Method for preparing double mesoporous high (100) crystal plane tungsten carbide material

A tungsten carbide material and double mesoporous technology, applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve the problems of increasing equipment cost, energy consumption, and low surface utilization, so as to enhance electrocatalytic performance and avoid hard agglomeration , The effect of pore structure maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

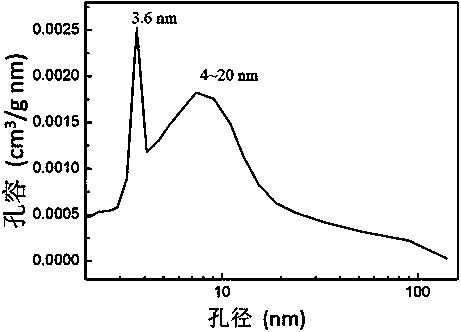

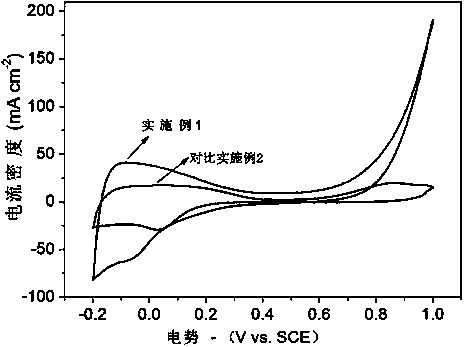

[0036] Configure solutions A and B. Solution A is ammonium metatungstate and copper sulfate plus deionized water (W:Cu mass ratio 1:0.5). The concentration of solution A is 20wt%, and solution B is 10wt% ammonium carbonate solution. While shaking solution A, add solution B dropwise at a rate of 50 μL / min. After the dropwise addition, the particles were filtered to obtain precursor particles (composite crystals); after vacuum drying at 100°C, the obtained precursor particles were 2Atmosphere (CO:H 2 The volume ratio is 1:2), and the carbonization treatment is carried out, and the temperature is raised to 800°C according to the 5°C / min program and kept for 6 hours to obtain a double-porous WC-metal material. Then, the double-porous WC-metal material was treated with 20% hydrochloric acid to obtain the expanded double-porous WC material. The shape of the particles can be seen in figure 1 , to further enlarge the topography as shown in figure 2 . The pore size distribution i...

Embodiment 2

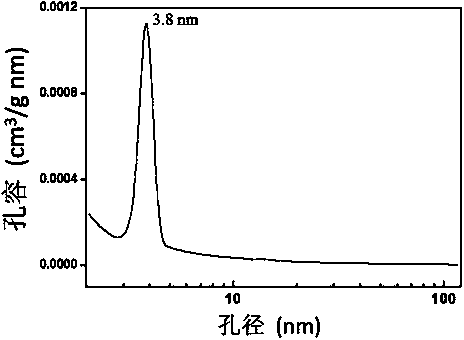

[0038] Configure solutions A and B. Solution A is ammonium metatungstate and copper sulfate plus deionized water (W:Cu mass ratio 1:0.1). The concentration of solution A is 5wt%, and solution B is 50wt% ammonium carbonate solution. While shaking solution A, add solution B dropwise at a rate of 200 μL / min. After the dropwise addition, the particles were filtered to obtain precursor particles (composite crystals); after vacuum drying at 60°C, the resulting precursor particles were 2 Atmosphere (CO:H 2 The volume ratio is 1:1.5), and the carbonization treatment is carried out, and the temperature is raised to 800°C according to the 2°C / min program and kept for 6 hours to obtain a double-porous WC-metal material. Then, the double-porous WC-metal material was treated with 20% hydrochloric acid to obtain the expanded double-porous WC material. The pore size of the sample is double-pore distribution, the small pore size is around 2.8nm, and the second mesopore is around 3-10nm. It...

Embodiment 3

[0040] Configure solutions A and B, A solution is ammonium metatungstate and copper sulfate plus deionized water (W:Cu mass ratio 1:0.2), A solution concentration is 20wt%, B solution is 5wt% ammonium carbonate solution, in While ultrasonically oscillating solution A, add solution B dropwise at a rate of 100 μL / min. After the dropwise addition, the particles were filtered to obtain precursor particles (composite crystals); after vacuum drying at 80°C, the obtained precursor particles were 2 Atmosphere (CO:H 2 The volume ratio is 1:2), and the carbonization treatment is carried out, and the temperature is raised to 750°C according to the 3°C / min program and kept for 8 hours to obtain a double-porous WC-metal material. Then, the double-porous WC-metal material was treated with 20% hydrochloric acid to obtain the expanded double-porous WC material. The pore size of the sample is double-pore distribution, the small pore size is around 5nm, and the second mesopore is around 5-30n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com