A kind of preparation method of strontium titanate lanthanum base powder material

A powder material, strontium lanthanum-based technology, applied in the field of preparation of strontium lanthanum titanate-based powder materials, can solve the problems of affecting battery performance, less active area, and unfavorable post-production of solid oxide fuel cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

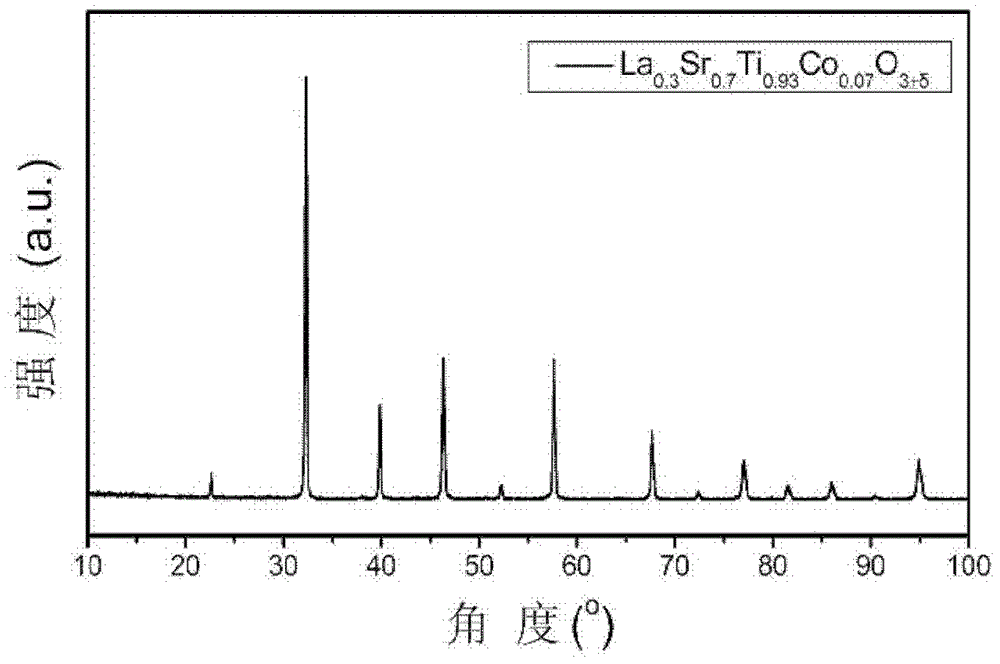

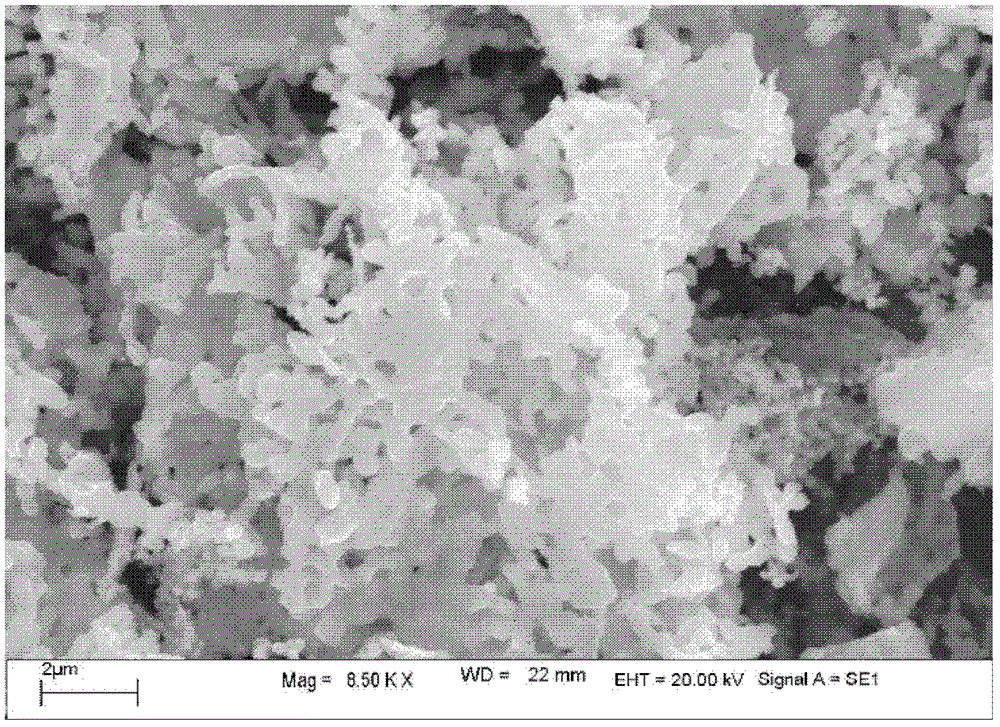

Image

Examples

example 1

[0021] La 0.3 Sr 0.7 Ti 0.99 co 0.01 o 3 ±δ (0≦δ≦1) powder synthesis, the specific steps are as follows:

[0022] The raw material is: tetrabutyl titanate (C 16 h 36 o 4 Ti), strontium nitrate (Sr(NO 3 ) 2 ), cobalt nitrate (Co(NO 3 ) 3 ·6H 2 O), calcined lanthanum oxide (La 2 o 3 ), citric acid, nitric acid, ammonia water, absolute ethanol.

[0023] Synthesize 0.01 mol La according to the stoichiometric ratio 0.3 Sr 0.7 Ti 0.99 co 0.01 o 3 ±δ (0≦δ≦1), weigh the required strontium nitrate, cobalt nitrate, lanthanum oxide, 20 ml deionized water, 15 ml concentrated nitric acid, and ammonia water to prepare a uniform light red solution A.

[0024] Weigh the required citric acid and dissolve it in 20 ml of deionized water to adjust the pH with ammonia water to obtain solution B; add 40 ml of absolute ethanol to the weighed tetrabutyl titanate solution to obtain a uniform solution C; Add it dropwise to the C solution, and keep stirring, then at 80 o C water b...

example 2

[0028] La 0.3 Sr 0.7 Ti 0.97 co 0.03 o 3 ±δ (0≦δ≦1) powder synthesis, the specific steps are as follows:

[0029] The raw material is: tetrabutyl titanate (C 16 h 36 o 4 Ti), strontium nitrate (Sr(NO 3 ) 2 ), cobalt nitrate (Co(NO 3 ) 3 ·6H 2 O), calcined lanthanum oxide (La 2 o 3 ), citric acid, nitric acid, ammonia water, absolute ethanol.

[0030] Synthesize 0.01 mol La according to the stoichiometric ratio 0.3 Sr 0.7 Ti 0.97 co 0.03 o 3 ±δ (0≦δ≦1), weigh the required strontium nitrate, cobalt nitrate, lanthanum oxide, 20 ml deionized water, 15 ml concentrated nitric acid, and ammonia water to prepare a uniform light red solution A.

[0031] Weigh the required citric acid and dissolve it in 20 ml deionized water to adjust the pH with ammonia water to obtain solution B. Add 40 ml of absolute ethanol to the weighed tetrabutyl titanate solution to obtain a homogeneous solution C. Then add the B solution dropwise to the C solution, and keep stirring, then...

example 3

[0035] La 0.3 Sr 0.7 Ti 0.95 co 0.05 o 3 ±δ (0≦δ≦1) powder synthesis, the specific steps are as follows:

[0036] The raw material is: tetrabutyl titanate (C 16 h 36 o 4 Ti), strontium nitrate (Sr(NO 3 ) 2 ), cobalt nitrate (Co(NO 3 ) 3 ·6H 2 O), calcined lanthanum oxide (La 2 o 3 ), citric acid, nitric acid, ammonia water, absolute ethanol.

[0037] Synthesize 0.01mol La according to the stoichiometric ratio 0.3 Sr 0.7 Ti 0.95 co 0.05 o 3 ±δ (0≦δ≦1), weigh the required strontium nitrate, cobalt nitrate, lanthanum oxide, 20 ml deionized water, 15 ml concentrated nitric acid, and ammonia water to prepare a uniform light red solution A.

[0038] Weigh the required citric acid and dissolve it in 20 ml deionized water to adjust the pH with ammonia water to obtain solution B. Add 40 ml of absolute ethanol to the weighed tetrabutyl titanate solution to obtain a homogeneous solution C. Then add the B solution dropwise to the C solution, and keep stirring, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com