Method for purifying and regenerating copper element in quinolinic acid production wastewater to prepare quinolinic acid copper salt

A technology for oxidizing wastewater and copper quinolinate, applied in organic chemistry and other fields, can solve problems such as discharge and water pollution, and achieve the effect of solving discharge and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

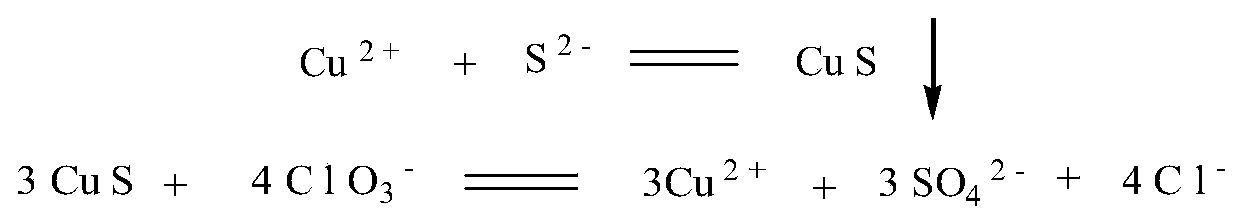

[0024] Pump the collected wastewater with a volume of 4 cubic meters into a 6000L reaction kettle, adjust the pH to 6.8-7.2 with 30% sodium hydroxide liquid alkali, add sodium sulfide in batches, take samples and filter from time to time, measure the pH value to 10, and the filtrate Use 1% silver nitrate reagent to check whether there is excess sulfide ion, silver sulfide Ksp1.09×10 -49 , stop adding sodium sulfide until there is black precipitate, react for 15 minutes, check again for black precipitate, and press filter to obtain copper sulfide, dry and store for future use or store the wet product for future use after measuring the moisture content.

[0025] Put 900kg of measured water, 7kg of recovered copper sulfide (dry basis) and 12.5kg of sodium chlorate into the zinc oxide according to the original process, heat up to 50°C and react for 2 hours, add 244kg of 80% sulfuric acid measured by the process 1. 1 kg of copper sulfate pentahydrate, 88 kg of copper hydroxide (dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com