Patents

Literature

35results about How to "Reduce the cost of waste treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

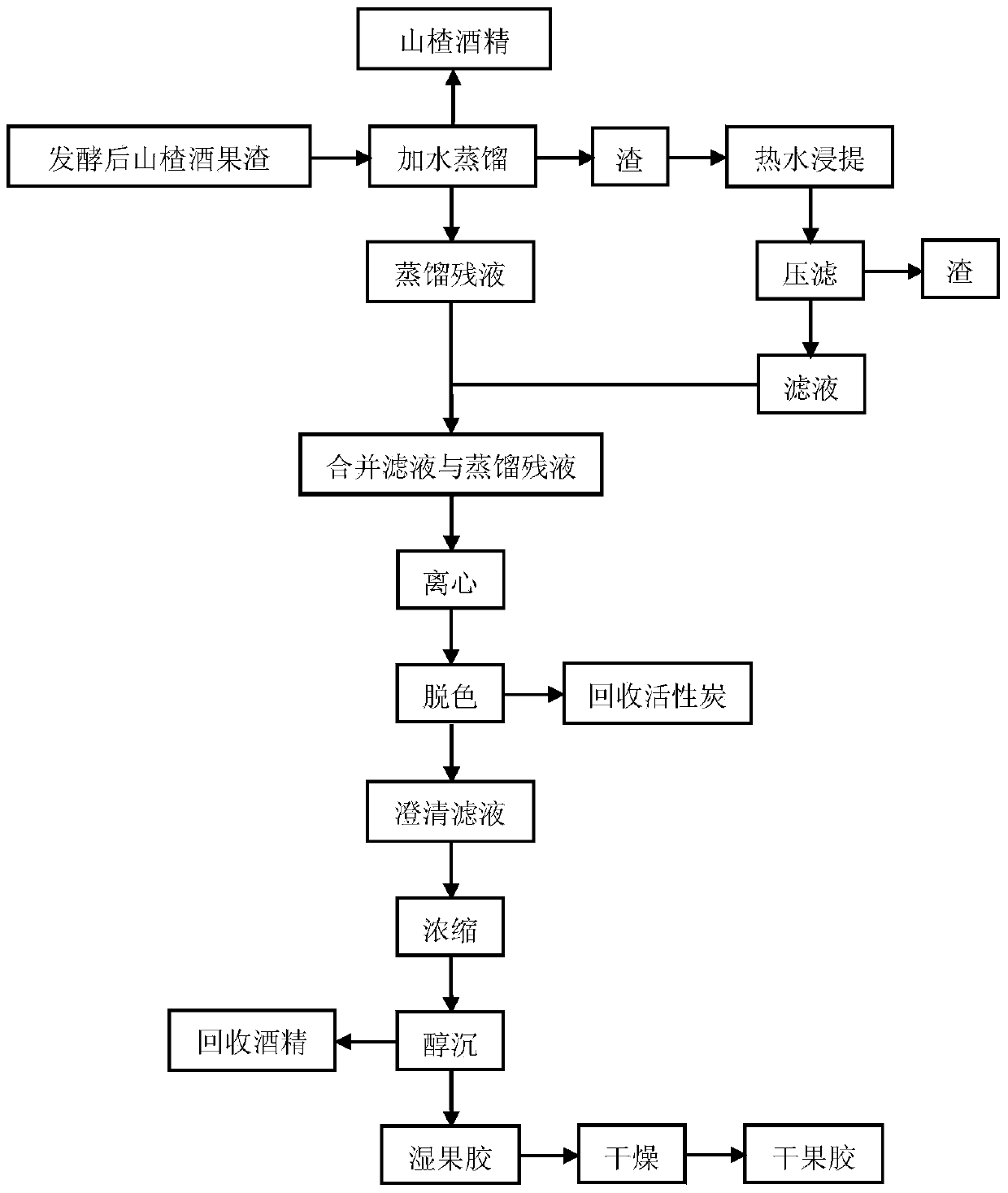

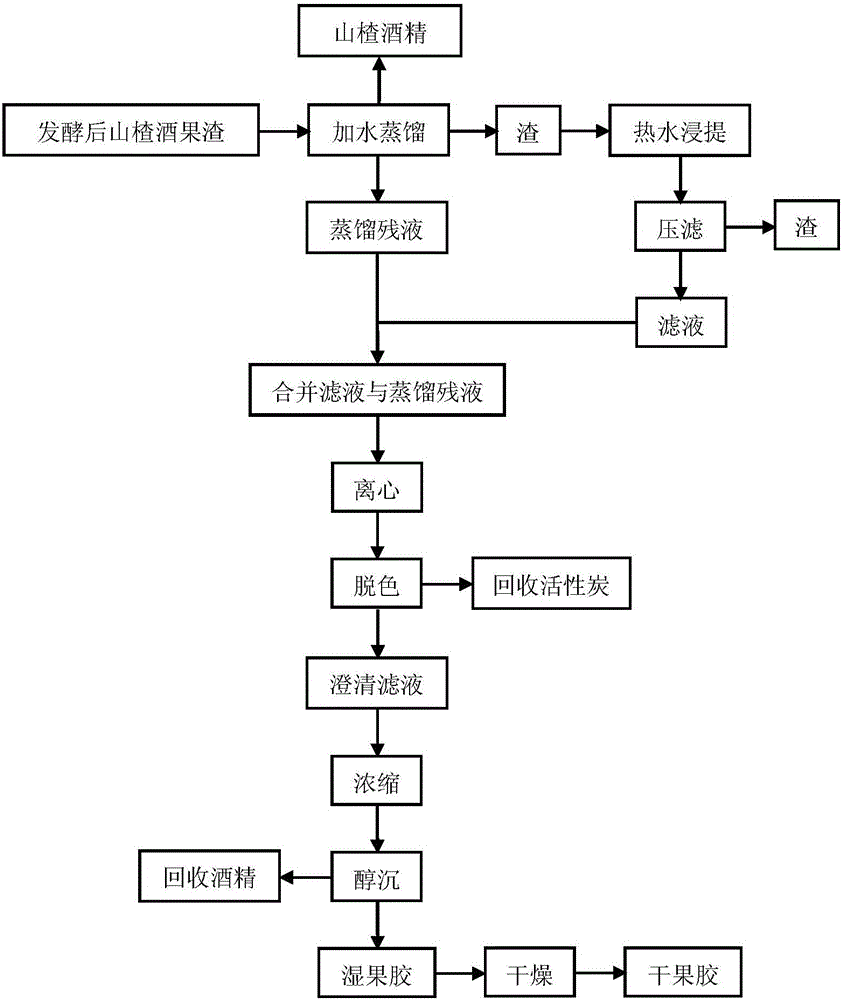

Method for extracting pectin from fermented hawthorn wine pomace

ActiveCN103739741ATake advantage ofFully extracted hawthorn wine pomace after alcohol fermentationRaffinateAcid substances

The invention provides a method for extracting pectin from fermented hawthorn wine pomace. The method comprises the following steps: distilling fermented hawthorn pomace with the ratio of the fermented hawthorn pomace to water being (1-2):2; leaching the distilled residue at 85-95 DEG C for an hour; decolorizing by using granular activated carbon (washed by 1%-5% (m / v) deionized water) at 80 DEG C for 30-90 minutes, carrying out low-temperature alcohol participation by using alcohol of which the concentration is 55% (V / V) at 5 DEG C for 12 hours and carrying out room-temperature alcohol washing by using the alcohol of which the concentration is 70% (V / V) for 1 hour; further hydrolyzing protopectin in the pomace into soluble pectin and transferring the soluble pectin into water, and carrying out filter pressing to obtain a filtrate; merging the filtrate with distilled raffinate, and centrifuging, so as to obtain a clear and transparent pectin solution; and carrying out decolorizing by utilizing granular activated carbon washed by deionized water and alcohol participation on the pectin solution, drying and crushing to obtain hawthorn pectin powder. Compared with an acid hydrolysis method, no acid is added to the pectin extraction process, a new acid substance is prevented from being introduced to the system, and the difficulty is reduced for development and utilization of the residue after pectin extraction.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

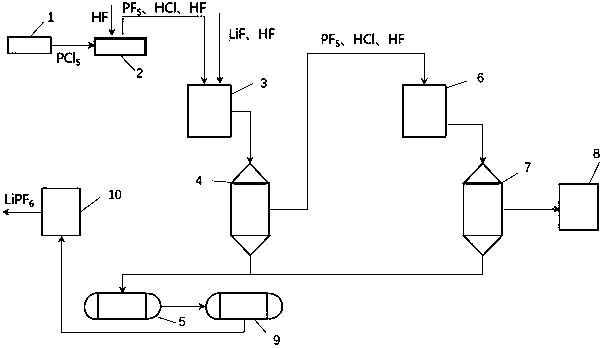

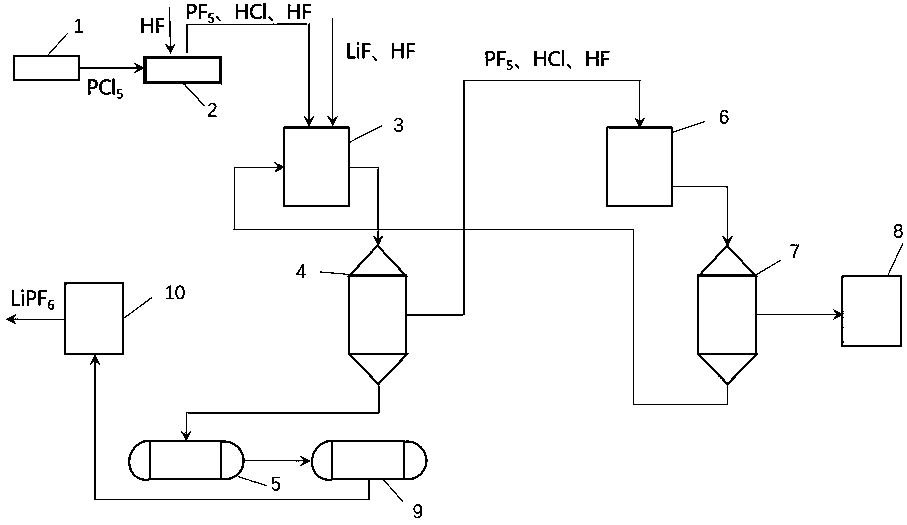

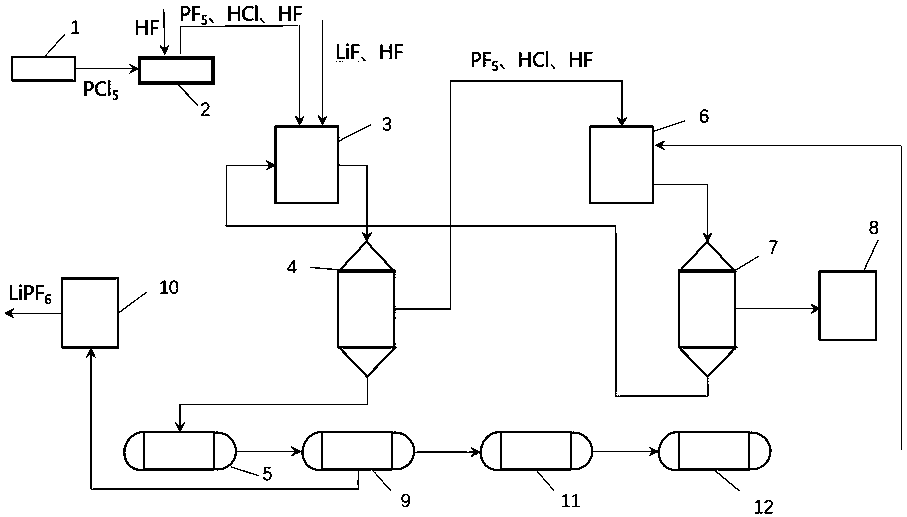

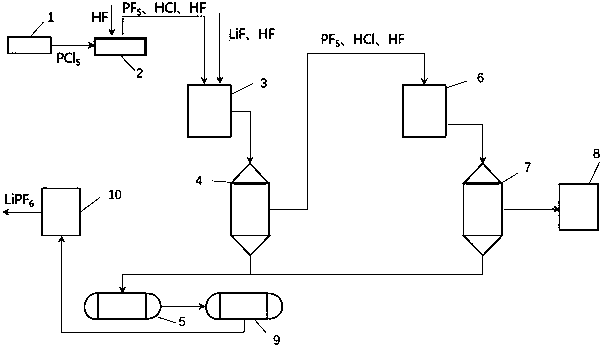

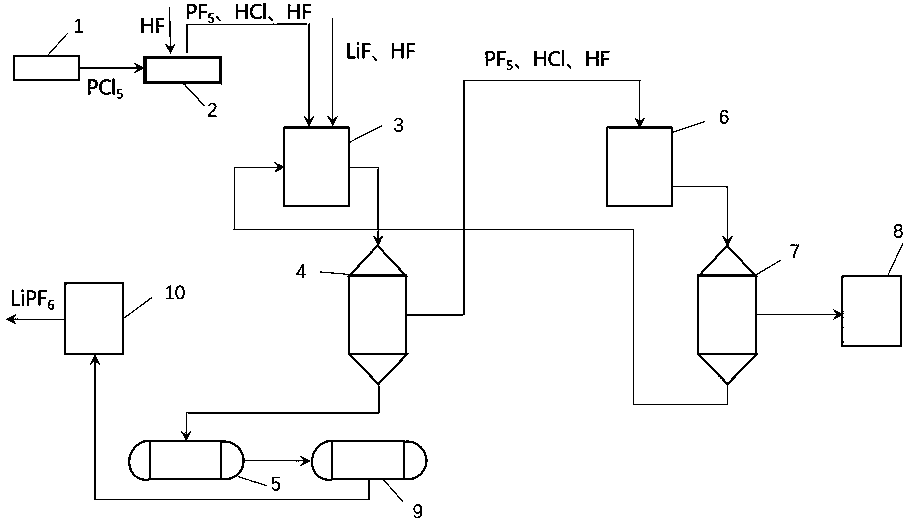

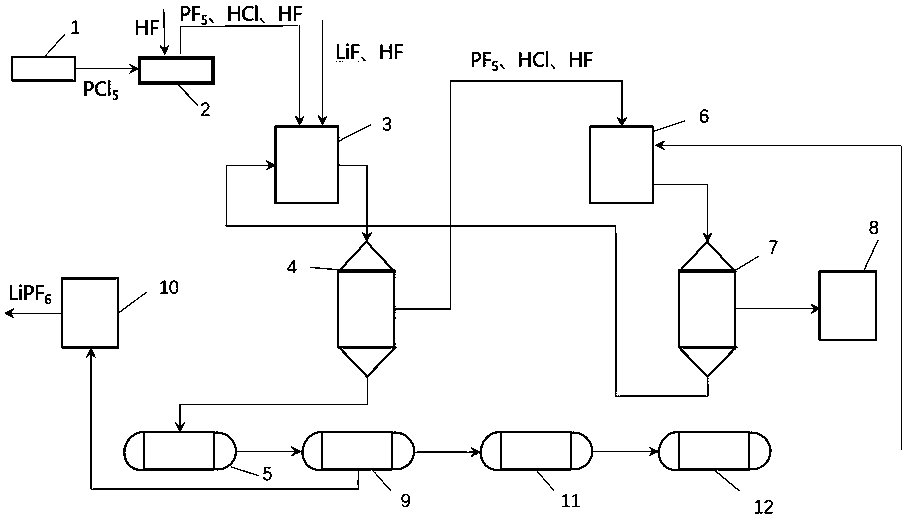

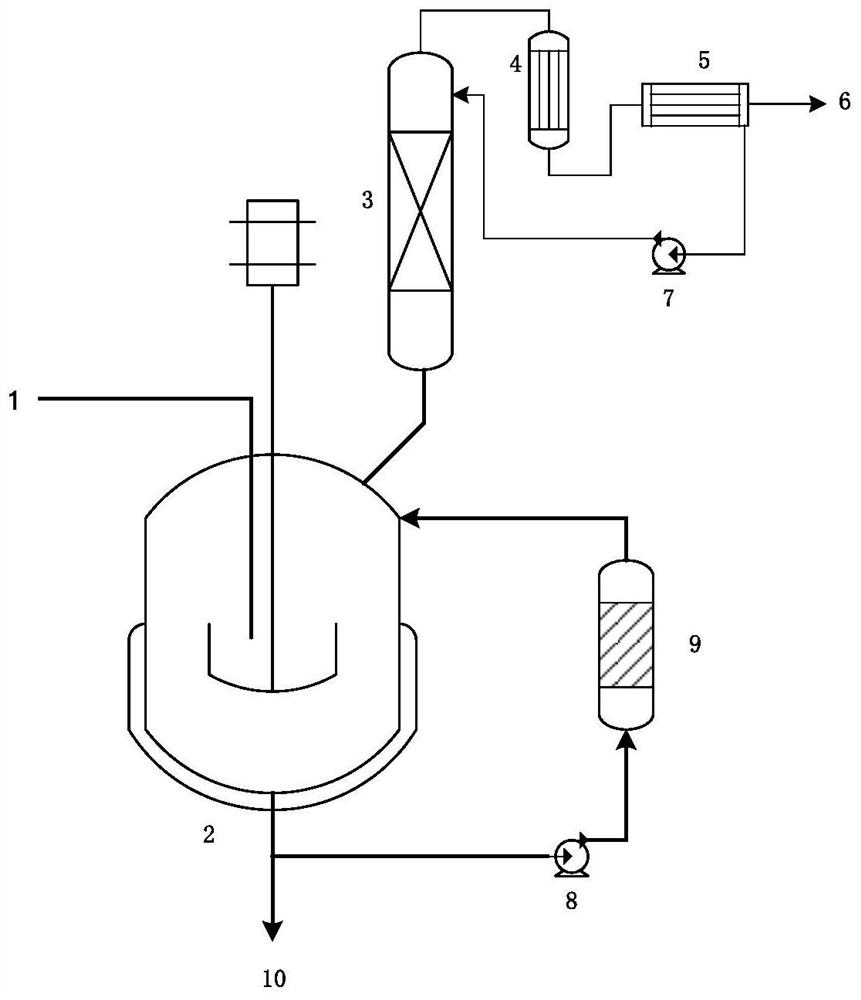

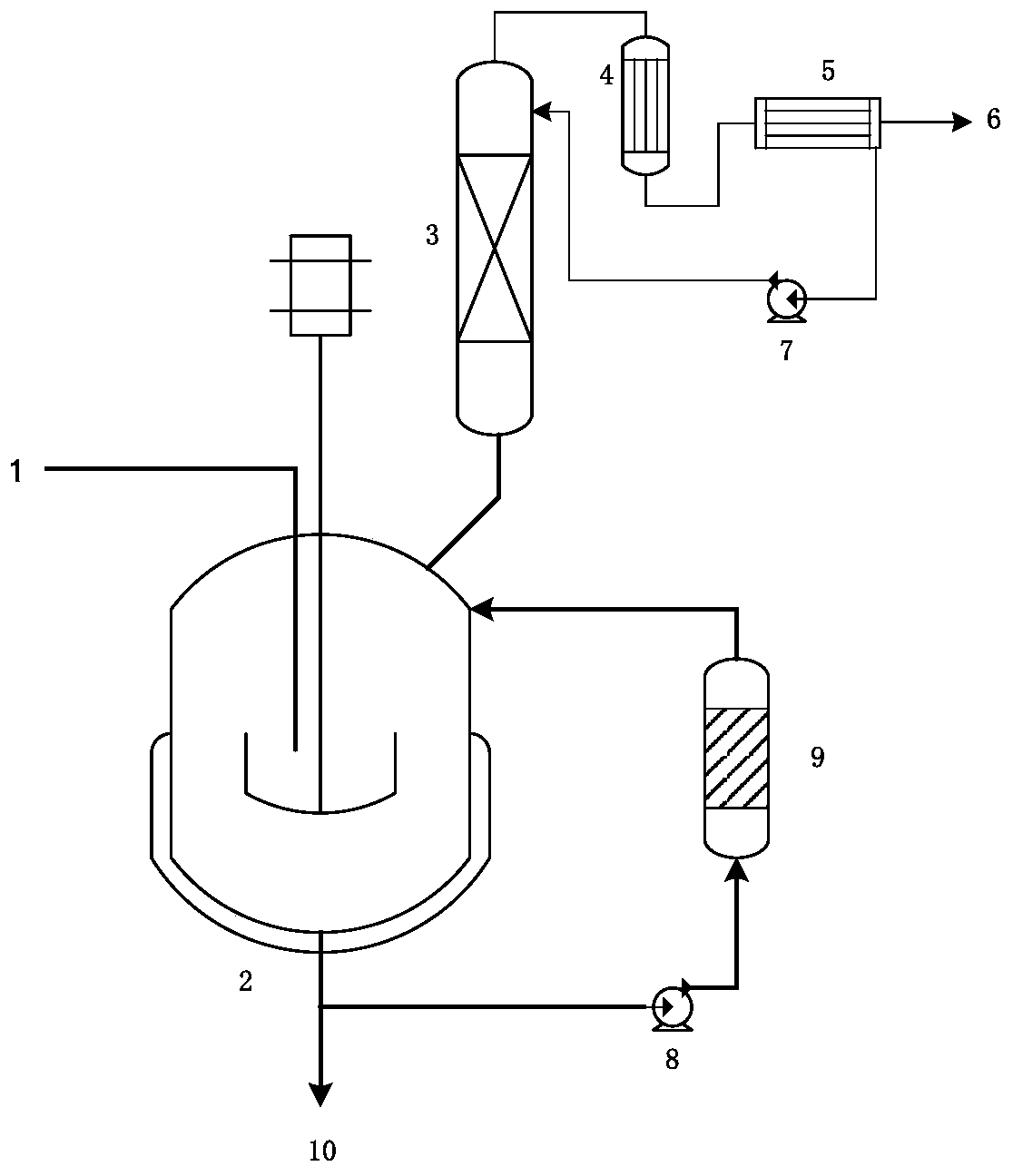

Continuous production system of lithium hexafluorophosphate

ActiveCN110683562AQuick responseShorten the timeSecondary cellsLithium hexafluorophosphateVapor–liquid separatorPhysical chemistry

The invention relates to a continuous production system of lithium hexafluorophosphate. The continuous production system comprises a phosphorus pentafluoride generator (2), a micro-channel reactor A (3), a gas-liquid separator A (4), a micro-channel reactor B (6) and a gas-liquid separator B (7), the gas generated by the phosphorus pentafluoride generator (2) is introduced into the micro-channel reactor A (3), the material output by the micro-channel reactor A (3) enters the gas-liquid separator A (4), the gas separated by the gas-liquid separator A (4) enters the micro-channel reactor B (6),and is used as a reaction raw material so as to continuously react, the material output by the micro-channel reactor B (6) enters the gas-liquid separator B (7), and a liquid component is separated out by the gas-liquid separator B (7) and is conveyed into the micro-channel reactor A (3). According to the invention, the raw materials and the by-products are recycled, so that the conversion rate and the utilization rate of the raw materials are improved, and the cost is reduced.

Owner:SINOCHEM LANTIAN +2

2-methyl-4-chlorophenoxyacetic acid preparation method

ActiveCN110028399AEasy to handleLow costPreparation from carboxylic acid saltsOrganic compound preparationSodium acetateSodium chloroacetate

The invention provides a 2-methyl-4-chlorophenoxyacetic acid preparation method, which comprises: carrying out a condensation reaction on sodium o-cresolate and sodium chloroacetate under the catalysis of a trimethylamine catalyst to obtain 2-methyl sodium phenoxyacetate, acidifying, and chlorinating to obtain 2-methyl-4-chlorophenoxyacetic acid. According to the present invention, under the catalysis of the trimethylamine catalyst, sodium o-cresolate and sodium chloroacetate can be subjected to the condensation reaction in the near-neutral environment with the temperature of lower than 70 DEGC, such that the main side reaction for hydrolyzing sodium chloroacetate into sodium glycolate is greatly reduced, the produced wastewater contains less o-methylphenol and glycolic acid (or sodium glycolate) so as to easily meet the nationally acceptable emission standards at a low treatment cost, the resource utilization of the waste acid solution can be achieved, the cost of the raw materials and the three-waste treatment cost are reduced, the purity of 2-methyl-4-chlorophenoxyacetic acid is higher than 95%, and the total yield is higher than 93%.

Owner:JIANGXI TIANYU CHEM CO LTD

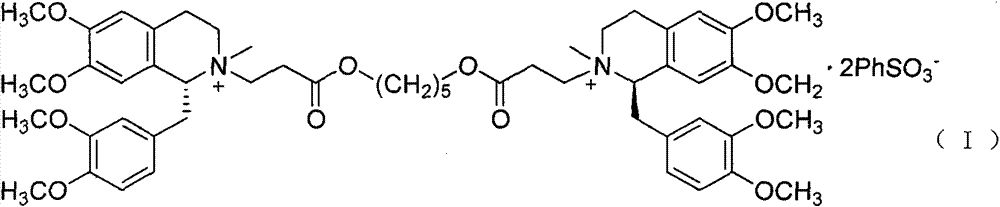

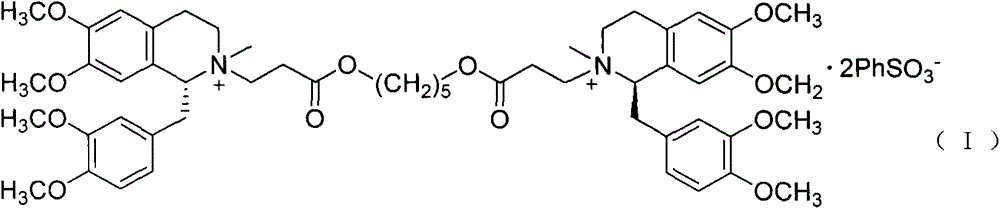

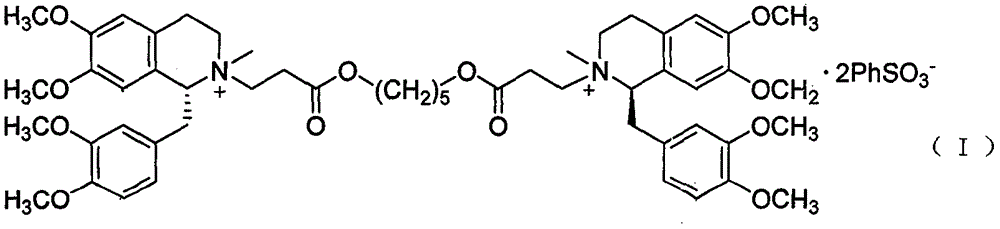

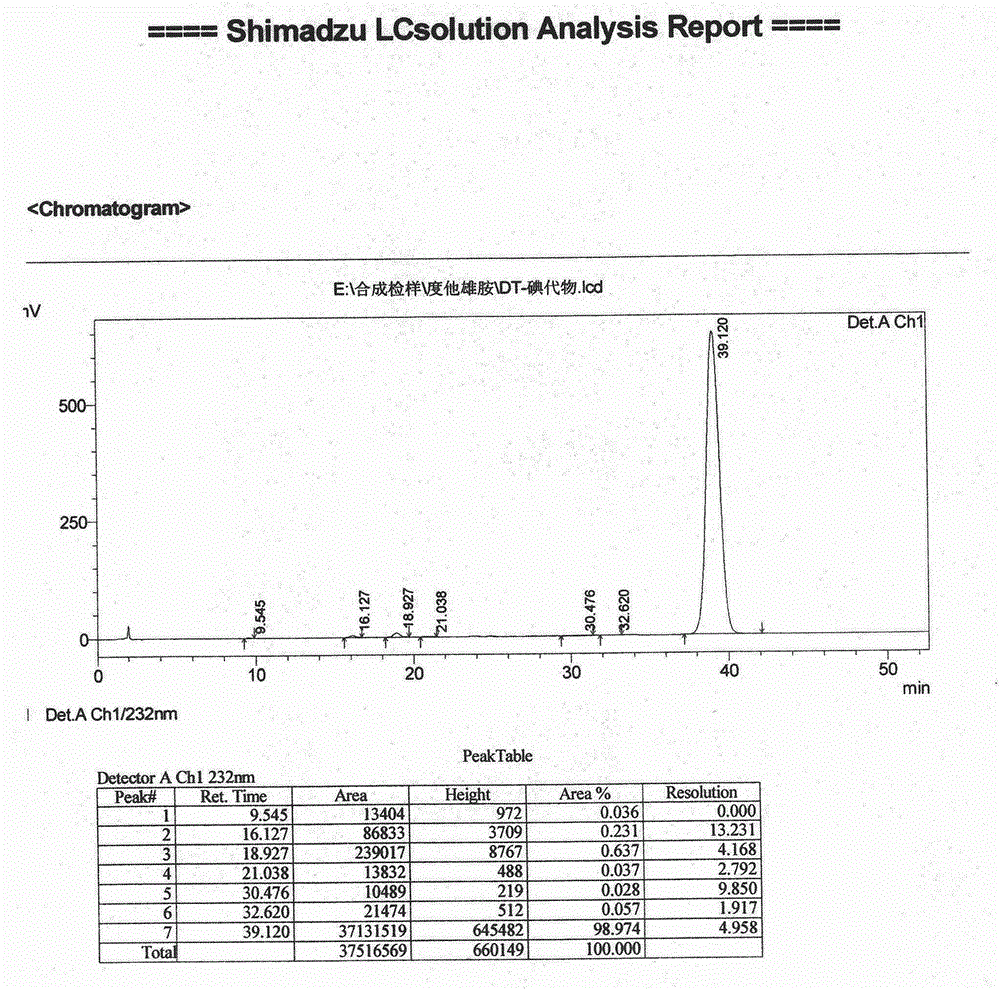

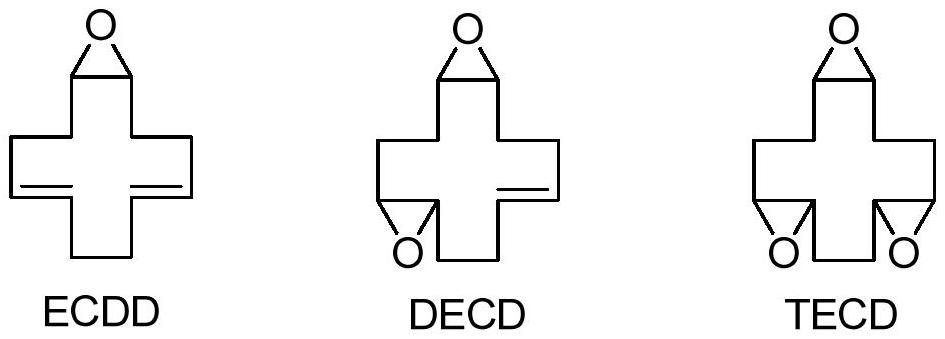

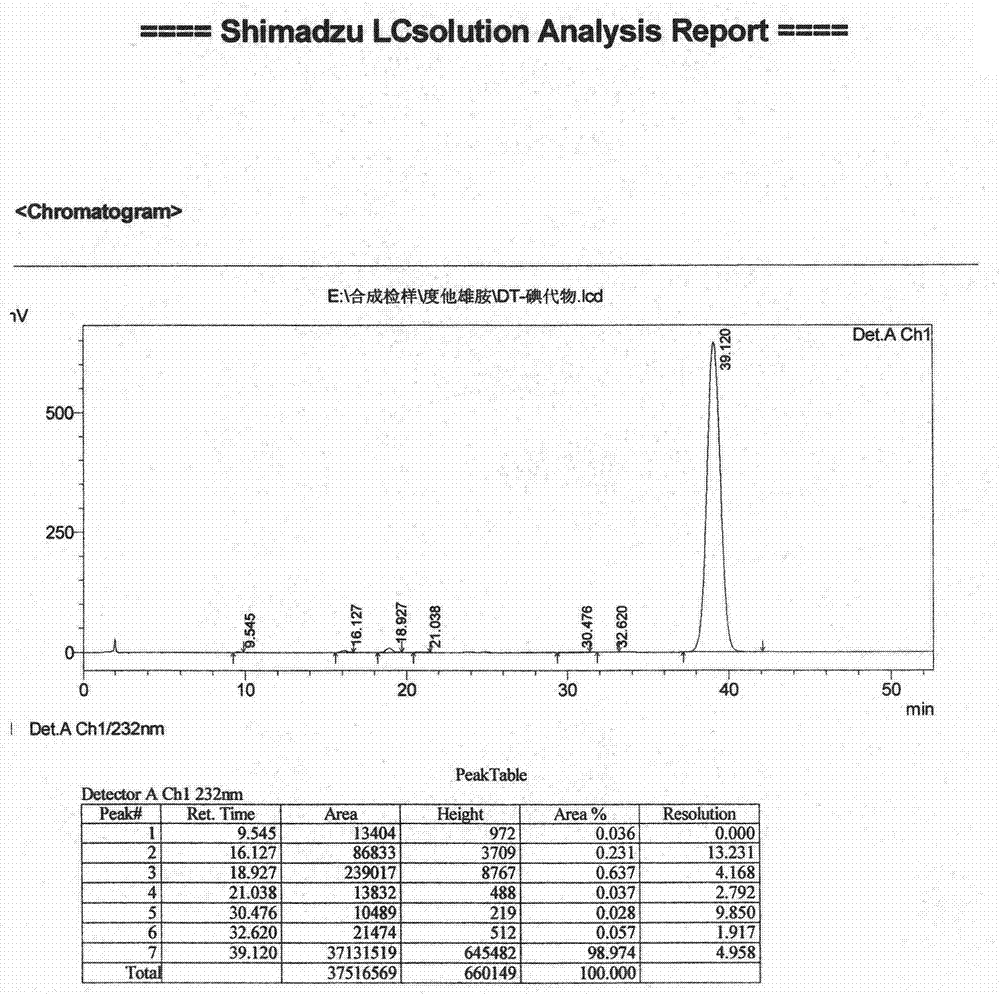

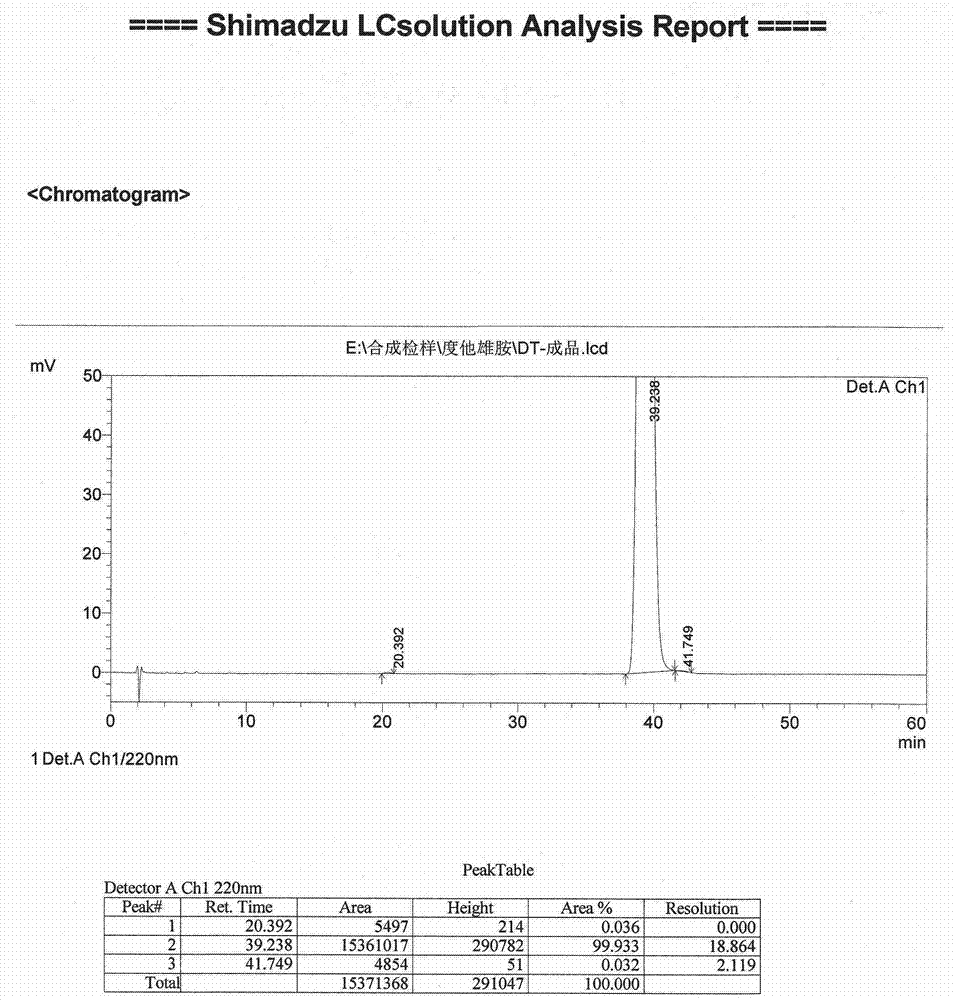

Refinement method of cisatracurium besylate

ActiveCN104292161AReduce consumptionSimplify the refining processOrganic chemistryCisatracurium BesylateChromatographic column

The invention relates to an industrial preparation method of cisatracurium besylate. The preparation method simplifies the refinement operation process, and obtains the high-purity cisatracurium besylate in a non-chromatographic column chromatography preparation mode under the condition of not changing the salt base for the first time. The preparation method can greatly shorten the production cycle, enhance the productivity and increase the yield to 45% above. In the product, the content of cisatracurium besylate is not lower than 98%, the content of total impurities does not exceed 2%, the content of mono quaternary ammonium salts does not exceed 0.2%, the content of other maximum individual impurities does not exceed 0.3%, and the content of isomers does not exceed 0.1%.

Owner:大道隆达(北京)医药科技发展有限公司

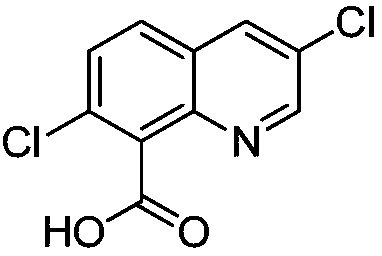

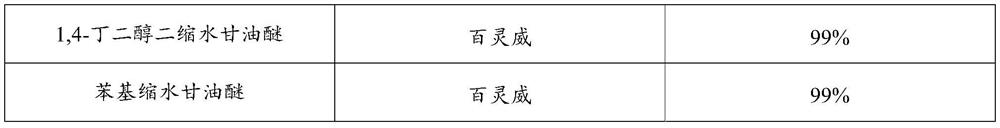

Preparation method of quinclorac

The invention relates to the field of herbicides, and discloses a preparation method of quinclorac, which comprises: 1) adopting an N-hydroxyphthalimide compound and azodiisobutyronitrile as catalysts, adopting oxygen as an oxidizing agent, and oxidizing 7-chloro-8-methylquinoline to obtain 7-chloro-8-quinoline carboxylic acid; and 2) by taking azodiisobutyronitrile as a catalyst, carrying out chlorination reaction on 7-chloro-8-quinoline carboxylic acid and chlorine to obtain 3,7-dichloro-8-quinoline carboxylic acid. By means of the method disclosed by the invention, the generation of a largeamount of waste acid and wastewater in a synthesis process can be reduced, and the product yield of quinclorac can be increased.

Owner:NUTRICHEM LAB CO LTD

Method for producing nadroparin calcium from heparin sodium crude product

The invention discloses a method for producing nadroparin calcium from a heparin sodium crude product. The method comprises the following steps: dissolving the raw material crude product heparin sodium in water, precipitating by centrifugation and secondary salting-out to remove impurities in the heparin sodium crude product, carrying out nitrous degradation and reduction to obtain low-molecular heparin containing free sulfates, adding barium chloride to remove the free sulfates generated by degradation, and using an anion exchange resin and adjusting to appropriate parameters to carry out calcium conversion and final impurity removal; and finally, carrying out oxidation decolorization, sterile filtration and dehydration to obtain the nadroparin calcium raw material. By using the crude product heparin sodium as the raw material, the production cost is lowered; the technical steps are simplified to enhance the yield of the nadroparin calcium and reduce the titer loss of the nadroparin calcium; and the method can ensure the safety of the product, and is convenient for industrialized mass production.

Owner:NANJING KING FRIEND BIOCHEM PHARMA CO LTD

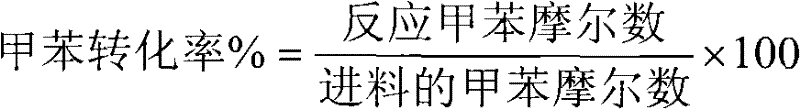

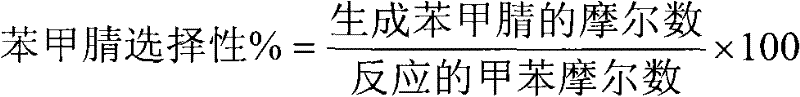

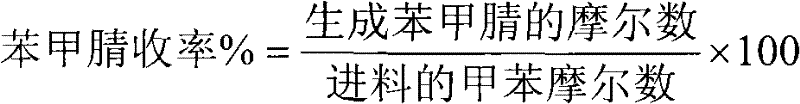

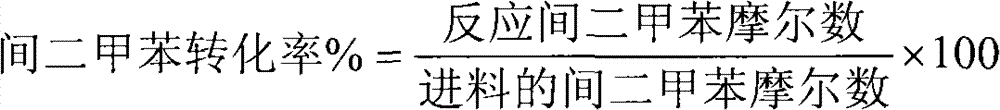

Method for preparing cyanobenzene

InactiveCN102219710AImprove physicsGood chemical propertiesPhysical/chemical process catalystsPreparation by hydrocarbon ammoxidationReaction temperatureCobalt

The invention relates to a method for preparing cyanobenzene through ammoxidation, which mainly solves the problems that in the prior art, the cyanobenzene production cost is high, or the target product-cyanobenzene is low in yield, or the engineering enlargement effect of a reactor exists, or pollution of three wastes during production process is serious. The method adopts the technical scheme comprising the steps of taking toluene, ammonia gas and air as raw materials in a weight ratio of 1:(2-10):(2-10) on the conditions that the reaction temperature is 300-500 DEG C, the reaction pressure is 0.01-0.1Mpa and the catalyst (WWH) is 0.03-0.1 hour <1>, and conducting contact reaction on the raw materials and a fluid catalyst, thus producing cyanobenzene. The catalyst is a composite with a chemical formula in an atom ratio as follows: V1.0SbaAbBcCdOx, wherein the A is selected from at least one of lithium, sodium, potassium, rubidium, caesium or compositions thereof; the B is selected from at least one of magnesium, calcium, barium, chromium, tungsten, molybdenum, manganese, ferrum, cobalt, nickel, tin or compositions thereof; and the C is selected from at least one of boron, phosphorus or compositions thereof; therefore, the problems in the prior art are better solved, and the cyanobenzene can be used for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of refining method of atracurium besylate

ActiveCN104292161BReduce cleaning pressureQuality assuranceOrganic chemistryCisatracurium BesylateChromatographic column

The invention relates to an industrial preparation method of cisatracurium besylate. The preparation method simplifies the refinement operation process, and obtains the high-purity cisatracurium besylate in a non-chromatographic column chromatography preparation mode under the condition of not changing the salt base for the first time. The preparation method can greatly shorten the production cycle, enhance the productivity and increase the yield to 45% above. In the product, the content of cisatracurium besylate is not lower than 98%, the content of total impurities does not exceed 2%, the content of mono quaternary ammonium salts does not exceed 0.2%, the content of other maximum individual impurities does not exceed 0.3%, and the content of isomers does not exceed 0.1%.

Owner:大道隆达(北京)医药科技发展有限公司

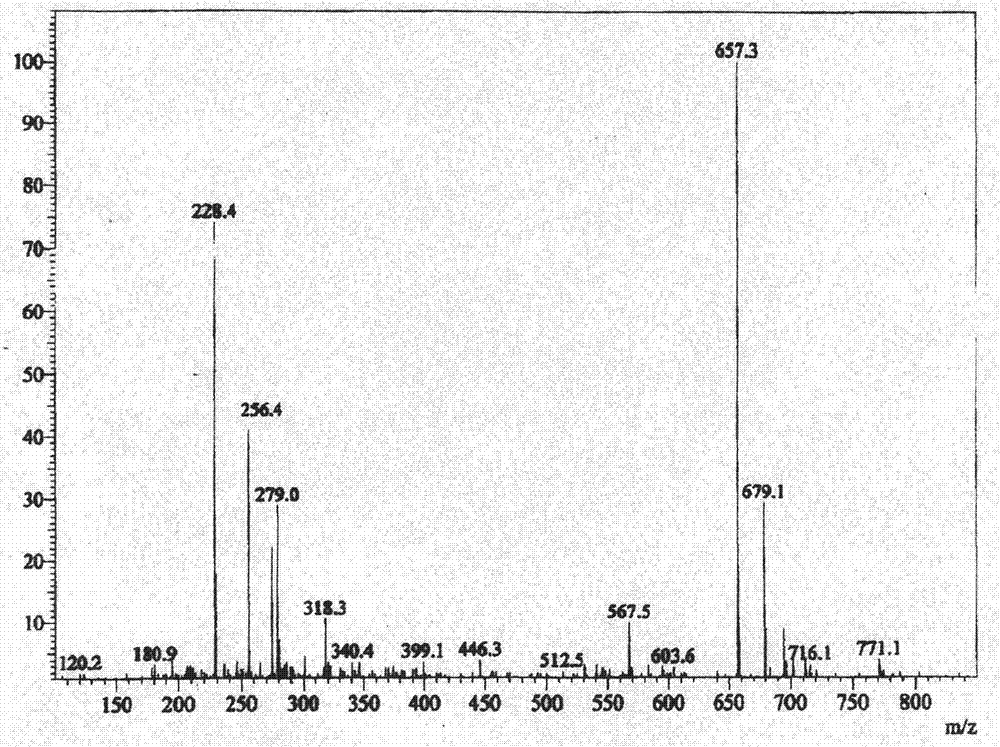

Green synthetic method of highly pure dutasteride

The invention discloses a new green industrial preparation method of highly pure dutasteride. The method is realized through a synthetic route represented by a figure shown in the specification. The preparation method is adopted to construct a steroid 1,2-olefinic bond in order to avoid raw materials being harmful to environment and having large toxicity, and use of a severely toxic oxidant DDQ is thoroughly avoided from a reaction principle; and the method has the advantages of high efficiency, high purity, greenization, clean industrialization, strong maneuverability and high yield, and the total yield of a two-step reaction is greater than 80%. An iodo intermediate is purified to easily control the quality of finished dutasteride, the purity of the obtained dutasteride product is not smaller than 99.5%, the content of any single impurity does not exceed 0.1%, and medicinal demands are completely met.

Owner:大道隆达(北京)医药科技发展有限公司

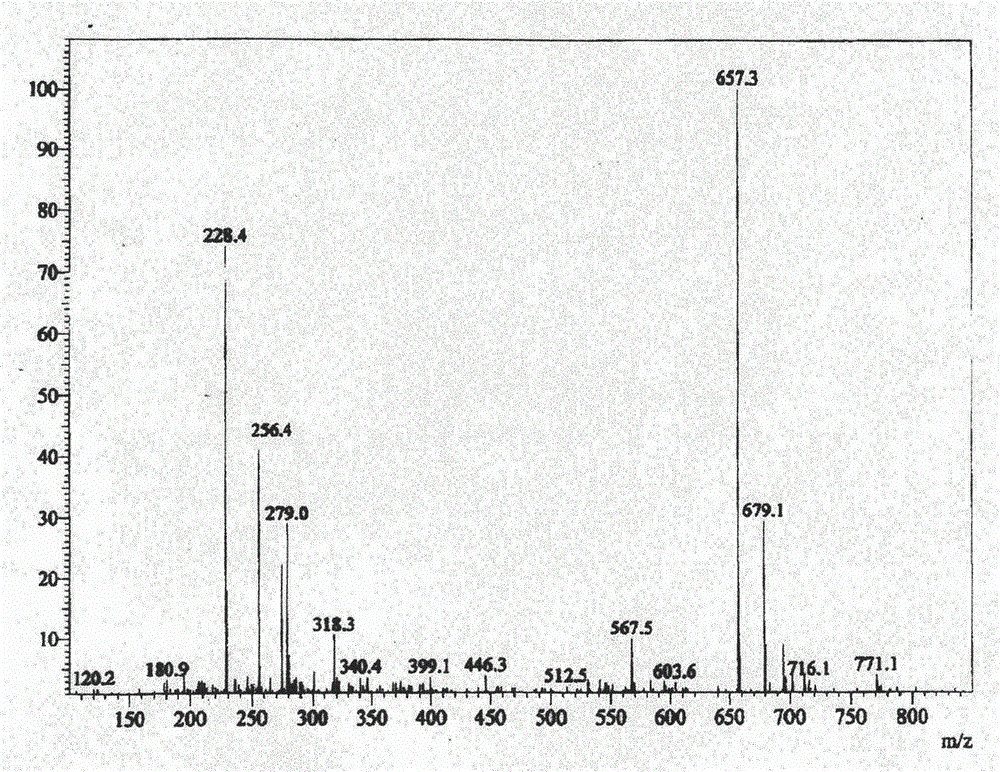

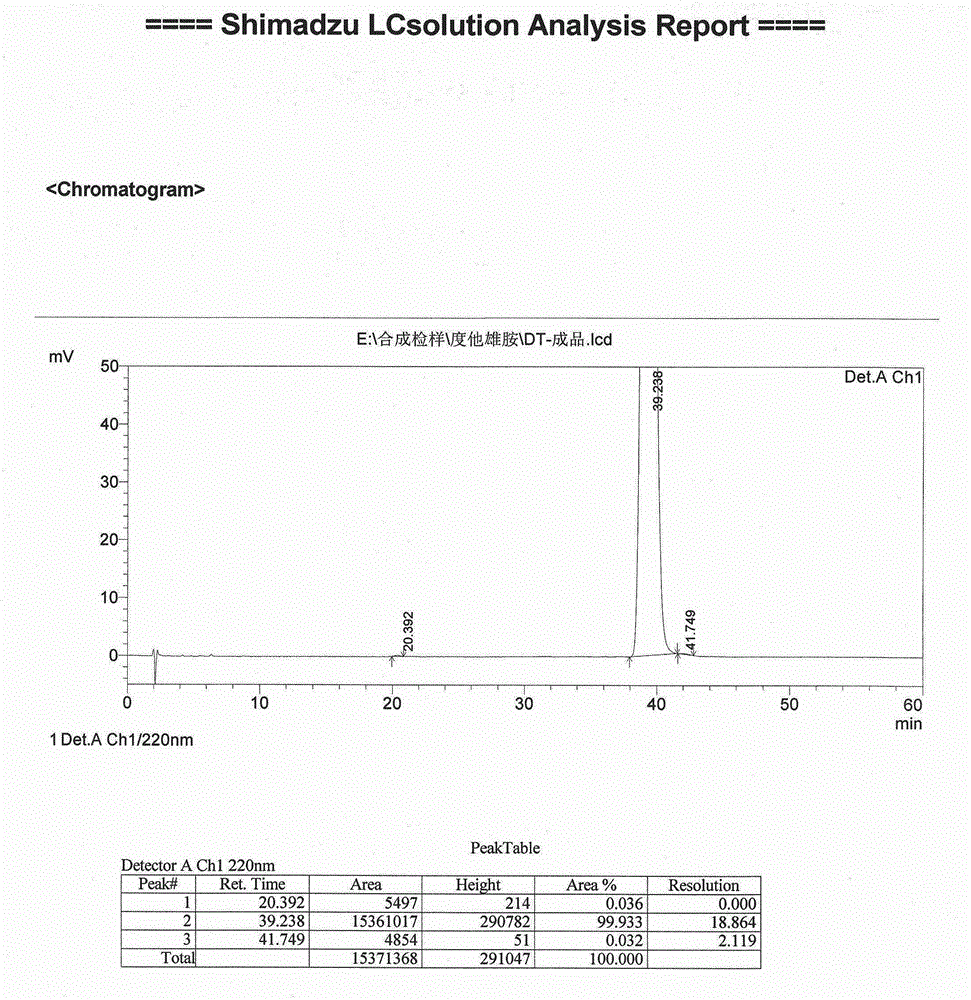

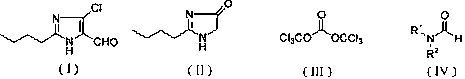

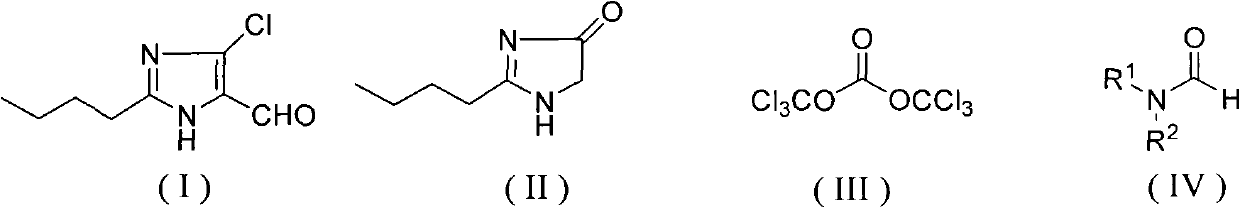

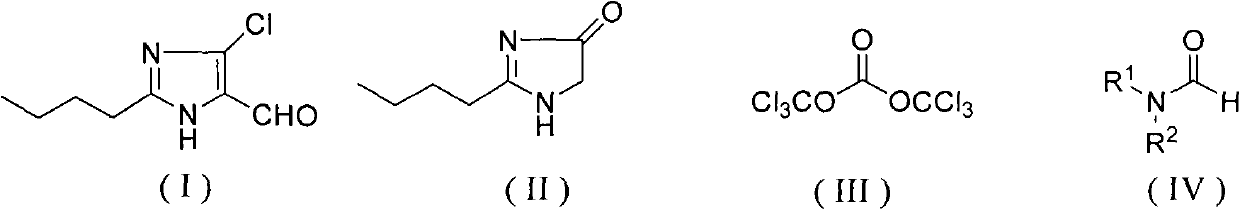

Method for synthesizing 2-normal-butyl-4-chloro-5-formylimidazole

The invention discloses a method for synthesizing 2-normal-butyl-4- chloro-5-formylimidazole shown by a formula (I). Imidazolone shown in the formula (II) reacts with bis (trichloromethyl) carbonate shown by a formula (III) and formamide shown by a formula (IV) in an organic solvent for 1-10 hours at the temperature of 20 DEG C below zero to 200 DEG C, and reaction solution is hydrolyzed to obtain 2-normal-butyl-4-chloro-5-formylimidazole. The invention has mild reaction conditions, good selectivity, no generation of phosphorus wastewater and low cost of proposal of waste water, waste gases and waste residues, and is suitable for industrial production.

Owner:ZHEJIANG UNIV OF TECH +1

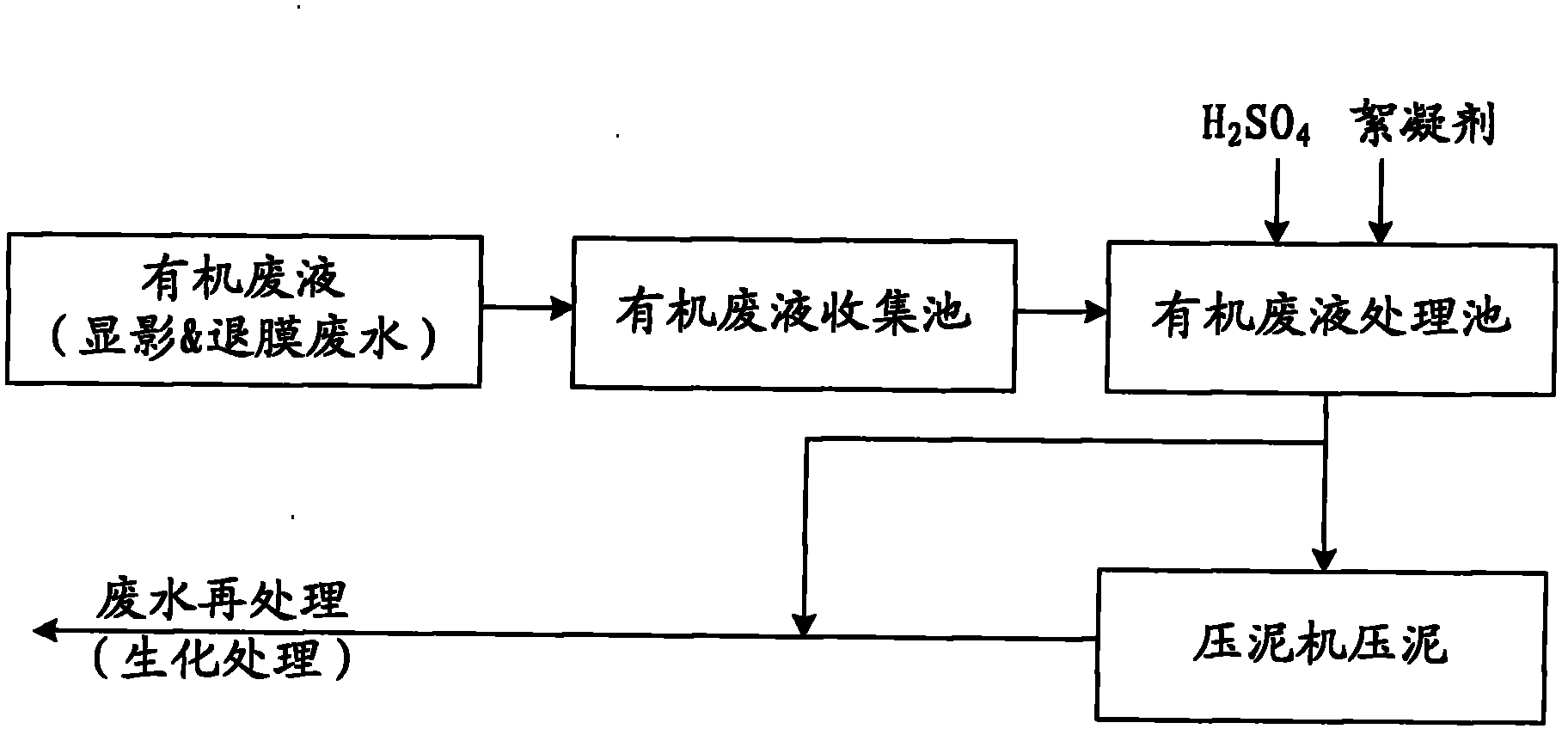

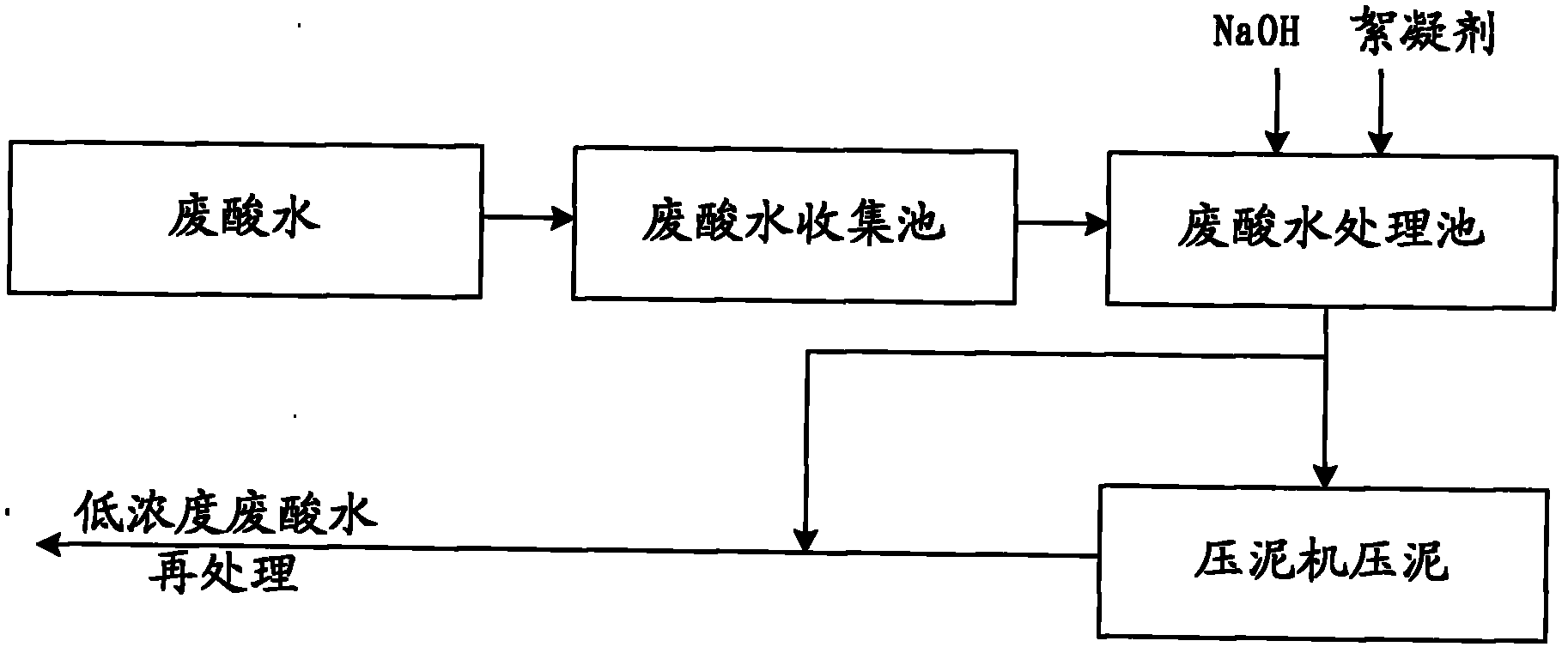

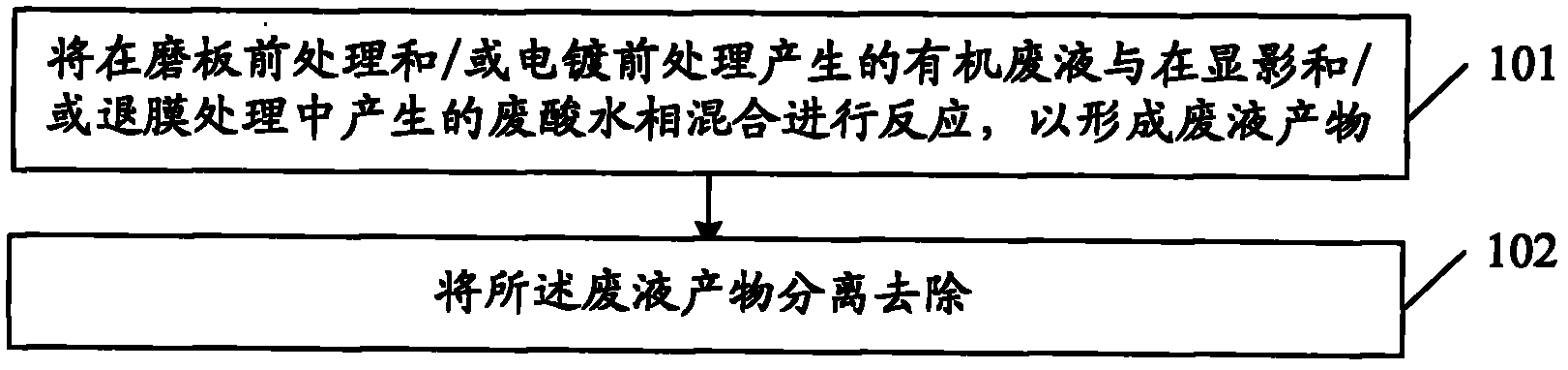

Method and device for treating waste liquid from circuit board preparation

InactiveCN102115278AReduce consumptionReduce the cost of waste treatmentMultistage water/sewage treatmentLiquid productProduction line

The embodiment of the invention discloses a method and device for treating waste liquid from a circuit board preparation and relates to the field of circuit board preparation. In the invention, waste liquid from a circuit board production line is directly used for acidifying organic waste liquid without adding any processing chemicals so as to directly remove the chemical oxygen demand of the organic waste liquid and reduce a large amount of alkali consumed in a waste acidic water treatment process. The method for treating waste liquid from a circuit board preparation comprises: mixing organic waste from plate grinding pretreatment and / or plating pretreatment with waste acidic water from development and / or membrane stripping treatment for reaction to form a waste liquid product; and separating and removing the waste liquid product. The method and the device are used for treating waste liquid from the circuit board preparation.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

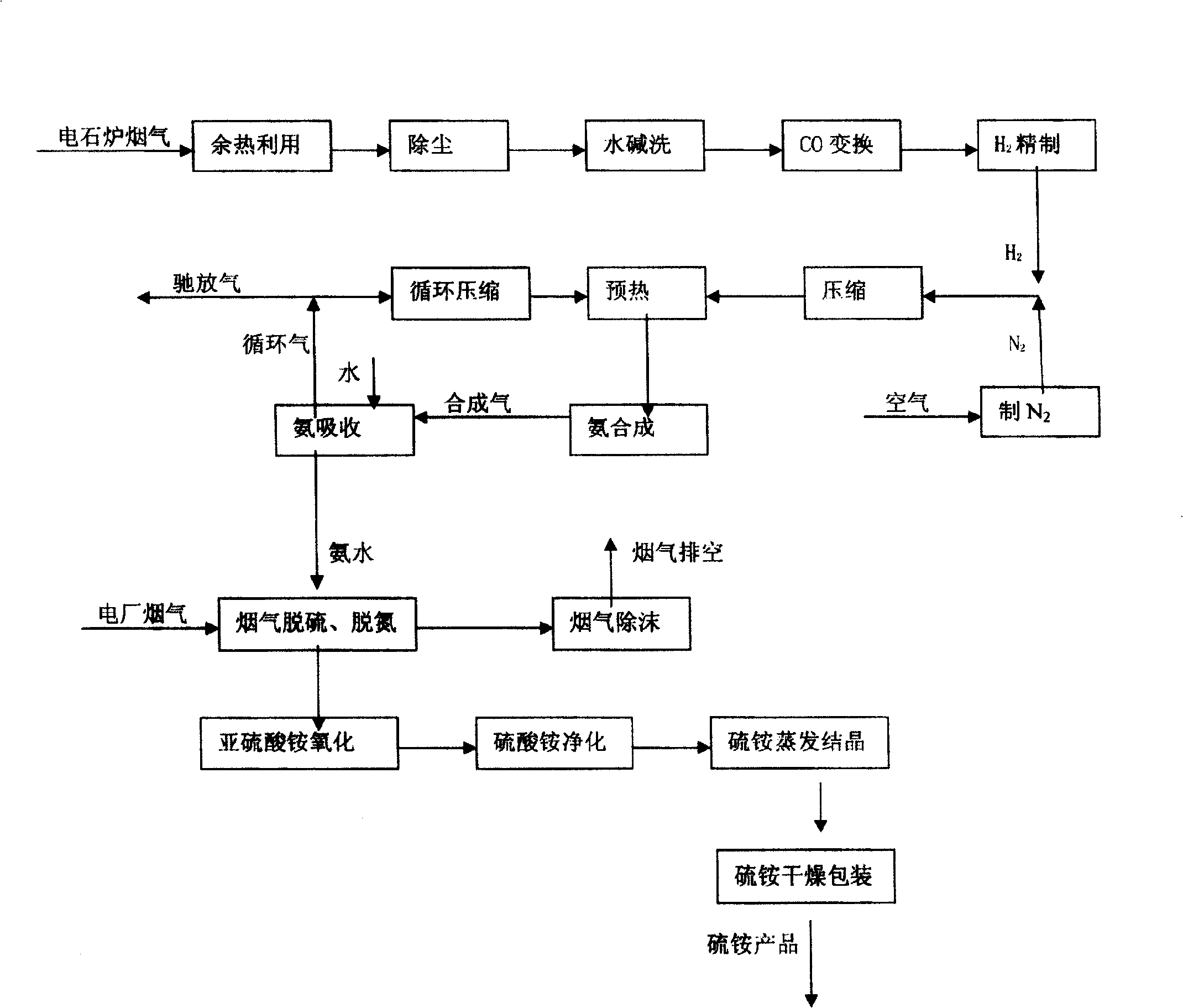

Tail gas treatment and reutilization for calcium carbide stove

InactiveCN100427391CImprove dust removal effectSimple production processHydrogenLighting and heating apparatusNitrogen oxidesFlue gas

Owner:国能英力特能源化工集团股份有限公司 +1

A continuous production system for lithium hexafluorophosphate

ActiveCN110683562BImprove conversion rateLow costSecondary cellsLithium hexafluorophosphateVapor–liquid separatorPhysical chemistry

The invention relates to a continuous production system of lithium hexafluorophosphate. The continuous production system comprises a phosphorus pentafluoride generator (2), a micro-channel reactor A (3), a gas-liquid separator A (4), a micro-channel reactor B (6) and a gas-liquid separator B (7), the gas generated by the phosphorus pentafluoride generator (2) is introduced into the micro-channel reactor A (3), the material output by the micro-channel reactor A (3) enters the gas-liquid separator A (4), the gas separated by the gas-liquid separator A (4) enters the micro-channel reactor B (6),and is used as a reaction raw material so as to continuously react, the material output by the micro-channel reactor B (6) enters the gas-liquid separator B (7), and a liquid component is separated out by the gas-liquid separator B (7) and is conveyed into the micro-channel reactor A (3). According to the invention, the raw materials and the by-products are recycled, so that the conversion rate and the utilization rate of the raw materials are improved, and the cost is reduced.

Owner:SINOCHEM LANTIAN +2

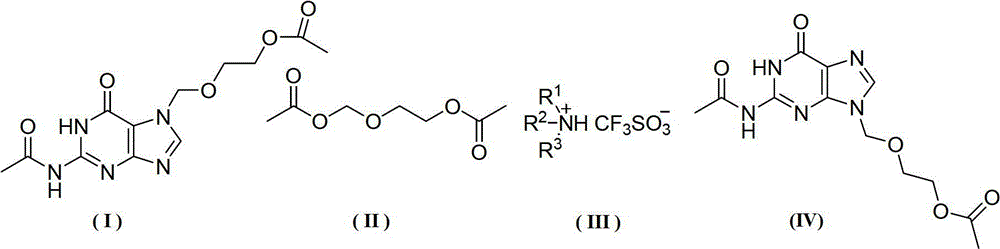

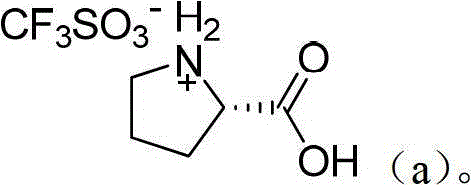

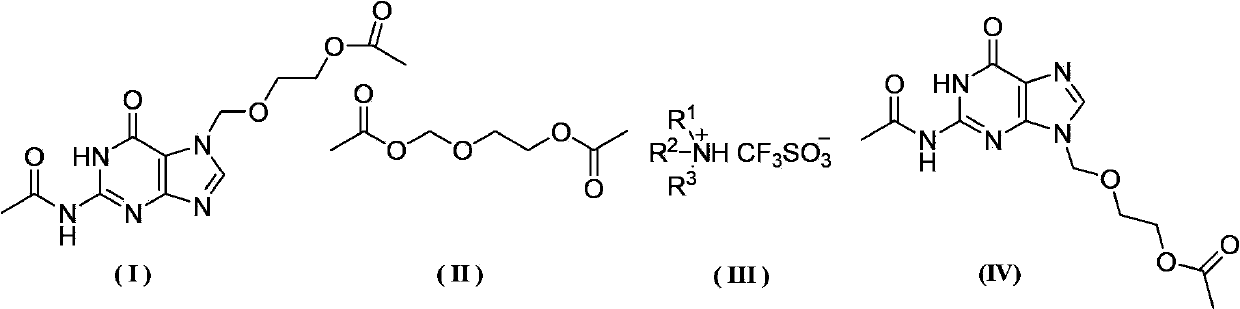

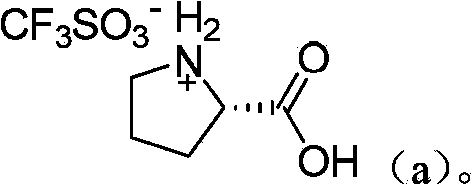

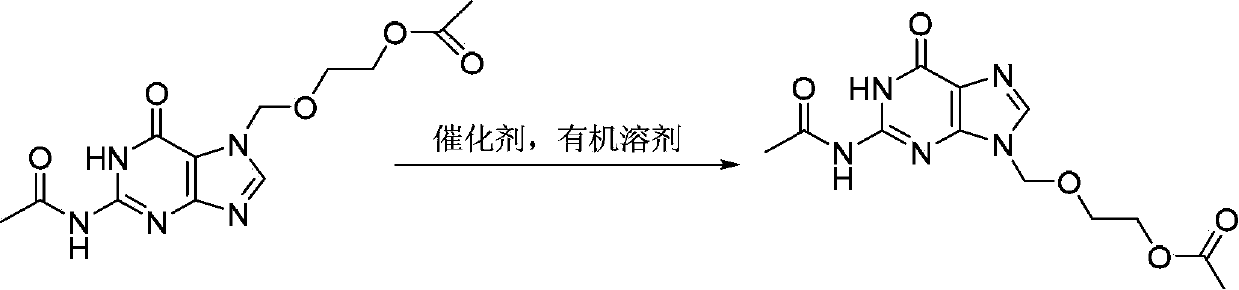

Method for preparing diacetylacyclovir with 7-bit diacetylacyclovir

ActiveCN102718766AMild reaction conditionsShort cycleOrganic chemistry1,4-ButanediolAcetic anhydride

The invention discloses a method for preparing diacetylacyclovir with 7-bit diacetylacyclovir. The 7-bit diacetylacyclovir, 2-oxa-1, 4-butanediol diethyl ester and acetic anhydride react in organic solvents at the controlled temperature of 30-150 DEG C for 1-30h under the action of trifluoromethanesulfonic acid ammonium salt catalysts, and the target product of diacetylacyclovir is obtained by means of separation and purification after reaction. The method is moderate in reaction condition, short in cycle and simple and convenient in operation, the reaction process is easy to control, the 7-bit diacetylacyclovir can be converted into the diacetylacyclovir, the conversion rate is high, and the product with high purity can be obtained by means of simple operation after conversion. By the aid of the conversion process, the cost for treating waste gas, waste water and waste residues is reduced, resource utilization rate is increased, and the method is suitable for industrial production.

Owner:ZHEJIANG UNIV OF TECH +1

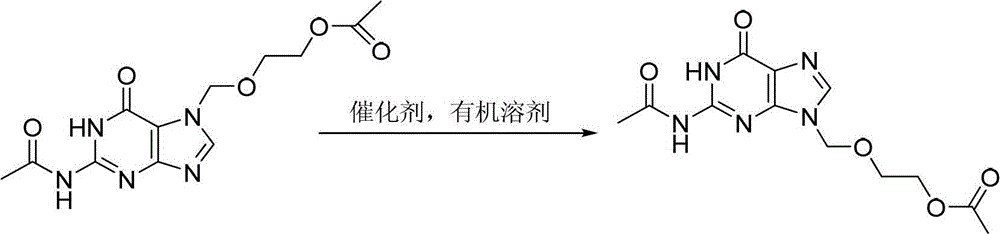

A kind of preparation method of 5-flucytosine suitable for industrialized production

ActiveCN105153041BLow costRaw materials are cheap and easy to getOrganic chemistryChemical synthesisAfter treatment

The invention relates to a 5-fluctyosine preparation method suitable for industrial production, belonging to the technical field of pharmaceutical chemical synthesis. The method comprises the following steps: by using 2-methoxy-5-fluorouracil as a raw material, chlorinating with phosphorous pentachloride to obtain 2-methoxy-4-chloro-5-fluoropyrimidine, and concentrating the acidic water phase obtained by after-treatment for later use; carrying out amination reaction on the 2-methoxy-4-chloro-5-fluoropyrimidine and an aminating agent to obtain 2-methoxy-4-amido-5-fluoropyrimidine; and carrying out acidic hydrolysis on the 2-methoxy-4-amido-5-fluoropyrimidine by using the concentrated acidic water phase recycled from chlorination to obtain the 5-fluctyosine. The 5-fluctyosine preparation method provided by the invention has the advantages of high yield, convenient after-treatment and fewer three-waste pollutants, solves the problems of high virulent product consumption, difficulty in acidic waste gas treatment, high pollution, high cost and the like in the traditional technique, and is suitable for industrial production application. The total mole yield is up to 70% or above.

Owner:ZHEJIANG XIANFENG TECH

Antimonial ammoxidation catalyst

ActiveCN102218334BReduce decompositionReduce unit consumptionPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsPhthalonitrileCobalt

The invention relates to an antimonial ammoxidation catalyst which mainly solves the problem that in the prior art the catalyst is difficult to adapt for the requirement of a fluidized bed and requires raw materials with higher price and the target outcome m-phthalonitrile has low yield. The antimonial ammoxidation catalyst comprises a catalyst active component which is a combination with the following chemical formula by atomic ratio: V1.0SbaAbBcCdOx, wherein A is at least one type of metal out of lithium, sodium, kalium or rubidium or cesium; B is at least one type of metal out of magnesium, calcium, barium, chrome, tungsten, molybdenum, manganese, iron, cobalt, nickel or tin; and C is at least one type of metal out of boron or phosphor. The technical scheme better solves the problem and can be used for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing potassium alum with aluminum-contained waste catalyst generated from petrochemical production

InactiveCN106892445AReduce the cost of waste treatmentSave resourcesAluminium sulfatesAluminium saltsPetrochemical

The invention discloses a method for preparing potassium alum with an aluminum-contained waste catalyst generated from petrochemical production. The method includes: adding sulfuric acid to the aluminum-contained waste catalyst subjected to drying treatment and generated from the production process of a petrochemical enterprise, performing stirring reaction under heating, controlling the mol ratio of Al<3+> to SO4<2> in a reaction system to obtain an aluminum sulfate extract; feeding the obtained aluminum sulfate extract to a reaction kettle, heating to add a saturated sulphate solution, performing stirring reaction, controlling the molar feed ratio of K<+> to Al<3+> to SO4<2> in a reaction system, performing immediate filtration to obtain a filtrate, and performing cooling crystallization and filtration to obtain a coarse potassium alum filter cake with the filtrate to be treated; crushing the coarse potassium alum filter cake, and washing the crushed coarse potassium alum filter cake by adding water to obtain the potassium-alum finished product via filtration and centrifugal dewatering. With the method, resources are saved, environment is protected, and resources are recycled; the method is simple in step and free of relying on expensive experiment and being constrained by rigorous process elements.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

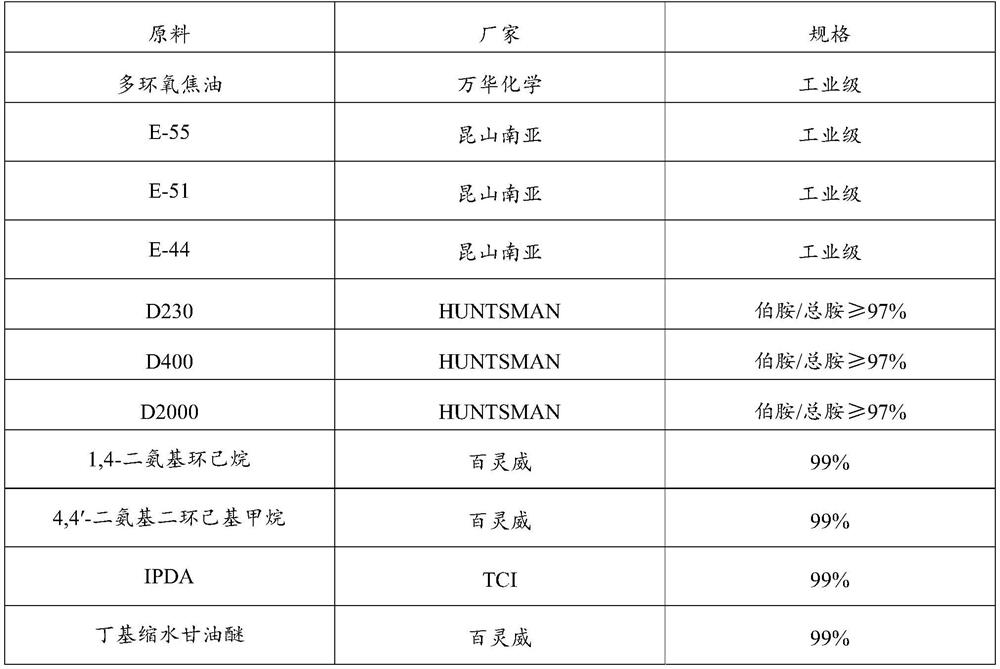

Vacuum infusion epoxy resin system and preparation method and application thereof

ActiveCN111234464BAchieve reuseReduce the cost of waste treatmentFinal product manufacturePolymer scienceCyclododecane

The invention provides a vacuum infusion epoxy resin system and a preparation method and application thereof. The vacuum infusion epoxy resin system of the present invention uses epoxy diluent raw materials including polyepoxy tar containing cyclododecane structure, and can obtain A vacuum infusion epoxy resin system with above-moderate initial mix viscosity, low midpoint peak exotherm temperature and long workability time. The present invention provides a vacuum infusion epoxy resin system, the epoxy resin system is prepared by mixing A component and B component, wherein the A component includes bisphenol A epoxy resin and epoxy diluent, The B component includes a polyetheramine curing agent and an alicyclic amine; the epoxy diluent includes a polyepoxy tar containing a cyclododecane structure, and optionally other epoxy diluents.

Owner:WANHUA CHEM GRP CO LTD +1

Quinmerac and preparation method thereof

ActiveCN112390752AReduce the cost of waste treatmentSave time and costOrganic chemistryCobalt metalPtru catalyst

The invention relates to the field of herbicide synthesis, particularly to quinmerac and a preparation method thereof. The method includes the steps: in the presence of a catalyst, carrying out an oxidation reaction on 3,8-dimethyl-7-chloroquine as a raw material, carboxylic acid as a solvent and oxygen-containing gas as an oxidizing agent, wherein the catalyst is one or more of a cobalt metal compound, a manganese metal compound and a vanadium metal compound. According to the method, a large amount of waste acid and waste water can be prevented from being generated, environmental protection is achieved, and the three-waste treatment cost is greatly reduced; and the method has the advantages of mild reaction conditions, simple post-treatment and high product purity and yield, and is very suitable for industrial production.

Owner:NUTRICHEM LAB CO LTD

Processing method of low-salt chopped pepper blank

InactiveCN104137977BReduce the cost of waste treatmentReduce processing costsInorganic compound food ingredientsFood preparationFlavorFood safety

The invention relates to a processing method of a low-salt chopped pepper blank. The processing method comprises the following steps of chopping peppers at source, adding 5%-7% of salt, 0.05%-0.15% of citric acid, 0.05%-0.10% of calcium chloride and 0.03%-0.05% of potassium sorbate into the chopped pepper, uniformly mixing, and packaging into a multi-layer plastic bag, tightening a bag opening together with an inflating-deflating mechanism, then inflating the multi-layer plastic bag until the pressure intensity reaches 0.5MPa-1.0MPa, and locally storing the multi-layer plastic bag. The low-salt chopped pepper blank prepared by virtue of the processing method can be preserved for 6-12 months; the processing method is easy and convenient to operate; the quality of the preserved pepper blank is close to that of a high-salt pepper blank; additives are accordant with a national food safety standard; a washing desalination process is omitted in a secondary seasoning processing process of the chopped pepper, so that not only are nutrients and flavor quality of the peppers preserved, but also the environmental pollution caused during the desalination is reduced.

Owner:HUNAN AGRICULTURAL UNIV +1

A kind of method of producing nadroparin calcium from heparin sodium crude product

ActiveCN104163878BEliminates the decolorization stepSimple processSulfate radicalsNadroparin calcium

The invention discloses a method for producing nadroparin calcium from crude heparin sodium. The present invention uses crude heparin sodium as a raw material, after adding water to dissolve, and then precipitates and removes impurities in the crude heparin sodium by centrifugation and secondary salting out, then degrades and reduces with nitrous acid to obtain low-molecular-weight heparin containing free sulfate radicals, and then adds chlorinated Barium removes free sulfate radicals produced by degradation, then uses anion exchange resin, and adjusts appropriate parameters for calcium conversion and final impurity removal, and finally oxidative decolorization, filter sterilization, dehydration and drying to obtain nadroparin calcium raw material. The invention uses crude heparin sodium as a raw material, reduces the production cost, improves the yield of nadroparin calcium by simplifying the process steps, reduces the potency loss of the nadroparin calcium, can ensure the safety of the product, and is convenient for large-scale industrial production.

Owner:NANJING KING FRIEND BIOCHEM PHARMA CO LTD

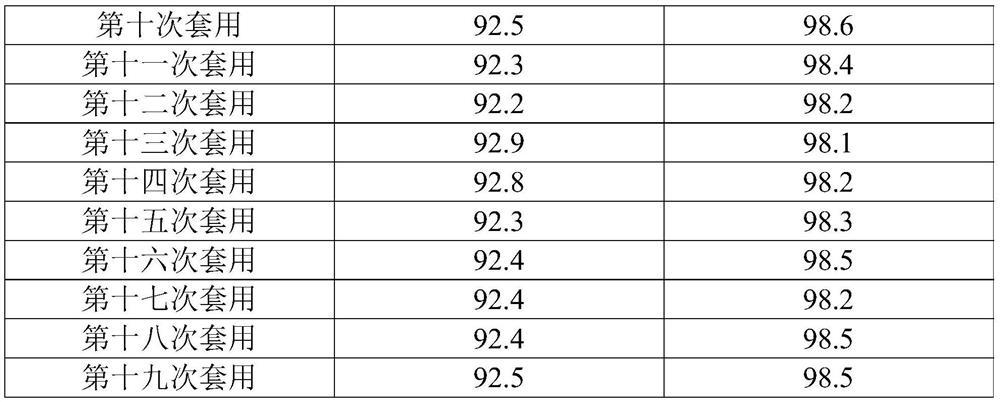

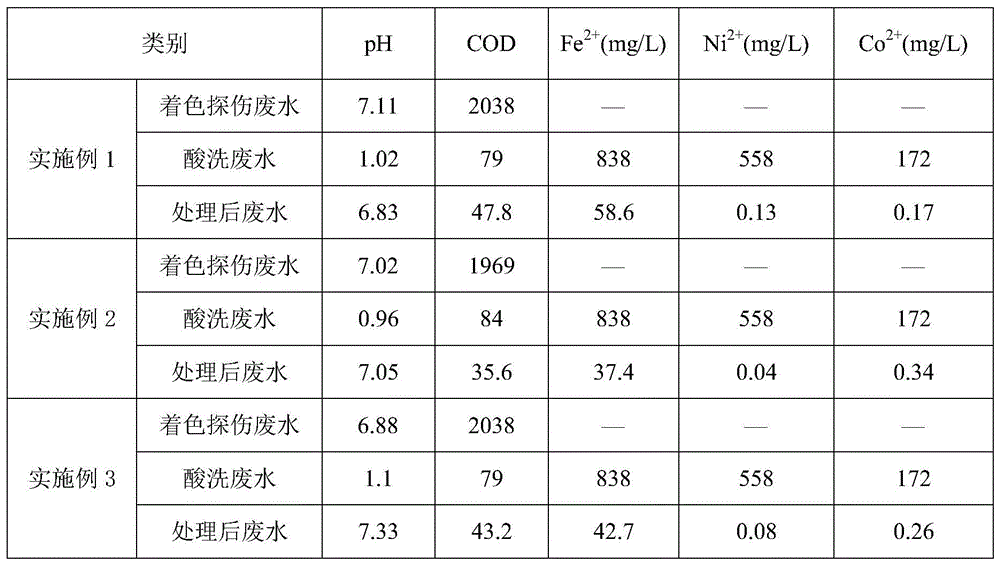

A method for synergistic treatment of coloring flaw detection wastewater and pickling wastewater

ActiveCN104609594BEnsure that the effluent discharges up to the standardReduce handling equipmentMultistage water/sewage treatmentActivated carbonWastewater

Owner:北京中科国益环保工程有限公司

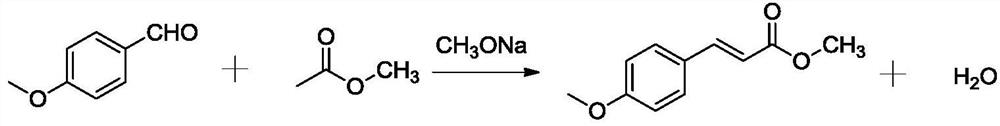

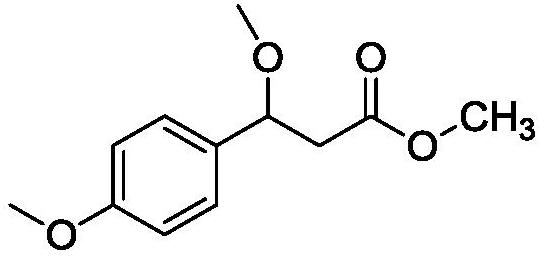

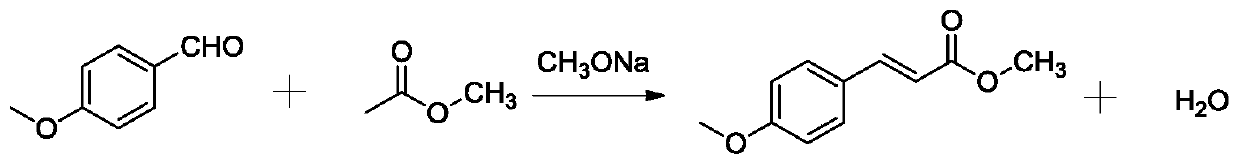

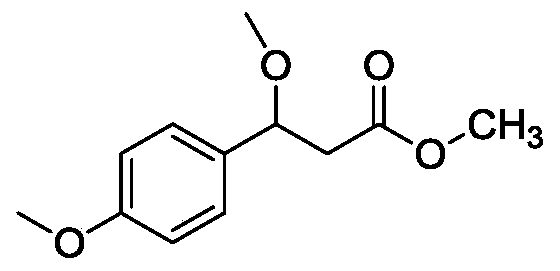

A kind of preparation method of methyl p-methoxycinnamate

ActiveCN110143878BReduce usageLow costOrganic compound preparationCarboxylic acid esters preparationSodium methoxidePtru catalyst

The invention discloses a preparation method of methyl p-methoxycinnamate. Add methyl acetate, methanol, sodium methoxide and cyclic ether into the condensation reactor, and react at reflux temperature; then add p-methoxybenzaldehyde, and circulate the reaction solution through the reaction bed filled with catalyst, After the addition of benzaldehyde is completed, the reaction is continued by reflux and insulation, and the water generated by the reaction is separated and removed. By adding methanol and cyclic ether and removing the generated water, the amount of catalyst used can be reduced to a very low level. By circulating the reaction solution through the reaction bed equipped with metal oxide catalysts, the 3 generated in the reaction process ‑Methoxy‑3‑methyl p-methoxyphenylpropionate is converted into methyl p-methoxy cinnamate in time, which improves the purity and yield of the product, and at the same time does not require acid-base neutralization process, and does not generate excess waste water and Compared with traditional processes, other solid wastes have equivalent or higher conversion rates and selectivity, lower production costs, and are more environmentally friendly.

Owner:WANHUA CHEM GRP CO LTD

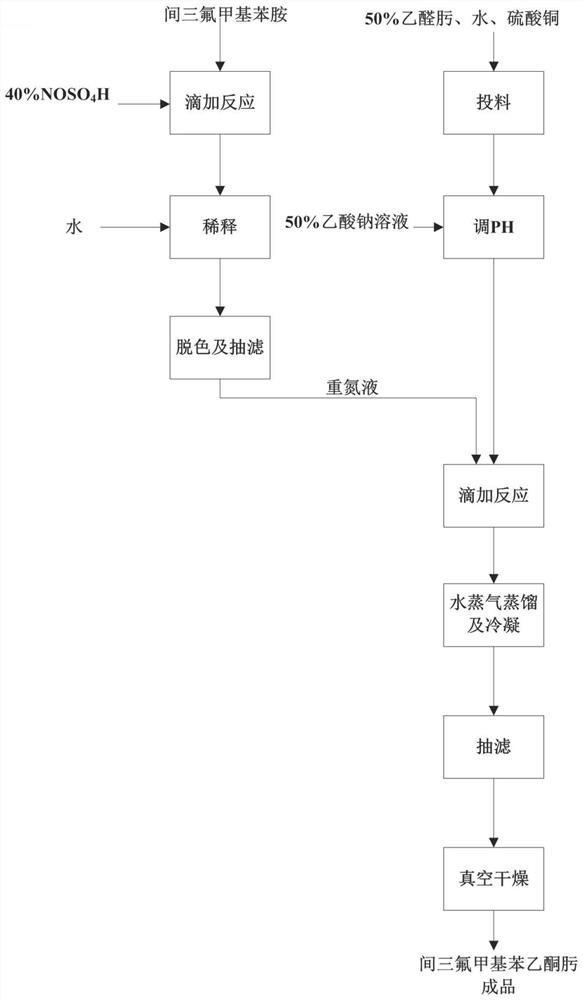

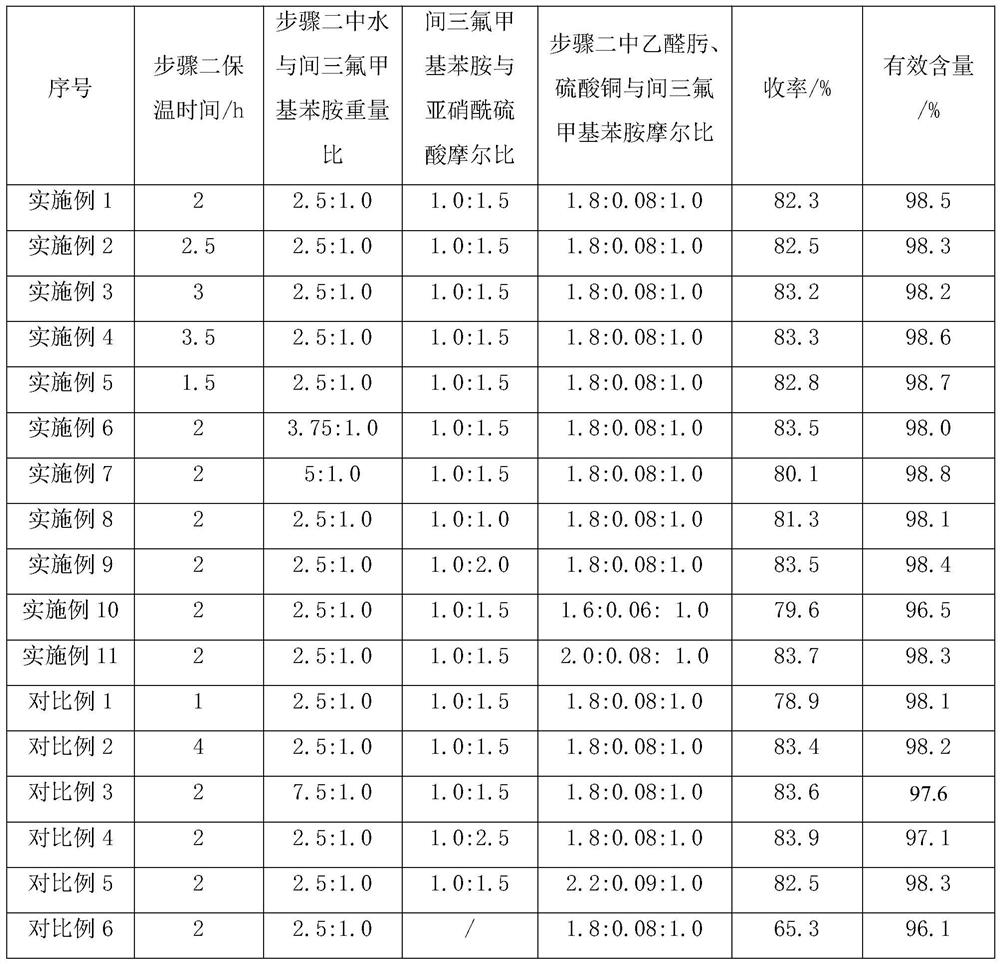

Preparation method of m-trifluoromethyl acetophenone oxime

The invention discloses a preparation method of m-trifluoromethyl acetophenone oxime. On the premise of not adding an organic solvent, the diazo liquid prepared by diazotization of nitrosyl sulfuric acid and m-trifluoromethylaniline reacts with acetaldehyde oxime to obtain the m-trifluoromethylacetophenone oxime suspension, and the product with high content is directly extracted by a steam distillation method. According to the preparation method, the obtained product is high in content, the synthesis process is simple, easy to implement, economical and environmentally friendly, and the long-term strategic target of green and sustainable development is met.

Owner:浙江欣禾生物股份有限公司

Preparation method for methyl p-methoxycinnamate

ActiveCN110143878AReduce usageLow costOrganic compound preparationCarboxylic acid esters preparationSodium methoxideCyclic ether

The invention discloses a preparation method for methyl p-methoxycinnamate. The preparation method comprises the following steps: adding methyl acetate, methanol, sodium methoxide and cyclic ether areinto a condensation reactor and performing a reaction at a reflux temperature; then adding p-methoxybenzaldehyde, and allowing a reaction solution to cyclically pass through a catalyst-loaded reaction bed at the same time; and after completion of the addition of p-methoxybenzaldehyde, carrying out reflux treatment, continuing the reaction under a heat preservation condition, and separating and removing water formed in the reaction. According to the invention, the use amount of a catalyst can be reduced to a low level by adding methanol and cyclic ether and removing the formed water; as the reaction solution cyclically passes through the reaction bed loaded with a metal oxide catalyst, 3-methoxy-3-p-methoxyphenylpropionate generated in the process of the reaction is timely converted into methyl p-methoxycinnamate, so the purity and yield of the product methyl p-methoxycinnamate is improve; meanwhile, the process of acid-base neutralization is not needed, so unwanted waste water and other solid waste are not produced; and compared with traditional processes, the preparation method of the invention has the advantages of higher conversion rate and selectivity, lower production cost and better environmental protection performance.

Owner:WANHUA CHEM GRP CO LTD

A method for extracting pectin from fermented hawthorn wine pomace

ActiveCN103739741BTake advantage ofFully extracted hawthorn wine pomace after alcohol fermentationRaffinateAcid substances

The invention provides a method for extracting pectin from fermented hawthorn wine pomace. The method comprises the following steps: distilling fermented hawthorn pomace with the ratio of the fermented hawthorn pomace to water being (1-2):2; leaching the distilled residue at 85-95 DEG C for an hour; decolorizing by using granular activated carbon (washed by 1%-5% (m / v) deionized water) at 80 DEG C for 30-90 minutes, carrying out low-temperature alcohol participation by using alcohol of which the concentration is 55% (V / V) at 5 DEG C for 12 hours and carrying out room-temperature alcohol washing by using the alcohol of which the concentration is 70% (V / V) for 1 hour; further hydrolyzing protopectin in the pomace into soluble pectin and transferring the soluble pectin into water, and carrying out filter pressing to obtain a filtrate; merging the filtrate with distilled raffinate, and centrifuging, so as to obtain a clear and transparent pectin solution; and carrying out decolorizing by utilizing granular activated carbon washed by deionized water and alcohol participation on the pectin solution, drying and crushing to obtain hawthorn pectin powder. Compared with an acid hydrolysis method, no acid is added to the pectin extraction process, a new acid substance is prevented from being introduced to the system, and the difficulty is reduced for development and utilization of the residue after pectin extraction.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Method for preparing diacetylacyclovir with 7-bit diacetylacyclovir

ActiveCN102718766BMild reaction conditionsShort cycleOrganic chemistry1,4-ButanediolAcetic anhydride

The invention discloses a method for preparing diacetylacyclovir with 7-bit diacetylacyclovir. The 7-bit diacetylacyclovir, 2-oxa-1, 4-butanediol diethyl ester and acetic anhydride react in organic solvents at the controlled temperature of 30-150 DEG C for 1-30h under the action of trifluoromethanesulfonic acid ammonium salt catalysts, and the target product of diacetylacyclovir is obtained by means of separation and purification after reaction. The method is moderate in reaction condition, short in cycle and simple and convenient in operation, the reaction process is easy to control, the 7-bit diacetylacyclovir can be converted into the diacetylacyclovir, the conversion rate is high, and the product with high purity can be obtained by means of simple operation after conversion. By the aid of the conversion process, the cost for treating waste gas, waste water and waste residues is reduced, resource utilization rate is increased, and the method is suitable for industrial production.

Owner:ZHEJIANG UNIV OF TECH +1

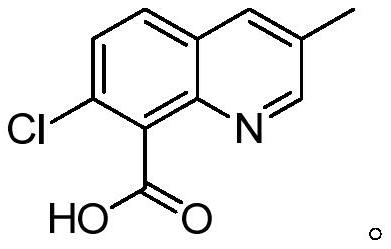

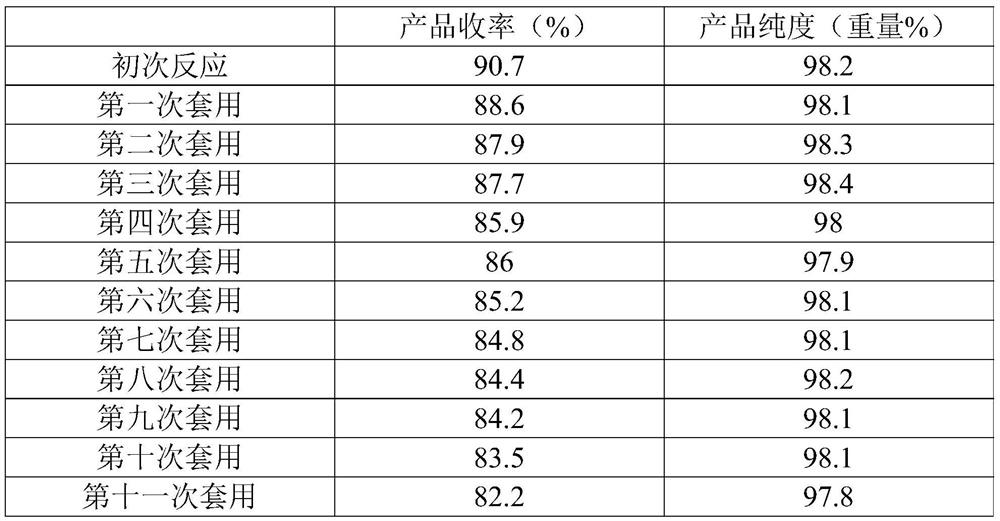

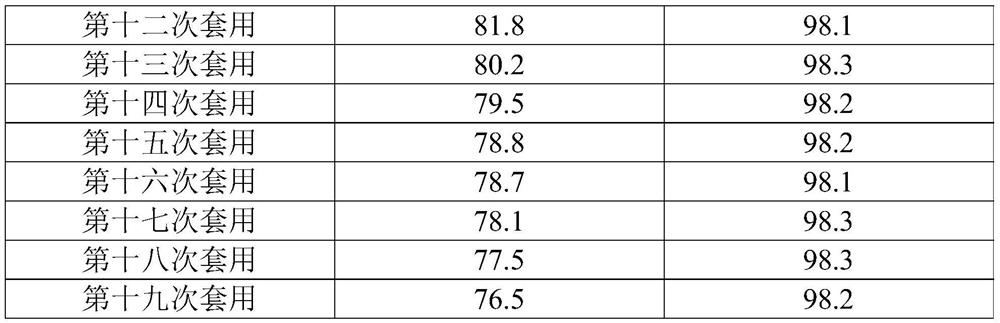

The preparation method of 7-chloro-8-quinoline carboxylic acid

ActiveCN111377863BAvoid it happening againReduce the cost of waste treatmentOrganic chemistryPtru catalystQuinoline

The present invention relates to the field of herbicides, in particular to a preparation method of 7-chloro-8-quinoline carboxylic acid, the method comprising the following steps: 1) dissolving N-hydroxyphthalimides as a catalyst In the reaction liquid of compound and azobisisobutyronitrile, with oxygen as oxidant, 7-chloro-8-methylquinoline is oxidized to obtain 7-chloro-8-quinoline carboxylic acid; 2) the oxidation of step 1) The product is separated into solid and liquid to obtain a solid phase and a reaction liquid phase. Through the method of the invention, the production of a large amount of waste acid and waste water in the synthesis process can be avoided, and the reaction liquid phase can be recovered and used mechanically.

Owner:NUTRICHEM LAB CO LTD

A kind of green synthesis method of high-purity tasteride

The invention discloses a new green industrial preparation method of highly pure dutasteride. The method is realized through a synthetic route represented by a figure shown in the specification. The preparation method is adopted to construct a steroid 1,2-olefinic bond in order to avoid raw materials being harmful to environment and having large toxicity, and use of a severely toxic oxidant DDQ is thoroughly avoided from a reaction principle; and the method has the advantages of high efficiency, high purity, greenization, clean industrialization, strong maneuverability and high yield, and the total yield of a two-step reaction is greater than 80%. An iodo intermediate is purified to easily control the quality of finished dutasteride, the purity of the obtained dutasteride product is not smaller than 99.5%, the content of any single impurity does not exceed 0.1%, and medicinal demands are completely met.

Owner:大道隆达(北京)医药科技发展有限公司

Colorant wastewater treatment agent and colorant wastewater treatment method

InactiveCN113562873ALow costReduce processingWater treatment parameter controlWater contaminantsZinc peroxideAluminium chloride

The invention discloses a dye penetrant inspection wastewater treatment agent, which is prepared from the following components in parts by weight: 2 to 4 parts of peroxide, 0.2 to 0.4 part of soluble ferrous salt and 0.8 to 3 parts of aluminum salt, wherein the peroxide is selected from any one or two of magnesium peroxide, zinc peroxide, calcium peroxide and sodium peroxide; the soluble ferrous salt is any one or more of ferrous sulfate, ferrous chloride and ferrous nitrate; and the aluminum salt is one or two of aluminum chloride or aluminum sulfate. According to the invention, a Fenton system is formed by .OH generated by the reaction of peroxide and water and the ferrous salt, COD in the dye penetrant inspection wastewater is removed, and the peroxide, the ferrous salt and the aluminum salt in the components of the treatment agent for the dye penetrant inspection wastewater are all solids, so that the treatment agent is convenient to store and low in cost. The invention also discloses a method for treating colorant wastewater by using pickling wastewater, which utilizes the pickling wastewater generated in the inspection and maintenance process of metal workpieces to treat wastes with wastes and reduce the waste treatment cost.

Owner:WUJIANG HYPERD NDT MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com