A kind of forming method of super wear-resistant alumina ceramic ball

A technology of alumina ceramics and a molding method, which is applied to ceramic molding machines, manufacturing tools, etc., can solve the problems of unfavorable mechanized production, high manual operation intensity, and low product qualification rate in roll forming, and improve the structure and performance. , Improve the reliability of materials, the effect of simple molding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

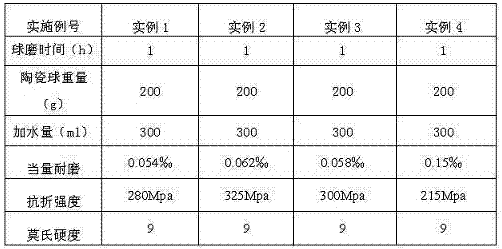

Examples

Embodiment 1

[0018] 1. Put the raw material mixture and water into the ball mill according to the proportion, and run for 20 hours to release the pulp;

[0019] 2. After the mud enters the tank, start the mixer and the pumping machine, filter it through the vibrating screen, and flow into the iron removal tank at the same time;

[0020] 3. After passing through the iron removal tank, the slurry is pumped to the mud press by the slurry pump to dehydrate the slurry to make mud cake;

[0021] 4. The mud cake is then refined by a vacuum mud refining machine, so that the water content is 21%;

[0022] 5. Put the mud obtained in step 4 into the injection molding machine and apply pressure to the plastic mud within 0.5, so that it can be injected into the metal model cavity at high speed and then molded; the injection pressure in this process is 1.5MPa , the temperature of the metal mold during molding is controlled at 150°C;

[0023] 6. Put the semi-finished product formed in step 5 into the s...

Embodiment 2

[0025] 1. Put the raw material mixture and water into the ball mill according to the proportion, and run for 25 hours to release the pulp;

[0026] 2. After the mud enters the tank, start the mixer and the pumping machine, filter it through the vibrating screen, and flow into the iron removal tank at the same time;

[0027] 3. After passing through the iron removal tank, the slurry is pumped to the mud press by the slurry pump to dehydrate the slurry to make mud cake;

[0028] 4. The mud cake is then refined by a vacuum mud refining machine, so that the water content is 23%;

[0029] 5. Send the mud material obtained in step 4 into the injection molding machine and apply pressure to the plastic mud material within 0.4, so that it is injected into the metal model cavity at a high speed and then molded to form; the injection pressure in this process is 1MPa, The temperature of the metal mold during molding is controlled at 180°C;

[0030] 6. Put the semi-finished product forme...

Embodiment 3

[0032] 1. Put the raw material mixture and water into the ball mill according to the proportion, and run for 27 hours to release the pulp;

[0033] 2. After the mud enters the tank, start the mixer and the pumping machine, filter it through the vibrating screen, and flow into the iron removal tank at the same time;

[0034] 3. After passing through the iron removal tank, the slurry is pumped to the mud press by the slurry pump to dehydrate the slurry to make mud cake;

[0035] 4. The mud cake is then refined by a vacuum mud refining machine, so that the water content is 25%;

[0036] 5. Send the mud obtained in step 4 into the injection molding machine and apply pressure to the plastic mud within 0.2 seconds, so that it can be injected into the metal model cavity at high speed and then molded to form; the injection pressure in this process is 2MPa , the temperature of the metal mold during molding is controlled at 200°C;

[0037] 6. Put the semi-finished product formed in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com