Structural-thermal-insulation integrated and high-strength alumina bubble ceramic and preparation method thereof

A high-strength aluminum oxide hollow ball technology, which is applied in the field of hollow ball ceramic preparation, can solve the problems of lower softening temperature under load, limited application range, and short service life, and achieve high softening temperature under load, low refiring line shrinkage, The effect of improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

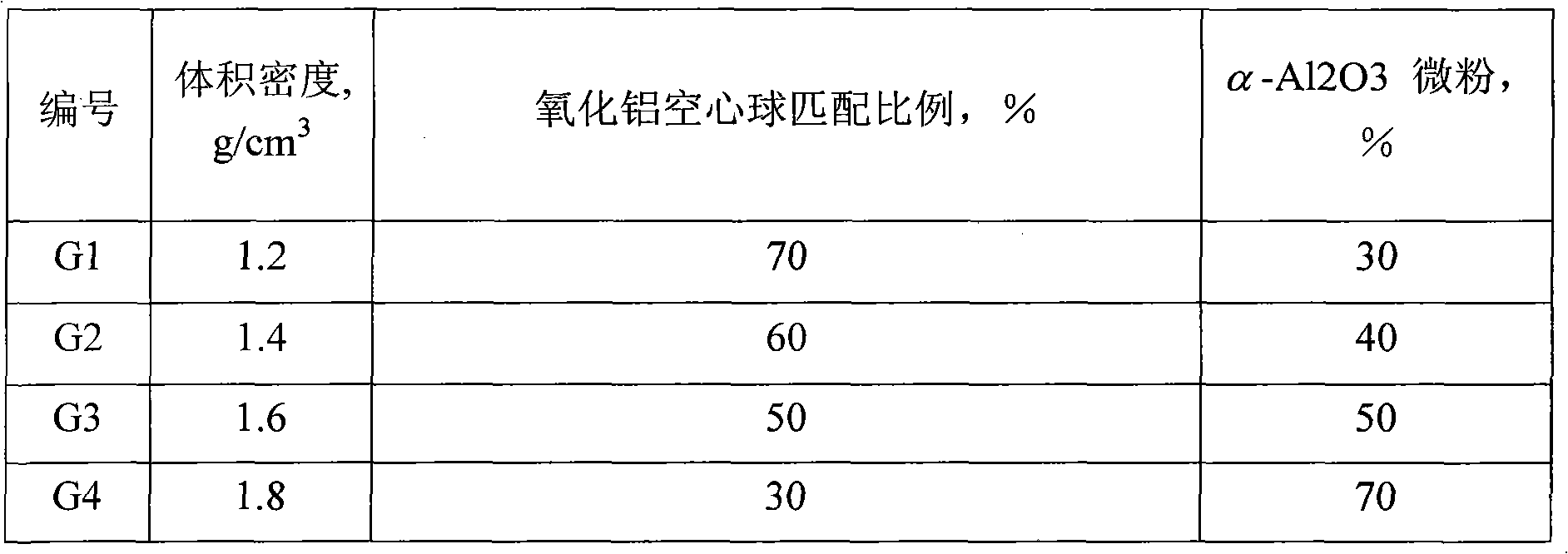

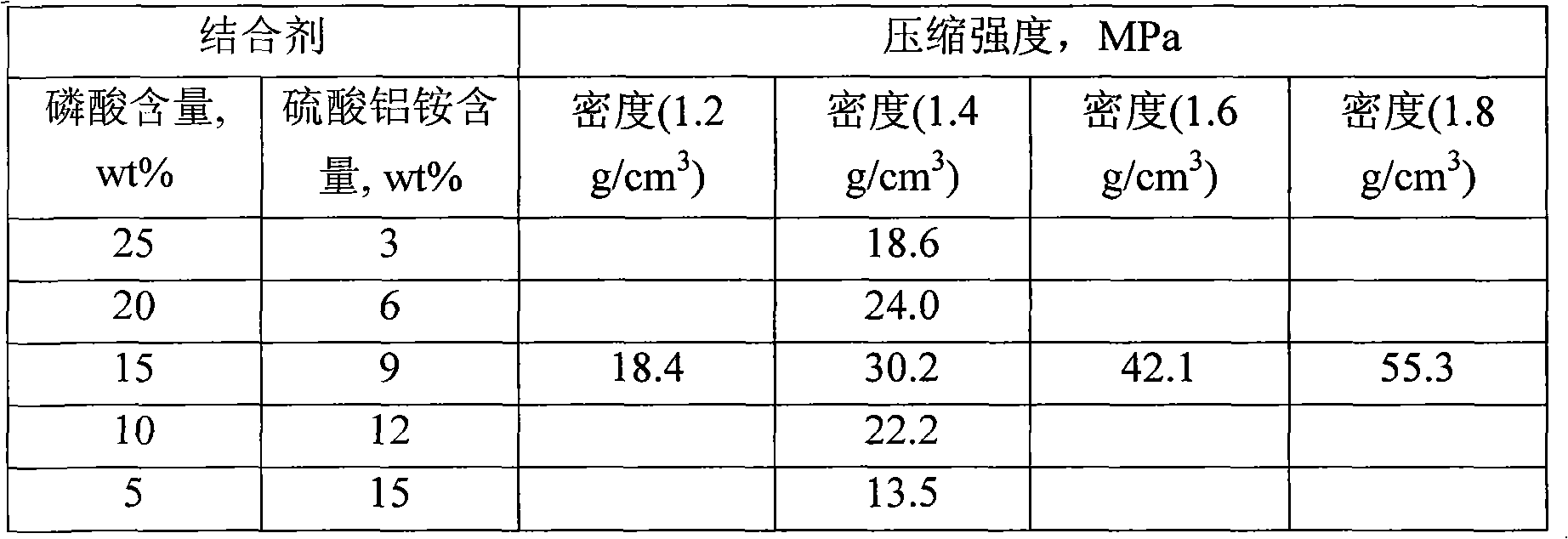

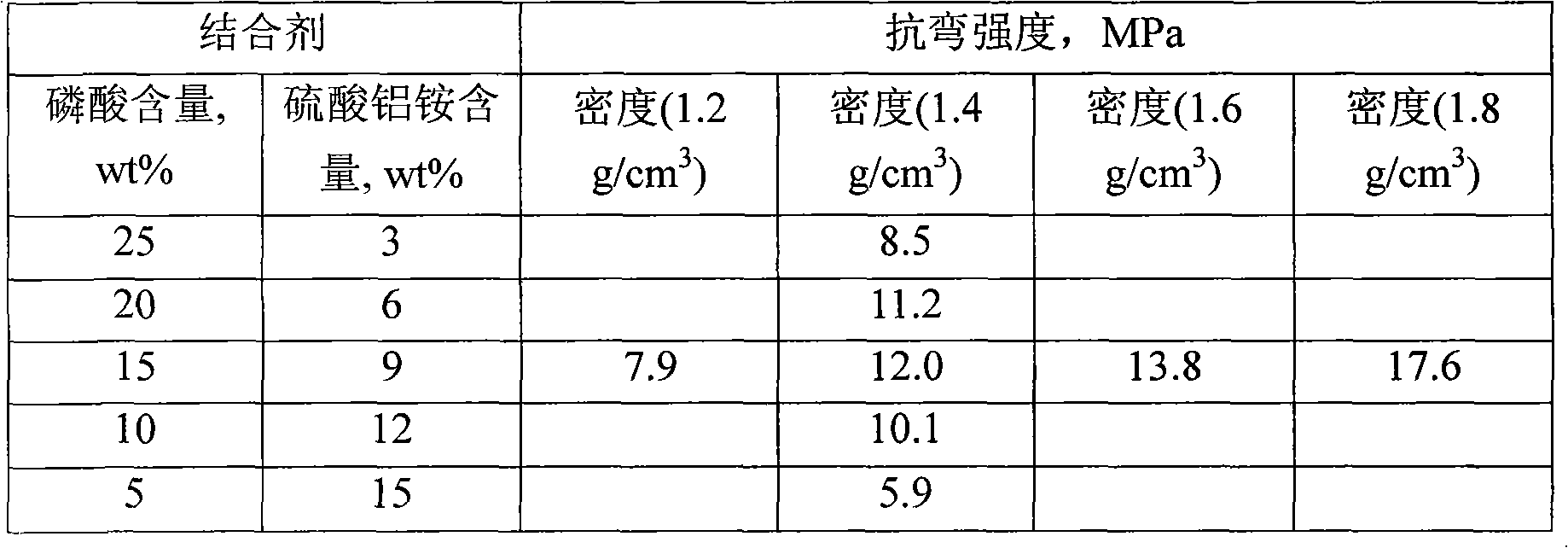

[0016] According to the needs, the formula of structural heat insulation integrated alumina hollow ball ceramics with different densities is shown in Table 1; the composite binder is an aqueous solution with a phosphoric acid content of 5-25wt% and an aluminum ammonium sulfate content of 3-15wt%; light The compressive strength of alumina hollow sphere ceramics is 10-55MPa, and the flexural strength is 5-13MPa. Table 2 and Table 3 are the compressive strength and flexural strength of lightweight alumina hollow sphere ceramics with different concentrations of binders and densities.

[0017] Table 1 The gradation and proportion of α-Al2O3 fine powder of light alumina hollow sphere ceramics with different densities

[0018]

[0019] Table 2 Compressive strength of composite binder combined with lightweight alumina hollow sphere ceramics

[0020]

[0021] Table 3 Bending strength of composite binder combined with lightweight alumina hollow sphere ceramics

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com