Patents

Literature

50 results about "Quinolinic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quinolinic acid (abbreviated QUIN or QA), also known as pyridine-2,3-dicarboxylic acid, is a dicarboxylic acid with a pyridine backbone. It is a colorless solid. It is the biosynthetic precursor to nicotine.

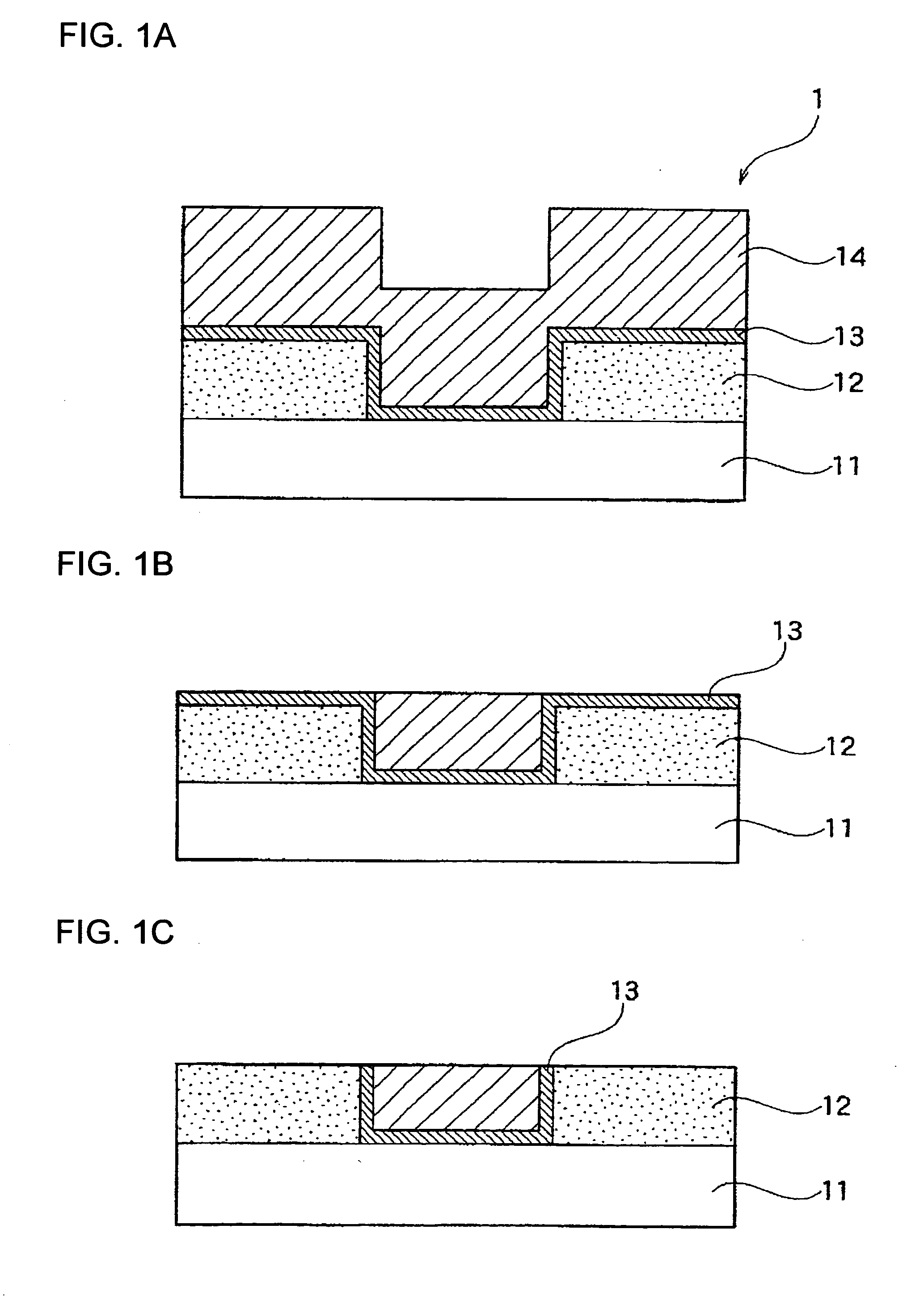

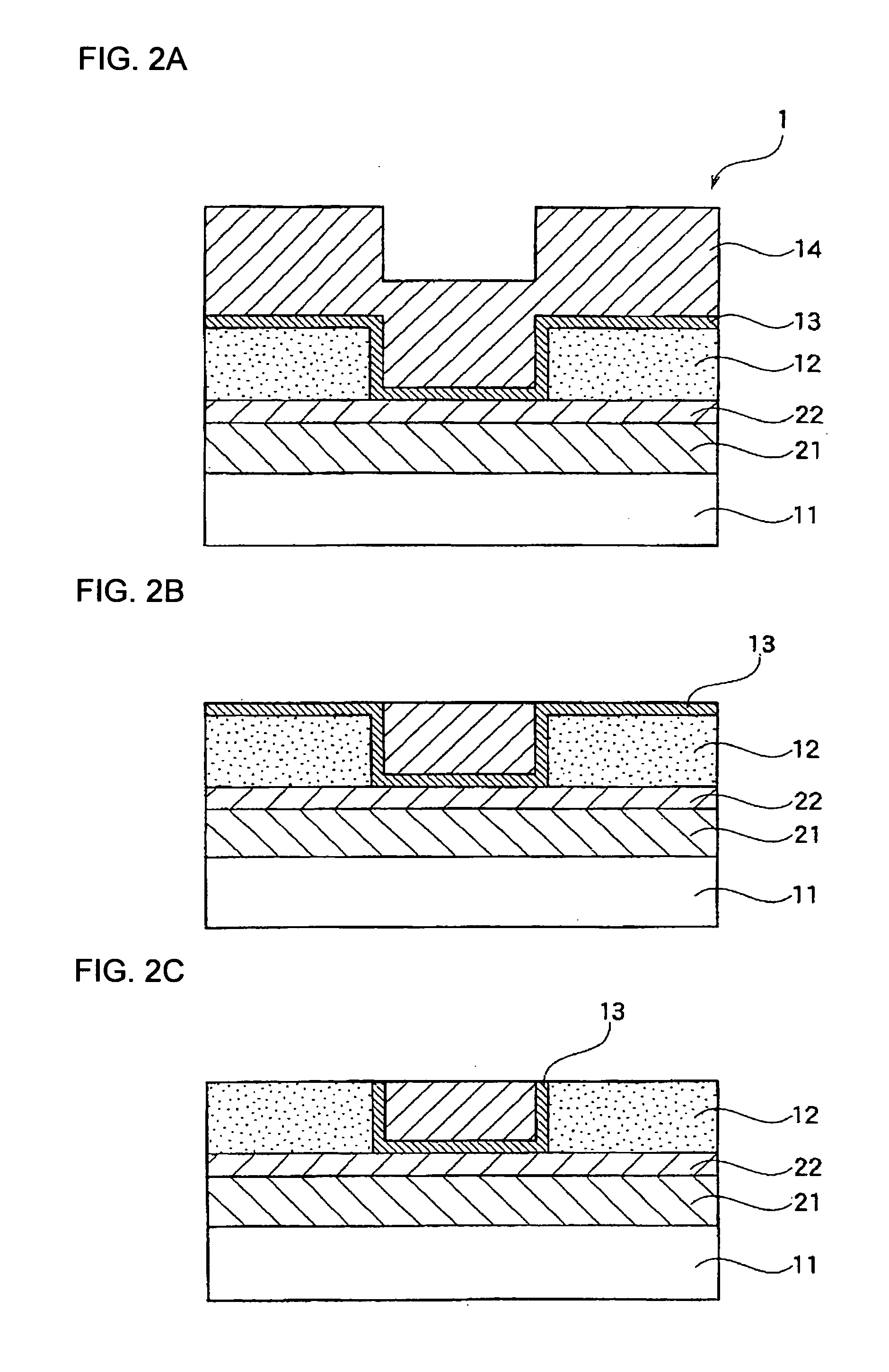

Chemical mechanical polishing aqueous dispersion, chemical mechanical polishing method, and kit for preparing chemical mechanical polishing aqueous dispersion

InactiveUS20060276041A1Efficient polishingSufficiently planarized and accuratelyOther chemical processesDecorative surface effectsQuinolineCarboxylic acid

A chemical mechanical polishing aqueous dispersion, including: (A) inorganic particles; (B) at least one type of particles selected from the group consisting of organic particles and organic-inorganic composite particles; (C) at least one compound selected from the group consisting of quinolinecarboxylic acid, quinolinic acid, a divalent organic acid (excluding quinolinic acid), and a hydroxyl acid; (D) at least one compound selected from the group consisting of benzotriazole and benzotriazole derivatives; (E) an oxidizing agent; and (F) water, the chemical mechanical polishing aqueous dispersion containing the component (A) in an amount of 0.05 to 2.0 wt % and the component (B) in an amount of 0.005 to 1.5 wt %, having a ratio (WA / WB) of the amount (WA) of the component (A) to the amount (WB) of the component (B) of 0.1 to 200, and having a pH of 1.0 to 5.0.

Owner:JSR CORPORATIOON

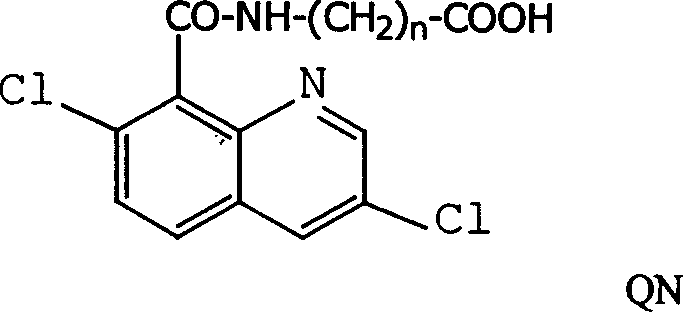

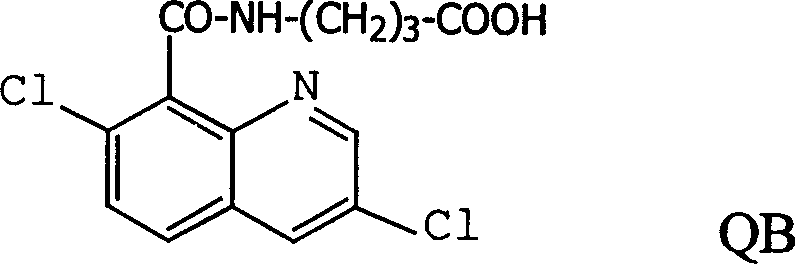

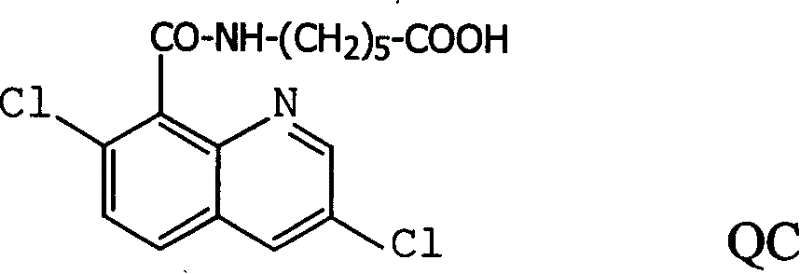

Production method and use for dichloro quinolinic acid artificial hapten, artificial antigen and specific antibody

InactiveCN1569835AEasy to handleFast and accurate analysis and detectionImmunoglobulinsTesting foodQuinolineCarboxylic acid

The invention discloses a process for preparing Quinclorac artificial semiantigen, artificial antigen, specific antibody and use thereof, wherein the preparation comprises, subjecting the dichloroquine (3,7-dichlorine-8-quinoline carboxylic acid) to sulfoxide chlorinated acylation, reacting with reanal and aminocaproic acid, thus obtaining semiantigen 4-(3,7-dichlorine-8-quinolineformyl) reanal or 6-(3,7-dichlorine-8-quinolineformyl) aminocaproic acid (QB or QC).

Owner:ZHEJIANG UNIV

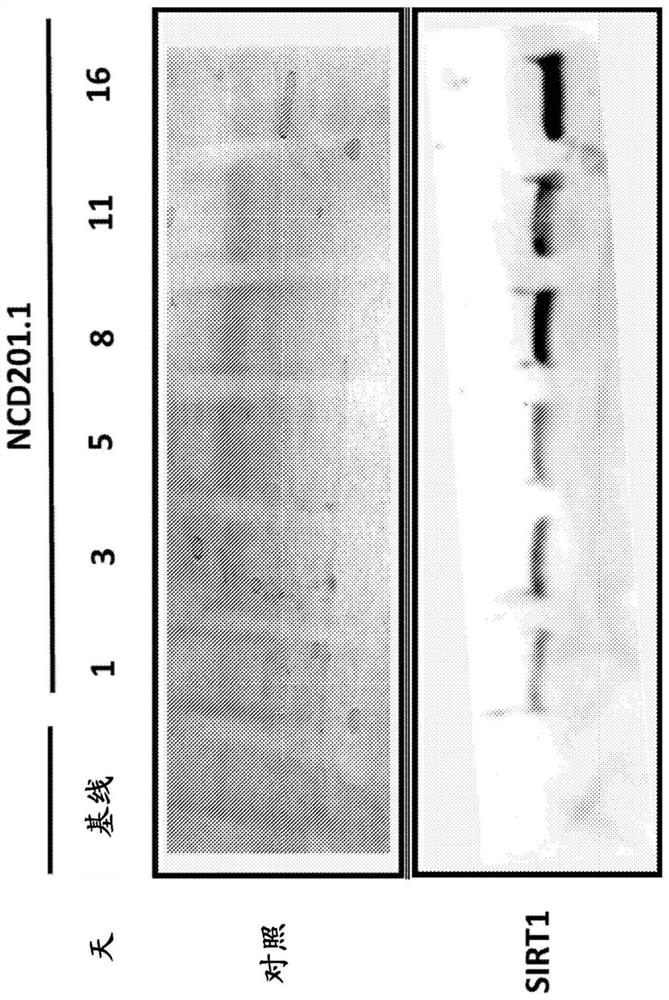

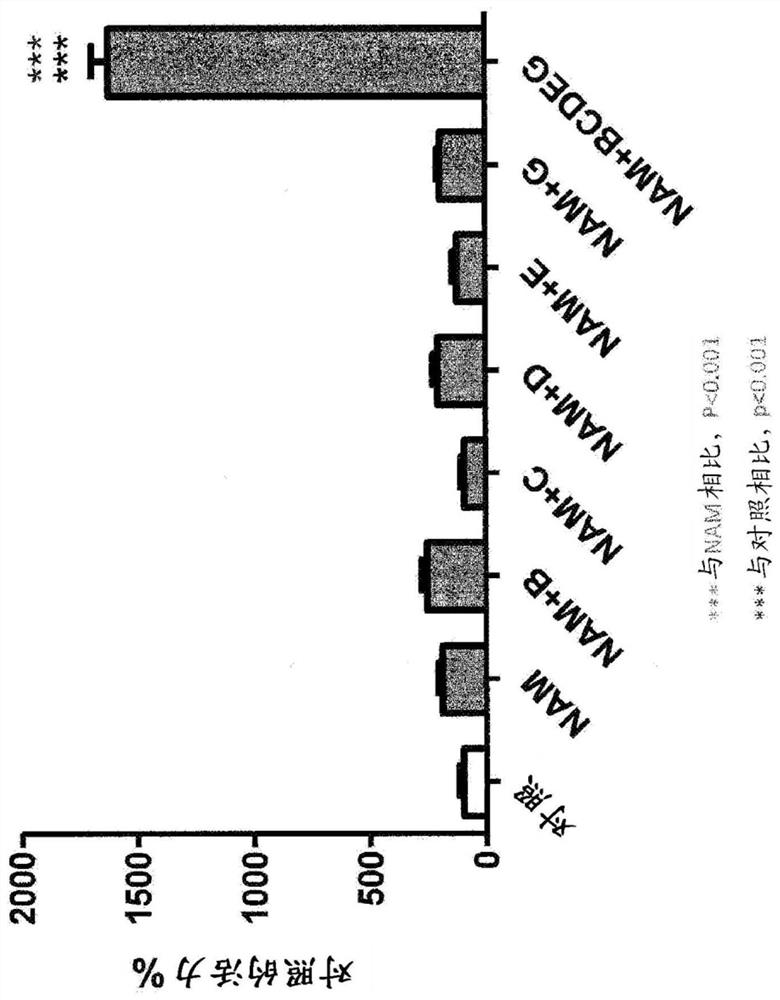

Anti-aging composition

InactiveCN107308160AImprove the level ofImprove repair effectHydroxy compound active ingredientsAntinoxious agentsTryptophanIn vivo

The invention relates to the technical field of health-care products, in particular to an anti-aging composition. The anti-aging composition is prepared from, by weight, 3-5 parts of nicotinic acid, 1-9 parts of methyl donor, 15-20 parts of tryptophan or 8-10 parts of quinolinic acid, 0.3-0.5 part of resveratrol and 8-10 parts of soluble magnesium. The composition containing the components can effectively improve the level of in-vivo NAD+ and accordingly keep PARP1 not damaged. The resveratrol further improves the gene repairing effect in the human body by improving the effect of the PARP1 from another perspective, and finally a strong anti-aging purpose is achieved.

Owner:孙冠辰

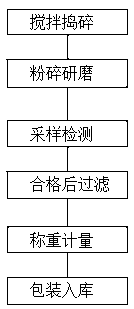

Herbicide composition containing metamifop and dichloro-quinolinic acid

InactiveCN108378043AEasy to removeThe preparation method is scientific and reasonableBiocideAnimal repellantsPollutionWeed

The invention discloses a herbicide composition containing metamifop and dichloro-quinolinic acid. The herbicide composition is prepared by stirring and mashing, crushing and grinding, sampling and detecting, filtering after the product is qualified, weighing and measuring, packaging and putting into storage. A preparation method of the herbicide composition is scientific and reasonable, easy to operate, convenient for improvement of production efficiency, low in production cost, environmentally-friendly and free from pollution; the metamifop has is efficient, low in toxicity and environmentally-friendly, and is almost absorbed by stems and leaves so as have no requirement for water and be used under the condition that water exists or does not exist; the dichloro-quinolinic acid can betterremove gramineous weeds such as barnyard grass and moleplant seed; the herbicide composition is very environmentally friendly.

Owner:安徽圣丰生化有限公司

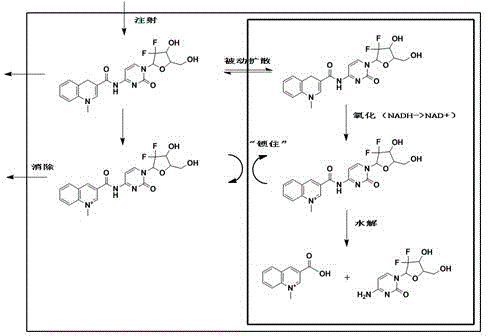

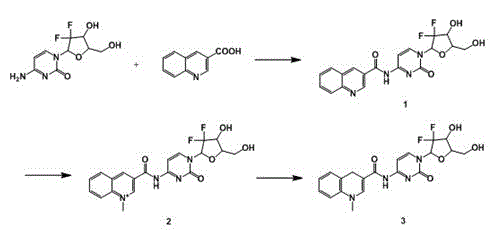

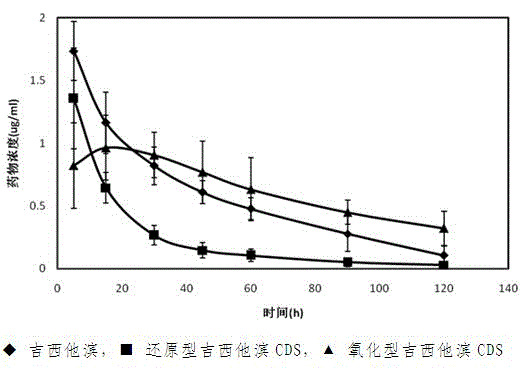

Gemcitabine chemical transfer prodrug, preparation method and applications thereof

ActiveCN105001291AHigh drug contentOrganic active ingredientsNervous disorderEfficacyDrug efficiency

The present invention discloses a gemcitabine chemical transfer prodrug, a preparation method and applications thereof, wherein the gemcitabine chemical transfer prodrug mainly comprises gemcitabine and a dihydropyridine chemical delivery system. According to the present invention, based on the dihydropyridine-pyridine ion oxidation-reduction reaction, gemcitabine and a targeting agent 3-quinolinic acid are bonded to prepare the reduced gemcitabine chemical transfer prodrug, the conjugate is promoted to diffuse into the brain tissue through the high lipid solubility, and in the brain, the pyridine part in the dihydropyridine brain-targeting chemical delivery system conjugate is oxidized into the oxidized gemcitabine chemical transfer prodrug by a coenzyme system; and the gemcitabine chemical transfer prodrug has effects of improvement of the amount of the drug entering the brain, enhancement of the drug efficacy, reduction of the drug consumption, and reduction of the drug toxic-side effect.

Owner:SHANGHAI ZHIMENG BIOLOGICAL PHARMA CO LTD

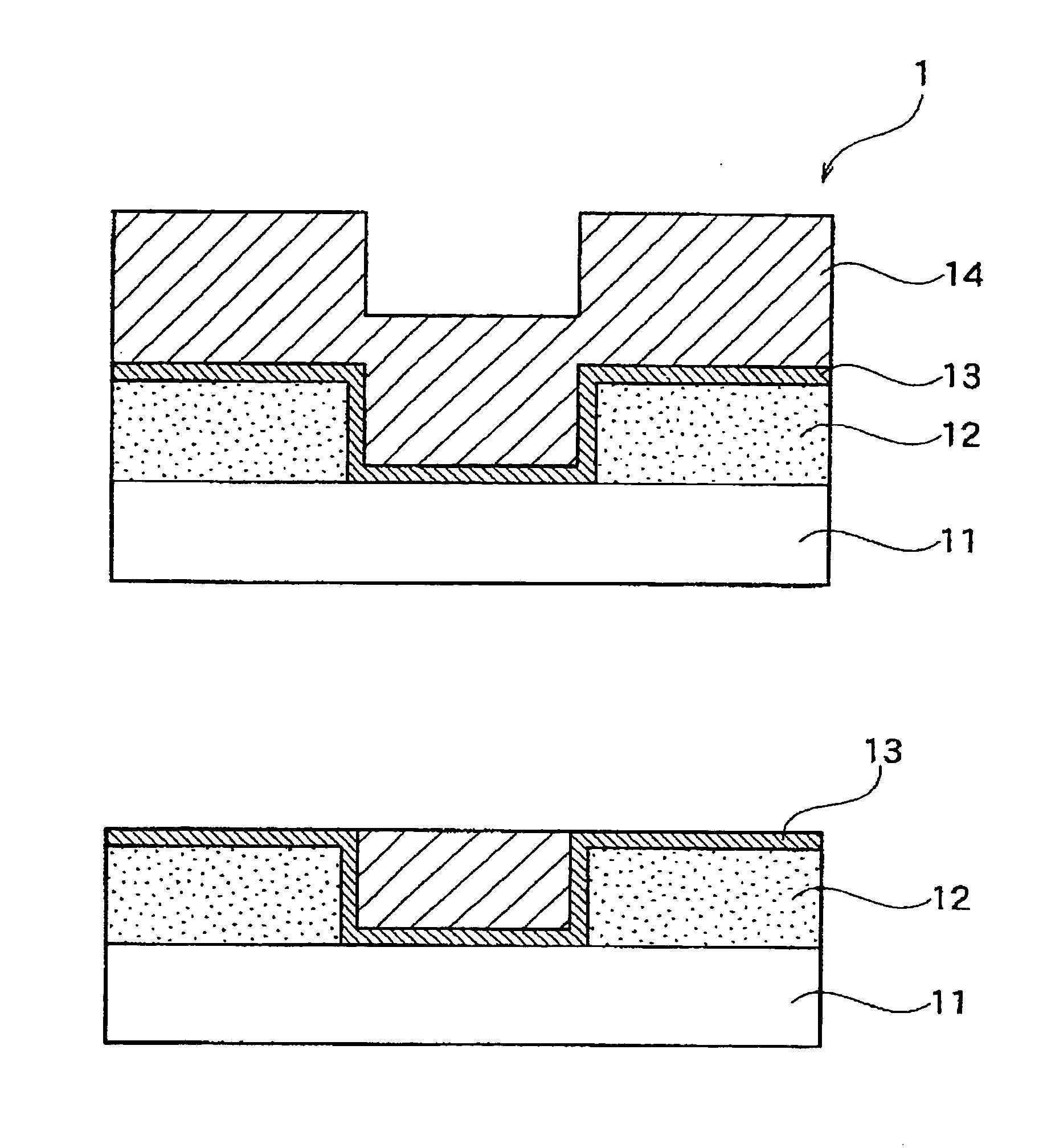

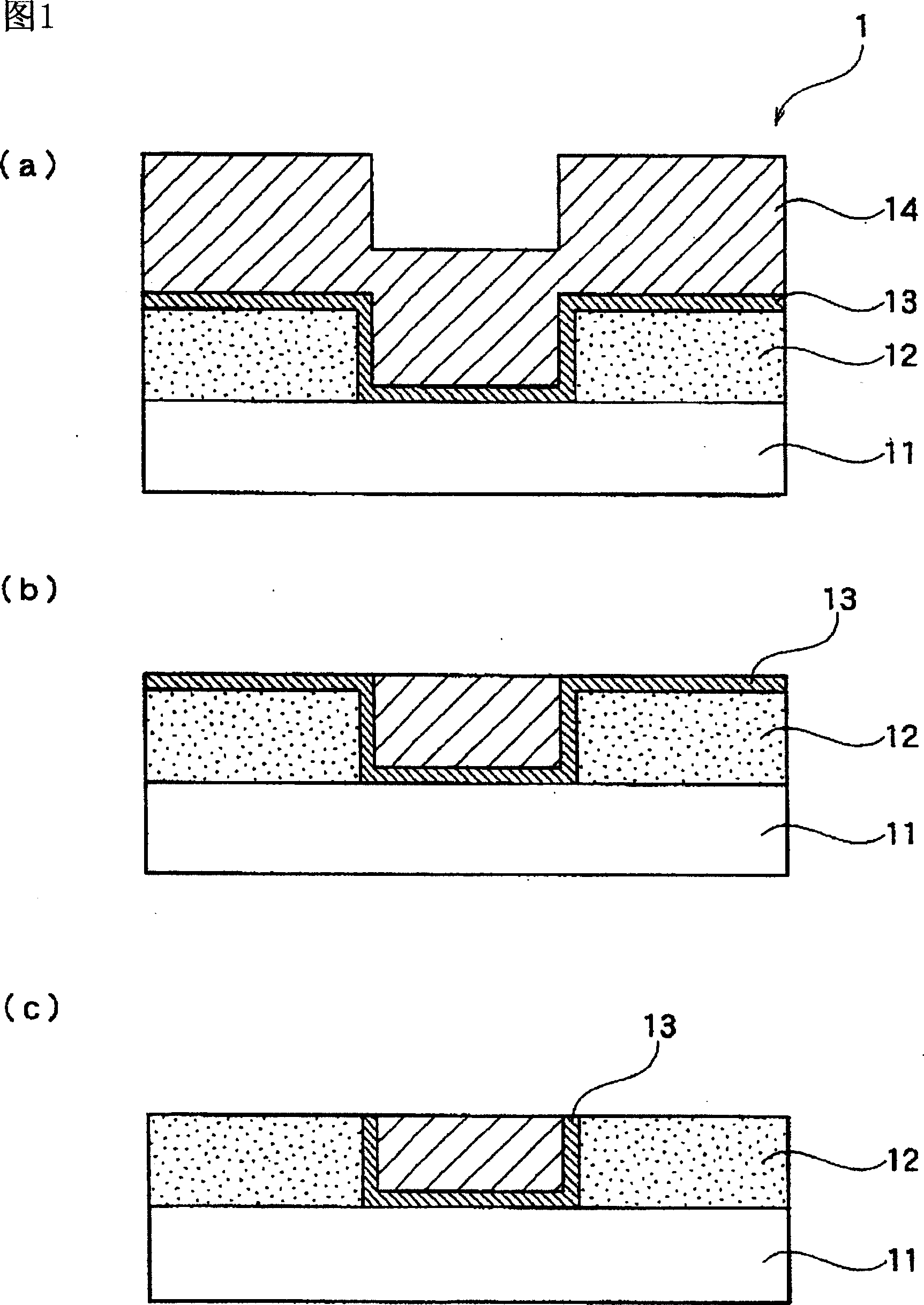

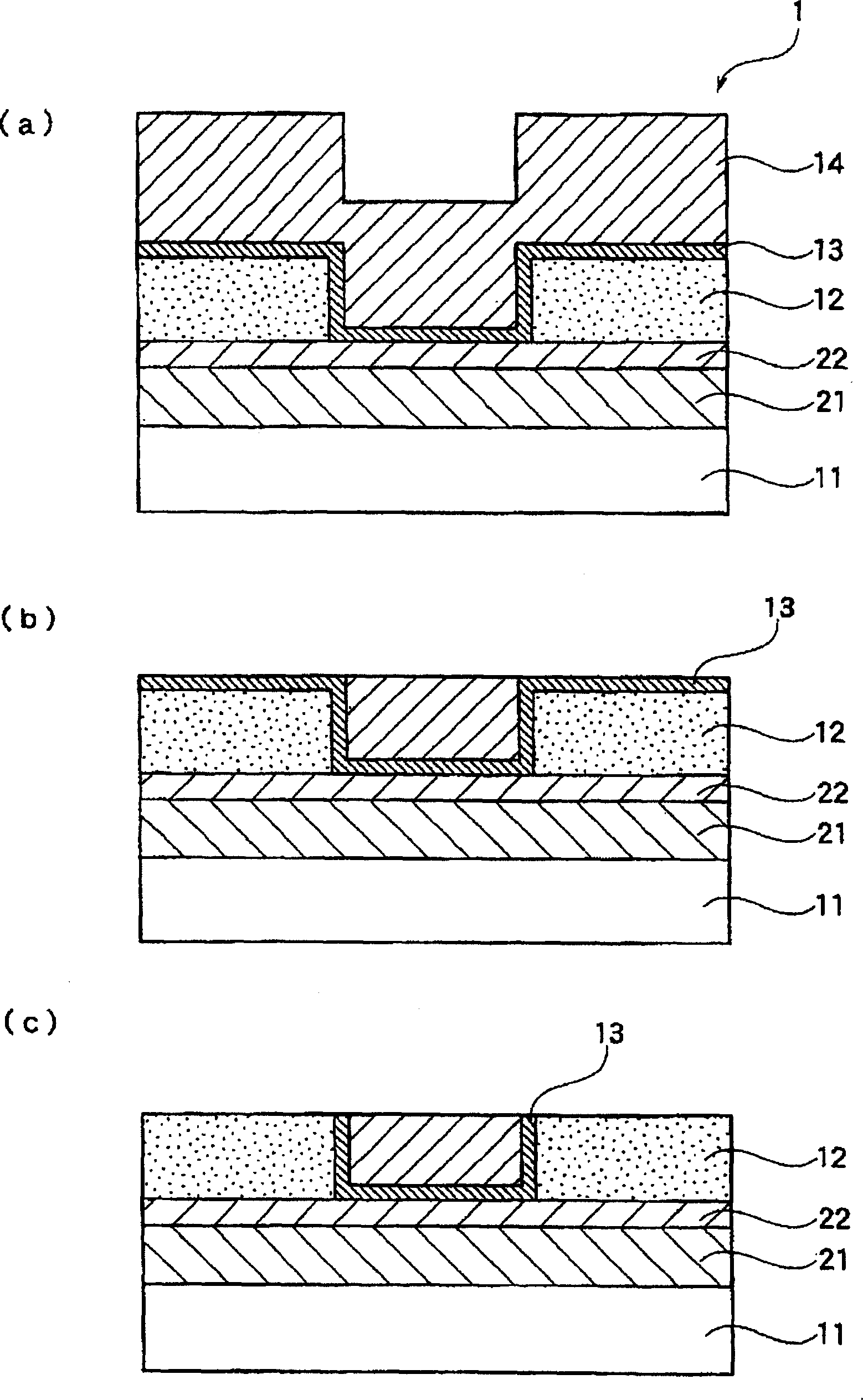

Aqueous dispersoid for chemical machinery grinding and grinding method and concocting reagent kit

InactiveCN1881539AEfficient grindingReduce scratchesOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidInorganic particle

A chemical mechanical polishing aqueous dispersion, including: (A) inorganic particles; (B) at least one type of particles selected from the group consisting of organic particles and organic-inorganic composite particles; (C) at least one compound selected from the group consisting of quinolinecarboxylic acid, quinolinic acid, a divalent organic acid (excluding quinolinic acid), and a hydroxyl acid; (D) at least one compound selected from the group consisting of benzotriazole and benzotriazole derivatives; (E) an oxidizing agent; and (F) water, the chemical mechanical polishing aqueous dispersion containing the component (A) in an amount of 0.05 to 2.0 wt% and the component (B) in an amount of 0.005 to 1.5 wt%, having a ratio (W A / W B ) of the amount (W A ) of the component (A) to the amount (W B ) of the component (B) of 0.1 to 200, and having a pH of 1.0 to 5.0. chemical mechanical grinding method adopting the chemical mechanical polishing aqueous dispersion and kit for concocting the the chemical mechanical polishing aqueous dispersion.

Owner:JSR CORPORATIOON

Quinolinic acid production method

The invention provides a quinolinic acid production method. Quinolinic acid is produced through the following steps: preparing quinoline acid copper through an oxidizing reaction, treating an oxidation reaction mother liquid, preparing quinoline acid sodium through an alkaline hydrolysis reaction, decolouring, preparing quinolinic acid through an acid separation reaction, and treating an acid separation reaction mother liquid. The oxidation reaction mother liquid, alkaline hydrolysis reaction filter cake washing water and the acid separation reaction mother liquid are comprehensively and effectively treated; active ingredients, including copper ions, quinolinic acid and the like, in each mother liquid and washing water are recycled and are utilized into the production of the next batch of the quinolinic acid; the control on an acid separation reaction is optimized, and the yield of the quinolinic acid is improved. When the active ingredients are applied, the recycled copper oxide and the recycled basic copper carbonate are purified; the yield of the quinoline acid is improved; meanwhile, the purity of the quinoline acid is ensured; refining steps of the quinoline acid are reduced; the production cost is reduced. Through the treatment of each mother liquid and the application of the washing water, water resources are saved; the wastewater discharge is reduced; the pressure on the environment is relieved.

Owner:湖北金玉兰医药科技有限公司

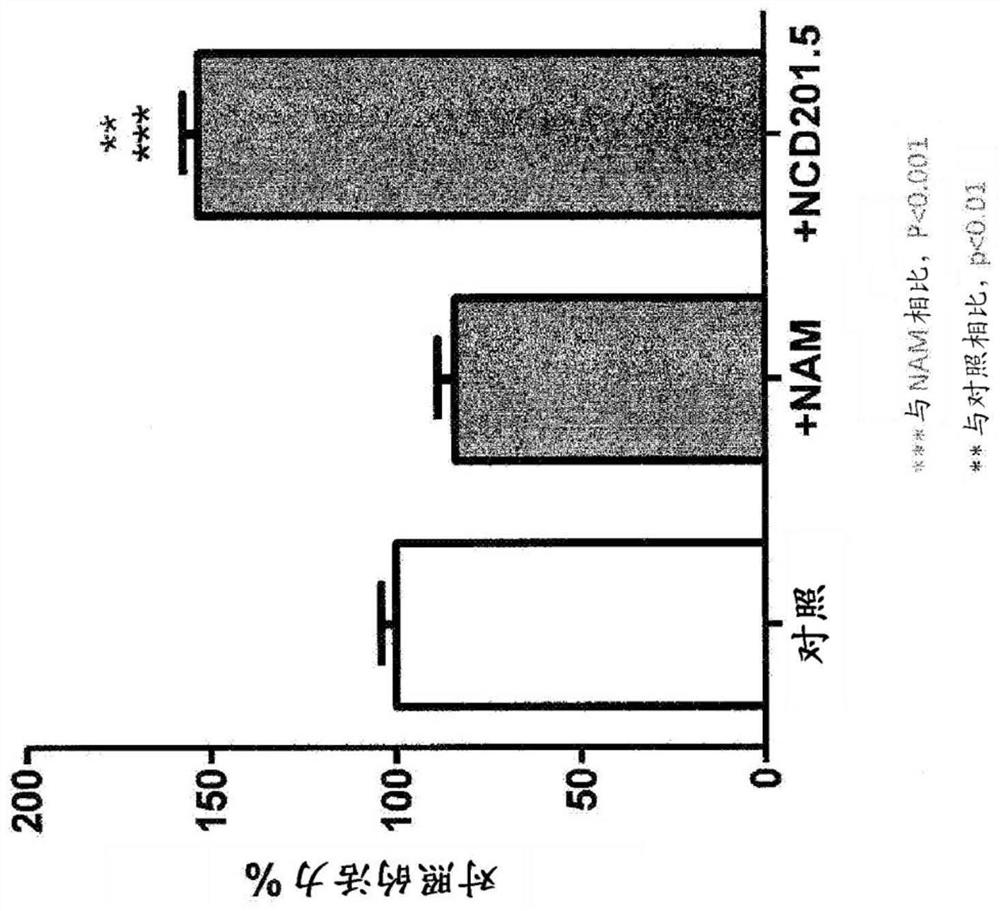

Method of modulating b cell functioning

Owner:太平洋治疗学控股有限公司

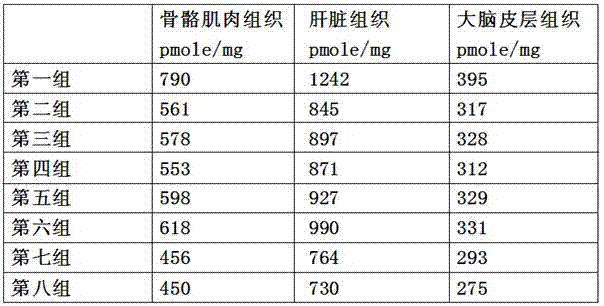

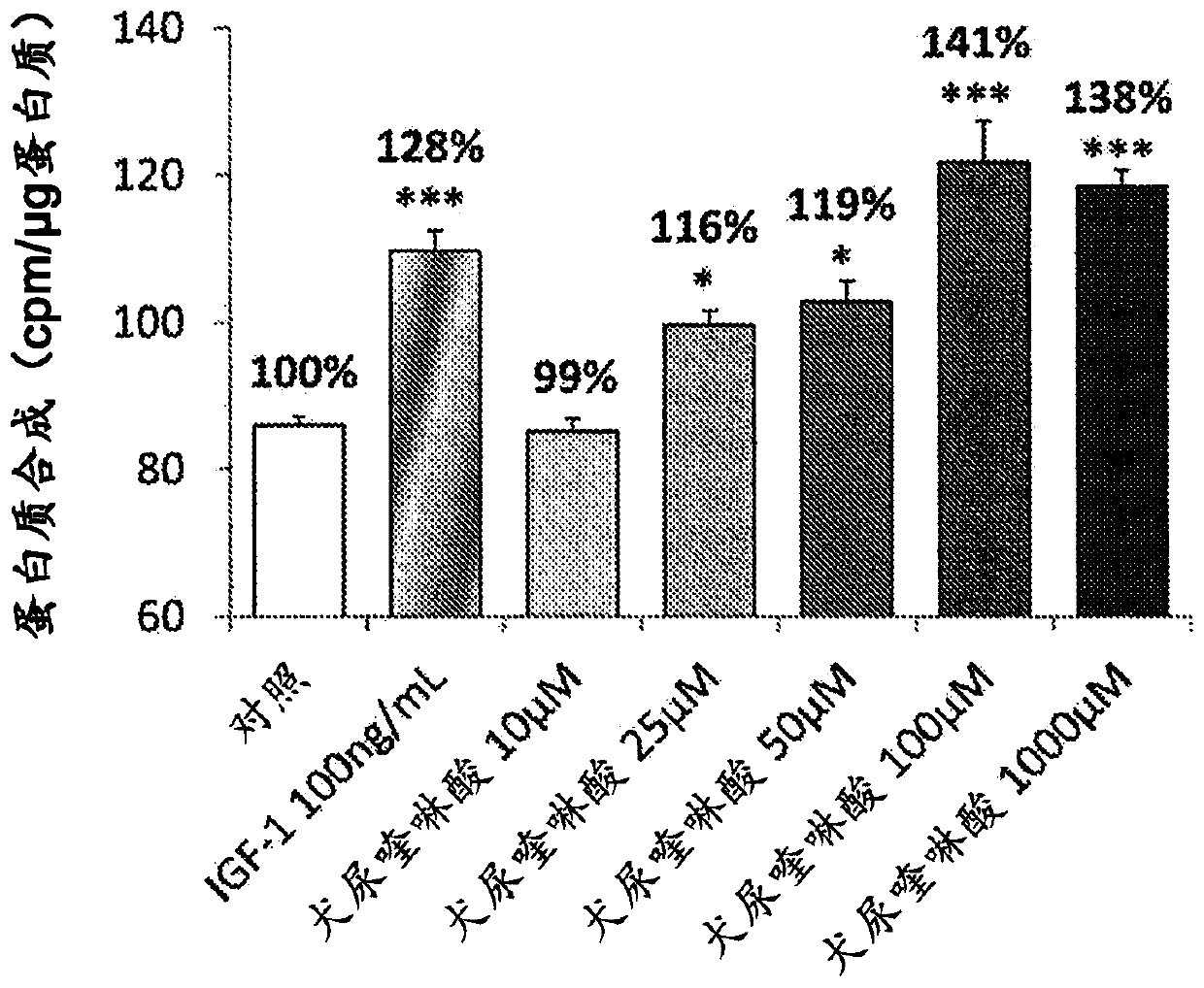

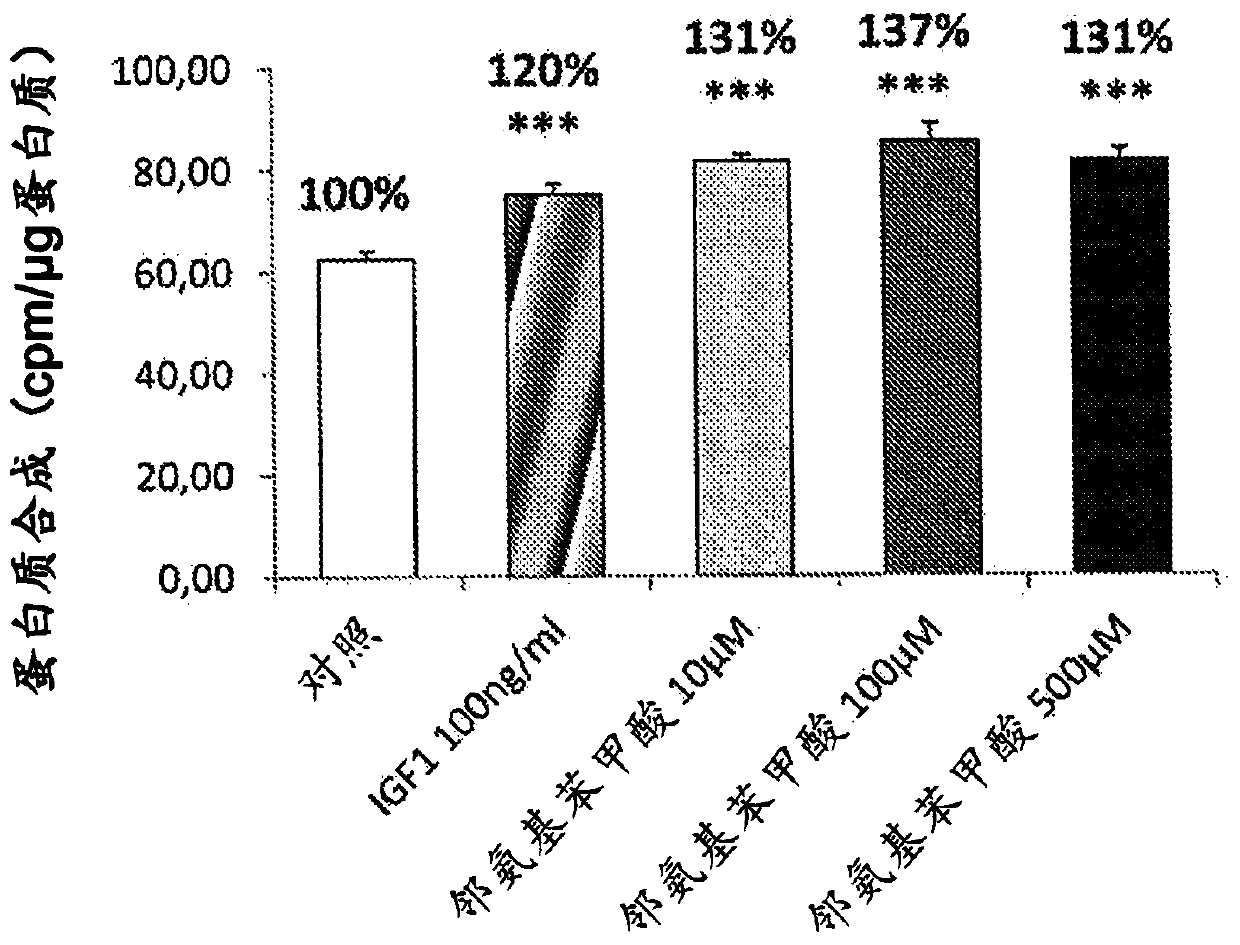

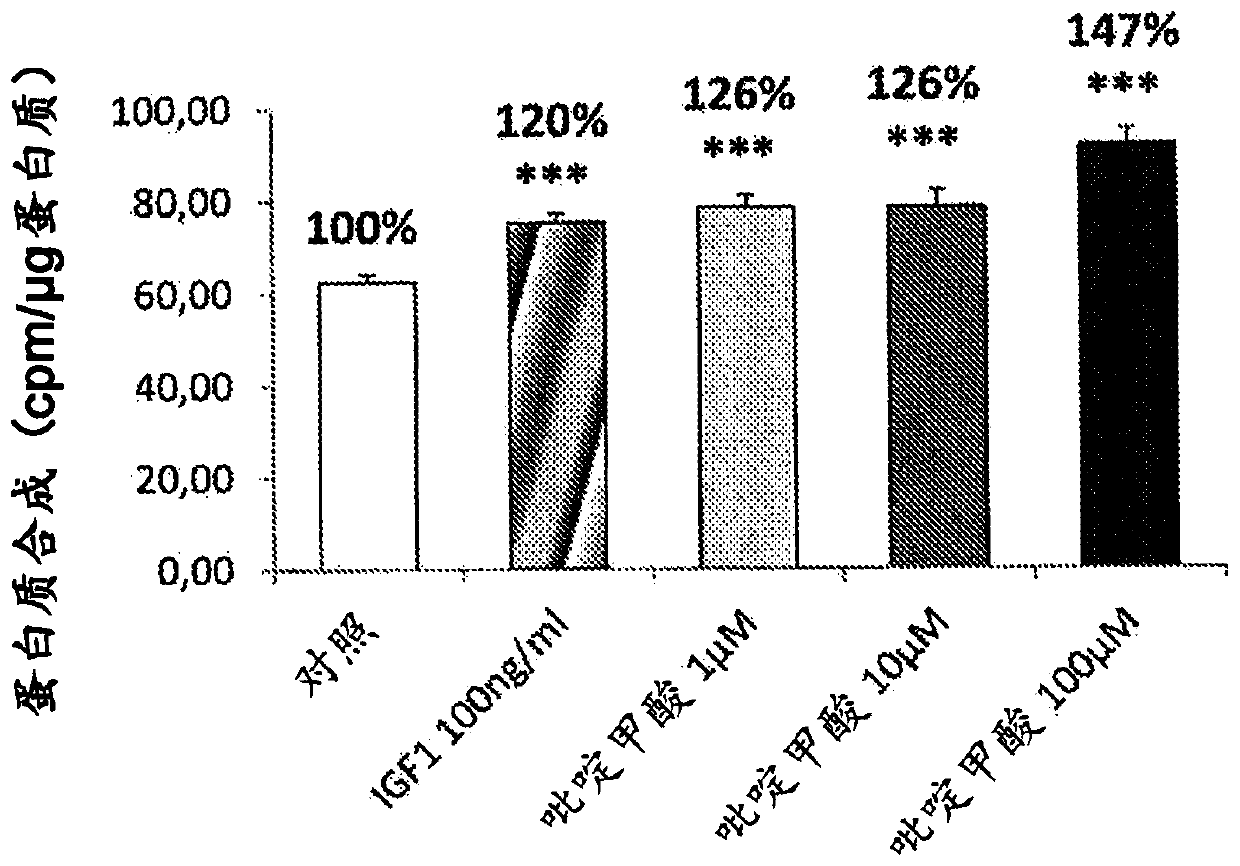

Use of tryptophan metabolites for treating muscle atrophy

PendingCN109952102ASpeed up recovery timeFast recovery timeMuscular disorderPharmaceutical delivery mechanismMetabolitePharmaceutical Substances

The present invention concerns a tryptophan metabolite chosen from kynurenic acid, anthranilic acid, quinolinic acid, picolinic acid, quinaldic acid and the mixtures of same or an enantiomer, diastereoisomer, hydrate, solvate, tautomer, racemic mixture or pharmaceutically acceptable salt of same, for use as a drug intended for increasing and / or maintaining muscle mass and / or strength in a mammal,and in particular intended for treating and / or preventing muscle atrophy in mammals and / or for promoting muscle growth in mammals doing exercise and aiming to increase muscle mass and / or quality and / or strength, for preventing the appearance of symptoms of sarcopenia or for rehabilitation following muscle loss and / or for improving recovery time after an intense physical effort.

Owner:METABRAIN RES

Dichloro quinolinic acid, its preparation method and solid preparation thereof

InactiveCN1803774AImprove solubilityPromote absorptionBiocideOrganic chemistrySolubilityWater soluble

The related preparation method for Na or K or ammonia dichloroquinolinecarboxylate comprises: mixing the dichloroquinoline acid and alkali to prepare salt; filtering, drying, and obtaining the product with 20-70% salt, 1-20% auxiliary agent and 20-70% filler. This product has higher water solubility than dichloroquinoline acid benefit to plant absorption, hard to produce local drug harm during the application, and convenient to mix with other herbicide for larger weed spectrum.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

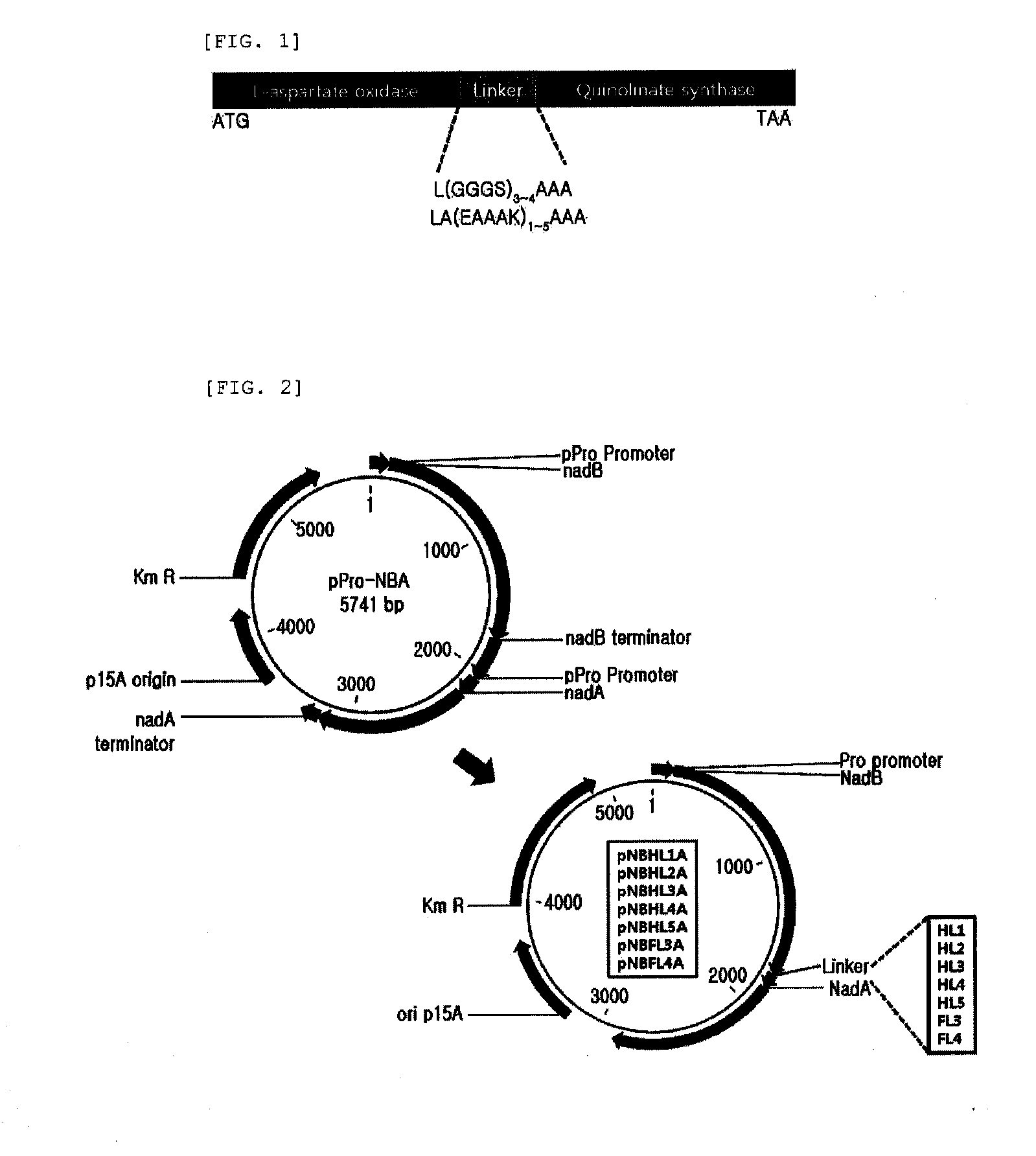

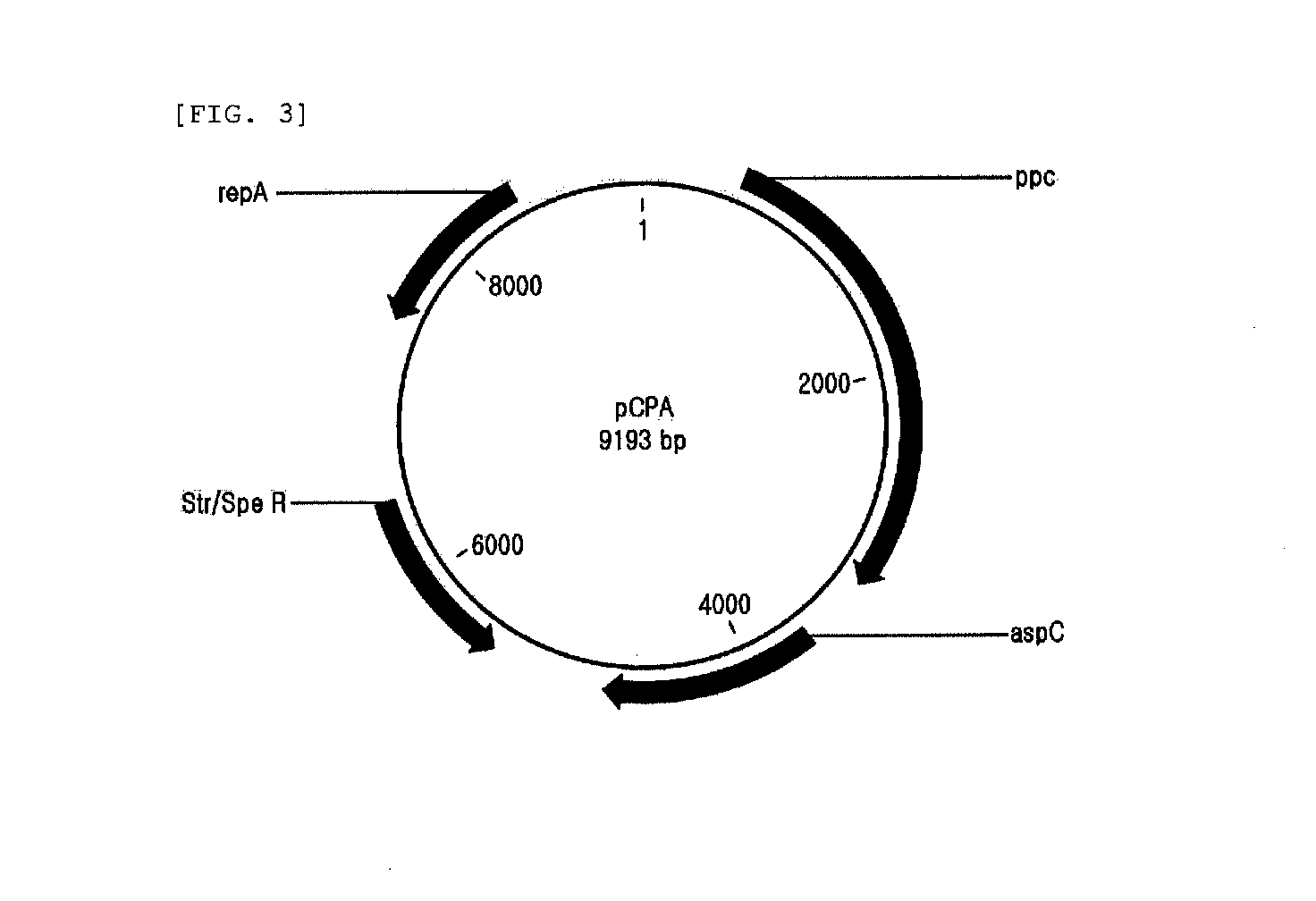

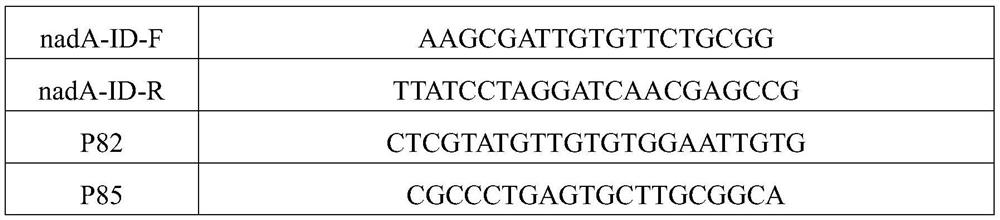

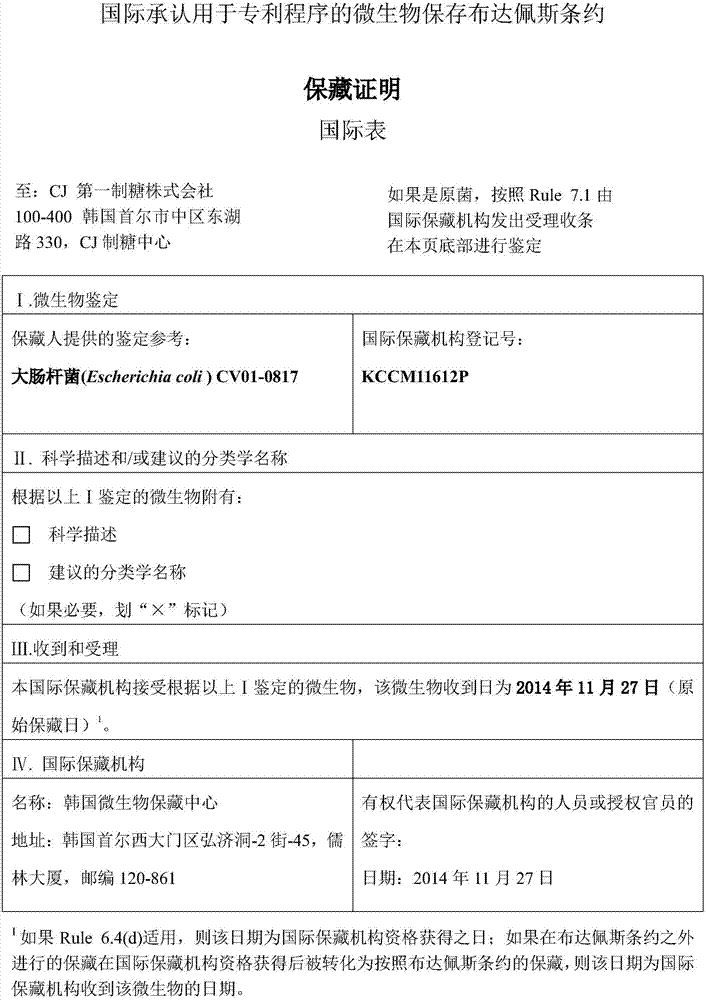

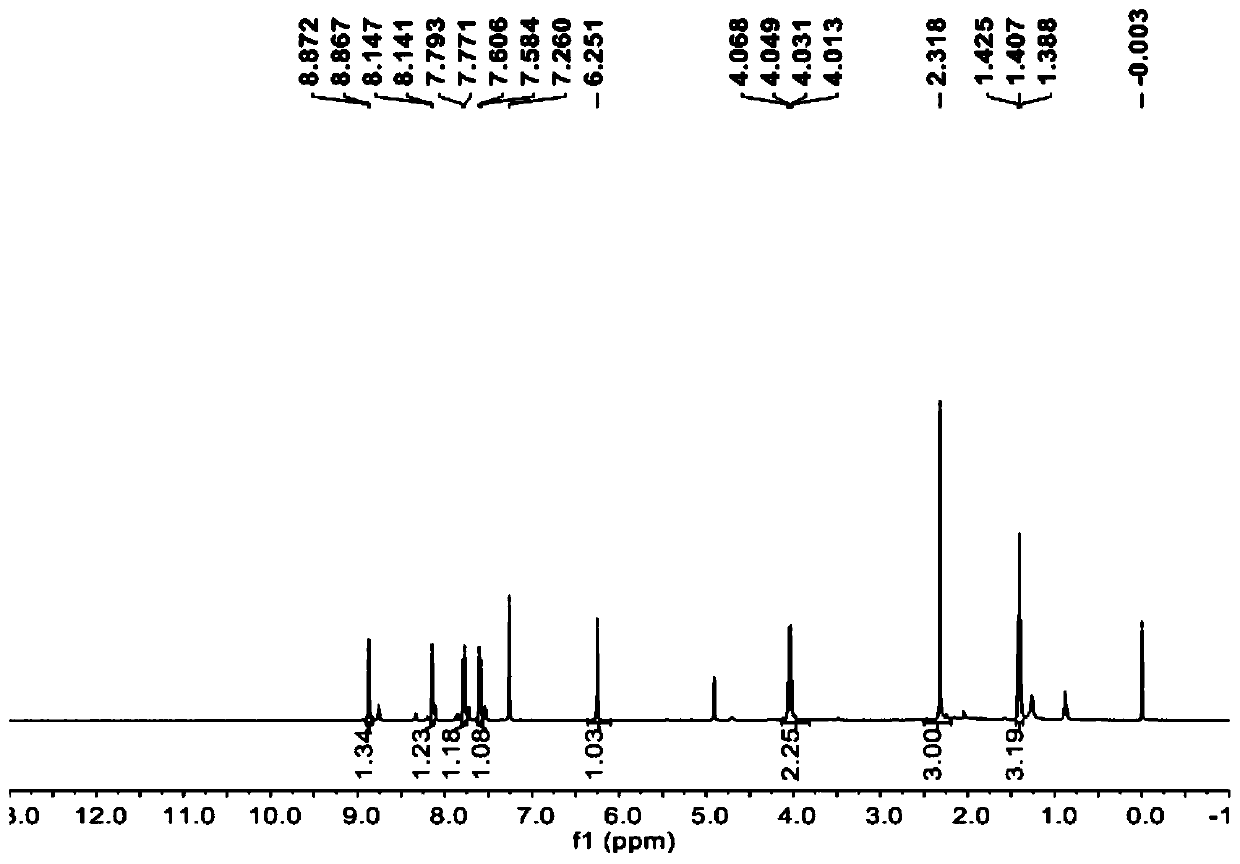

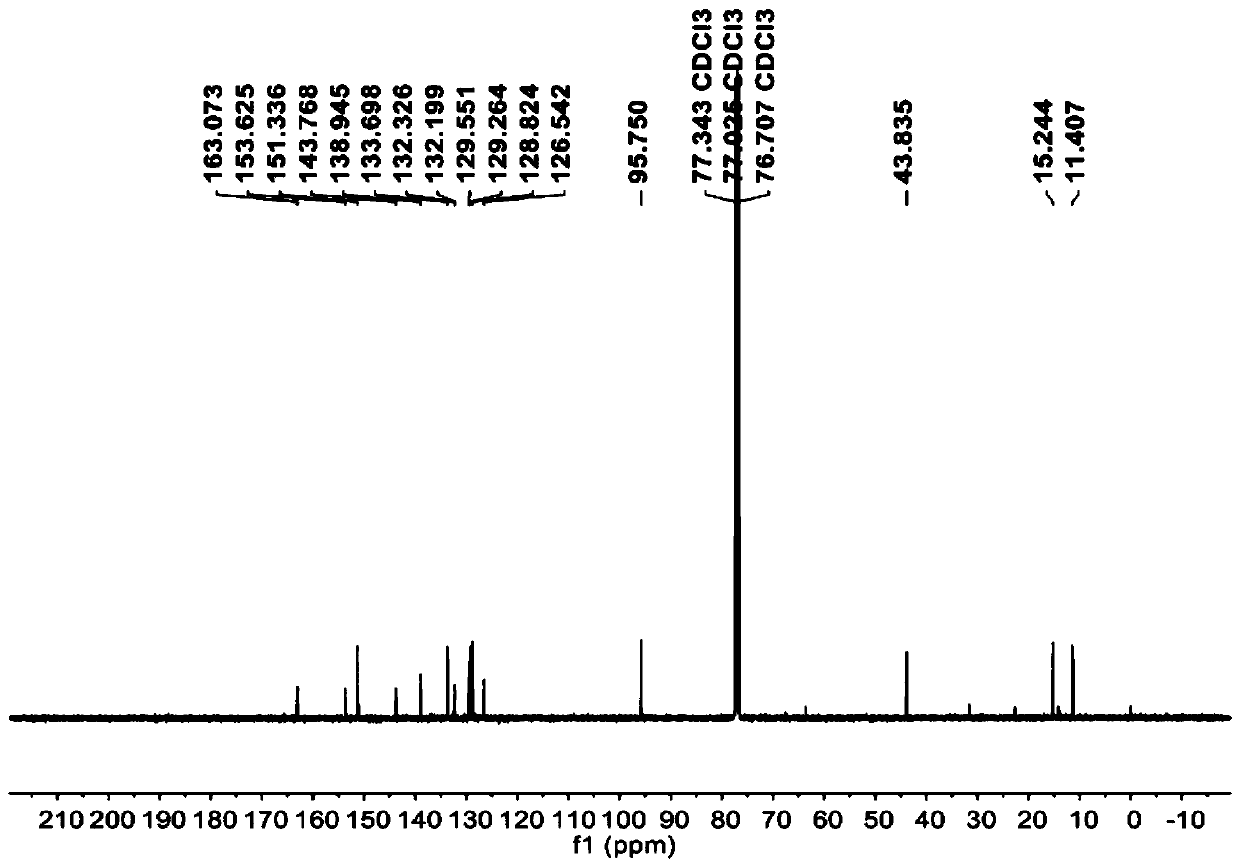

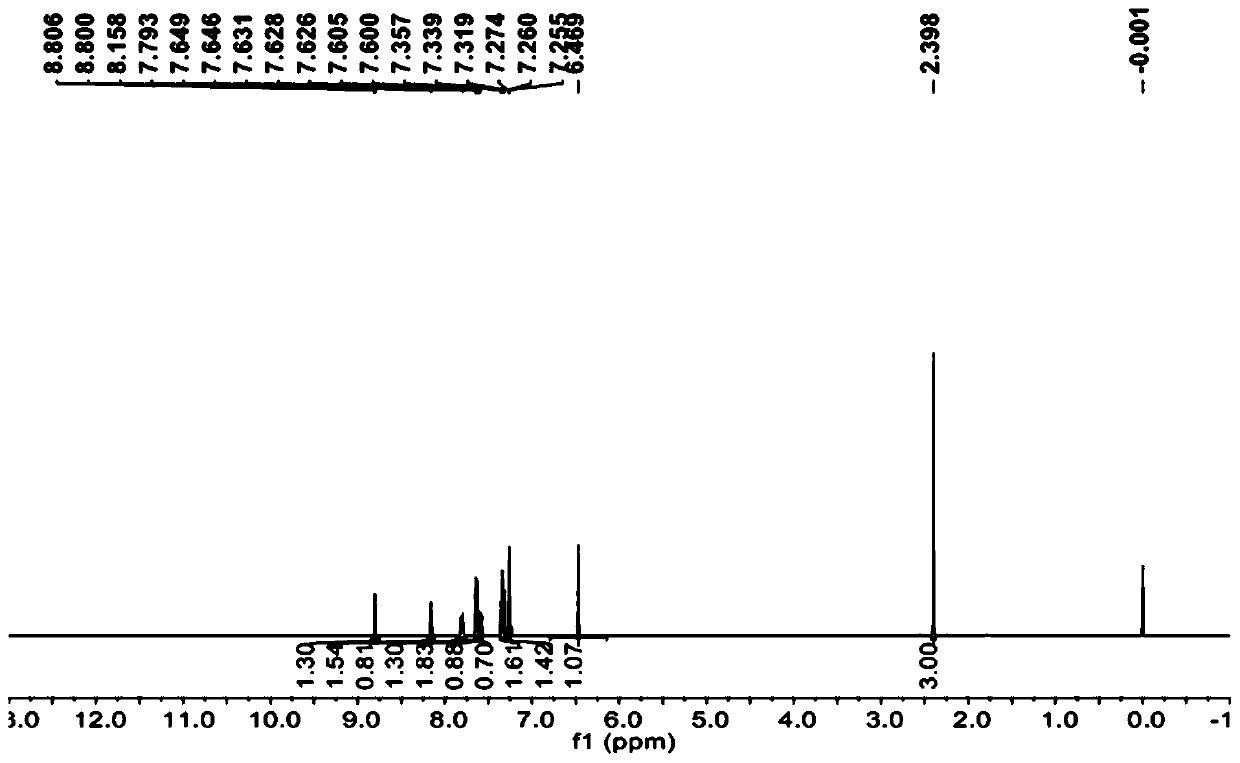

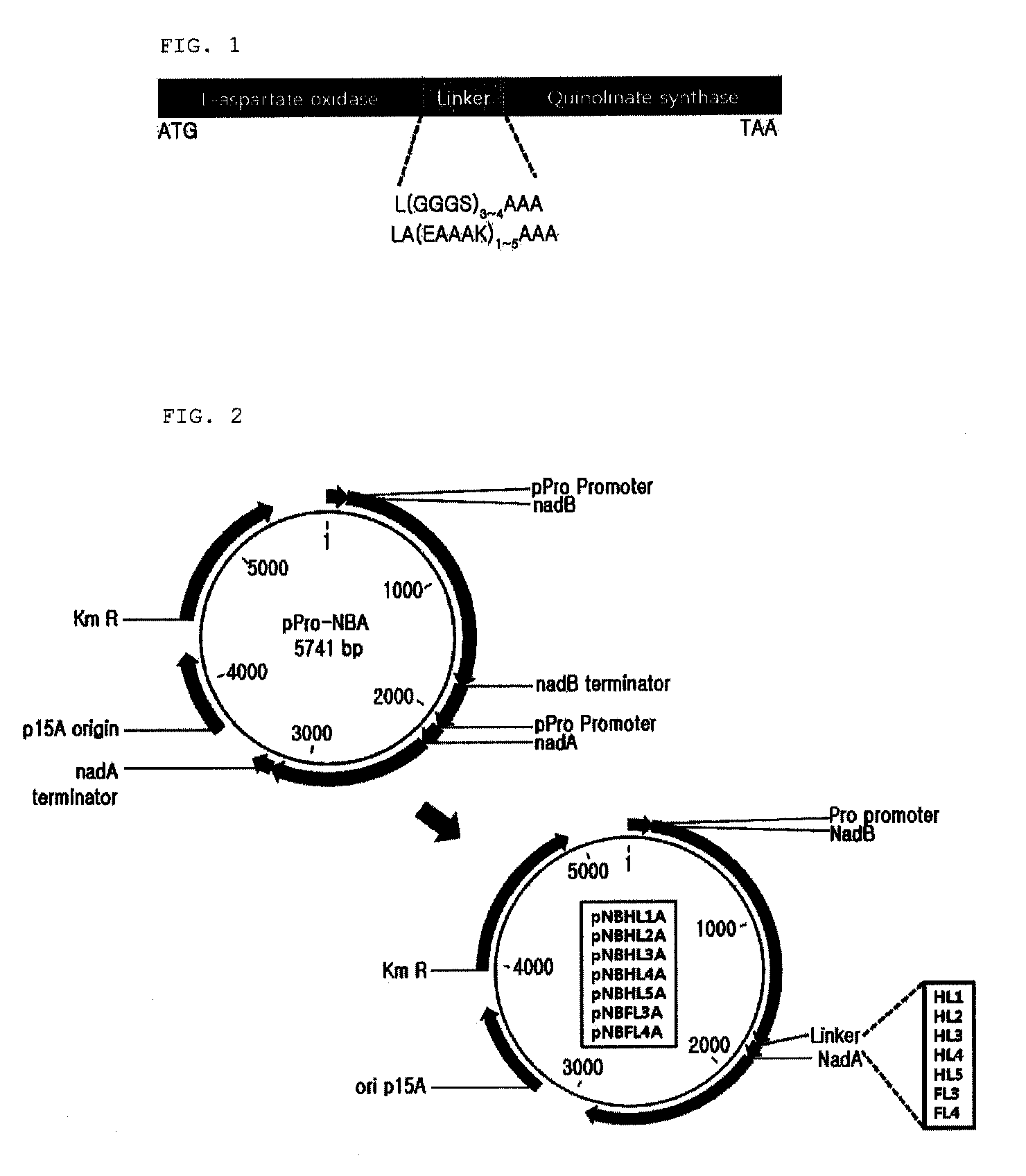

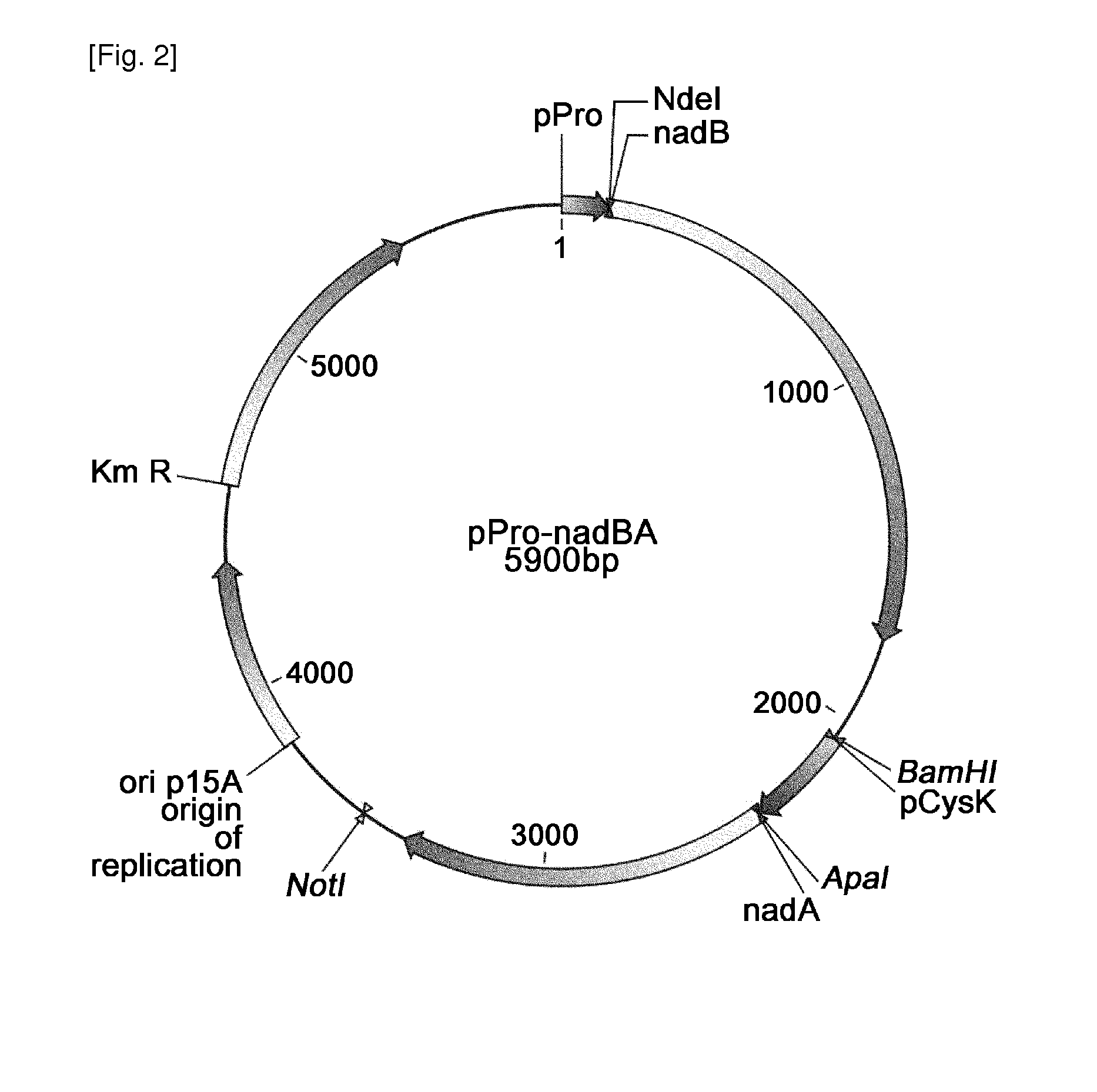

Recombinant microorganism producing quinolinic acid and a method for producing quinolinic acid using the same

ActiveUS20150037850A1Minimizing reactionImprove productivityValve arrangementsBacteriaMicroorganismQuinolinic acid

The present invention relates to a quinolinic acid-producing recombinant microorganism expressing a fusion protein of L-aspartate oxidase and quinolinate synthase linked via a linker, and a method for producing quinolinic acid using the same.

Owner:CJ CHEILJEDANG CORP

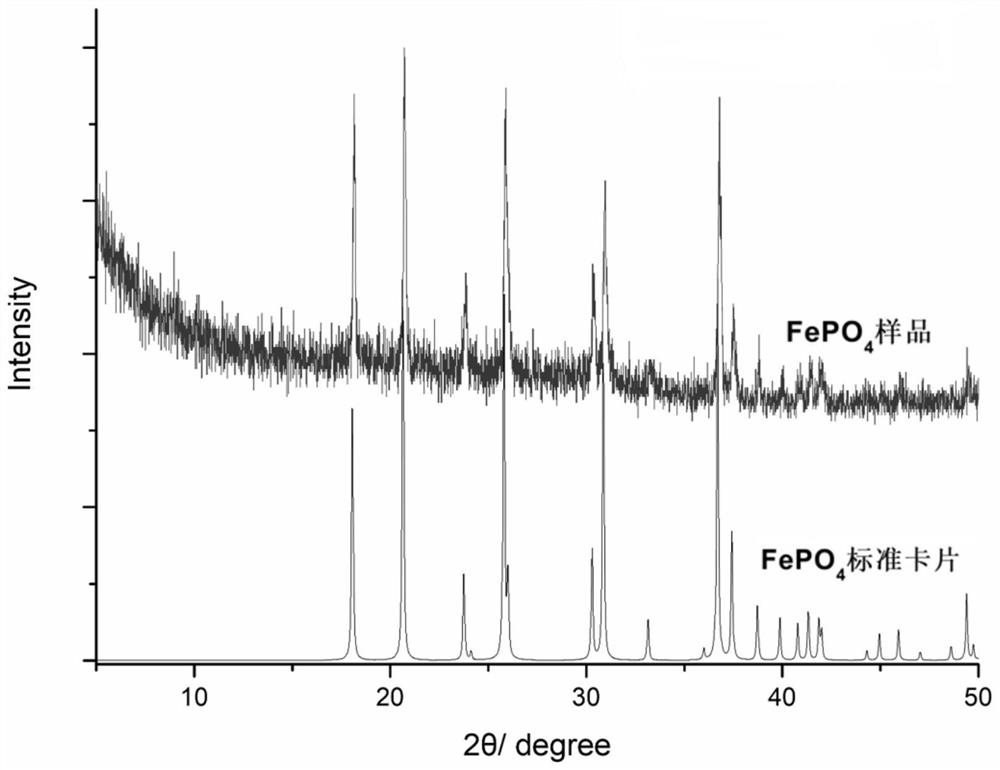

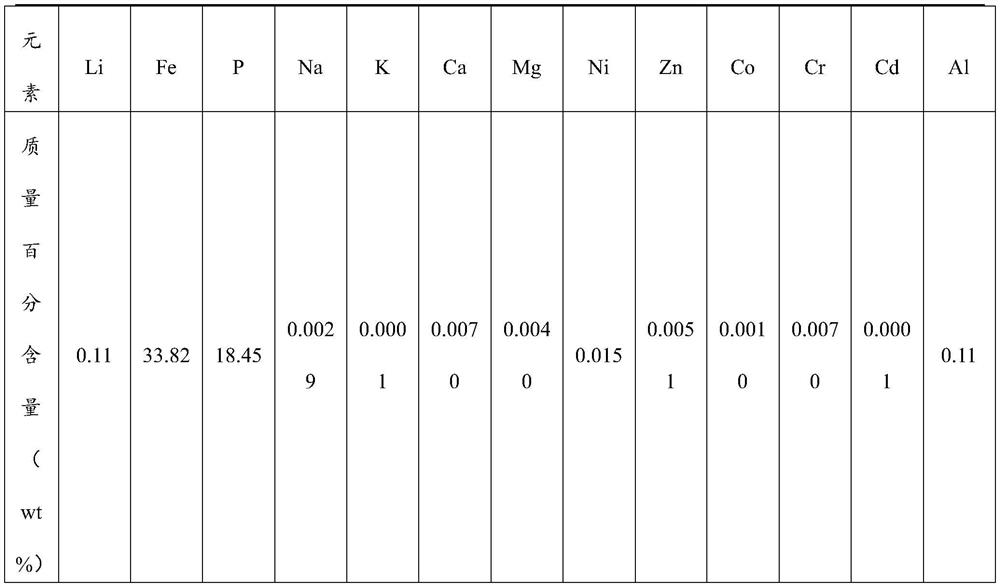

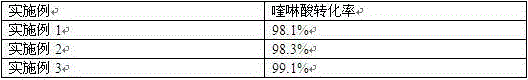

Method for removing aluminum from ferrophosphorus slag after lithium extraction of waste lithium iron phosphate and preparation method of battery-grade iron phosphate

ActiveCN113880063AAmplify the difference in solubilityEfficient removalPhosphorus compoundsBattery recyclingQuinolinePhosphoric acid

The invention relates to a method for removing aluminum from ferrophosphorus slag after lithium extraction of waste lithium iron phosphate and a preparation method of battery-grade iron phosphate. The method for removing aluminum comprises the following steps: mixing ferrophosphorus slag obtained after lithium extraction of waste lithium iron phosphate, elemental iron, acid and water, and carrying out an acid leaching reaction to prepare slurry A; mixing the slurry A with an aluminum removal agent, carrying out an aluminum removal reaction, and then removing solids to obtain aluminum-removed ferrophosphorus liquid; the aluminum removal agent is selected from at least one of picolinic acid compounds, quinolinic acid compounds and isoquinoline-3-formic acid compounds. The organic aluminum removal agent can be complexed with iron and aluminum to form metal organic complex precipitates with different solubility, the solubility difference of iron and aluminum can be effectively amplified, and preferential precipitation of aluminum is ensured so that aluminum impurities are effectively removed, the product purity of iron phosphate is improved, and the high yield of iron phosphate can be ensured. In addition, the method for removing aluminum is easy to operate, low in equipment investment, environmentally friendly, controllable in quality and easy to industrialize.

Owner:GUANGDONG GUANGHUA SCI TECH +1

Preparation method of quinolinic acid

The invention discloses a preparation method of quinolinic acid. The preparation method uses quinoline as the raw material, and comprises the following steps of oxidizing, alkaline hydrolysis and acidifying. The preparation method has the advantages that the preparation is simple and quick, and the sewage zero-drainage is realized in the production process; compared with the quinolinic acid produced by the electrolysis method, the production efficiency is increased by 3 to 4 times; compared with common sodium chloride oxidizing method, the cost is low; the auxiliary material for production can be repeatedly recycled; the filtrate after separation of quinolinic acid can be repeatedly added with acid to separate, the recycling rate can reach 90%, the resource is greatly saved, and the market prospect is broad.

Owner:FOSHAN SHANGHAO DOOR & WINDOW CO LTD

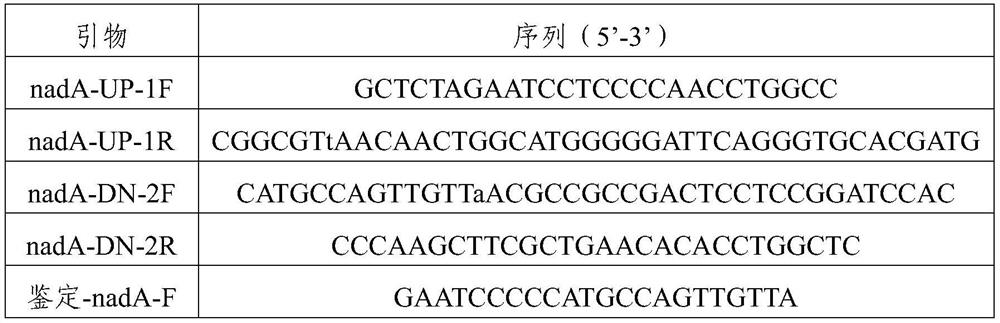

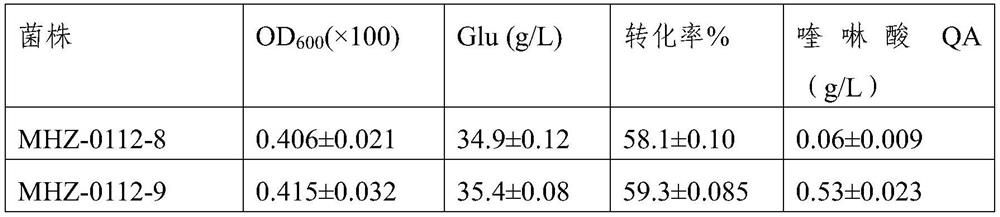

Quinolinic acid synthase mutant and application thereof

ActiveCN113512540AHigh catalytic activityImprove synthesis abilityBacteriaTransferasesMetaboliteBacilli

The invention relates to the technical field of microorganisms, and concretely relates to a quinolinic acid synthase mutant and application thereof. The provided quinolinic acid synthase mutant takes an amino acid sequence of corynebacterium glutamicum wild type quinolinic acid synthase as a reference sequence, and the quinolinic acid synthase mutant contains mutation in which aspartic acid at the 312th site is substituted by asparagine. The quinolinic acid synthase mutant has significantly enhanced catalytic activity of quinolinic acid synthase, can enhance the synthesis ability of microbial cells NADH and NADPH, improves the reducing power level of the microbial cells, and further can significantly promote accumulation of quinolinic acid and metabolites synthesized depending on the reducing power. According to the present invention, the reducing power level of the recombinant microorganism expressing the quinolinic acid synthase mutant is significantly improved, such that the yield and the conversion rate of the reducing power dependent metabolites such as quinolinic acid, glutamic acid, lysine and the like can be easily improved;.

Owner:MEIHUA BIOTECH LANGFANG CO LTD

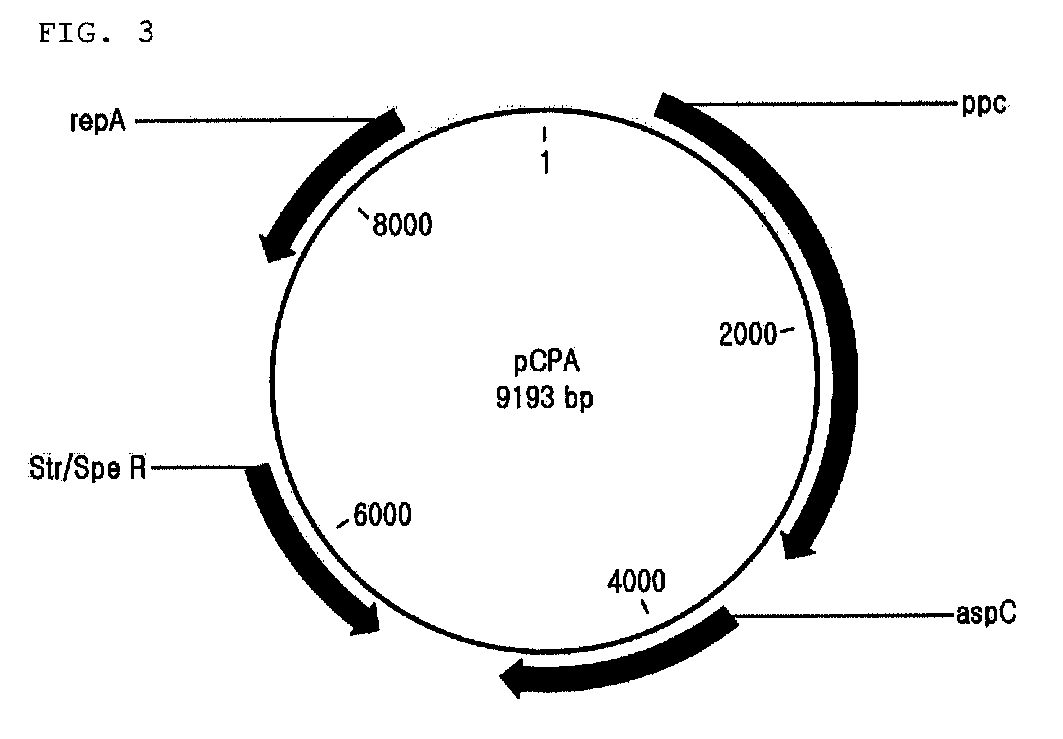

Microorganism capable of producing quinolinic acid, and method for producing quinolinic acid utilizing the microorganism

The present invention relates to a microorganism capable of producing quinolinic acid, and to a method for producing same utilizing the microorganism.

Owner:CJ CHEILJEDANG CORP

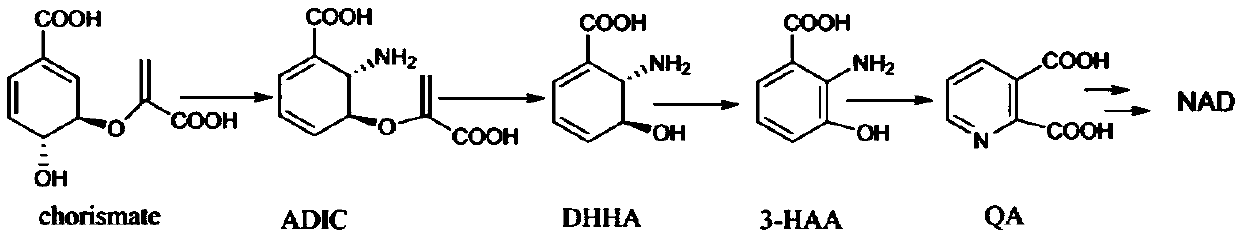

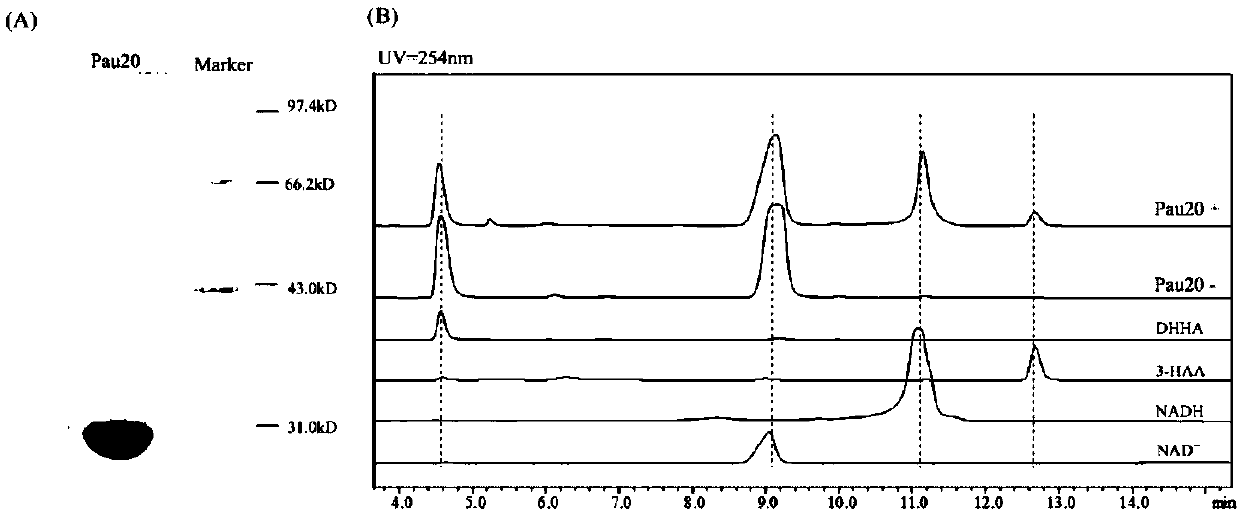

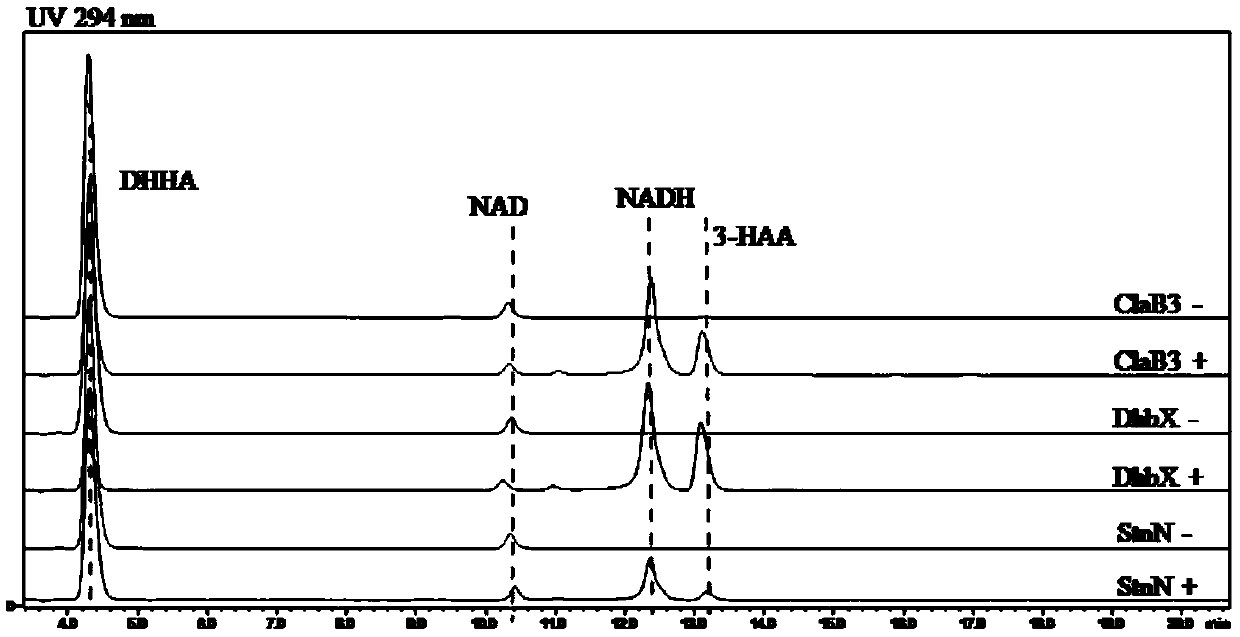

Biosynthesis method of nicotinamide adenine dinucleotide compound

ActiveCN110607335ADecouplingIncrease productionMicroorganism based processesFermentationBenzoic acidNucleotide

The invention discloses a biosynthesis method of a nicotinamide adenine dinucleotide compound. A synthesis path provided by the invention takes chorismic acid as a starting point, under the action ofPhzD protein, a transamination rearrangement reaction is carried out to generate amino deoxy isobranched acid, pyruvic acid is removed from amino deoxy isobranched acid under the catalysis of the PhzEprotein to generate 2,3-dihydro-3-hydroxyanthranilicacid, 2,3-dihydro-3- hydroxyanthranilicacid is catalyzed to generate 3-hydroxyanthranilicacid by adopting a specific enzyme, quinolinic acid is generated from 3-hydroxyanthranilicacid through an oxidation ring-opening rearrangement reaction under the action of nabC protein, and then enters an NAD remediation way to finish NAD synthesis. According to the present invention, the coupling between the NAD synthesis and the tryptophan or aspartic acid synthesis is removed, and the chorismic acid widely exists in various life forms, and has less influence on other life essential metabolic pathways.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

Compositions that protect cells from oxidative and mitochondrial stress

There are described compositions comprising an effective amount of a combination of two or more components, said components selected from acacetin, ACT1 peptide, alpha-lipolic acid, alprostadil, anisomycin, apigenin, ascorbic acid, astragalus, berberine, beta-lapachone, beta-hydroxy-beta-methyl-butyrate, bacopa monnieri, catechin, catechol, chamomile, chrysin, coumestrol, curcumin, dinitrophenol,dinoprost, ellagic acid, (-)-epigallocatechin gallate, green tea extract, fisetin, genistein, ginsenoside RE, glabridin, 18-alfa-glycyrrhetinic acid, 18-beta-glycyrrhetinic acid, glycyrrhizin, hydroquinone, isoquercitrin (EMIQ), kaempferol, kuromanin, leucine, lithium, luteolin, luteolin, luteolinidin, melatonin, menadione, 1-methylnicotinamide (MNA), methyl salicylate, myricetin, nadide, niacin (vitamin B3), nicotinamide (NAM), nicotinamide mononucleotide (NMN), nicotinamide riboside (NR), nicotinic acid adenine dinucleotide (Na AD), nicotinic acid mononucleotide (Na MN), parsley (petroselinium crispum), phenylephrine, pokeweed mitogen, 15-Delta prostaglandin J2, puromycin, quercetin, quinolinic acid, retinoic acid, trichostatin A, troxrutin, rutin, tryptophan, vitamin D3, withaferin A, wortmannin and zinc (including salts thereof).

Owner:努其杜有限公司

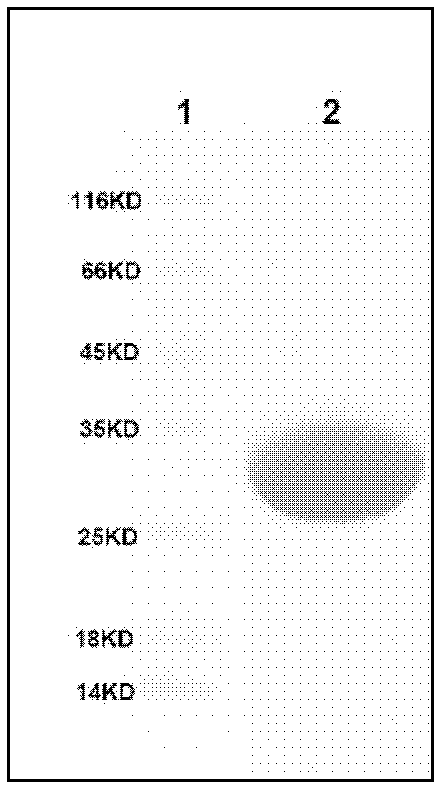

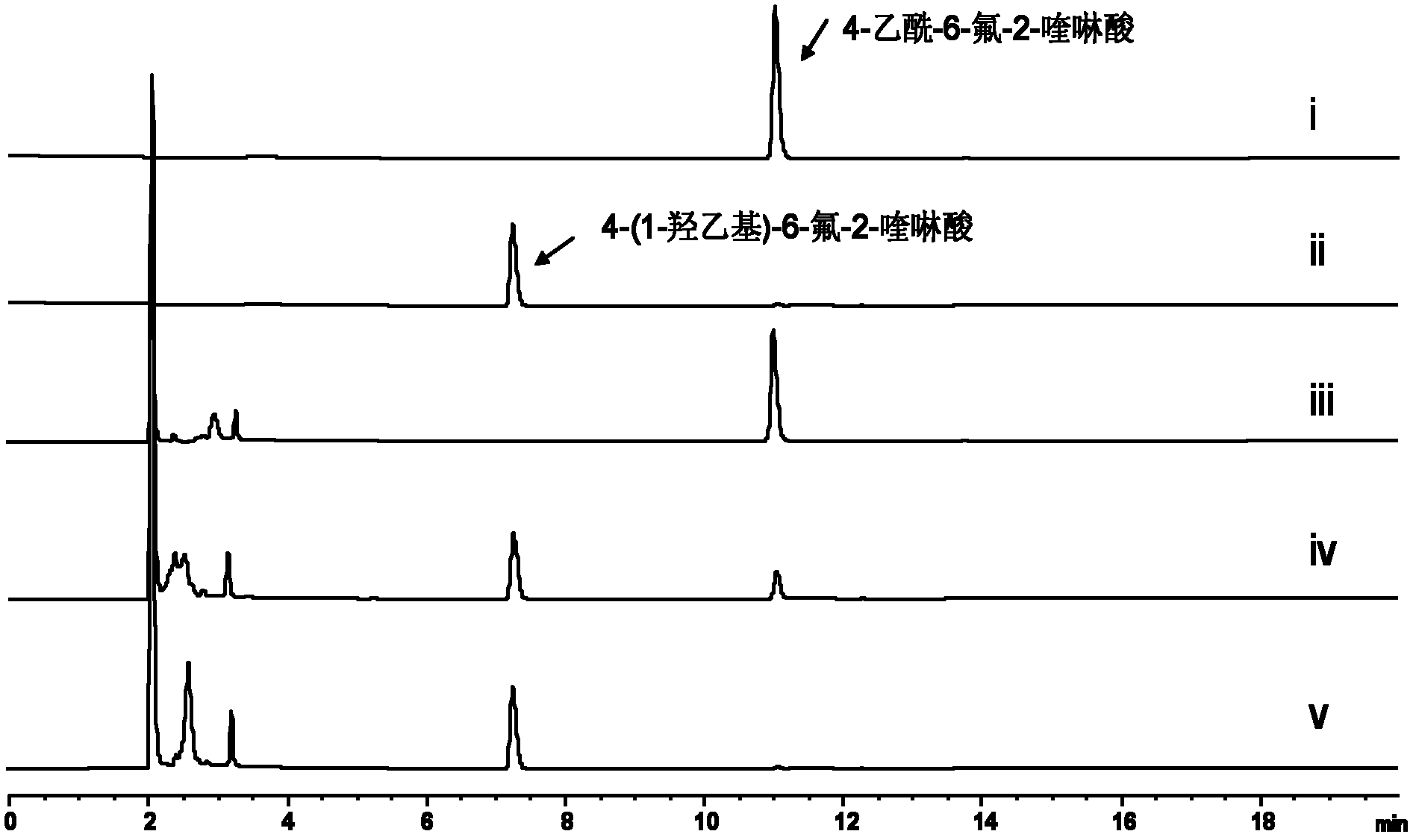

Functions and application of short chain dehydrogenase TsrU

ActiveCN103205470AImprove toleranceHigh catalytic efficiencyOxidoreductasesFermentationSide chainStructural analog

The invention discloses functions and application of a short chain dehydrogenase TsrU. Specifically, the short chain dehydrogenase TsrU can catalyze the carbonyl chiral single reduction reaction of 4-acetyl-2-quinolinic acid or its analogues, can be used for in-vitro efficient production of 4-(1-hydroxymethyl)-2-quinolinic acid or its structural analogues, and in a side chain reaction of thiostrepton biosynthesis, the enzyme has a high tolerance to a substrate, so that the short chain dehydrogenase TsrU can be widely applied to chiral reduction reactions of other similar substrates.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

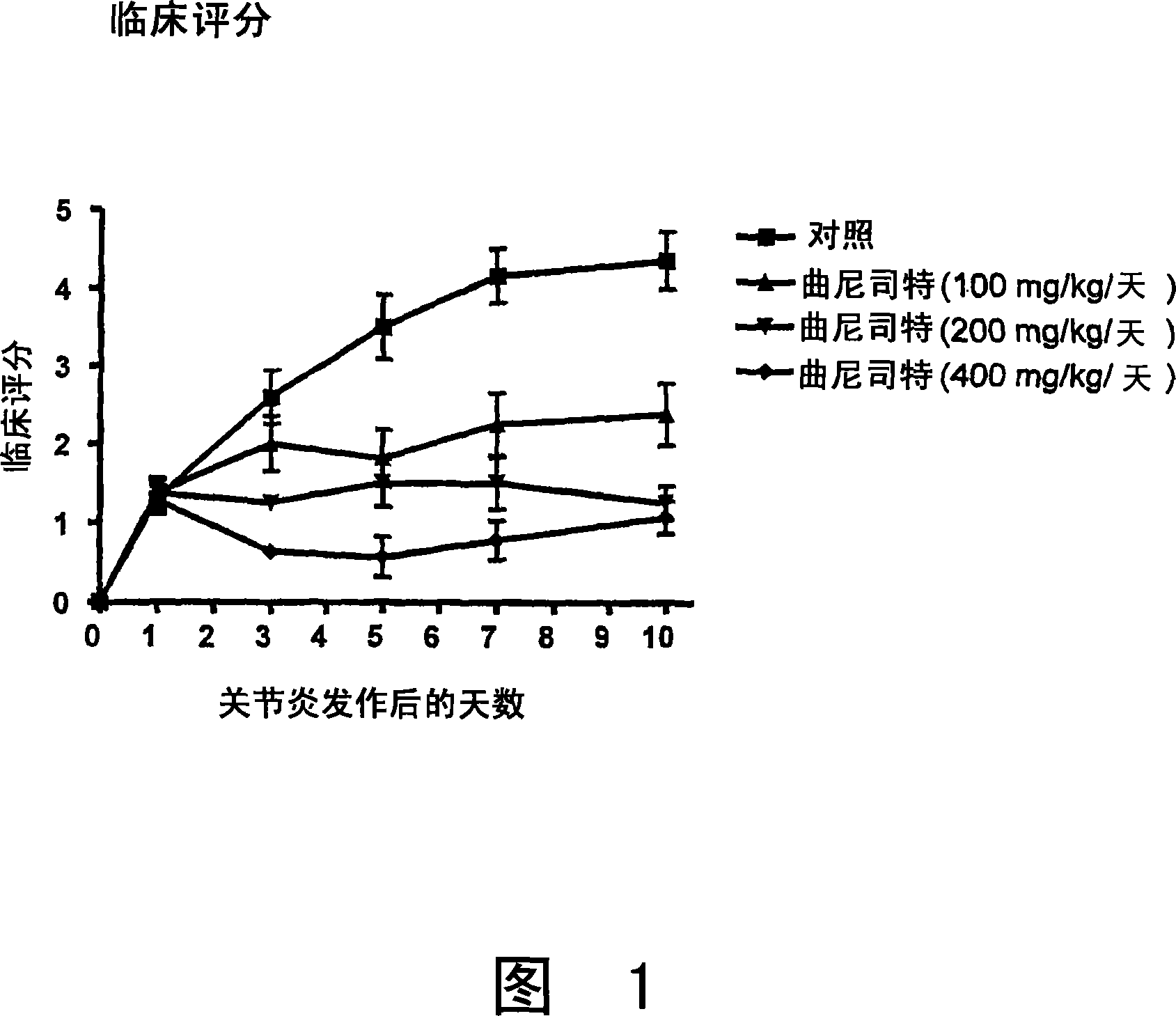

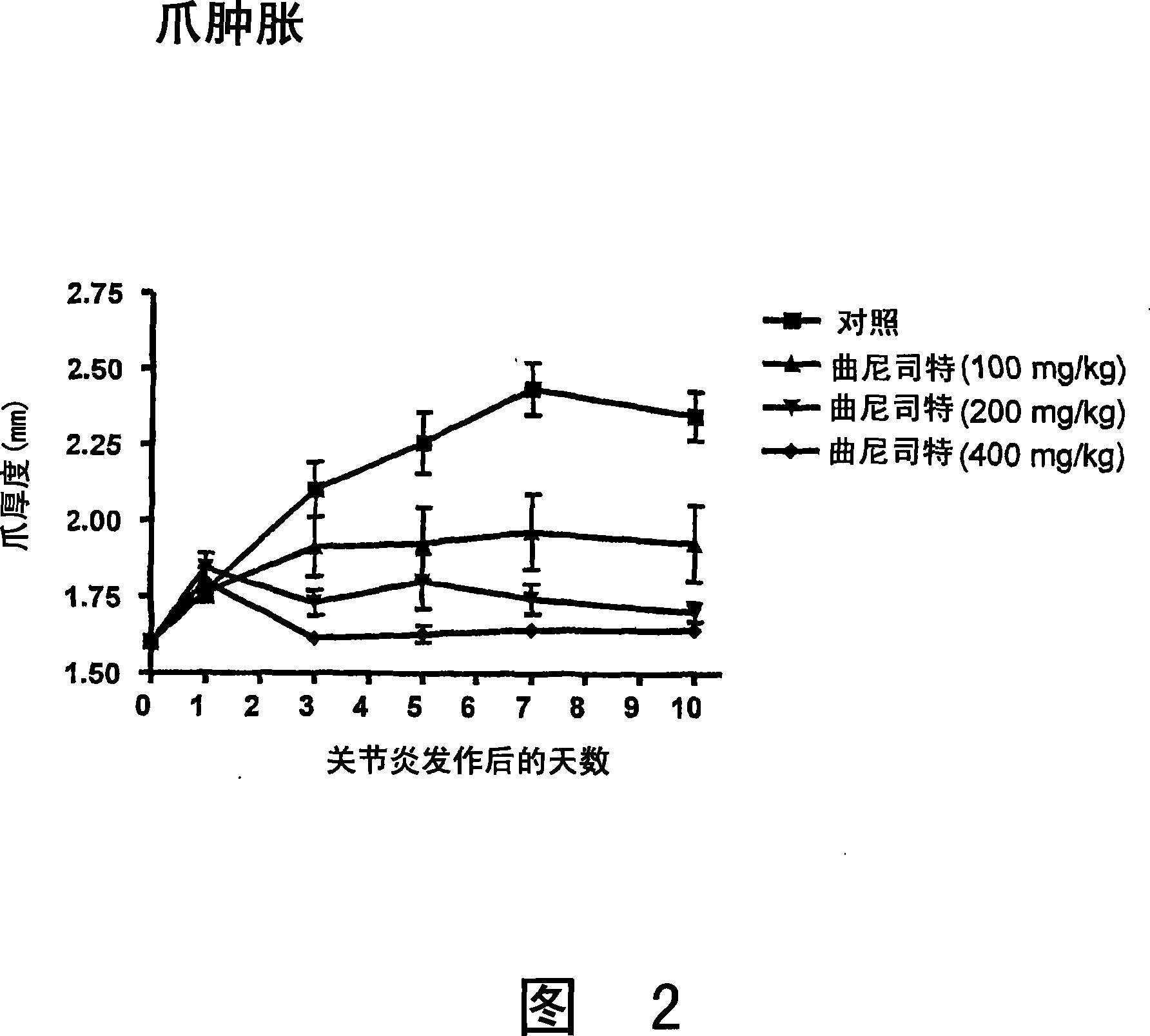

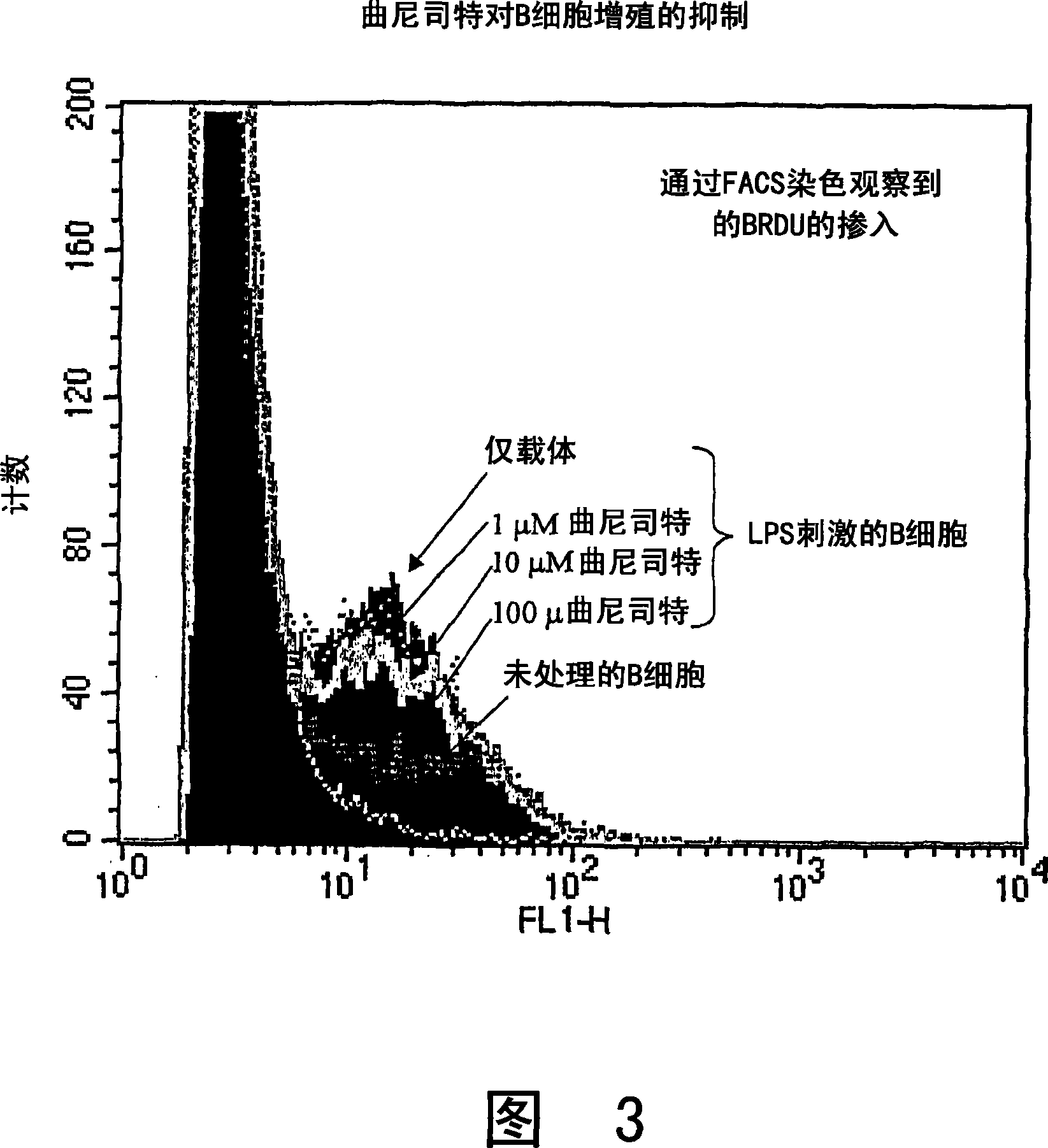

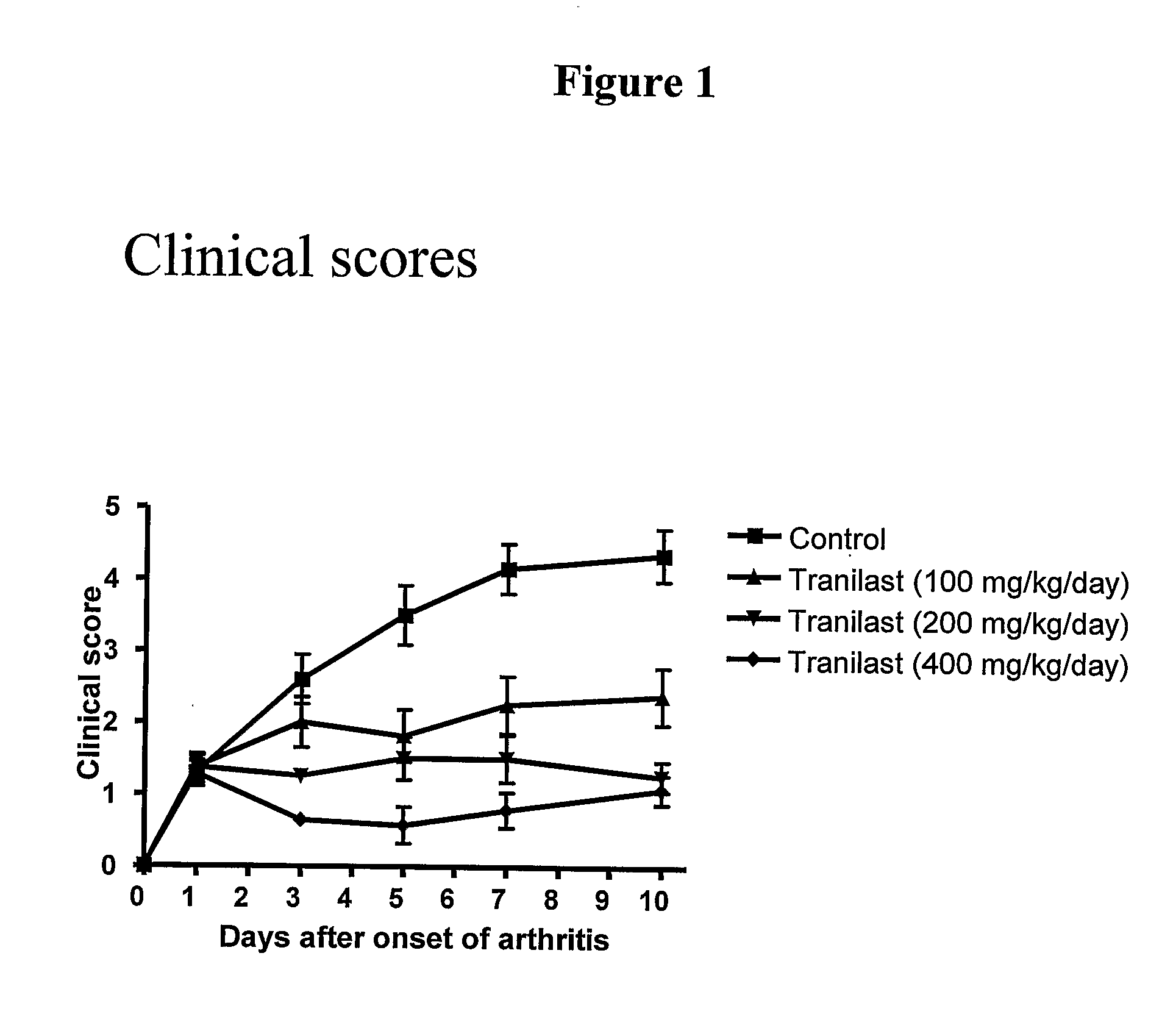

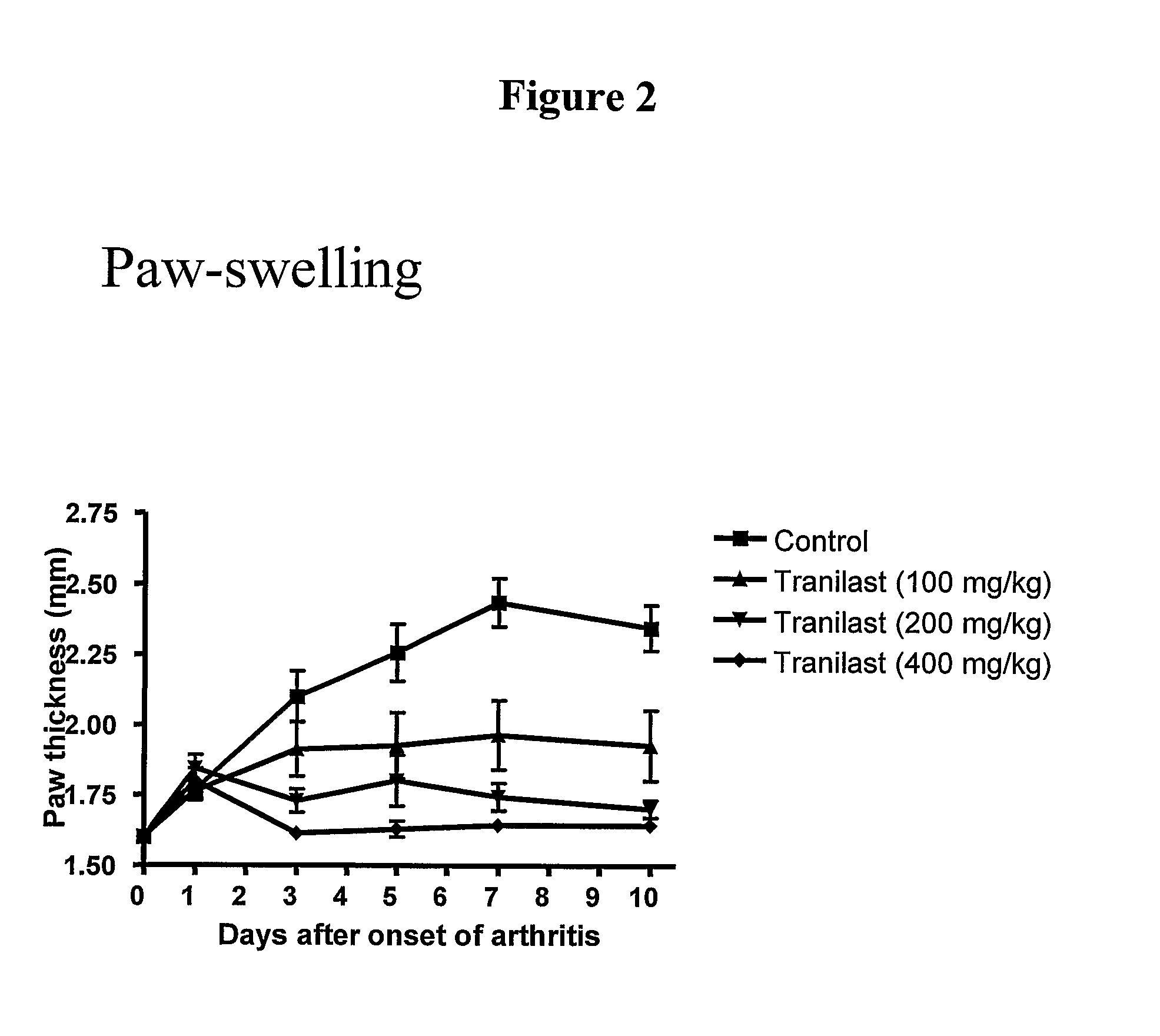

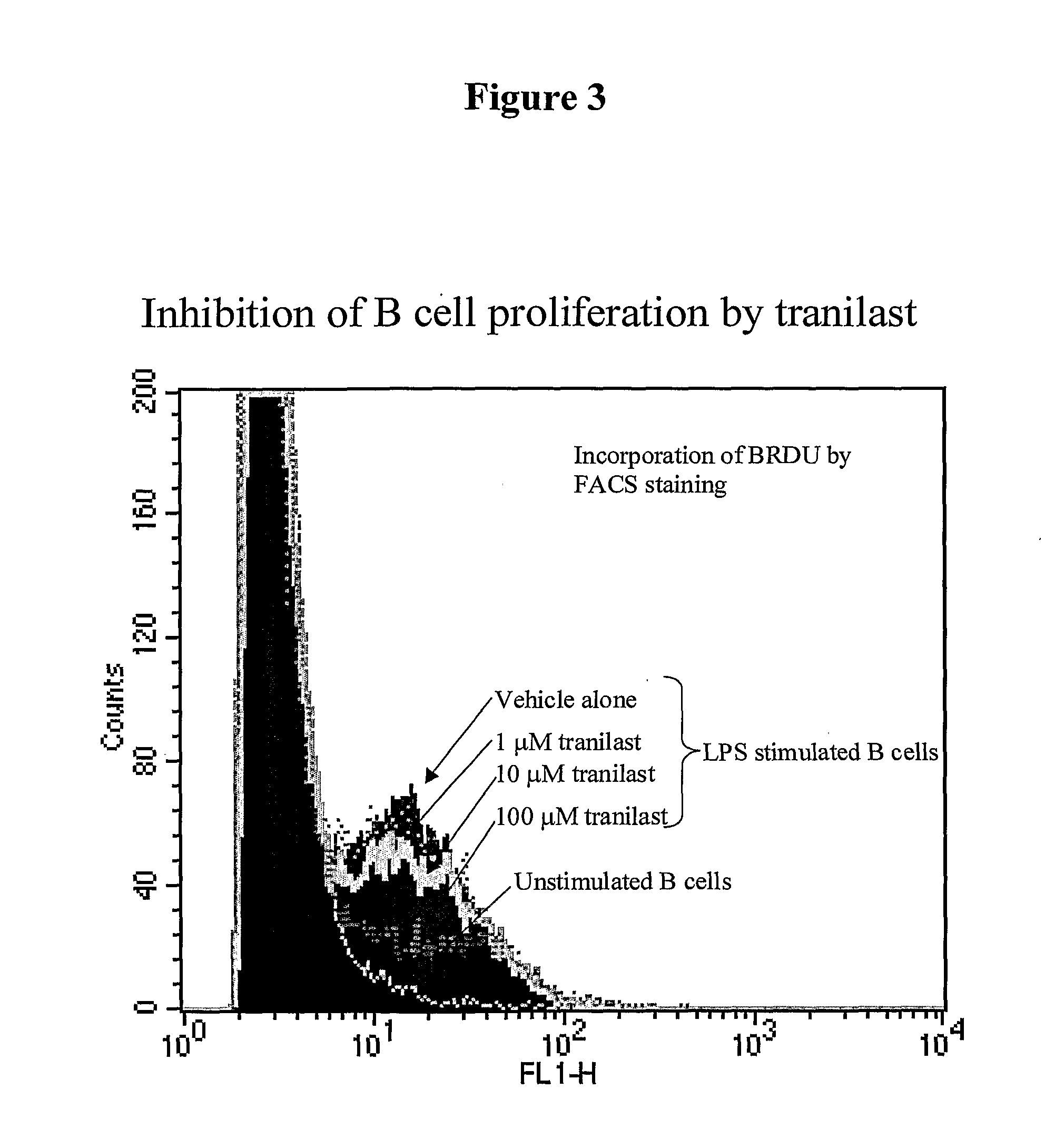

Method of modulating b cell functioning

InactiveUS20100041756A1Cell from functioningAntibacterial agentsBiocideMetaboliteAutoimmune condition

The present invention relates generally to a method of modulating cellular functioning. More particularly, the present invention relates to a method of modulating B cell functioning, for example B cell proliferation, utilising an IDO-mediated tryptophan metabolite as herein defined (particular examples of such IDO-mediated tryptophan metabolites include 3-hydroxykynurenic acid, 3-hydroxyanthranilic acid, picolinic acid, quinolinic acid and tranilast). The method of the present invention is useful, inter alia, in the treatment and / or prophylaxis of conditions characterised by aberrant, unwanted or otherwise inappropriate B cell functioning such as antibody production, autoimmune conditions and B cell proliferation and neoplasias. In a related aspect, the present invention is directed to a method of therapeutically and / or prophylactically treating rheumatoid arthritis via the administration of the above-mentioned compounds.

Owner:NUON THERAPEUTICS PTY LTD

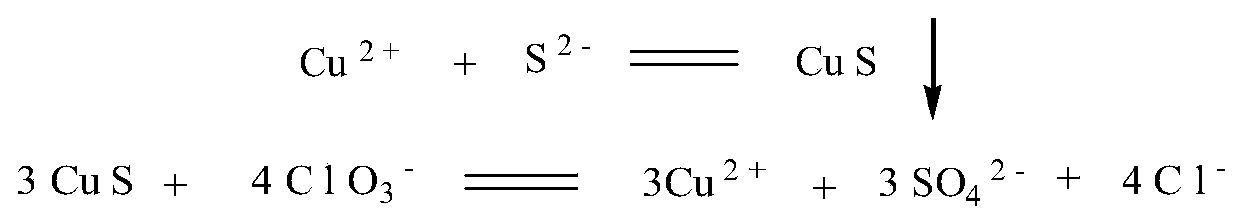

Method for purifying and regenerating copper element in quinolinic acid production wastewater to prepare quinolinic acid copper salt

The invention discloses a method for purifying and regenerating a copper element in quinolinic acid production wastewater to prepare quinolinic acid copper salt and belongs to the technical field of quinolinic acid production wastewater treatment. The method comprises the following steps: (1) regulating the pH value of wastewater by using alkali, then slowly adding sodium sulfide while stirring, detecting the value by using a pH reagent, and carrying out filter pressing to collect black CuS precipitate; (2) adding the recycled CuS and water into an oxidation reaction kettle, and then executingstirring and adding a sodium chlorate water solution for oxidation reaction; (3) adding copper sulfate pentahydrate, recycled copper hydroxide, quinoline and sulfuric acid into the oxidation reactionkettle, dropwise adding the sodium chlorate water solution, heating the reaction kettle, carrying out heat preservation reaction, then executing cooling after heat preservation, executing crystallizing to separate out solid, and executing filtration to obtain a quinolinic acid copper salt. According to the method, the copper in the wastewater is reduced to below 2ppm, the utilization rate of thecopper is improved, the waste can also be changed into wealth, and the discharge problem of high-copper ion wastewater is solved.

Owner:FUJIAN TAIFENG PHARMA & CHEM CO LTD

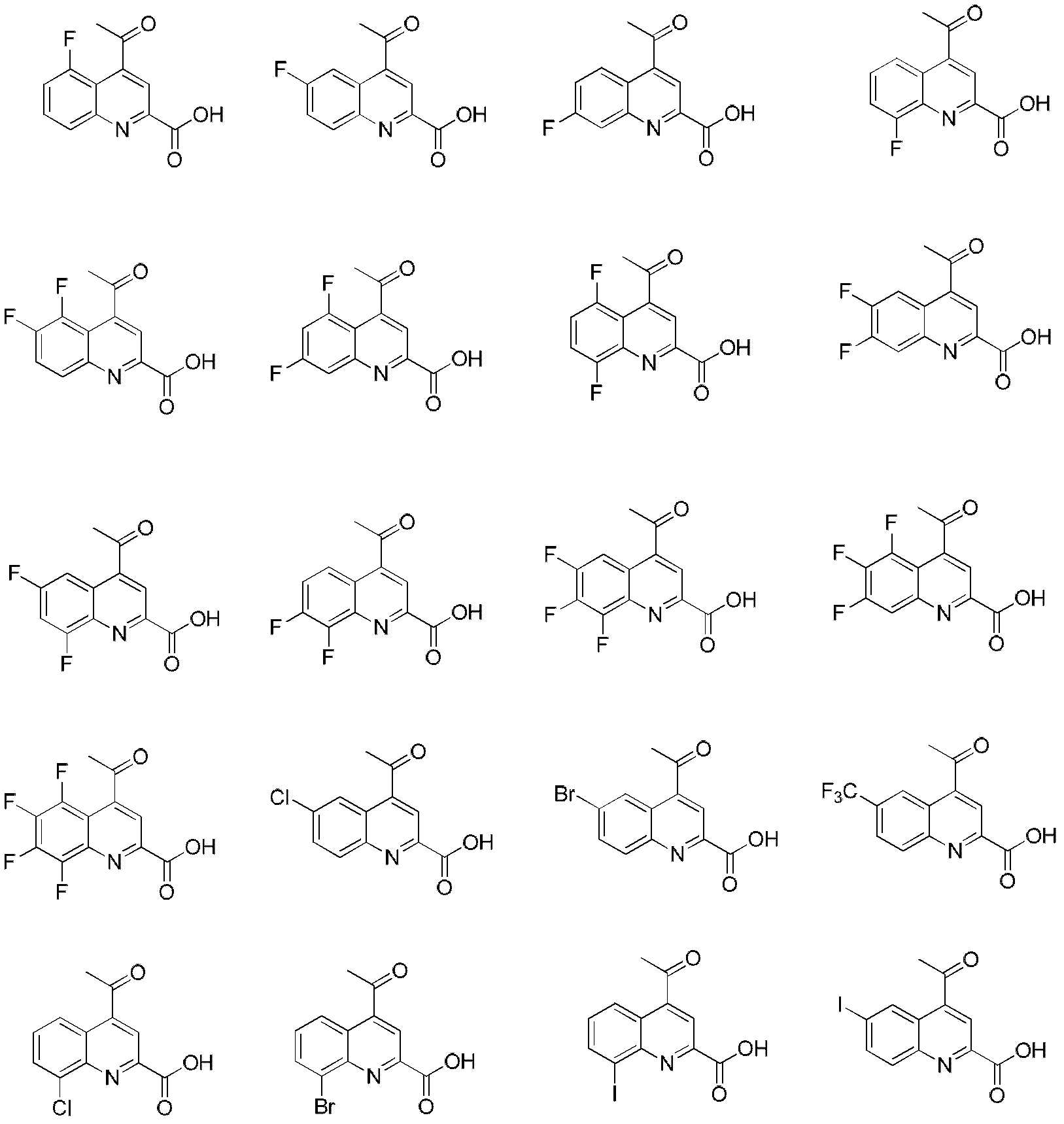

Quinoline compound and synthetic method and application thereof

ActiveCN110143946AThe synthesis method is simpleEasy to achieve mass productionBiocideOrganic chemistryQuinolineCombinatorial chemistry

The invention discloses a quinoline compound and a synthetic method and application thereof. The structure is as follows: on the basis of a traditional quinolinic acid structure, a pyrazol structure is introduced to form a new quinolinic acid derivative. The synthetic method of the quinoline compound in the invention is simple and feasible, and mass production is easy to implement. The quinoline compound of the invention has a good weed control effect and has a good effect on weeds having resistance.

Owner:HUNAN AGRI BIOTECH RES CENT

Recombinant microorganism producing quinolinic acid and method for producing quinolinic acid using same

The present invention relates to a recombinant microorganism producing quinolinic acid, more particularly, a microorganism producing quinolinic acid and having attenuated activity or eliminated activity of a protein having a sequence of SEQ ID NO: 1 and a method of producing quinolinic acid by using the recombinant microorganism.

Owner:CJ CHEILJEDANG CORP

Recombinant microorganism producing quinolinic acid and a method for producing quinolinic acid using the same

ActiveUS9534240B2Minimizing reactionImprove productivityValve arrangementsBacteriaMicroorganismQuinolinic acid

The present invention relates to a quinolinic acid-producing recombinant microorganism expressing a fusion protein of L-aspartate oxidase and quinolinate synthase linked via a linker, and a method for producing quinolinic acid using the same.

Owner:CJ CHEILJEDANG CORP

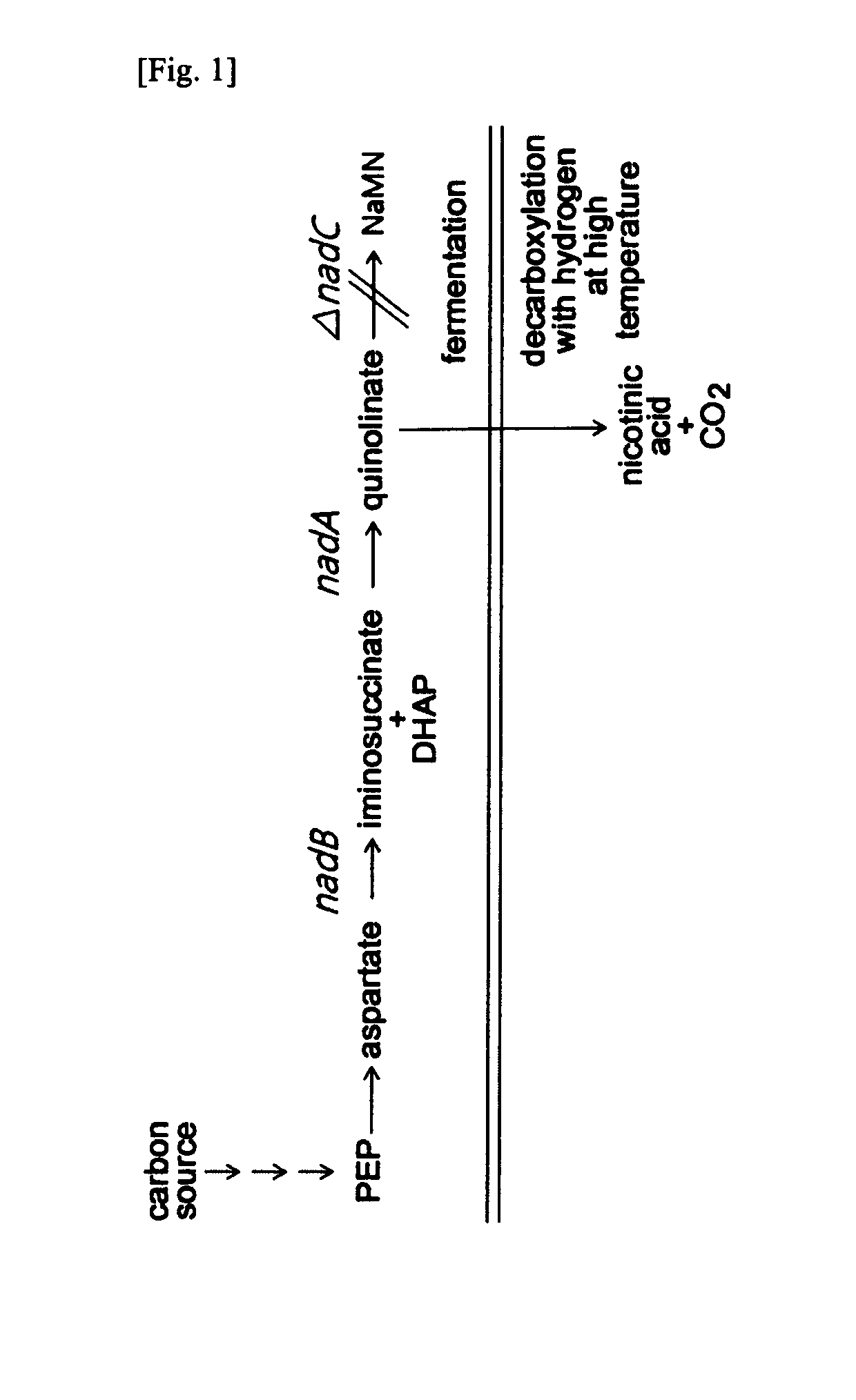

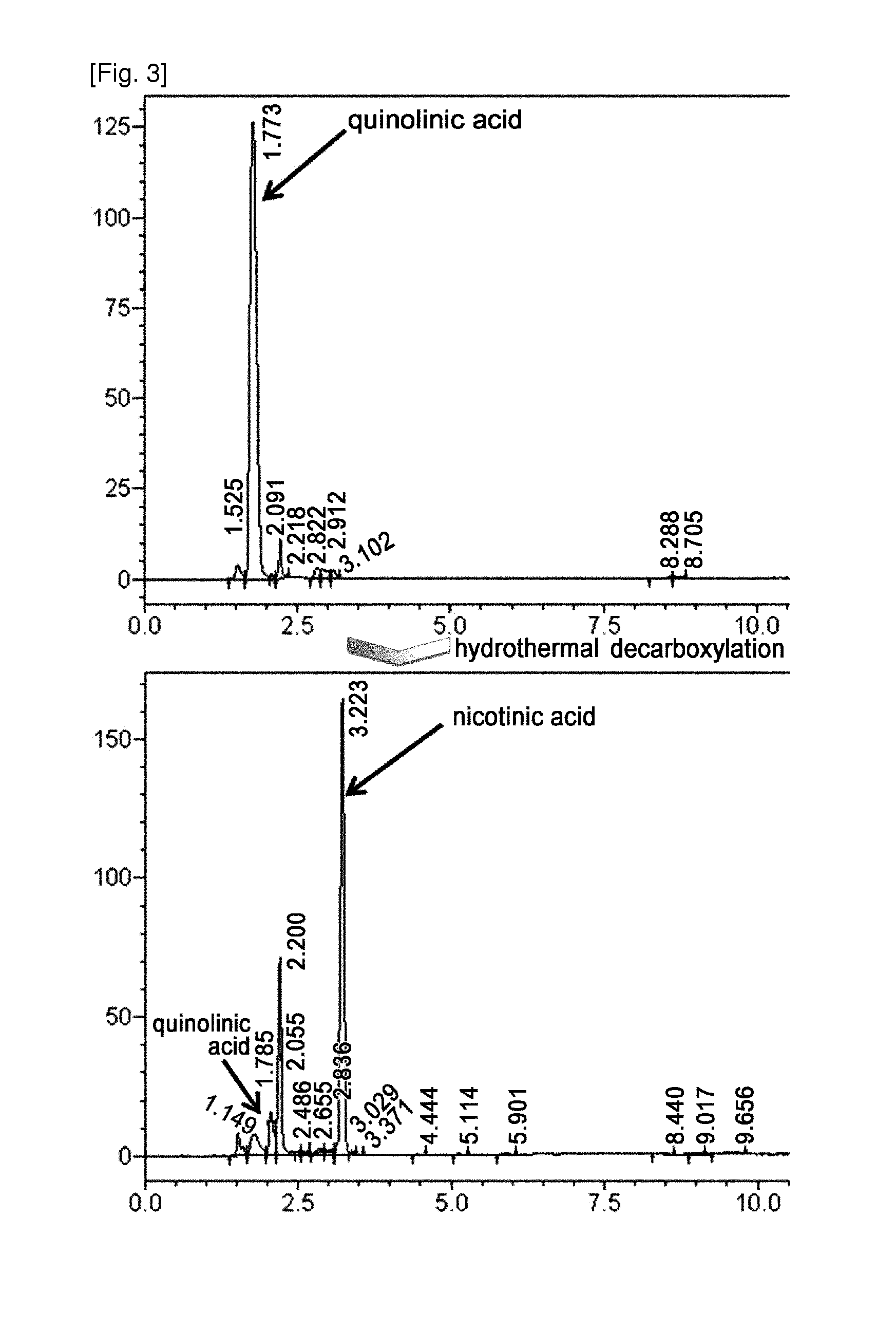

Method for the preparation of nicotinic acid

A method for the preparation of nicotinic acid, which includes the step of obtaining a culture solution containing quinolinic acid by incubating a microorganism having an ability to produce quinolinic acid, and the step of adding an acid to the culture solution and conducting a decarboxylation reaction.

Owner:CJ CHEILJEDANG CORP

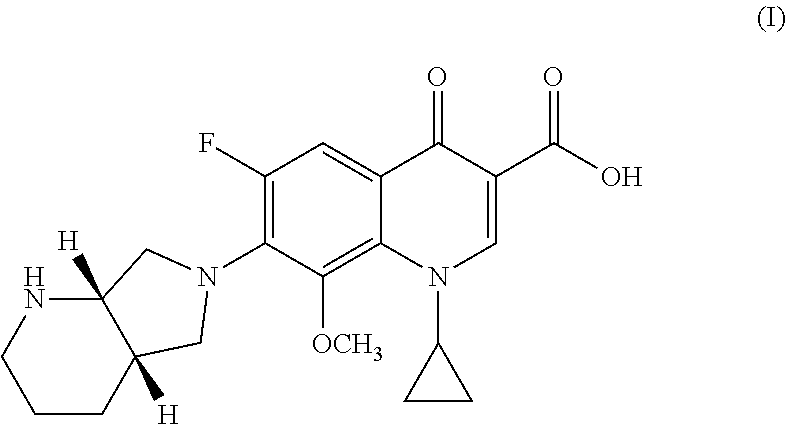

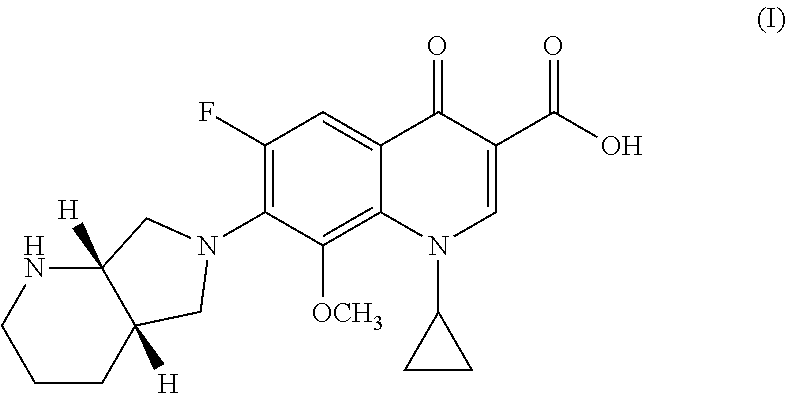

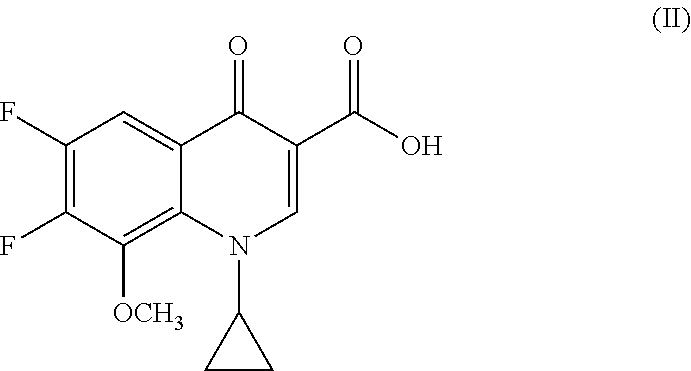

Process for preparing Moxifloxacin and salts thereof

The present invention relates to a process for the synthesis of Moxifloxacin of Formula (I) and salts thereofby means of a process providing the coupling reaction of 1-cyclopropril-6,7-difluoro-1,4-dihydro-8-methoxy-4-oxo -3-quinolinic acid or ester thereof with (4aS, 7aS) -octahydro-1H-pyrrole[3,4-b]pyridine using a magnesium salt.

Owner:F I S FAB ILTALIANA SINTETICI SPA

A kind of production method of quinolinic acid

The invention provides a quinolinic acid production method. Quinolinic acid is produced through the following steps: preparing quinoline acid copper through an oxidizing reaction, treating an oxidation reaction mother liquid, preparing quinoline acid sodium through an alkaline hydrolysis reaction, decolouring, preparing quinolinic acid through an acid separation reaction, and treating an acid separation reaction mother liquid. The oxidation reaction mother liquid, alkaline hydrolysis reaction filter cake washing water and the acid separation reaction mother liquid are comprehensively and effectively treated; active ingredients, including copper ions, quinolinic acid and the like, in each mother liquid and washing water are recycled and are utilized into the production of the next batch of the quinolinic acid; the control on an acid separation reaction is optimized, and the yield of the quinolinic acid is improved. When the active ingredients are applied, the recycled copper oxide and the recycled basic copper carbonate are purified; the yield of the quinoline acid is improved; meanwhile, the purity of the quinoline acid is ensured; refining steps of the quinoline acid are reduced; the production cost is reduced. Through the treatment of each mother liquid and the application of the washing water, water resources are saved; the wastewater discharge is reduced; the pressure on the environment is relieved.

Owner:湖北金玉兰医药科技有限公司

Method for quickly preparing [beta]-nicotinamide mononucleotide by enzymic method

ActiveCN112646851AObvious advantagesThe synthesis process is stable and rapidLigasesFermentationNucleotideOrganosolv

The invention discloses a method for quickly preparing [beta]-nicotinamide mononucleotide by an enzymic method. The method comprises the following steps of: taking PRPP as a raw material, and on the basis, adding nicotinic acid and / or quinolinic acid, ammonium ions, ATP and magnesium ions and / or manganese ions to form a reaction system; and under catalysis of an EC 6.3.4.21 enzyme and an EC 6.3.1.5 enzyme, or under the catalysis of an EC 2.4.2.19 enzyme and an EC 6.3.1.5 enzyme or under the catalysis of the EC 6.3.4.21 enzyme, the EC 6.3.1.5 enzyme and the EC 2.4.2.19 enzyme, enabling the reaction system to react to quickly prepare the [beta]-nicotinamide mononucleotide. Compared with a chemical method and a mixing method, the method disclosed by the invention has a stable and quick synthesis technology, no pollutants, including organic solvents and the like, are added in a whole process, and the method disclosed by the invention is environmentally friendly and is safe in production. Compared with other enzymic method production methods, the method disclosed by the invention has the advantages of a high reaction speed, a high conversion rate, a low production cost and a wide substrate range.

Owner:ANHUI GSH BIO TECH CO LTD

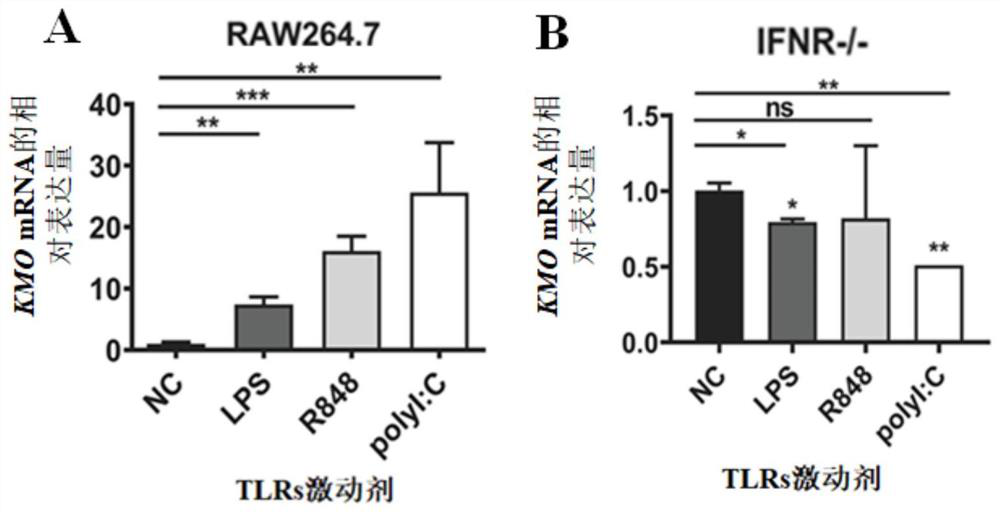

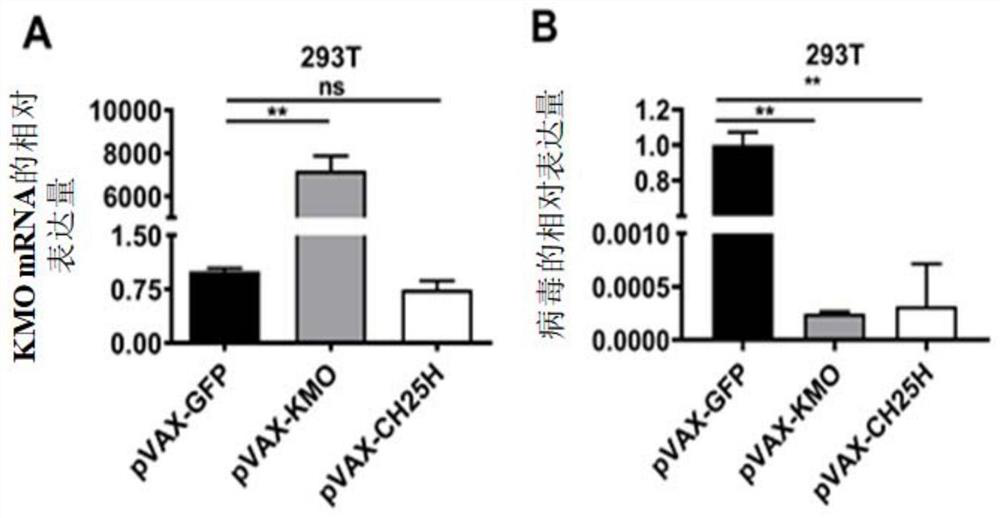

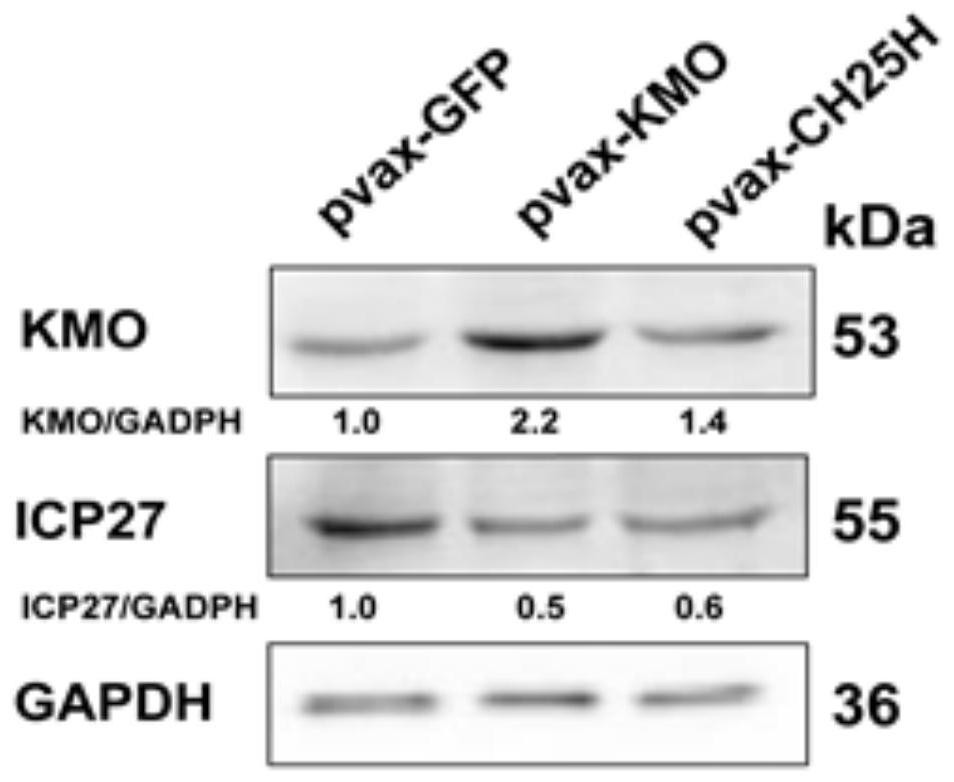

Anti-herpes simplex virus type I drug and preparation method and application thereof

PendingCN112076322AGrowth inhibitionInhibition of reproductionPeptide/protein ingredientsMicrobiological testing/measurementKynurenine HydroxylaseEnzyme Gene

The invention relates to an anti-herpes simplex virus type I drug and a preparation method and application thereof. The anti-herpes simplex virus type I drug comprises any one or a combination of at least two of a kynurenine hydroxylase gene, kynurenine hydroxylase or a metabolite quinolinic acid of the kynurenine hydroxylase. The kynurenine hydroxylase gene belongs to an interferon activation gene, after the kynurenine hydroxylase gene is overexpressed to generate the kynurenine hydroxylase, the expression of IFN-beta in a host cell can be promoted, the growth and reproduction of HSV-1 are effectively inhibited, and thus the host cell is protected.

Owner:SUN YAT SEN UNIV

Treatment method of high-salt organic wastewater containing quinolinic acids

InactiveCN113003792AEffective combinationEfficient removalSpecific water treatment objectivesWater contaminantsCu2 ionsQuinoline

The invention discloses a method for treating high-salt organic wastewater containing quinolinic acids, and belongs to the field of water treatment. The method comprises the following steps: 1) pretreating wastewater generated in production of quinolinic acid by adding alkali and heating, 2) carrying out copper adsorption treatment on the wastewater through copper removal resin, and 3) finally carrying out organic matter adsorption treatment on the wastewater through styrene-series hypercrosslinked resin. Through combination of an oxidation process and a resin adsorption process of the copper ions and the organic matters, the copper ions can be separated from the organic matters in the wastewater, regenerated liquid generated in a resin regeneration process can be effectively treated, and the salt production quality of the wastewater is improved.

Owner:江苏国创新材料研究中心有限公司

Recombinant microorganism producing quinolinic acid and method for producing quinolinic acid using same

The present invention relates to a recombinant microorganism producing quinolinic acid, more particularly, a microorganism producing quinolinic acid and having attenuated activity or eliminated activity of a protein having a sequence of SEQ ID NO: 1 and a method of producing quinolinic acid by using the recombinant microorganism.

Owner:CJ CHEILJEDANG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for quickly preparing [beta]-nicotinamide mononucleotide by enzymic method Method for quickly preparing [beta]-nicotinamide mononucleotide by enzymic method](https://images-eureka.patsnap.com/patent_img/f9c4ba4a-a37d-4355-b100-acf8032ccb4c/HDA0002228304460000011.png)

![Method for quickly preparing [beta]-nicotinamide mononucleotide by enzymic method Method for quickly preparing [beta]-nicotinamide mononucleotide by enzymic method](https://images-eureka.patsnap.com/patent_img/f9c4ba4a-a37d-4355-b100-acf8032ccb4c/HDA0002228304460000021.png)

![Method for quickly preparing [beta]-nicotinamide mononucleotide by enzymic method Method for quickly preparing [beta]-nicotinamide mononucleotide by enzymic method](https://images-eureka.patsnap.com/patent_img/f9c4ba4a-a37d-4355-b100-acf8032ccb4c/HDA0002228304460000031.png)