic glass

InactiveCN108516665APromote meltingLow costGlass shaping apparatusMohs scale of mineral hardnessChemical composition

The invention discloses a preparation method of lead-free electronic glass. The preparation method comprises the following steps: S1: carrying out ultrasonic high-speed dispersion on a non-transparentsintered matter prepared from silicate and silicon dioxide, wherein the ultrasonic frequency is 50 to 60kHz, the dispersion speed is 5500 to 6000r / min and the dispersion time is 30 to 60min; then putting the non-transparent sintered matter into a combustion vessel and melting; adding a fluxing agent, wherein the temprature in the combustion vessel is 1800 to 2000 DEG C; S2: melting for 20 to 40min until the non-transparent sintered matter does not contain unreacted mixture particles, so as to form transparent glass liquid; adding a glass clarifying agent into the transparent glass liquid andremoving visible bubbles; S3: raising the temprature of the glass liquid to homogenize the glass liquid, and removing stripes and other non-uniform bodies, so as to enable chemical compositions of allparts of the glass to reach expectation. The glass prepared by the preparation method does not contain lead and has no damages to human bodies; the glass also has the advantages of high Moh's hardness, high sealing strength, high expansion coefficient, high light transmittance and good insulation performance; practical and industrial conditions are realized, and the glass can be widely applied toelectronics and electrical apparatus industries.

Owner:NANAN CHUANGPEI ELECTRONICS TECH CO LTD

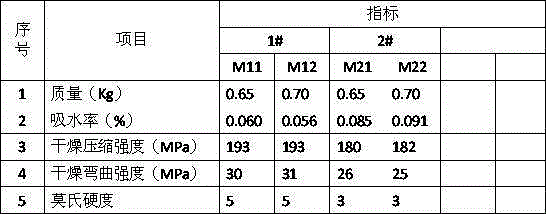

A vitrified brick and its preparation method

The invention provides a vitrified tile and a preparation method of the vitrified tile and belongs to the technical field of ceramic. The vitrified tile provided by the invention is prepared from the following raw materials: Linyi porcelain stone, Mengyin feldspar, pyrophyllite, Zhucheng soil, quartz, alumina, Laiyang soil, soapstone, diopside and fat clay. All raw materials can take synergistic effect under the action of high temperature, the firing temperature can be reduced to some extent, the firing cycle is shortened, and the processing property and the physical and chemical properties of the product are qualitatively improved in comparison with a conventional process.

Owner:临沂市顺弘陶瓷科技有限公司

A kind of colored antistatic anticorrosion coating and its application method

ActiveCN107987566BHigh hardnessImprove wear resistanceAlkali metal silicate coatingsAnti-corrosive paintsSilicic acidActive agent

The invention relates to the field of building materials, aiming at providing colored antistatic and anticorrosive paint and a using method thereof. The paint is prepared from the following componentsby mass percent: 5-15% of a lithium silicate solution, 0.5-3% of a glucose solution, 3-10% of inorganic toner, 0.6-1% of a surfactant, 5-10% of ethanol, 15-35% of alumina sol, 5-12% of a silver ammonia solution, 0.5-6% of conductive powder, 0.1-0.5% of a brightener, 1.5-4% of a silane coupling agent and the balance of distilled water. The colored antistatic and anticorrosive paint is prepared from water-based materials, is simple and convenient to construct, and can be directly applied to the surface of a terrace in a way of roller coating or spraying for construction; the terrace treated byusing the colored antistatic and anticorrosive paint has the characteristics of being high in hardness, wear resistance and gloss, antistatic, and the like, and is especially excellent in antistatic property; furthermore, a variety of colors are available for adjustment and selection. The surface gloss of the terrace becomes more durable after the terrace is used for a longer time, and the terraceshows waxing luster.

Owner:ZIGONG GELING NEW MATERIAL TECH CO LTD

Thermally conductive complex oxide, production method therefor, thermally conductive complex oxide-containing composition, and use therefor

ActiveUS10072195B2Improve conductivityIncrease resistancePigmenting treatmentCalcium aluminatesPhysical propertyComplex oxide

The thermally conductive composite oxide of the present invention has excellent physical properties, such as high thermal conductivity, water resistance, acid resistance, electric resistance, and electric insulation, required for coating films, films, and articles thereof. Paints or resins including the composite oxide can provide coating films, films, and articles having such properties without treating of a surface, etc. The composite oxide has a spinel structure and contains aluminum as a main metal component and at least one metal other than aluminum, which is magnesium, zinc, calcium, and / or strontium, and has a ratio (b mol) / (a mol) in a range of 0.1 or more and 1.0 or less, where the ratio (b mol) / (a mol) is a number of moles (b) of the metal other than aluminum to that of moles (a) of an aluminum element derived from an alumina-based compound. The thermally conductive composite oxide has Mohs hardness of less than 9.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

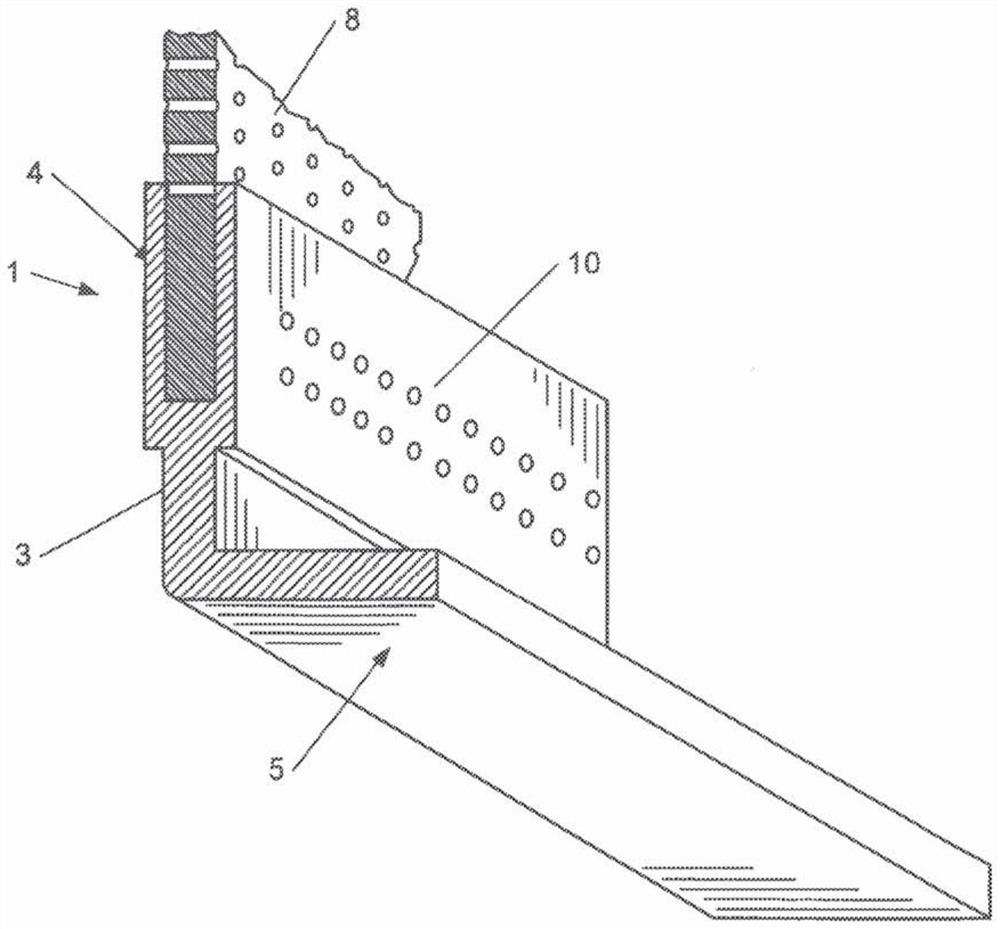

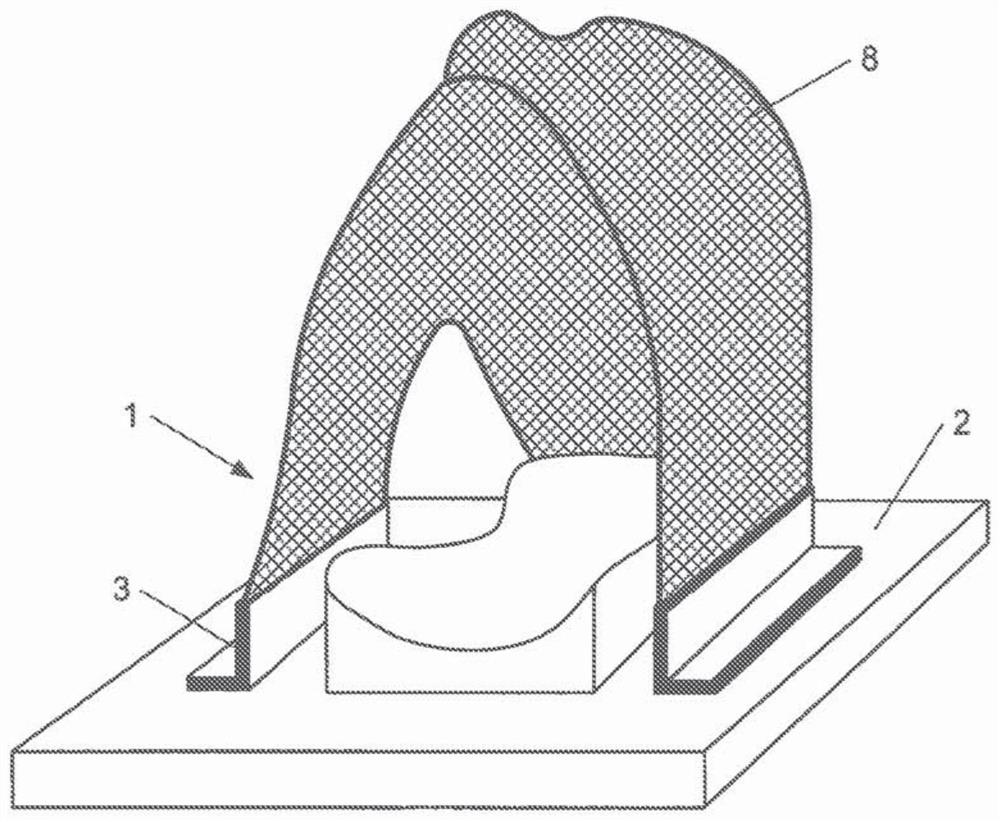

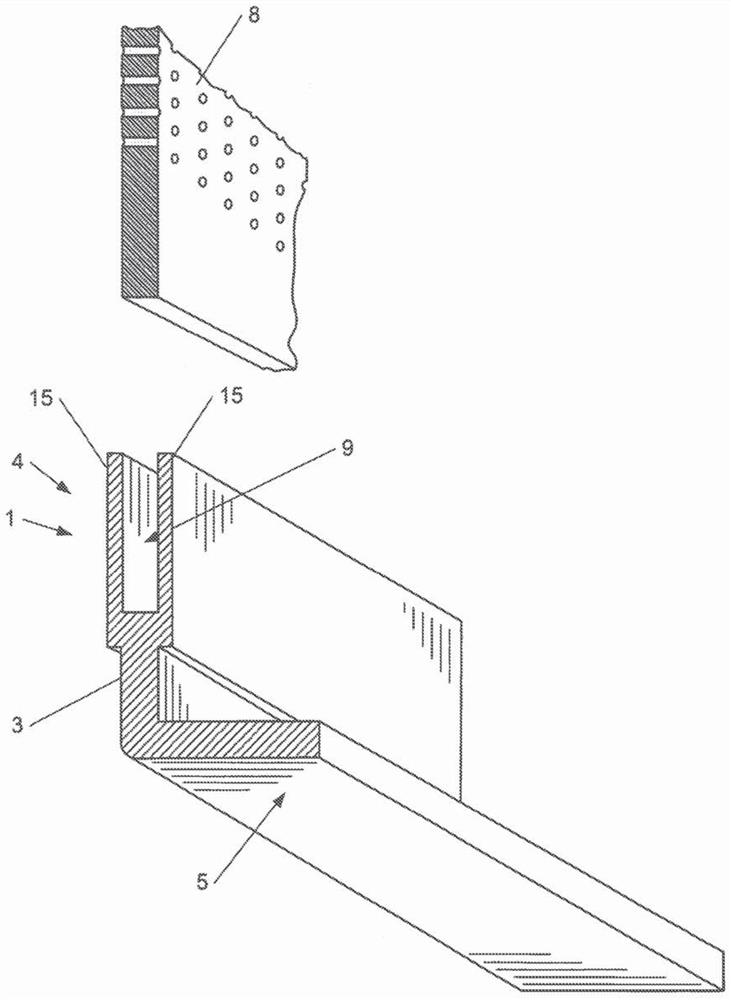

Immobilisation element with profile provided with protrusions

PendingCN111629698AReliable anchoringNot affected by environmental factors such as humidityRestraining devicesNon-surgical orthopedic devicesEngineeringBody region

Method for producing an immobilisation element (1) for immobilising a body part of a patient on a supporting surface, wherein the immobilisation element (1) comprises a sheet (8) of thermoplastic material for receiving the body part to be immobilised, and at least one profile (3) for fixing the immobilisation element (1) to the supporting surface, wherein the profile (3) comprises a first fixing means for fixing the profile (3) to the sheet (8), wherein the fixing means comprises a groove (9) delimited by a first contact surface (6) and a second contact surface (7) opposite the first contact surface (6), wherein the groove (9) receives the sheet (8) so that the first and the second contact surfaces (6, 7) lie along the sheet (8), and wherein at least one of the first contact surface (6) and the second contact surface (7) is provided with at least one protrusion (10), wherein the protrusion (10) penetrates the sheet (8) of thermoplastic material in the thickness direction of the sheet (8) in order to anchor the sheet (8) of thermoplastic material in the groove (9).

Owner:ORFIT IND

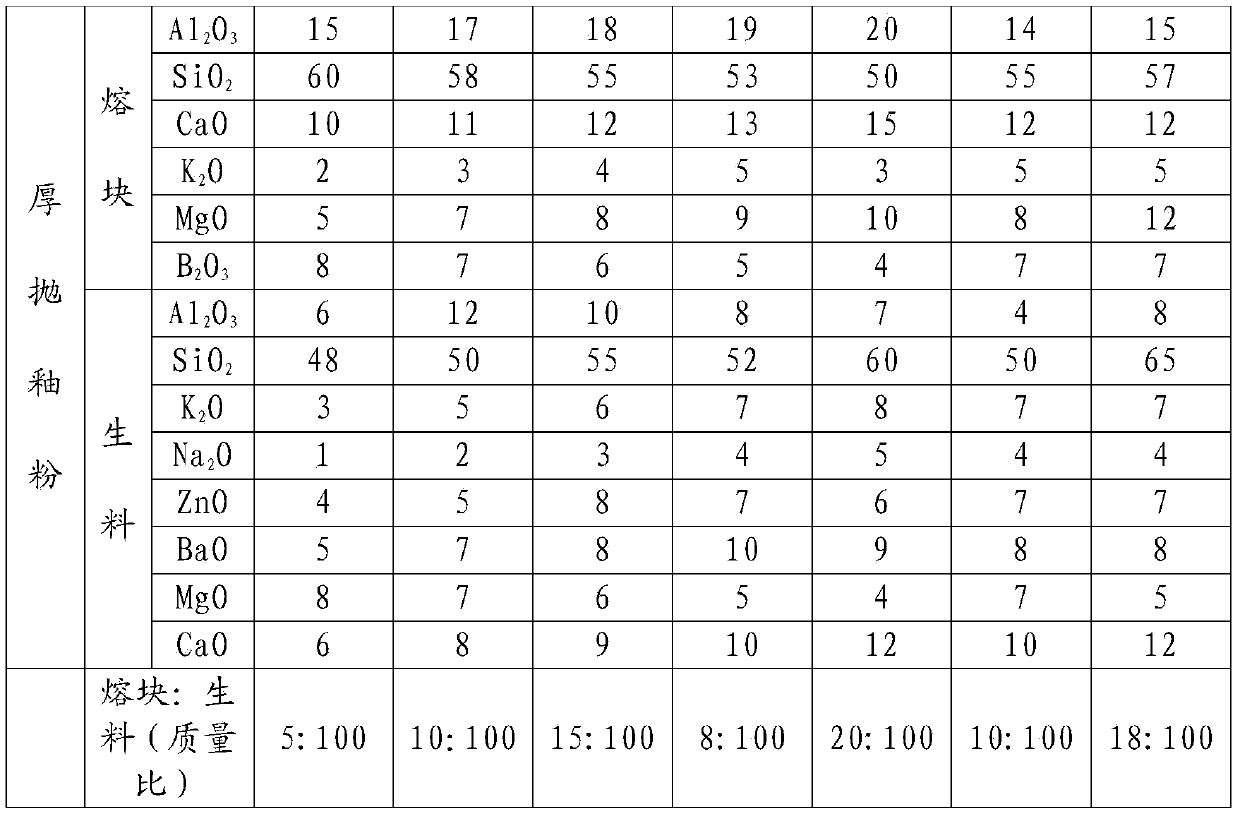

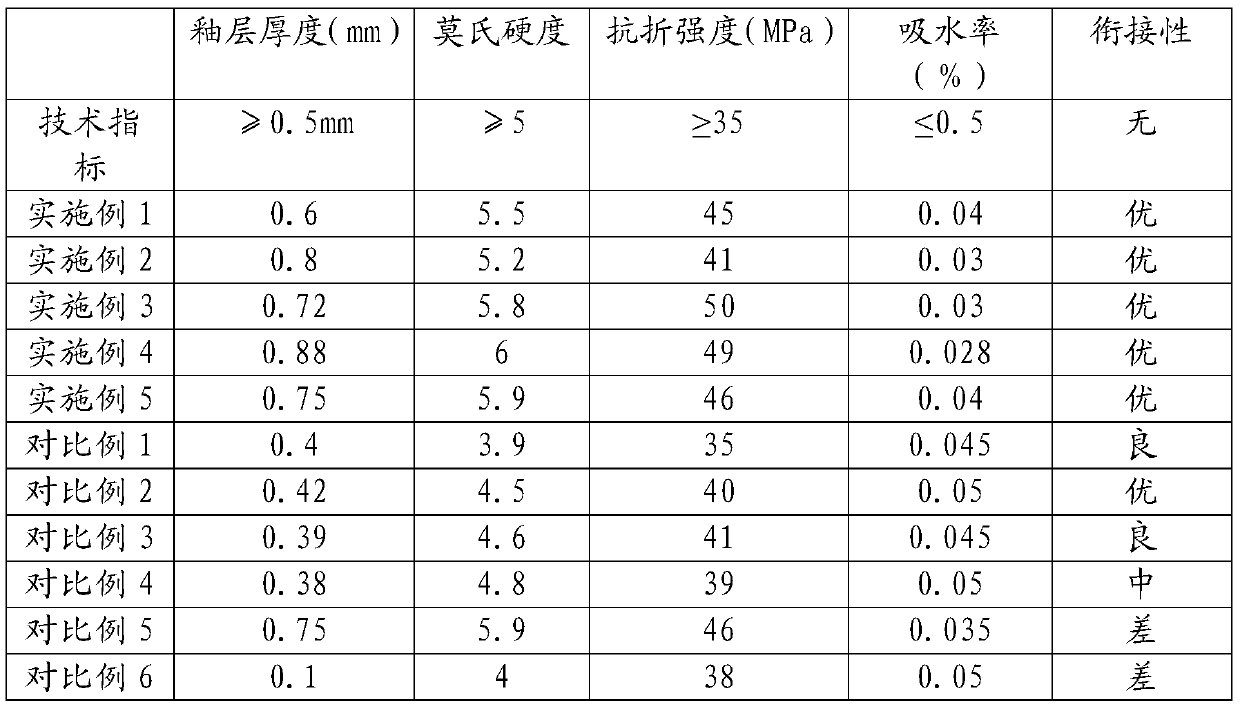

A preparation method of background wall brick and preparation method of background wall

ActiveCN106007800BPromote meltingLow meltingCovering/liningsMohs scale of mineral hardnessBreaking strength

The invention provides a background wall brick preparing method. The background wall brick preparing method comprises the following steps: 1, forming a green body and drying the green body to obtain the dry green body; 2, applying ground coat enamel on the surface of the dry green body to obtain a first green brick; 3, inkjet printing the ground coat enamel of the first green brick to obtain a second green brick; 4, drying the second green brick to obtain a third green brick; 5, applying cover glaze on the inkjet-printed side of the third green brick to obtain a fourth green brick; 6, drying the fourth green brick to obtain a fifth green brick; 7, roasting the fifth green brick at high temperature to obtain a sixth green brick; 8, polishing the sixth green brick to obtain the background wall brick. The background wall brick is large in moh hardness and breaking strength and low in water absorption. The invention further provides a background wall preparing method, and the background wall is good in link and attractive and elegant in appearance.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com