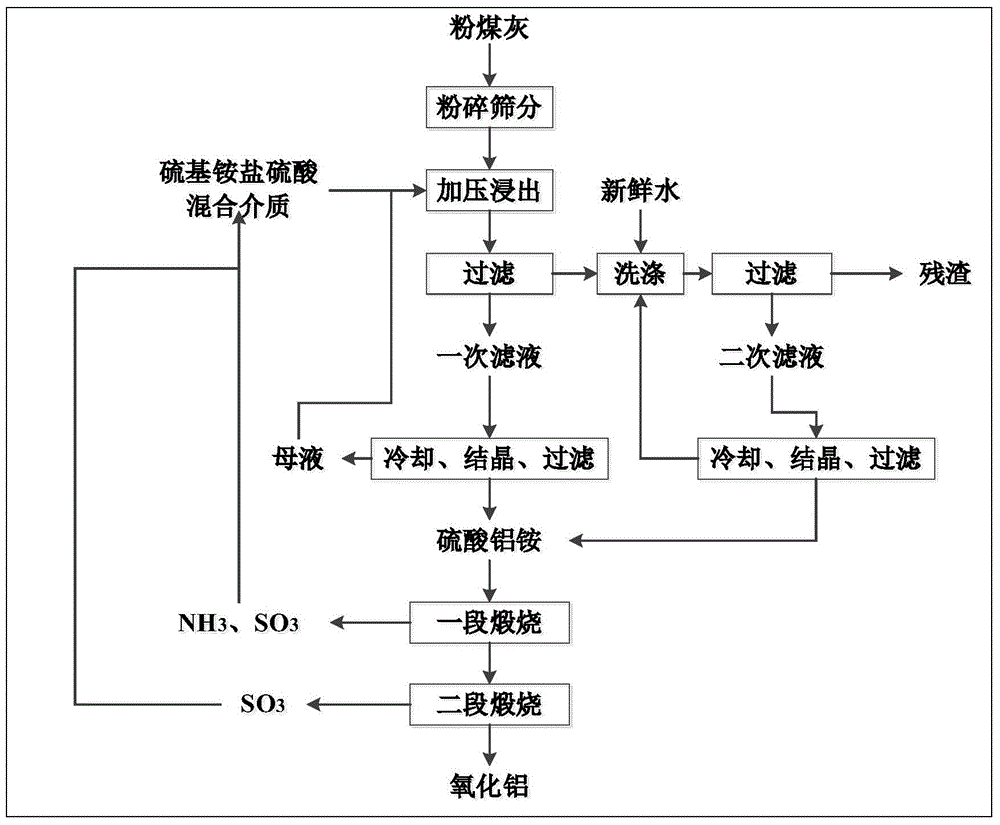

Method for extracting alumina from fly ash through sulfo ammonium salt mixing medium system

A technology of mixed media and sulfammonium salt, which is applied in the direction of alumina/aluminum hydroxide, can solve the problems of difficult recovery of ammonia gas, difficult separation of impurities, and large consumption of sulfide ammonium salt, so as to achieve efficient utilization and improve extraction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

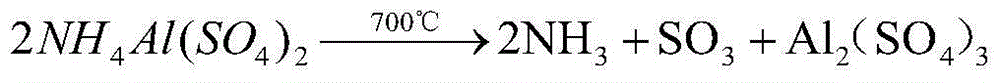

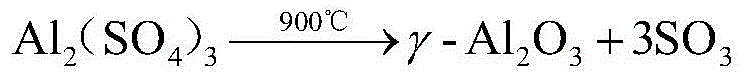

[0056] The fly ash of a coal-fired power plant selected in this embodiment has an alumina content of 47.58% and a silicon oxide content of 44.30%. The specific process is as follows:

[0057] 1) Mechanically pulverize and sieve the fly ash to a particle size smaller than 100 mesh;

[0058] 2) Prepare NH 4 + The concentration is 5mol / L, H + A mixed medium system of ammonium sulfate and sulfuric acid with a concentration of 15mol / L;

[0059] 3) According to the liquid-solid ratio of 10 / 3 (ml / g), add 33.3g of the fly ash obtained in step 1) and 100ml of the mixed medium solution obtained in step 2) into the closed reactor with stirring , carry out alumina leaching reaction;

[0060] 4) Heat the closed system in step 3) to 220°C, the pressure is about 0.25MPa, and react for 6h;

[0061] 5) Cool the system after the reaction in step 4) to 90°C, and filter to obtain the primary filtrate and primary filter residue;

[0062] 6) Cool the primary filtrate obtained in step 5) to 10...

Embodiment 2

[0071] The fly ash of a coal-fired power plant selected in this embodiment has an alumina content of 25.58% and a silicon oxide content of 67.12%. The specific process is as follows:

[0072] 1) Mechanically pulverize and sieve the fly ash to a particle size smaller than 200 mesh;

[0073] 2) Prepare NH 4 + The concentration is 20mol / L, H + A mixed medium system of ammonium sulfate and sulfuric acid with a concentration of 20mol / L;

[0074] 3) Add 50.0g of the fly ash obtained in step 1) and 100ml of the mixed medium solution obtained in step 2) into a closed reactor with stirring at a liquid-solid ratio of 10 / 2 (ml / g) , carry out alumina leaching reaction;

[0075] 4) Heat the closed system in step 3) to 240°C, the pressure is about 0.4MPa, and react for 0.5h;

[0076] 5) Cool the system after the reaction in step 4) to 95°C, and filter to obtain the primary filtrate and primary filter residue;

[0077] 6) Cool the primary filtrate obtained in step 5) to 15°C, a large a...

Embodiment 3

[0086] The fly ash of a coal-fired power plant selected in this embodiment has an alumina content of 32.29% and a silicon oxide content of 60.06%. The specific process is as follows:

[0087] 1) Mechanically pulverize and sieve the fly ash to a particle size smaller than 300 mesh;

[0088] 2) Prepare NH 4 + The concentration is 15mol / L, H + A mixed medium system of ammonium sulfate and sulfuric acid with a concentration of 25mol / L;

[0089] 3) According to the liquid-solid ratio of 10 / 4 (ml / g), add 25.0g of the fly ash obtained in step 1) and 100ml of the mixed medium solution obtained in step 2) into the closed reactor with stirring , carry out alumina leaching reaction;

[0090] 4) Heat the closed system in step 3) to 120°C, the pressure is about 0.2MPa, and react for 6h;

[0091] 5) Cool the system after the reaction in step 4) to 75°C, and filter to obtain the primary filtrate and primary filter residue;

[0092] 6) Cool the primary filtrate obtained in step 5) to 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com