The preparation method of 7-chloro-8-quinoline carboxylic acid

A technology of quinoline carboxylic acid and methyl quinoline, which is applied in the field of herbicides, can solve a large number of waste acids and waste water, and achieve the effects of reducing the cost of three wastes treatment, low oxidation reaction temperature, and avoiding waste acid and waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of 7-chloro-8-quinoline carboxylic acid, the method comprises the following steps:

[0023] 1) In the reaction solution in which N-hydroxyphthalimide compounds and azobisisobutyronitrile are dissolved as catalysts, oxygen is used as an oxidant to oxidize 7-chloro-8-methylquinoline to obtain 7-Chloro-8-quinolinecarboxylic acid;

[0024] 2) separating the oxidation product from step 1) into solid and liquid to obtain a solid phase and a reaction liquid phase.

[0025] According to the method of the present invention, by using N-hydroxyphthalimide compounds and azobisisobutyronitrile as a catalyst, oxygen is used as an oxygenant to oxidize 7-chloro-8-methylquinoline, which can The generation of waste acid and waste water in the oxidation process is avoided, and high-purity 7-chloro-8-quinolinecarboxylic acid can be obtained with low reaction temperature and simple post-treatment.

[0026] In addition, by adopting the ab...

Embodiment 1

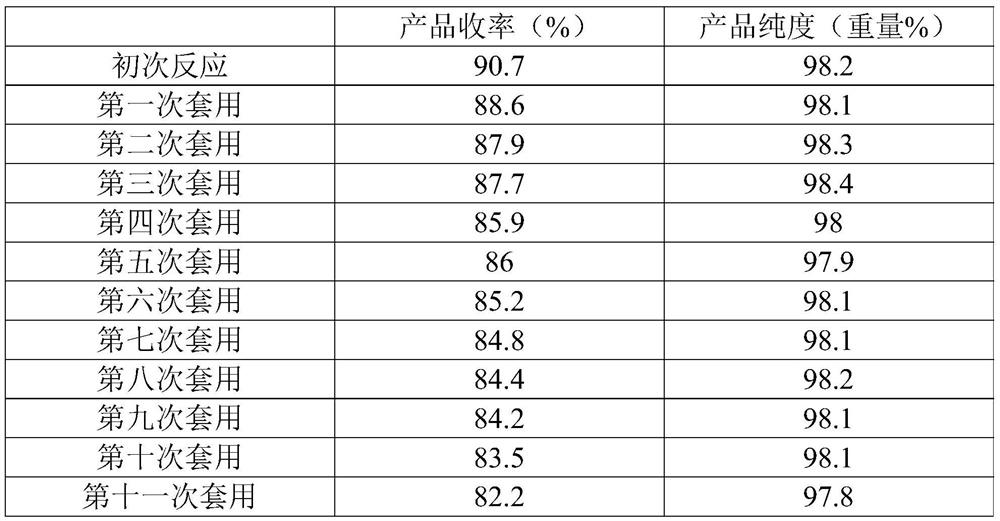

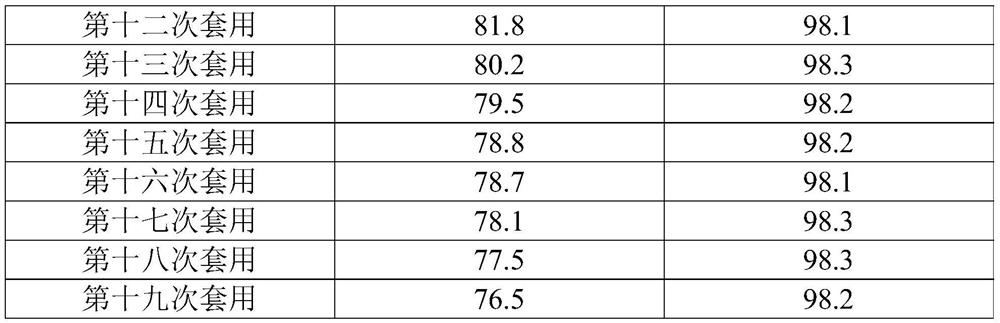

[0046] 1) In a 100 milliliter Hastelloy autoclave, add 10 grams of 7-chloro-8-methylquinoline, 40 milliliters of acetonitrile, 0.18 grams (0.02 equivalents) of N-hydroxyphthalimide, azobis Isobutyronitrile 0.093 grams (0.01 equivalent), closed autoclave, nitrogen replacement 2 times, oxygen replacement 3 times, oxygen pressurization 4MPa, be warming up to 80 ℃ of reaction 6 hours, the oxygen pressure in the reactor must not be lower than 4MPa in the reaction process. After the reaction, the temperature and pressure were lowered, and the reaction solution was filtered. The filter cake was slurried with 20 ml of acetonitrile, filtered, and the solid was dried to obtain 10.8 g of 7-chloro-8-quinolinecarboxylic acid, with a content of 98.2% by weight and a yield of 90.7%. After filtering the mother liquor, the corresponding 7-chloro-8-methylquinoline was added, and the reaction was continued.

[0047] 1 H-NMR(500MHz,d6-DMSO):δ13.645(s,1H),8.986-8.974(dd,1H,J 1 =1.5Hz,J 2 =2Hz),...

Embodiment 2

[0054] 1) In a 100 ml Hastelloy autoclave, add 10 grams of 7-chloro-8-methylquinoline, 40 milliliters of acetonitrile, 0.38 grams (0.04 equivalents) of N-hydroxyphthalimide, and azobis Isobutyronitrile 0.18 grams (0.02 equivalent), closed autoclave, nitrogen replacement 2 times, oxygen replacement 3 times, oxygen pressure 4MPa, be warming up to 90 ℃ of reaction 9 hours, the oxygen pressure in the reactor must not be lower than 4MPa in the reaction process. After the reaction was finished, the temperature and pressure were lowered, the reaction solution was filtered, and the filter cake was beaten with 30 milliliters of acetonitrile, filtered, and after the solid was dried, it was identified by NMR and mass spectrometry to obtain 11.1 grams of 7-chloro-8-quinoline carboxylic acid, with a content of 98.7% by weight. Yield 93.6%. After filtering the mother liquor, the corresponding 7-chloro-8-methylquinoline was added, and the reaction was continued.

[0055] 2) Apply mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com