Neutralization-free furfural waste-water biochemical treatment process

A technology for biochemical treatment and waste water, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as poor operation effect, instability, and difficulty in achieving discharge standards. Achieve the effects of reducing loss, strong decomposition ability, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

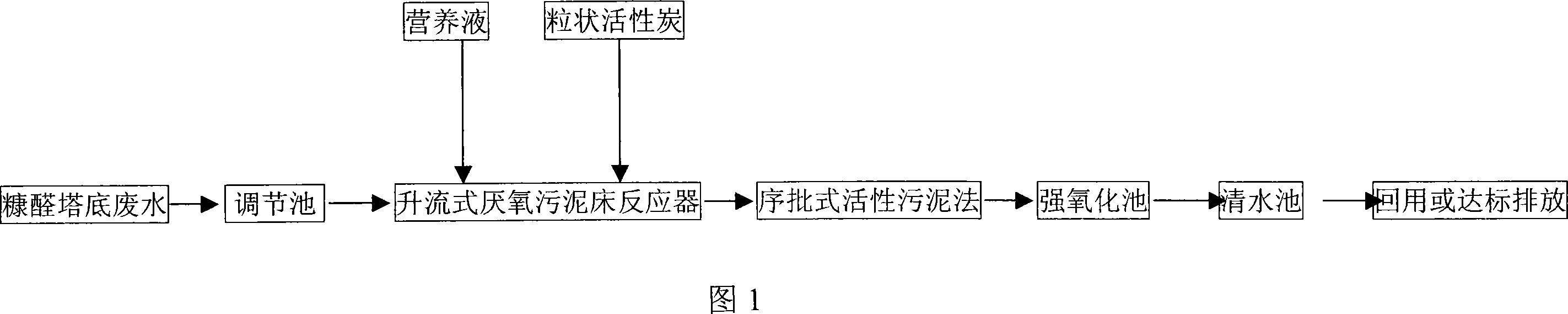

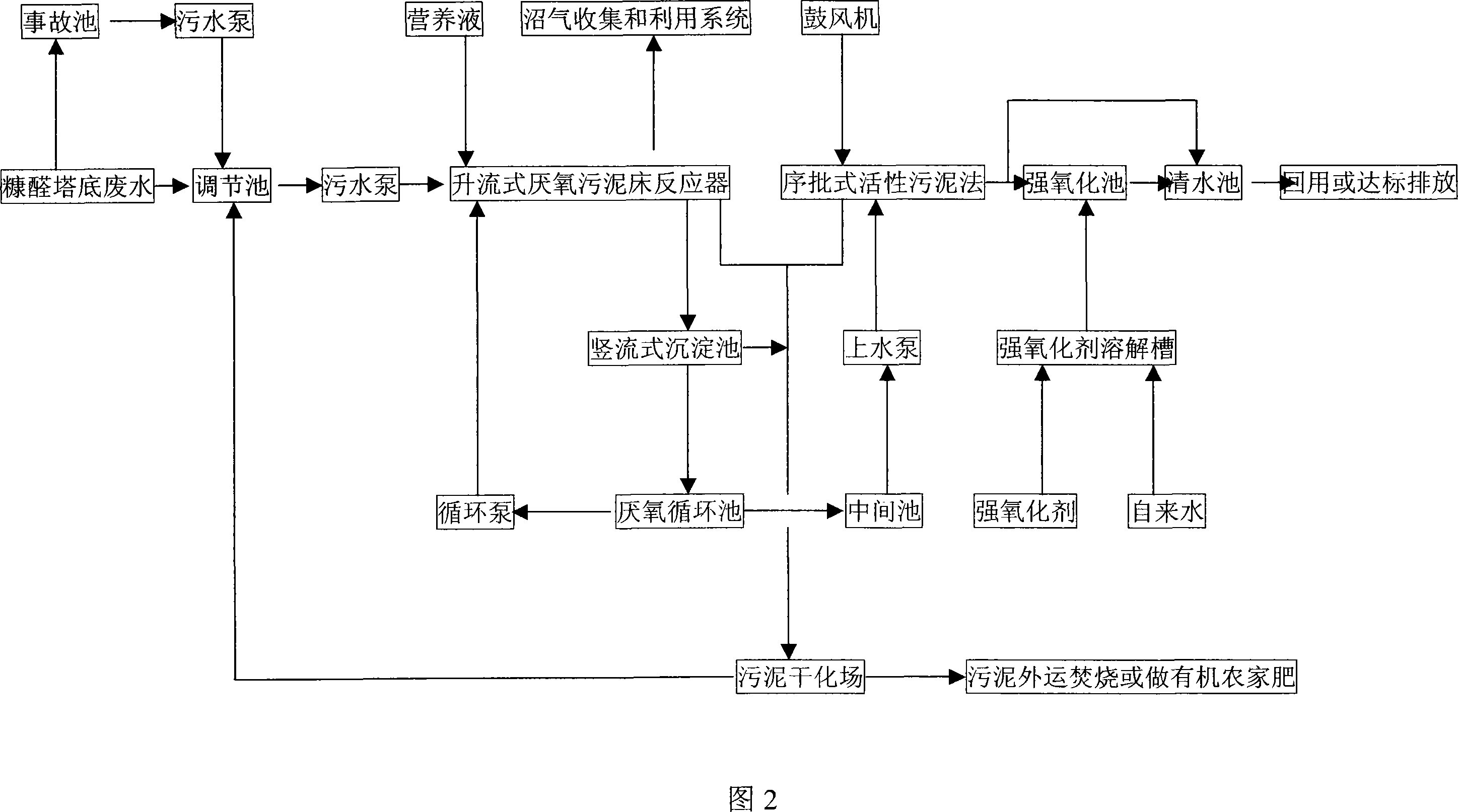

[0021] As shown in Figure 1-2: a neutralization-free furfural wastewater biochemical treatment process, characterized in that: furfural wastewater first enters the regulating tank, and then enters the upflow anaerobic sludge bed reactor under the lift of the sewage pump, to Furfural wastewater nutrient solution and granular activated carbon are added to the pool of the upflow anaerobic sludge bed reactor, and the water treated by the upflow anaerobic sludge bed reactor enters the vertical flow sedimentation tank, and then flows into the middle pool The water enters the pool of the sequencing batch activated sludge method according to the operation rules of the sequencing batch activated sludge method under the promotion of the inlet pump of the sequencing batch activated sludge method, and comes out of the pool of the sequencing batch activated sludge method The water flows into the clear water pool, and then reused or discharged up to the standard. The nutrient solution is 80....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com