Preparation method of high-current-carrying multi-core Bi-2223 superconducting tape under magnetic field

A technology of bi-2223 and superconducting tape, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problem of weak vortex pinning force, fast performance attenuation, and penetration depth Large and other problems, to achieve the effect of improving current carrying capacity, improving orientation and grain boundary quality, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment includes the following steps:

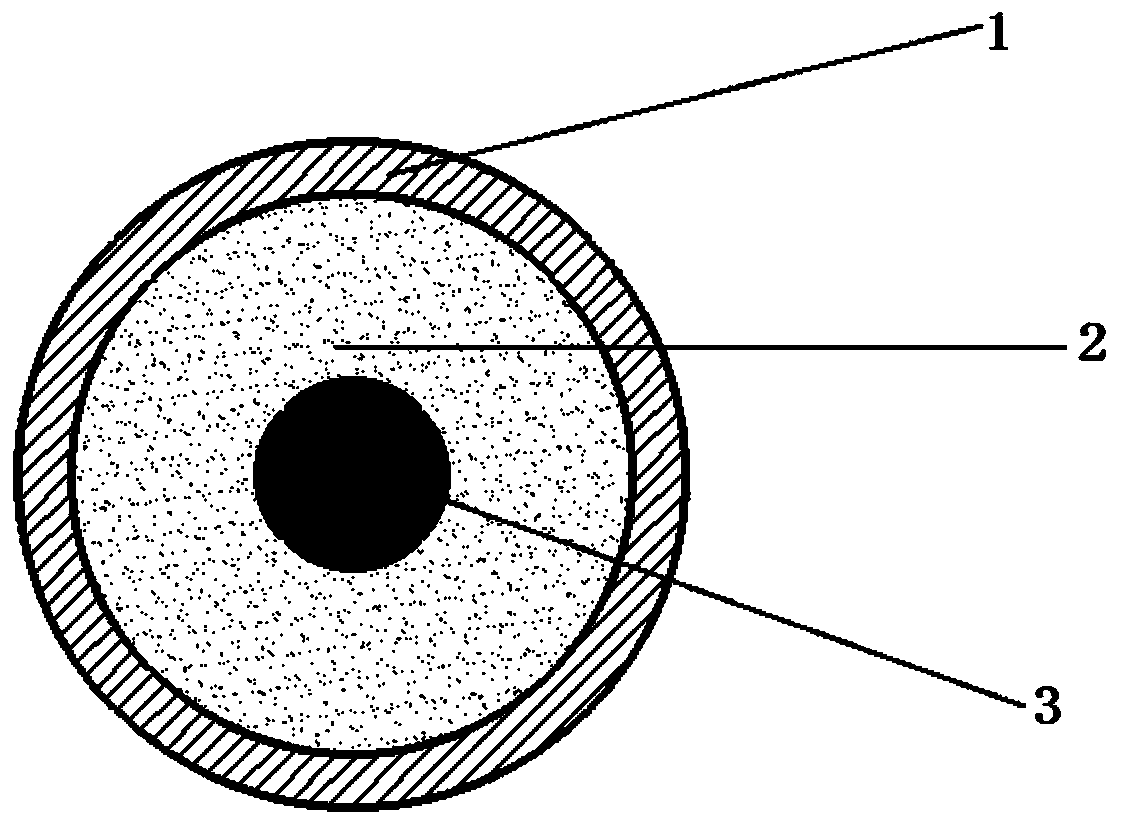

[0030] Step 1. In a glove box with an oxygen partial pressure content of 7.5% and an equilibrium gas of argon gas with a mass purity of 99.995%, use a vibrating table to vibrate the tube under the condition of a vibration frequency of 40Hz, and first introduce the Bi-2223 precursor powder In the metal funnel, start the vibrating table at the same time to vibrate the silver casing, so that the Bi-2223 precursor powder is filled into the gap formed by the inner silver tube and the outer silver tube of the silver casing, and then the CaCuO prepared by the co-precipitation method 2 The powder is filled into the inner silver tube of the silver sleeve. During the vibration filling process, the positions of the inner silver tube and the outer silver tube in the silver sleeve are fixed, and then the inner silver tube is taken out, and the outer silver tube is sealed to obtain the second A tube complex, such as figure 1 As shown; ...

Embodiment 2

[0037] This embodiment includes the following steps:

[0038] Step 1. In a glove box with an oxygen partial pressure content of 7.5% and an equilibrium gas of argon gas with a mass purity of 99.995%, use a vibrating table to vibrate the tube under the condition of a vibration frequency of 40Hz, and first introduce the Bi-2223 precursor powder In the metal funnel, start the vibrating table at the same time to vibrate the silver casing, so that the Bi-2223 precursor powder is filled into the gap formed by the inner silver tube and the outer silver tube of the silver casing, and then the CaCuO prepared by the co-precipitation method 2 The powder is filled into the inner silver tube of the silver sleeve. During the vibration filling process, the positions of the inner silver tube and the outer silver tube in the silver sleeve are fixed, and then the inner silver tube is taken out, and the outer silver tube is sealed to obtain the second A tube complex, such as figure 1 As shown; ...

Embodiment 3

[0045] This embodiment includes the following steps:

[0046] Step 1. In a glove box with an oxygen partial pressure content of 7.5% and an equilibrium gas of argon gas with a mass purity of 99.995%, use a vibrating table to vibrate the tube under the condition of a vibration frequency of 40Hz, and first introduce the Bi-2223 precursor powder In the metal funnel, start the vibrating table at the same time to vibrate the silver casing, so that the Bi-2223 precursor powder is filled into the gap formed by the inner silver tube and the outer silver tube of the silver casing, and then the CaCuO prepared by the co-precipitation method 2 The powder is filled into the inner silver tube of the silver sleeve. During the vibration filling process, the positions of the inner silver tube and the outer silver tube in the silver sleeve are fixed, and then the inner silver tube is taken out, and the outer silver tube is sealed to obtain the second A tube complex, such as figure 1 As shown; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com