Multielement high-strength wear-resistant composite paint and preparation method thereof

A composite coating, high-strength technology, applied in the field of refractory materials and its preparation, can solve the strict requirements of wear resistance, corrosion resistance, erosion resistance and thermal shock stability, which affect the normal operation of circulating fluidized bed boilers, circulating flow Problems such as the complex construction system of the chemical bed boiler, to achieve the effect of good wear resistance, high hardness and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

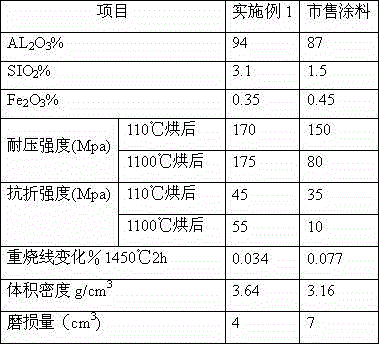

Examples

Embodiment 1

[0020] The multi-component high-strength wear-resistant composite coating is composed of main materials and auxiliary materials, and the weight ratio of main materials and auxiliary materials is 67:27; the main materials and auxiliary materials are composed of the following raw materials in parts by weight:

[0021] Main ingredients, 19 parts of zirconium corundum fine powder with a particle size of 1-2.5 mm; 27 parts of zirconium corundum fine powder with a particle size of 0.5-1 mm; 7 parts of zirconium corundum fine powder with a particle size of 0.072-0.093 mm; 10 parts of kyanite; 9 parts of pure calcium aluminate cement; 8 parts of aluminum titanate; 4 parts of magnesia-zirconium sand; 9 parts of silicon micropowder; 5 parts of alumina micropowder; 0.3 part of sodium triphosphate; 1 part of calcium chromate; Among them, the silica powder is fused silica powder with a silicon content ≥ 98%, the magnesium oxide content in the magnesia-zircon sand is 92%, and the titanium di...

Embodiment 2

[0029] The multi-component high-strength wear-resistant composite coating is composed of main materials and auxiliary materials, and the weight ratio of main materials and auxiliary materials is 70:12; the main materials and auxiliary materials are respectively composed of the following raw materials in parts by weight:

[0030] Main ingredients, 23 parts of zirconium corundum fine powder with a particle size of 1-2.5 mm; 23 parts of zirconium corundum fine powder with a particle size of 0.5-1 mm; 16 parts of zirconium corundum fine powder with a particle size of 0.072-0.093 mm; 16 parts of kyanite; 7 parts of pure calcium aluminate cement; 4 parts of aluminum titanate; 7 parts of magnesia-zircon sand; 5 parts of silicon micropowder; 3 parts of alumina micropowder; Among them, the silica powder is fused silica powder with a silicon content ≥ 98%, the magnesium oxide content in the magnesia-zircon sand is 92%, and the titanium dioxide content in aluminum titanate is 45%.

[003...

Embodiment 3

[0038] The multi-component high-strength wear-resistant composite coating is composed of main materials and auxiliary materials, and the weight ratio of main materials and auxiliary materials is 78:20; the main materials and auxiliary materials are composed of the following raw materials in parts by weight:

[0039] Main ingredients, 17 parts of zirconium corundum fine powder with a particle size of 1-2.5 mm; 18 parts of zirconium corundum fine powder with a particle size of 0.5-1 mm; 10 parts of zirconium corundum fine powder with a particle size of 0.072-0.093 mm; 9 parts of kyanite; 5 parts of pure calcium aluminate cement; 2 parts of aluminum titanate; 5 parts of magnesia-zircon sand; 7 parts of silicon micropowder; 7 parts of alumina micropowder; Among them, the silica powder is fused silica powder with a silicon content ≥ 98%, the magnesium oxide content in the magnesia-zircon sand is 92%, and the titanium dioxide content in aluminum titanate is 45%.

[0040] Auxiliary m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com