Method for synthesizing electrolyte powder of solid oxide fuel cell based on complexing freeze-drying method

A freeze-drying, electrolyte powder technology, applied in solid electrolyte fuel cells, electrolyte immobilization/gelation, circuits, etc., can solve problems such as poor powder uniformity, achieve high repeatability, avoid spontaneous combustion process, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

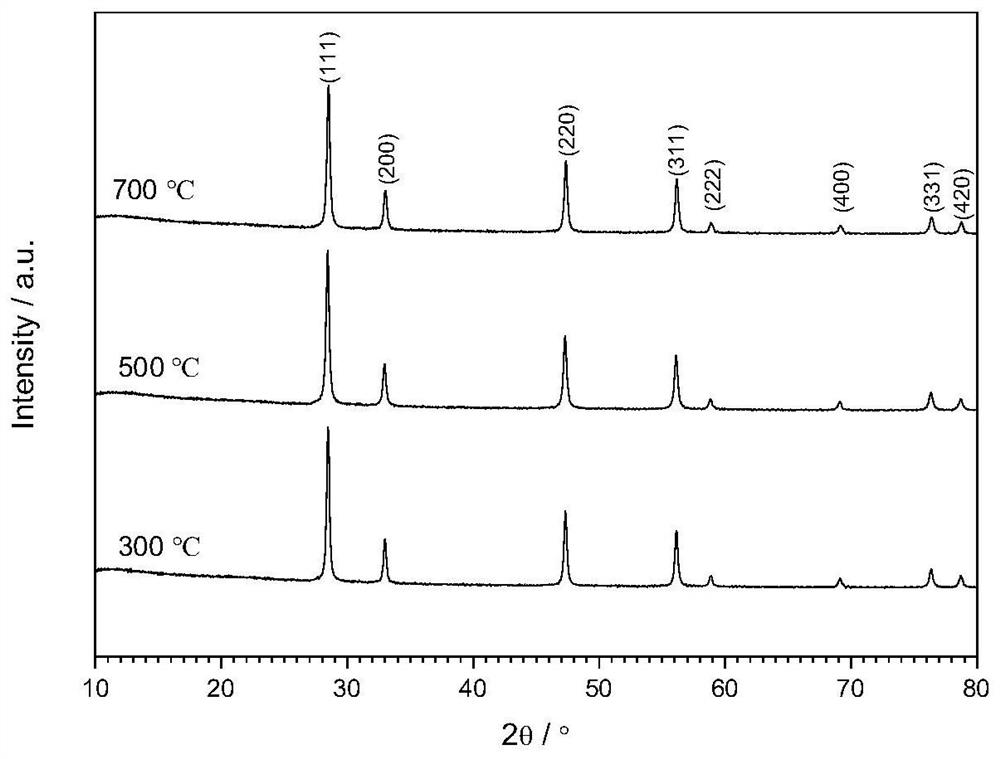

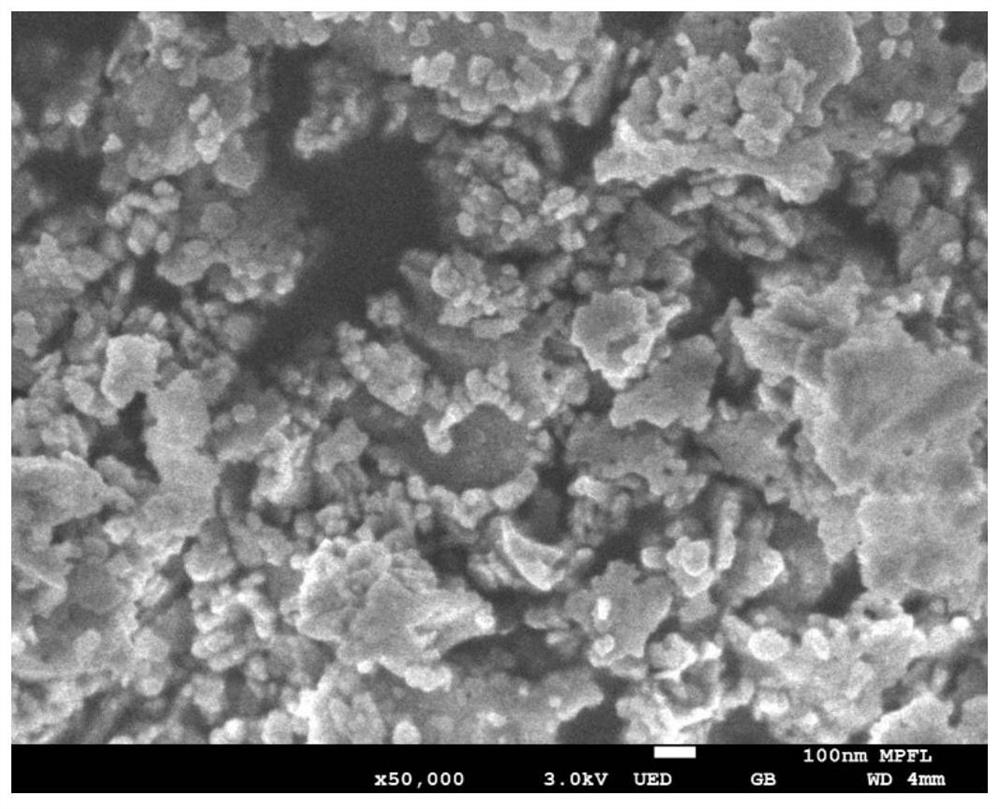

[0060] Synthesis of SDC Electrolyte Powder by Complexation-Freeze Drying Method

[0061] 1) Synthesis of SDC electrolyte powder

[0062] With Ce(NO 3 ) 3 ·6H 2 O and Sm (NO 3 ) 3 ·6H 2 O is the raw material, according to Ce 3+ with Sm 3+ The mol ratio of 4:1 respectively weighs the corresponding metal nitrates, adds deionized water to dissolve, and stirs evenly to obtain mixed metal ion solution;

[0063] 2) adding complexing agent citric acid and glycine to the mixed solution, so that the molar ratio of total metal ions, citric acid, and glycine in the solution is 1:0.6:0.4 to obtain a precursor solution;

[0064] 3) The precursor solution is continuously stirred under the condition of heating in a water bath at 60 °C, and finally a stable metal ion complex solution is formed. At this time, the total metal ion concentration in the solution is 2.5 mol·L -1 ;

[0065] 4) After the complex solution is cooled, freeze it at -80°C for 12 hours to completely freeze it;

...

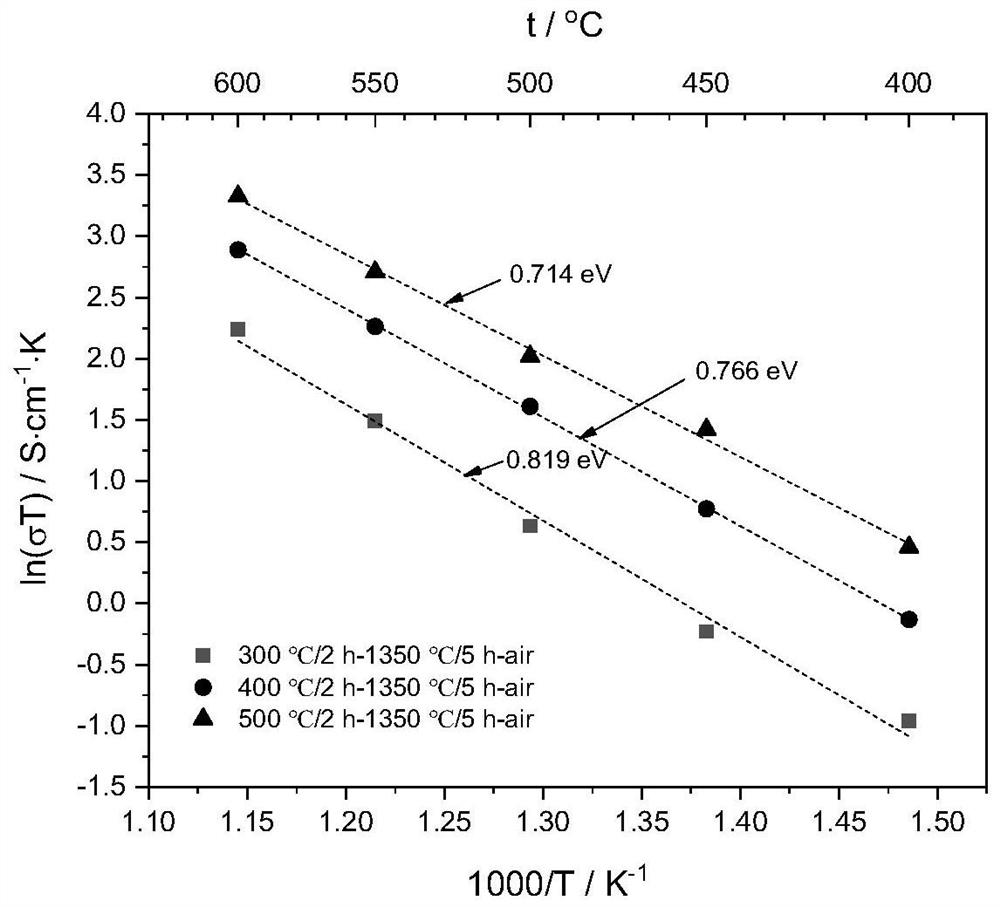

Embodiment 2

[0072] Preparation of single cell with integrated electrolyte matrix structure based on the SDC electrolyte powder in Example 1

[0073] Use graphite powder and the SDC electrolyte powder and graphite pore-forming agent described in Example 1 to form by dry pressing, and sinter at 1350°C for 5h to prepare a porous / dense / porous three-layer integrated SDC electrolyte matrix (see Figure 4 a), in which the thickness of the dense SDC layer is about 70 μm, and then the NiO anode and the Ba 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3-δ (BSCF) cathode, when the anode impregnation amount is 20wt.%, the cathode impregnation amount is 30wt.%, using hydrogen / air operation, the maximum output power density of the single cell at 600 ° C is 249mW·cm -2 ,like Figure 4 as shown in b.

Embodiment 3

[0075] Preparation of Sinterless Symmetrical Electrode Structure Single Cell Based on the SDC Electrolyte Powder in Example 1

[0076] Use the SDC electrolyte powder described in embodiment 1 and Ni 0.8 co 0.15 Al 0.05 LiO 2 (NCAL)-coated nickel foam electrodes were prepared by co-pressing a sintered symmetrical electrode structure single cell, in which the thickness of the electrolyte was about 500 μm, operated with hydrogen / air, and the maximum output power density of the single cell at 550 °C was 969 mW· cm -2 ,like Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com