Preparation method of quinolinic acid

A technology of quinolinic acid and quinoline, which is applied in the field of quinolinic acid preparation, can solve the problems of low equipment utilization, short reaction time, and restrictions on the mass production of quinolinic acid, and achieve the effects of reducing production costs and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

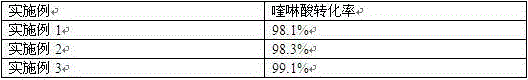

Examples

Embodiment 1

[0018] 1. Oxidation.

[0019] Put copper oxide and dilute sulfuric acid in a 1:1 mixture into a reaction vessel and heat to 40°C.

[0020] After the copper oxide is completely dissolved, add quinoline and 2% potassium permanganate, stir and heat to 97°C.

[0021] Sodium chlorate solution was added dropwise and cooled to 30°C after completion.

[0022] The copper quinolinic acid filter cake was obtained by vacuum filtration, the filter cake was washed with water at 30°C until the filtrate was neutral, and the blue copper quinolinic acid product was obtained after the filter cake was dried.

[0023] 2. Alkaline hydrolysis

[0024] Stir and heat the copper quinolinic acid product and lye to 70°C, adjust the pH to 10, after the reaction is completed, cool down to 60°C, vacuum filter while it is hot, wash the filter cake copper oxide with hot water at 50°C, and then recycle it, and the filtrate Sodium quinolinate solution.

[0025] 3. Acidification

[0026] Add the sodium quin...

Embodiment 2

[0029] 1. Oxidation.

[0030] Put copper oxide and dilute sulfuric acid in a 1:1 mixture into a reaction vessel and heat to 45°C.

[0031] After the copper oxide is completely dissolved, add quinoline and 3% potassium permanganate, stir and heat to 100°C.

[0032] Sodium chlorate solution was added dropwise and cooled to 35°C after completion.

[0033] The copper quinolinic acid filter cake was obtained by vacuum filtration, the filter cake was washed with water at 35°C until the filtrate was neutral, and the blue copper quinolinic acid product was obtained after the filter cake was dried.

[0034] 2. Alkaline hydrolysis

[0035] Stir and heat the copper quinolinic acid product and lye to 70°C, adjust the pH to 10, after the reaction is completed, cool down to 60°C, vacuum filter while it is hot, wash the filter cake copper oxide with hot water at 50°C, and then recycle it, and the filtrate Sodium quinolinate solution.

[0036] 3. Acidification

[0037] Add the sodium qui...

Embodiment 3

[0040] 1. Oxidation.

[0041] Put copper oxide and dilute sulfuric acid in a 1:1 mixture into a reaction vessel and heat to 50°C.

[0042] After the copper oxide is completely dissolved, add quinoline and 4% potassium permanganate, stir and heat to 103°C.

[0043] Sodium chlorate solution was added dropwise and cooled to 40°C after completion.

[0044] The copper quinolinic acid filter cake was obtained by vacuum filtration, the filter cake was washed with water at 40°C until the filtrate was neutral, and the blue copper quinolinic acid product was obtained after the filter cake was dried.

[0045] 2. Alkaline hydrolysis

[0046] Stir and heat the copper quinolinic acid product and lye to 70°C, adjust the pH to 10, after the reaction is completed, cool down to 60°C, vacuum filter while it is hot, wash the filter cake copper oxide with hot water at 50°C, and then recycle it, and the filtrate Sodium quinolinate solution.

[0047] 3. Acidification

[0048] Add the sodium qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com