A kind of preparation method of nasicon type lithium ion solid electrolyte

A solid electrolyte, lithium ion technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrolyte immobilization/gelation, etc., can solve the problems of low conductivity, high conductivity of solid electrolyte, complicated preparation process, etc. The effect of uniform and fine grains, improvement of sinterability and relative density, and improvement of ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

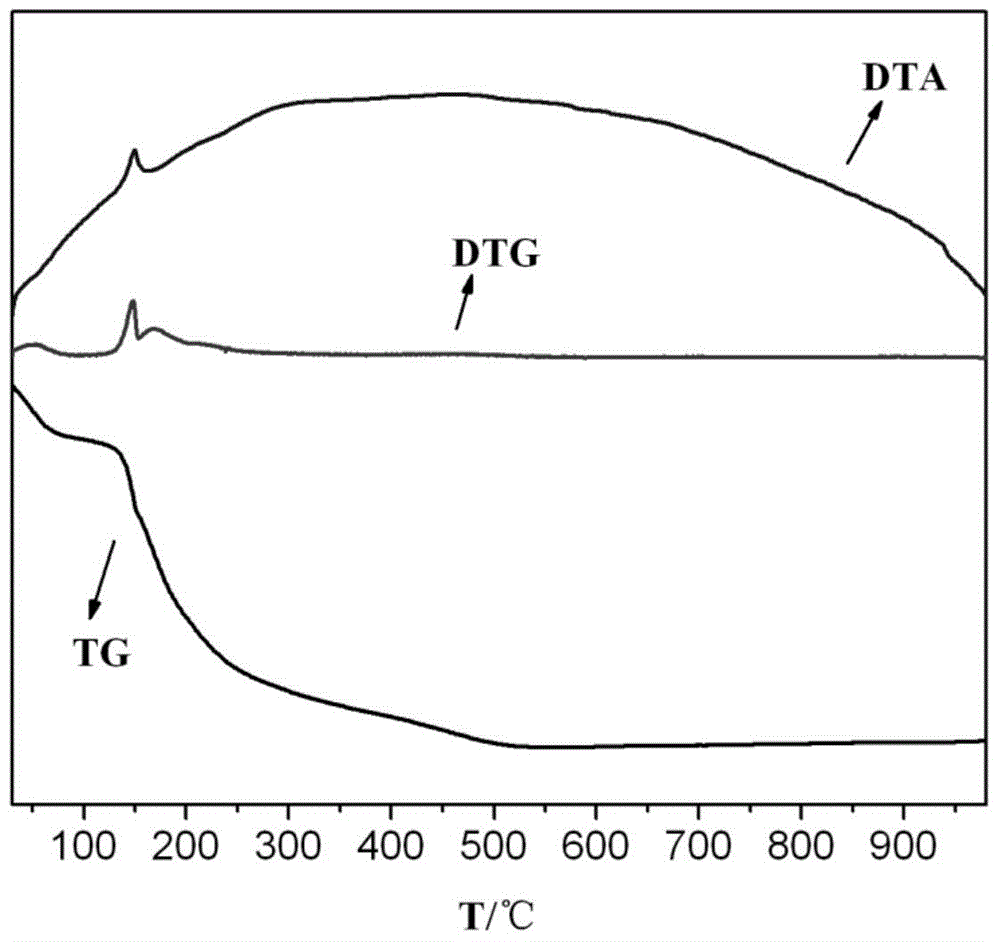

[0027] The preparation method of the NASICON type lithium ion solid electrolyte of the embodiment of the present invention comprises the following steps:

[0028] (1) Weigh lithium nitrate, aluminum nitrate, tetrabutyl titanate and ammonium dihydrogen phosphate according to the stoichiometric ratio.

[0029] (2) Dissolving citric acid in water to obtain a citric acid solution with a concentration of 1-2 mol / L.

[0030] (3) Dissolve lithium nitrate and aluminum nitrate in citric acid solution, stir to form a transparent and uniform nitrate mixed solution. Wherein, the ratio of the amount of citric acid to the metal cation in the nitrate mixed solution is 1:1.

[0031] (4) Prepare absolute ethanol with the same volume as the water in step (2), dissolve tetrabutyl titanate in absolute ethanol, stir to make it clear and transparent, and form an alcohol solution of tetrabutyl titanate.

[0032] (5) In a constant temperature environment, slowly add the tetrabutyl titanate alcohol ...

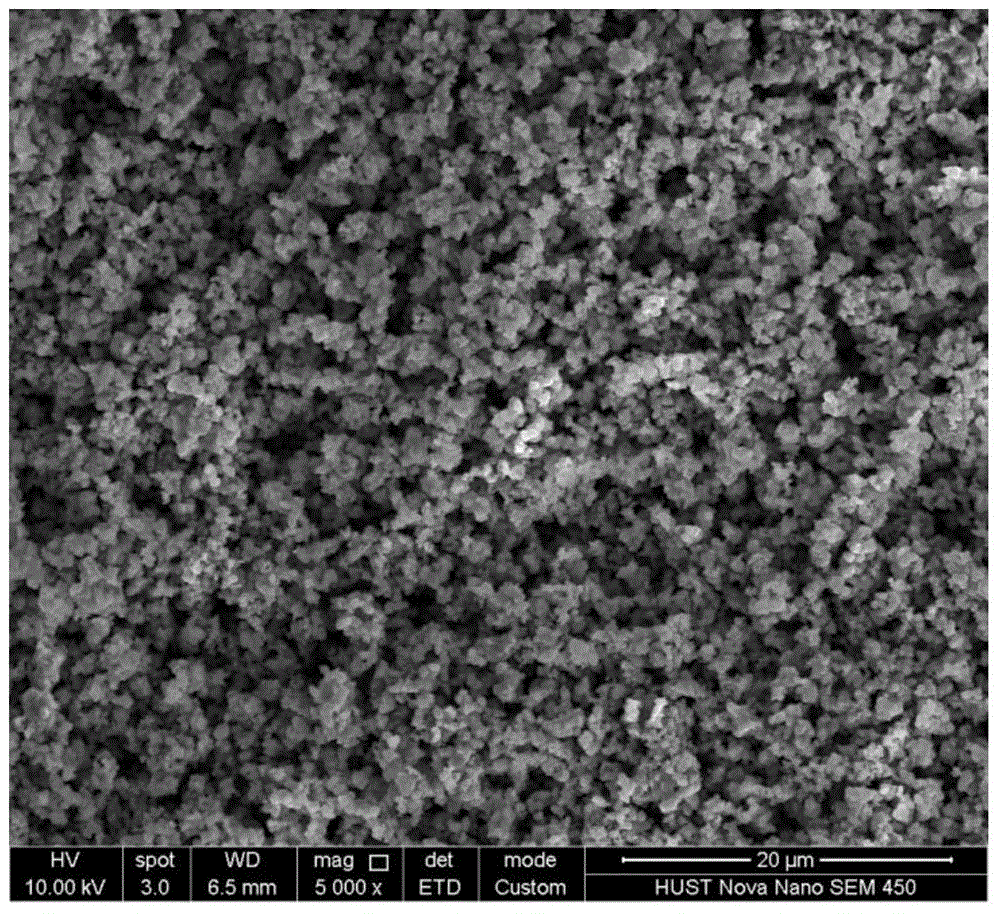

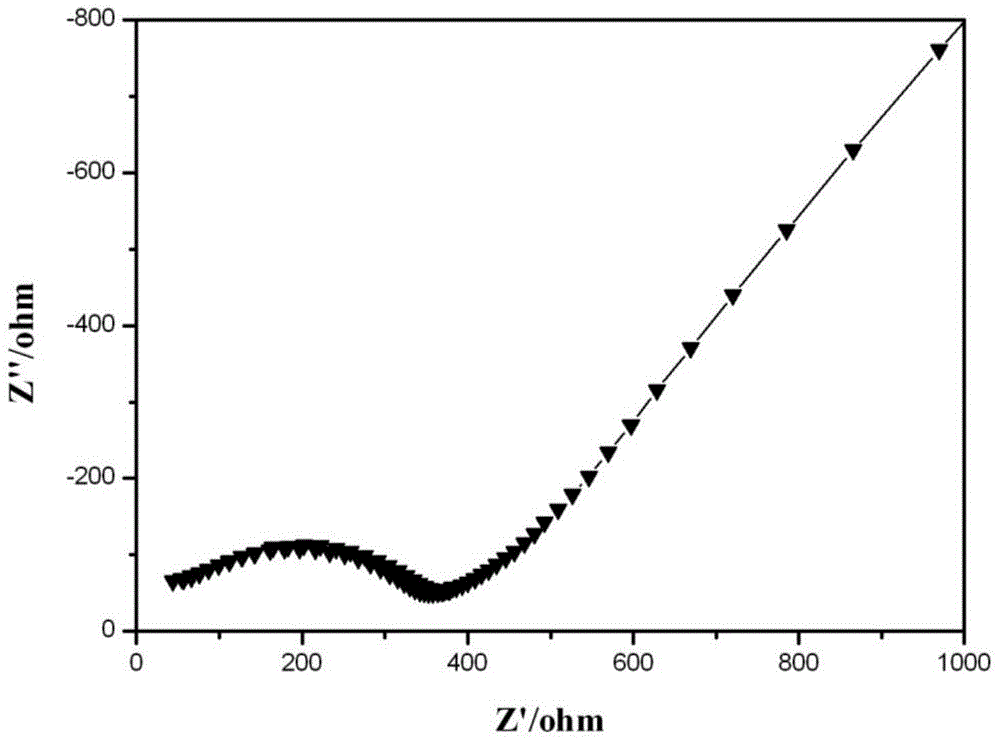

Embodiment 1

[0041] The preparation method of NASICON type lithium ion solid electrolyte comprises the steps:

[0042](1) Weigh lithium nitrate, aluminum nitrate, tetrabutyl titanate and ammonium dihydrogen phosphate according to the stoichiometric ratio.

[0043] (2) Dissolve citric acid in water to obtain a citric acid solution with a concentration of 1mol / L.

[0044] (3) Dissolve lithium nitrate and aluminum nitrate in citric acid solution, stir to form a transparent and uniform nitrate mixed solution. Wherein, the ratio of the amount of citric acid to the metal cation in the nitrate mixed solution is 1:1.

[0045] (4) Prepare absolute ethanol with the same volume as the water in step (2), dissolve tetrabutyl titanate in absolute ethanol, stir to make it clear and transparent, and form an alcohol solution of tetrabutyl titanate.

[0046] (5) In a constant temperature environment of 80°C, slowly add the tetrabutyl titanate alcohol solution prepared in step (4) into the nitrate mixed so...

Embodiment 2

[0054] The preparation method of NASICON type lithium ion solid electrolyte comprises the steps:

[0055] (1) Weigh lithium nitrate, aluminum nitrate, tetrabutyl titanate and ammonium dihydrogen phosphate according to the stoichiometric ratio.

[0056] (2) Dissolve citric acid in water to obtain a citric acid solution with a concentration of 1mol / L.

[0057] (3) Dissolve lithium nitrate and aluminum nitrate in citric acid solution, stir to form a transparent and uniform nitrate mixed solution. Wherein, the ratio of the amount of citric acid to the metal cation in the nitrate mixed solution is 1:1.

[0058] (4) Prepare absolute ethanol with the same volume as the water in step (2), dissolve tetrabutyl titanate in absolute ethanol, stir to make it clear and transparent, and form an alcohol solution of tetrabutyl titanate.

[0059] (5) In a constant temperature environment of 80°C, slowly add the tetrabutyl titanate alcohol solution prepared in step (4) into the nitrate mixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com