Method for comprehensively utilizing kaliophilite ores

A potash nepheline, roasting technology, applied in chemical instruments and methods, applications, potash fertilizers and other directions, can solve the problems of reducing the utilization rate of potassium and aluminum, low production added value, and acid method is not easy to decompose, etc. Useful, suitable for mass production effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

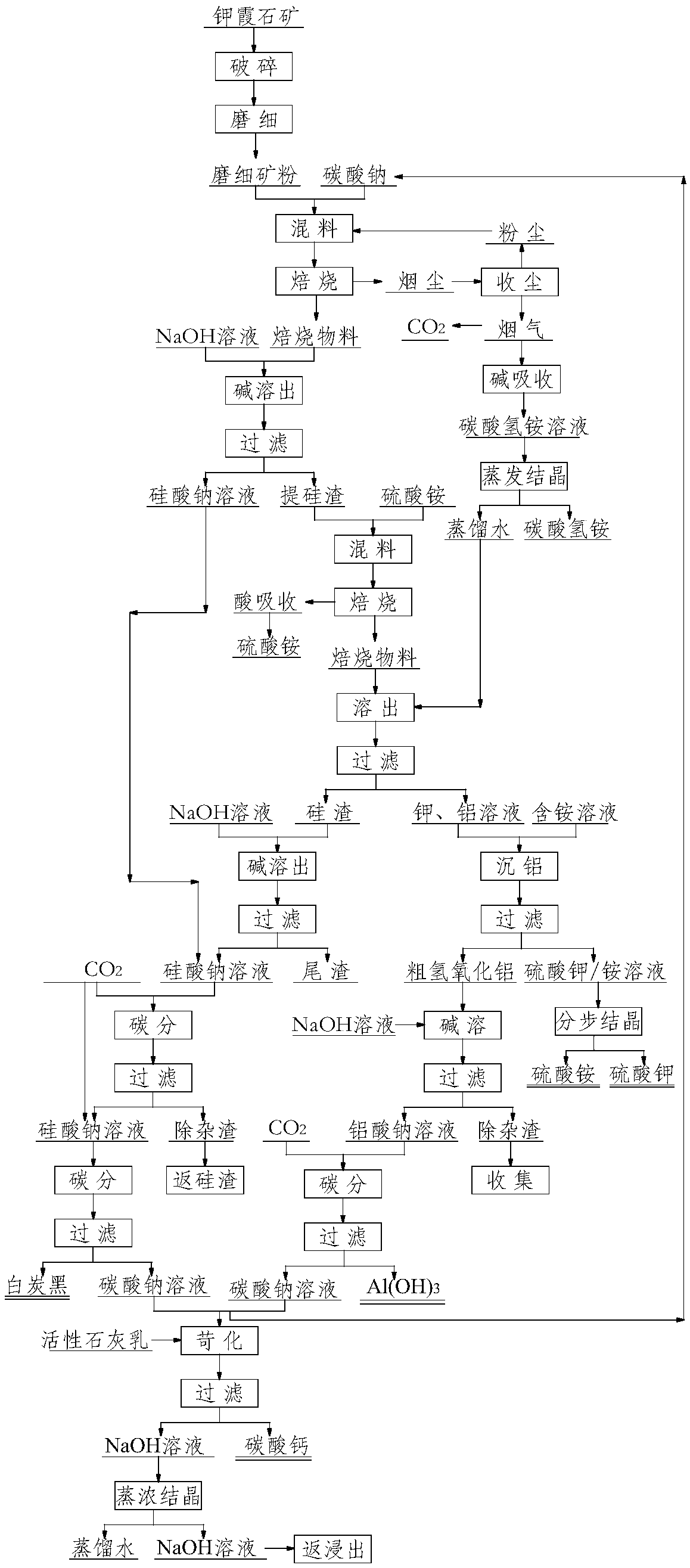

Image

Examples

Embodiment 1

[0037] The present embodiment provides a method for comprehensive utilization of potassium nepheline ore, which specifically comprises the following steps:

[0038] S1. Pretreatment: Pretreatment of potassium nepheline ore.

[0039] Specifically, the chemical composition of the potash nepheline used in the present embodiment mainly includes by weight: SiO 2 62.35%, Al 2 O 3 20.78%, K 2 O 12.66%, Na 2 O 0.70% and Fe 2 O 3 3.16%. The pretreatment mainly includes crushing the nepheline ore first, and then grinding the particle size of the nepheline ore to less than 80 μm, so as to make the subsequent reaction more sufficient.

[0040] S2, mixing and roasting pre-desilication: the pretreated potassium nepheline ore is mixed with sodium carbonate (Na 2 CO 3 ) is mixed evenly, and then a mechanical activation method is used to carry out roasting treatment, the roasting temperature is 850° C., and the roasting holding time is 90 min to obtain the first roasting material. ...

Embodiment 2

[0095] The present embodiment provides a method for comprehensive utilization of potassium nepheline ore, which specifically comprises the following steps:

[0096] S1. Pretreatment: Pretreatment of potassium nepheline ore. Specifically, the chemical composition of the potash nepheline used in the present embodiment mainly includes by weight: SiO 2 55.90%, Al 2 O 3 19.83%, K 2 O 13.72%, Na 2 O 0.02% and Fe 2 O 3 7.65%. Refer to Embodiment 1 for the preprocessing process, which is not repeated here.

[0097] S2, mixing and roasting pre-desilication: the pre-treated potassium nepheline ore is mixed with Na 2 CO 3 Mix evenly, and then use mechanical activation to carry out roasting treatment, the roasting temperature is 875 DEG C, and the roasting holding time is 75min to obtain the first roasting material. Among them, the amount of sodium carbonate is SiO in potassium nepheline ore 2 Just the Na required for the complete reaction 2 CO 3 1.25 times the theoretical...

Embodiment 3

[0113] The present embodiment provides a method for comprehensive utilization of potassium nepheline ore, which specifically comprises the following steps:

[0114] S1. Pretreatment: Pretreatment of potassium nepheline ore. Specifically, the chemical composition of the potash nepheline used in the present embodiment mainly includes by weight: SiO 2 52.82%, Al 2 O 3 22.50%, K 2 O 14.22%, Na 2 O 0.54% and Fe 2 O 3 4.88%. Refer to Embodiment 1 for the preprocessing process, which is not repeated here.

[0115] S2, mixing and roasting pre-desilication: the pre-treated potassium nepheline ore is mixed with Na 2 CO 3 Mix uniformly, and then use mechanical activation to carry out roasting treatment, the roasting temperature is 800 DEG C, and the roasting holding time is 120min to obtain the first roasting material. Among them, the amount of sodium carbonate is SiO in potassium nepheline ore 2 Just the Na required for the complete reaction 2 CO 3 0.8 times the theoreti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com