Preparation method of lead-free electronic glass

A glass and electronic technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of cumbersome manufacturing methods, low manufacturing efficiency, and high processing costs, and achieve shortened melting time, low cost, and high sealing strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

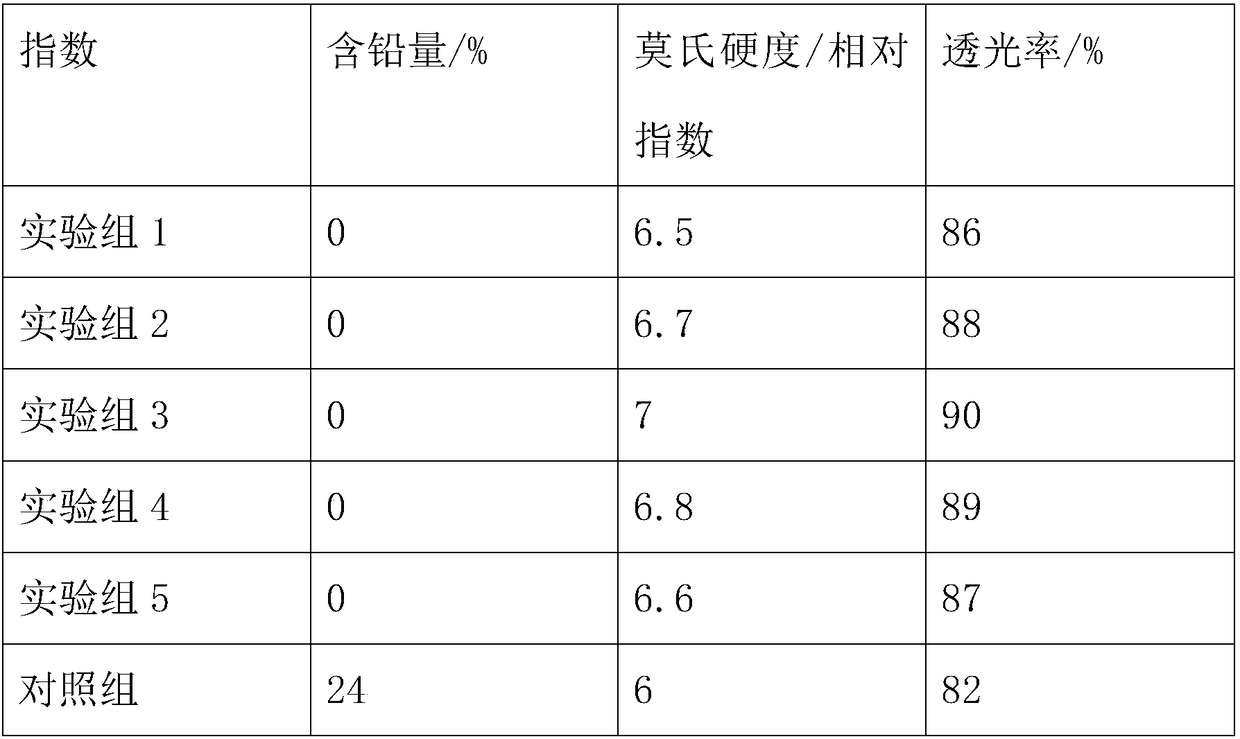

Examples

Embodiment 1

[0026] This embodiment provides a method for preparing lead-free electronic glass, and the specific steps are as follows:

[0027] S1: After mixing silicate and silicon dioxide, disperse at high speed by ultrasonic, the ultrasonic frequency is 50kHz, the dispersion speed is 5500r / min, and the dispersion time is 30 minutes. Then put it in a burning dish to melt, and add flux, The temperature in the combustion vessel is 1800℃;

[0028] S2: After melting for 20 minutes, until it does not contain unreacted batch particles to form a transparent glass liquid, add a glass clarifier to the transparent glass liquid to remove visible bubbles;

[0029] S3: Heat the glass liquid to homogenize it, eliminate streaks and other inhomogeneities, and make the chemical composition of each part of the glass consistent with expectations;

[0030] S4: Pour the molten glass into ionized water for quenching, filter to obtain filamentous vitreous powder, put the obtained vitreous powder into a crucible, then ...

Embodiment 2

[0034] This embodiment provides a method for preparing lead-free electronic glass, and the specific steps are as follows:

[0035] S1: After mixing silicate and silicon dioxide, disperse at high speed by ultrasonic, the ultrasonic frequency is 60kHz, the dispersion speed is 6000r / min, and the dispersion time is 60 minutes. Then it is melted in a burning dish, and flux is added. The temperature in the combustion vessel is 2000℃;

[0036] S2: After melting for 40 minutes, until it does not contain unreacted batch particles to form a transparent glass liquid, add a glass clarifier to the transparent glass liquid to remove visible bubbles;

[0037] S3: Heat the glass liquid to homogenize it, eliminate streaks and other inhomogeneities, and make the chemical composition of each part of the glass consistent with expectations;

[0038] S4: Pour the molten glass into ionized water for quenching, filter to obtain filamentous glass body powder, put the obtained glass body powder into a crucible...

Embodiment 3

[0042] This embodiment provides a method for preparing lead-free electronic glass, and the specific steps are as follows:

[0043] S1: After mixing silicate and silicon dioxide, disperse at high speed by ultrasonic, the ultrasonic frequency is 55kHz, the dispersion speed is 5750r / min, and the dispersion time is 45 minutes. Then put it in a burning dish to melt, and add flux, The temperature in the combustion vessel is 1900℃;

[0044] S2: After melting for 30 minutes, until it does not contain unreacted batch particles to form a transparent glass liquid, add a glass clarifier to the transparent glass liquid to remove visible bubbles;

[0045] S3: Heat the glass liquid to homogenize it, eliminate streaks and other inhomogeneities, and make the chemical composition of each part of the glass consistent with expectations;

[0046] S4: Pour the molten glass into ionized water for quenching, filter to obtain filamentous vitreous powder, put the obtained vitreous powder into a crucible, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com