Three chemical treatment methods for landfill leachate membrane filtration concentrate

A technology of landfill leachate and treatment method, which is applied in the field of landfill leachate membrane filtration concentrated liquid three-in-one treatment, which can solve the problems of high comprehensive treatment cost, low degree of reduction, unreasonable membrane process design, etc., and achieve improved water production The effect of reducing the concentration of COD and reducing the risk of membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

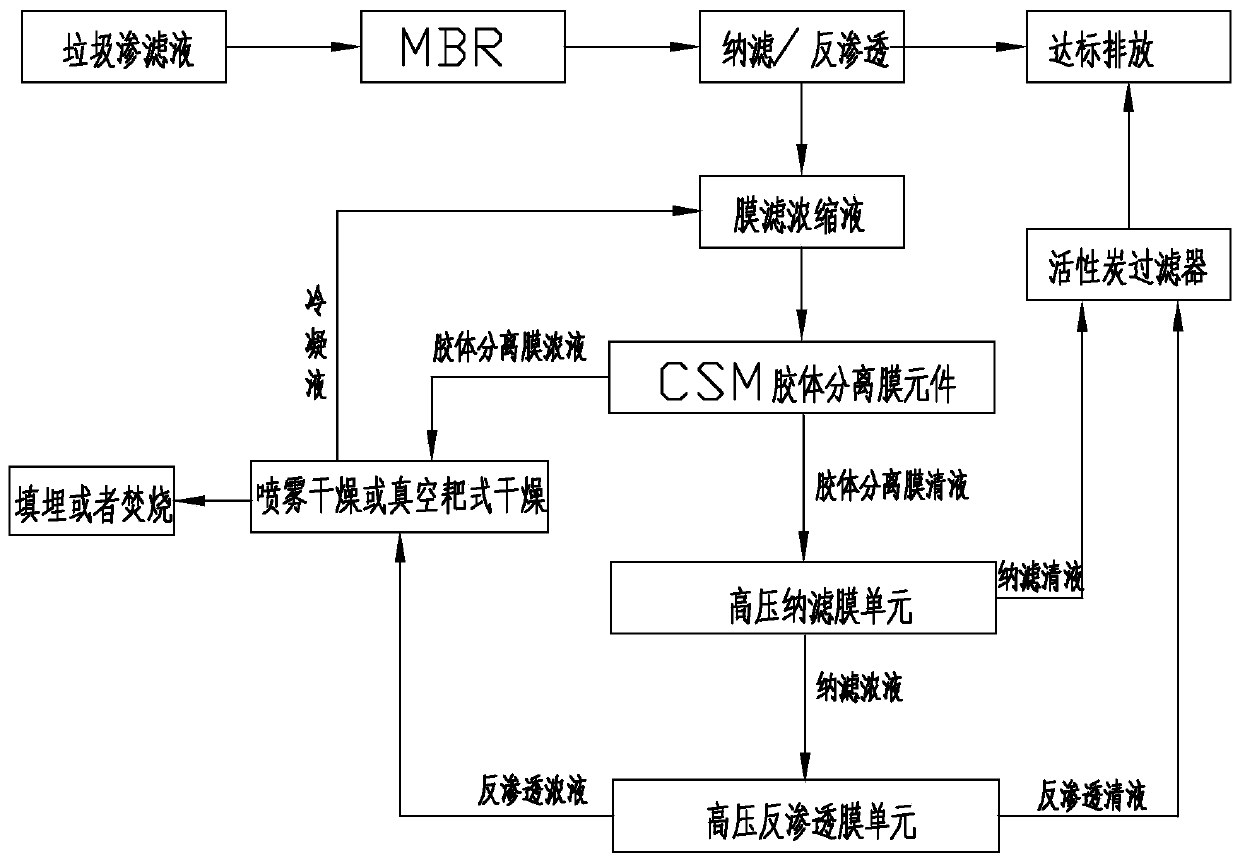

[0023] See figure 1 As shown, the landfill leachate membrane filtration concentrated liquid three-chemical treatment method of the present invention includes the following steps.

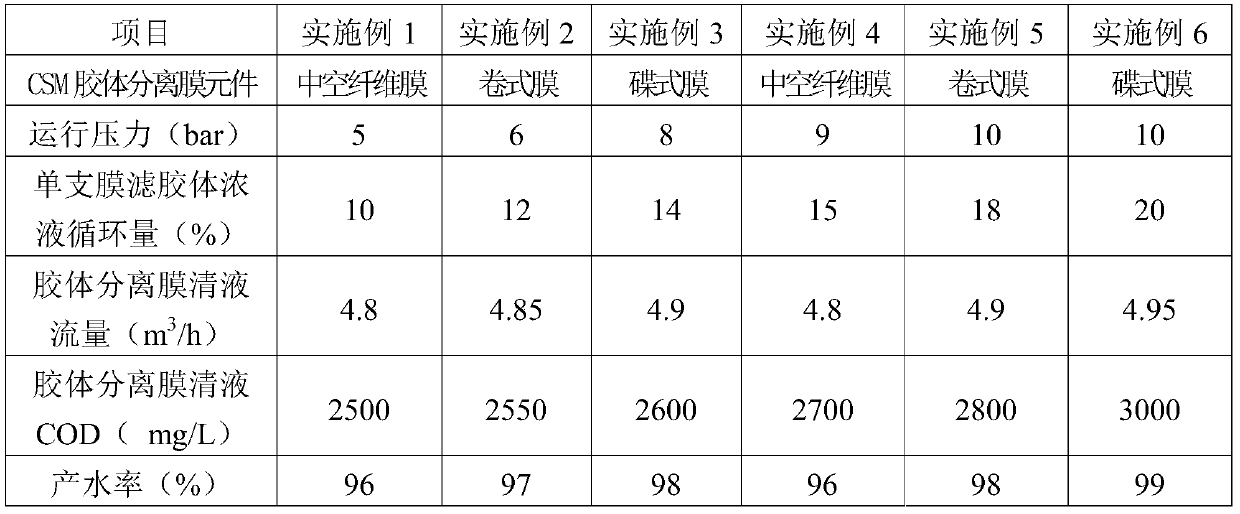

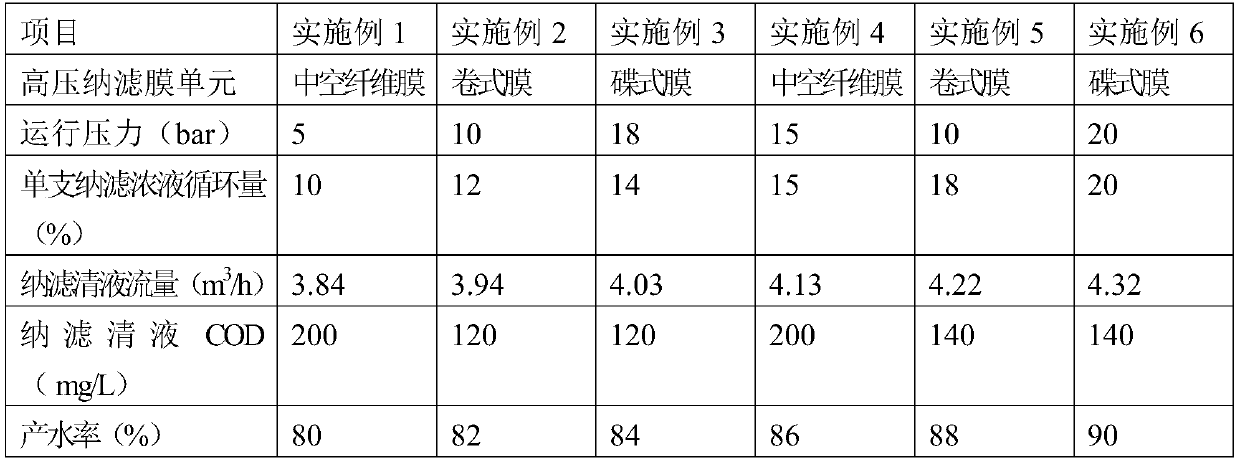

[0024](1) Colloidal separation treatment: The membrane filtration concentrate after the landfill leachate treatment is pumped into the CSM (Colloidseparation membrane) colloidal separation membrane element, and the landfill leachate can be processed by the "MBR+nanofiltration / reverse osmosis process to produce membrane filtration The concentrated solution is stored in the membrane filtration concentrated solution tank, and is pumped into the CSM colloidal separation membrane element to separate the colloidal organic matter with a molecular weight above 1000Da in the membrane filtration concentrated solution. The CSM colloidal separation membrane element of the present invention is a roll type One of membrane, disc membrane or hollow fiber membrane, the CSM colloidal separation membrane element is at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com