Alkylation product treatment method

A treatment method, an alkylation technology, which is only applied in the fields of multi-stage series refining process treatment, organic chemistry, adsorption purification/separation, etc., and can solve problems such as separation system corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

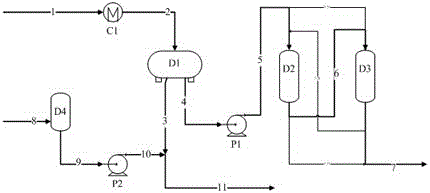

[0021] The specific implementation is as figure 1 figure 2 The device flow shown. Alkylation product 1 contains formic acid, acetic acid and other impurities, after being cooled to 60°C by cooler C1, it enters oil-water separation tank D1, and the water phase 3 and oil phase 4 separated by oil-water separation tank D1 are sent into the oil phase 4 through pump P1 Adsorption beds D2 and D3 (adsorption beds D2 and D3 can be switched according to the life of the adsorbent, or can be operated in cascade), and the oil phase 7 after adsorption is sent to the subsequent separation system for separation. The dilute lye 8 first enters the lye tank D4, and is sent to the pipeline of the water phase 3 through the pump P2, and undergoes a neutralization reaction with the water phase 3, and the neutralized water phase 11 is sent to the subsequent processing system.

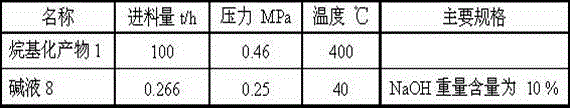

[0022] Table 1 is the composition of the alkylation product. Table 2 is the feeding conditions of alkylation product and...

Embodiment 2

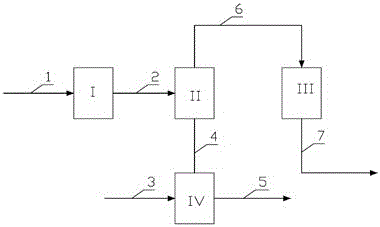

[0032] Such as figure 1 As shown, in the process flow of a treatment method for alkylation products, the gas phase reaction product 1 first enters the reaction product cooling system I to be cooled to the liquid phase, and the liquid phase reaction product is then sent to the oil-water separator II, and in the oil-water separator II The oil phase 6 separated in the process is sent to the oil phase adsorption bed III for adsorption treatment, and the treated oil phase 7 is sent to the subsequent separation system. The separated water phase 4 undergoes a neutralization reaction with the lye 3, and the neutralized water phase 5 is sent to a subsequent treatment system.

[0033] Such as figure 2 The industrial device process of the treatment method of the alkylation product shown, the alkylation product 1 contains formic acid, acetic acid and other impurities, after being cooled to 60°C by the cooler C1, it enters the oil-water separation tank D1, and the water separated by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com