Resourceful treatment process of waste acid

A treatment process and recycling technology, applied in the field of waste acid recycling treatment process, can solve the problems of low value of polyaluminum sulfate products, and achieve the effect of increasing acid recovery rate, reducing waste and high value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

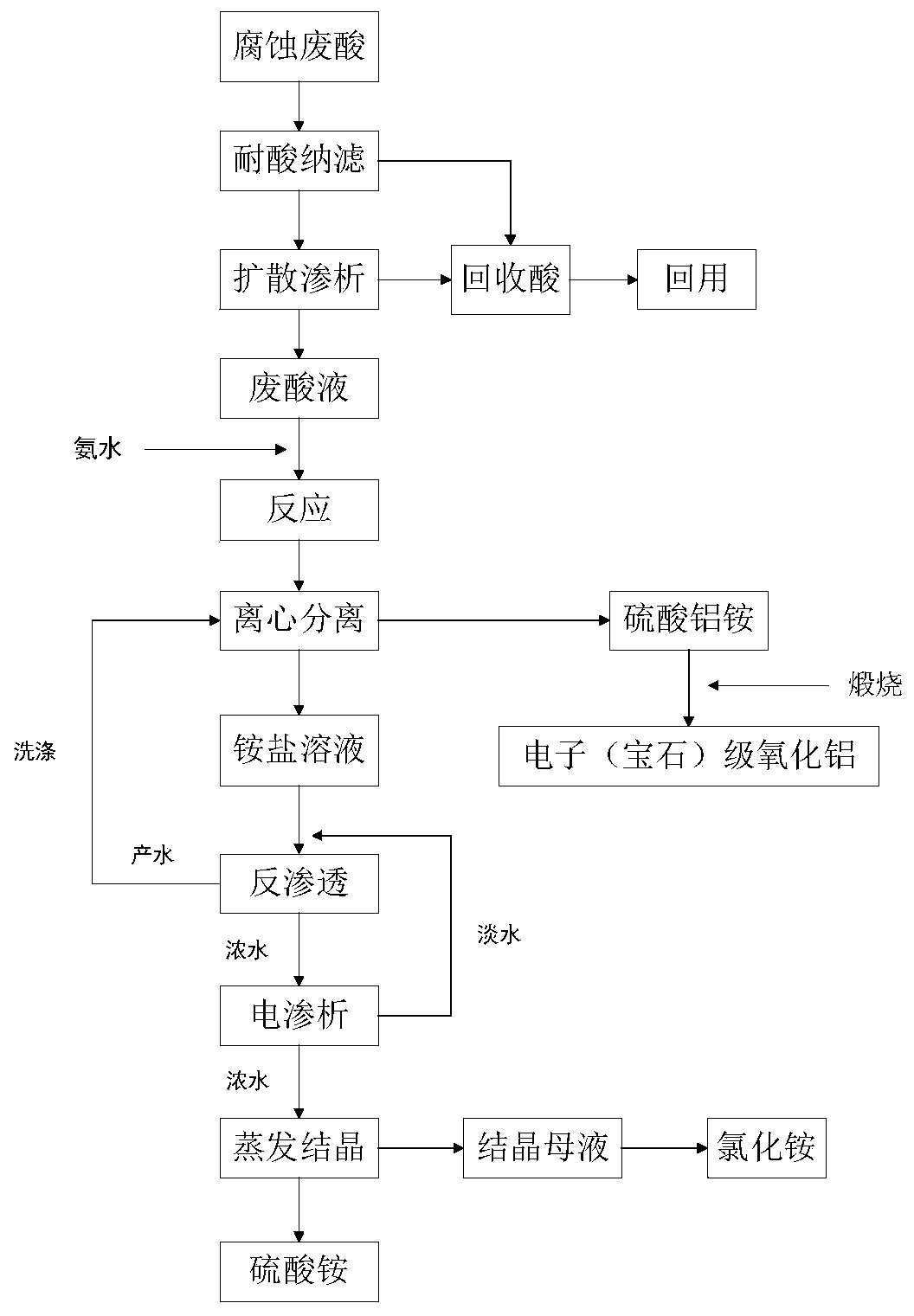

[0030] See figure 1 , the waste acid recycling process of the present embodiment comprises the following steps:

[0031] Step 1: Use the acid-resistant nanofiltration process to filter the corrosion waste acid solution to remove Al in the waste acid 3+ , to obtain permeate and concentrate. The molecular weight cut-off of the nanofiltration membrane in the acid-resistant nanofiltration process is 150Da-300Da, the operating pressure of the nanofiltration membrane is 2.0MPa-6.0MPa, and the operating temperature is 20°C-35°C. The permeate is recycled acid that meets the reuse standard and can be recycled. The relevant data after acid-resistant nanofiltration process are shown in the following table:

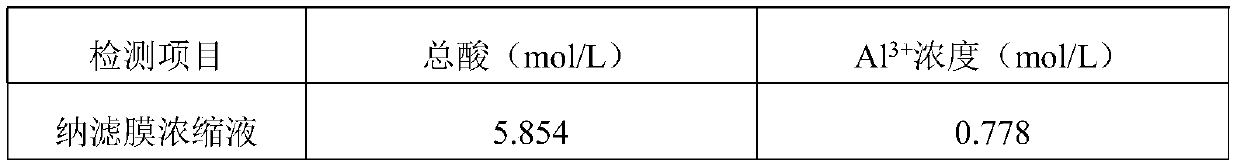

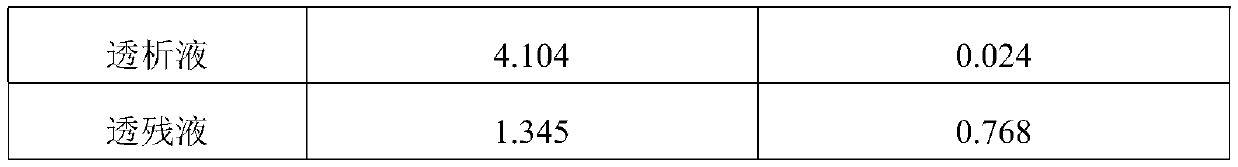

[0032] Test items Total acid (mol / L) Al 3+ Concentration (mol / L)

Waste acid stock solution 5.298 0.446 recovery acid 4.862 0.014 Nanofiltration Membrane Concentrate 5.854 0.778

[0033] The recovery rate of nanofiltration membrane to aci...

Embodiment 2

[0044] The recycling process of waste acid of the present embodiment comprises the following steps:

[0045] Step 1: Use the acid-resistant nanofiltration process to filter the corrosion waste acid solution to remove Al in the waste acid 3+ , to obtain permeate and concentrate. The molecular weight cut-off of the nanofiltration membrane in the acid-resistant nanofiltration process is 150Da-300Da, the operating pressure of the nanofiltration membrane is 2.0MPa-6.0MPa, and the operating temperature is 20°C-35°C. The permeate is recycled acid that meets the reuse standard and can be recycled. The relevant data after acid-resistant nanofiltration process are shown in the following table:

[0046] Test items Total acid (mol / L) al 3+ Concentration (mol / L)

Waste acid stock solution 6.323 0.266 recovery acid 5.782 0.008 Nanofiltration Membrane Concentrate 6.852 0.464

[0047] The recovery rate of nanofiltration membrane to acid is 50%, and...

Embodiment 3

[0057] The recycling process of waste acid of the present embodiment comprises the following steps:

[0058] Step 1: Use the acid-resistant nanofiltration process to filter the corrosion waste acid solution to remove Al in the waste acid 3+ , to obtain permeate and concentrate. The molecular weight cut-off of the nanofiltration membrane in the acid-resistant nanofiltration process is 150Da-300Da, the operating pressure of the nanofiltration membrane is 2.0MPa-6.0MPa, and the operating temperature is 20°C-35°C. The permeate is recycled acid that meets the reuse standard and can be recycled. The relevant data after acid-resistant nanofiltration process are shown in the following table:

[0059] Test items Total acid (mol / L) al 3+ Concentration (mol / L)

Waste acid stock solution 8.530 0.330 recovery acid 7.828 0.010 Nanofiltration Membrane Concentrate 9.425 0.575

[0060] The recovery rate of nanofiltration membrane to acid is 50%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com