Method for extracting pectin from fermented hawthorn wine pomace

A technology for hawthorn wine and pomace, which is applied in the field of food processing, can solve the problems of pollution, affecting the processing and utilization of hawthorn pomace, waste of resources and the environment, and achieves the effects of reducing difficulty, saving enzyme inactivation steps, and reducing the cost of three-waste treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

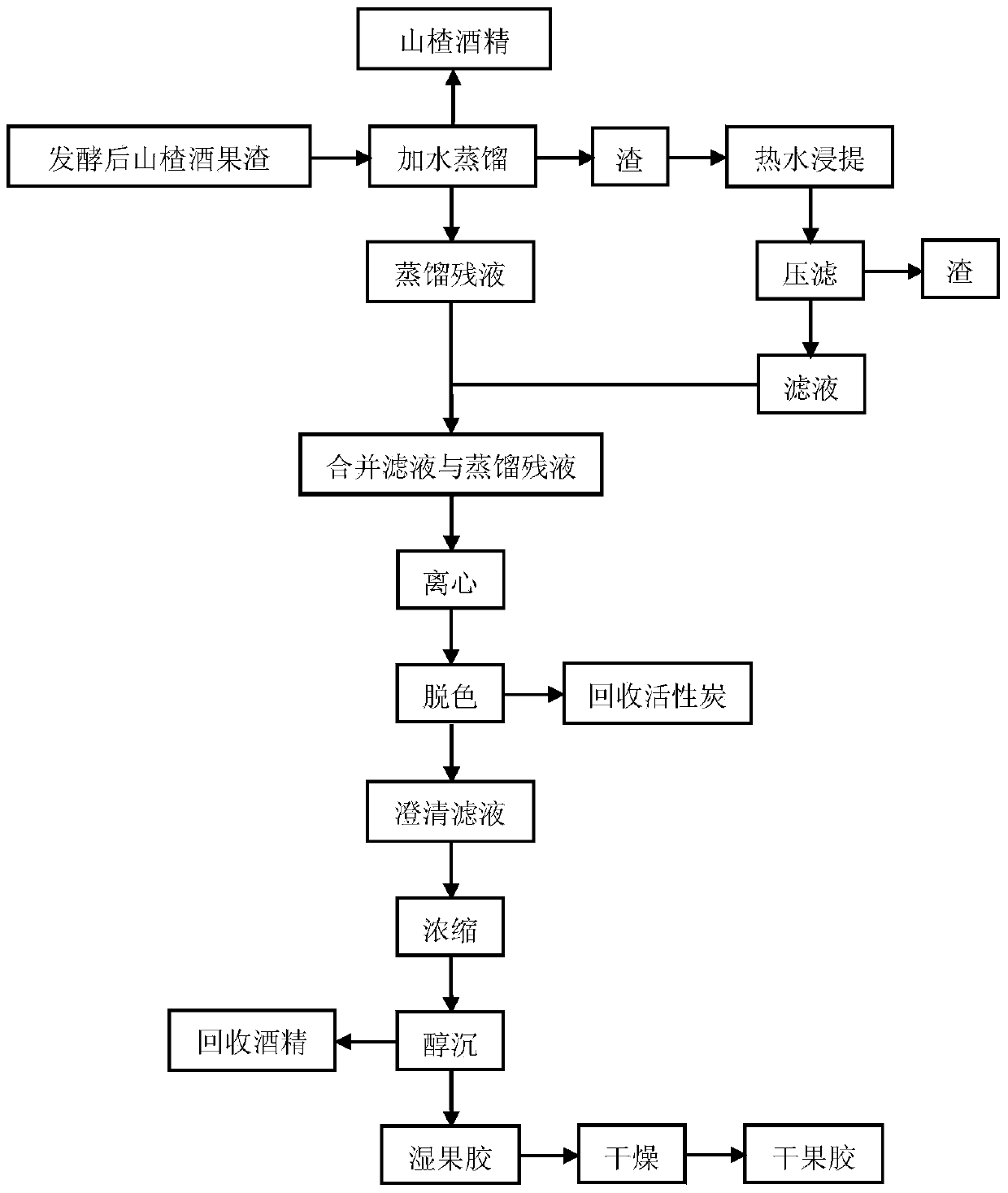

Image

Examples

Embodiment 1

[0020] 1 Distillation Wrap the fermented hawthorn wine pomace (pectin content is 1.2% in wet weight) with gauze, add deionized water according to the ratio of pomace to water 1:2 (m / m) to distill hawthorn alcohol (distilled out The hawthorn alcohol can be used to make hawthorn distilled wine). Separate distillation bottoms and raffinate.

[0021] 2 Extraction According to the ratio of slag water ratio 1:1 (m / m), add deionized water to the distillation residue, stir and extract at 85-95°C for 1h.

[0022] 3 Press filtration After leaching, press filtration, rinse the filter residue with a small amount of hot water, and collect the filtrate.

[0023] 4 Centrifuge to mix the filtrate and distillation residue, and centrifuge at 4500r / min for 10min to obtain the supernatant.

[0024] 5 After decolorization and centrifugation, add water-washed granular activated carbon to the supernatant until the concentration of water-washed granular activated carbon in the supernatant is 2% (m / ...

Embodiment 2

[0032] 1 Distillation Wrap the fermented hawthorn wine pomace (pectin content is 1.2% by wet weight) with gauze, add deionized water according to the ratio of pomace to water 1:2 (m / m), and distill hawthorn alcohol. Separate distillation bottoms and raffinate.

[0033] 2 Extraction According to the ratio of slag water ratio 1:1 (m / m), add deionized water to the distillation residue, stir and extract at 85-95°C for 1h.

[0034] 3 Press filtration After leaching, press filtration, rinse the filter residue with a small amount of hot water, and collect the filtrate.

[0035] 4 Centrifuge to mix the filtrate and distillation residue, and centrifuge at 4500r / min for 10min to obtain the supernatant.

[0036] 5 After decolorization and centrifugation, add water-washed granular activated carbon to the supernatant until the concentration of water-washed granular activated carbon in the supernatant is 2%; heat the supernatant to 80°C for 30 minutes for decolorization.

[0037] 6 Filter...

Embodiment 3

[0044] 1 Distillation Wrap the fermented hawthorn wine pomace (pectin content is 1.2% by wet weight) with gauze, add deionized water according to the ratio of pomace to water 1:2 (m / m), and distill hawthorn alcohol. Separate distillation bottoms and raffinate.

[0045] 2 Extraction According to the ratio of slag water ratio 1:1 (m / m), add deionized water to the distillation residue, stir and extract at 85-95°C for 1 hour.

[0046] 3 Press filtration After leaching, press filtration, rinse the filter residue with a small amount of hot water, and collect the filtrate.

[0047] 4 Centrifuge to mix the filtrate and distillation residue, and centrifuge at 4500r / min for 10min to obtain the supernatant.

[0048]5 After decolorization and centrifugation, add water-washed granular activated carbon to the supernatant to a concentration of 2% (m / v) of water-washed granular activated carbon in the supernatant, and heat the supernatant to 80°C for 30 minutes for decolorization.

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com