A method for synergistic treatment of coloring flaw detection wastewater and pickling wastewater

A coloring flaw detection and collaborative processing technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high operating cost, complicated recycling process, and large energy consumption. Achieve the effects of reducing construction and operation costs, simple operation and management, and reducing waste treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

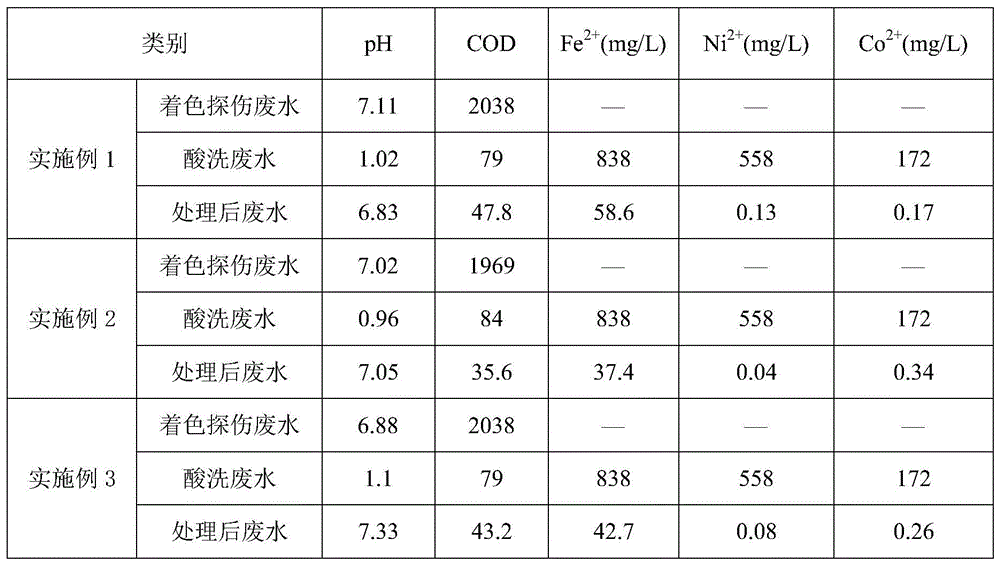

Embodiment 1

[0021] (1) The dyed flaw detection wastewater is subjected to ozone oxidation treatment in the ozone reaction tower, and the ozone aeration time is 3h, 1m 3 The dosage of wastewater ozone is about 600g to obtain the first solution;

[0022] (2) Add the first solution of the above step (1) into the pickling wastewater and mix, the volume ratio of the pickling wastewater and the first solution is 1:1, mix evenly with a mixer to obtain the second solution, and then add 20% NaOH solution, adjust the pH value to 9 to obtain the third solution;

[0023] (3) The third solution of the above step (2) is first subjected to solid-liquid separation through a plate and frame filter press, and then filtered through a quartz sand filter to obtain the fourth solution;

[0024] (4) the fourth solution of above-mentioned steps (3) is adsorbed through activated carbon adsorption tower, and the residence time 30min obtains the fifth solution, selects 10-24 mesh particle size, iodine value is gre...

Embodiment 2

[0027] (1) The dyed flaw detection wastewater is subjected to ozone oxidation treatment in the ozone reaction tower, and the ozone aeration time is 2.5h, 1m 3 The dosage of wastewater ozone is about 500g to obtain the first solution;

[0028] (2) Add the first solution of the above step (1) into the pickling waste water and mix it. The volume ratio of the pickling waste water and the first solution is 1:1.5. Mix evenly with a mixer to obtain the second solution, and then add 15% NaOH solution, adjust the pH value to 10 to obtain the third solution;

[0029] (3) The third solution of the above step (2) is first subjected to solid-liquid separation through a plate and frame filter press, and then filtered through a quartz sand filter to obtain the fourth solution;

[0030] (4) the 4th solution of above-mentioned steps (3) is adsorbed through activated carbon adsorption tower, and residence time 40min obtains the 5th solution, selects 10-24 mesh particle diameter, the coconut sh...

Embodiment 3

[0033] (1) The dyed flaw detection wastewater is subjected to ozone oxidation treatment in the ozone reaction tower, and the ozone aeration time is 2.7h, 1m 3 The dosage of wastewater ozone is about 540g to obtain the first solution;

[0034] (2) Add the first solution of the above step (1) into the pickling waste water and mix, the volume ratio of the pickling waste water and the first solution is 1:2, mix evenly with a mixer to obtain the second solution, and then add 10% NaOH solution, adjust the pH value to 9.5 to obtain the third solution;

[0035] (3) The third solution of the above step (2) is first subjected to solid-liquid separation through a plate and frame filter press, and then filtered through a quartz sand filter to obtain the fourth solution;

[0036] (4) the 4th solution of above-mentioned steps (3) is adsorbed through activated carbon adsorption tower, and residence time 45min obtains the 5th solution, selects 10-24 mesh particle diameter, the coconut shell ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com