Antimonial ammoxidation catalyst

A catalyst, ammoxidation technology, applied in the direction of physical/chemical process catalyst, hydrocarbon ammoxidation preparation, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of low yield of isophthalonitrile and difficult catalyst Adapt to fluidized bed requirements, expensive raw materials and other issues, to achieve the effect of improving reaction selectivity, reducing the cost of three wastes treatment, and reducing unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

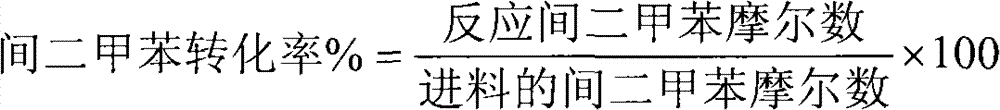

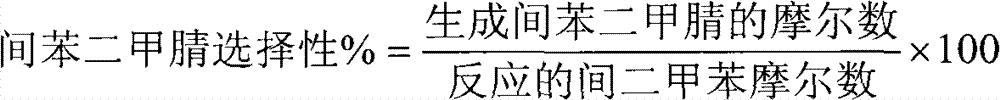

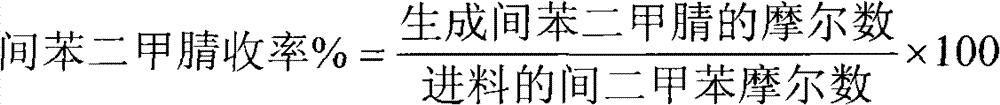

Method used

Image

Examples

Embodiment 1

[0049] Catalyst preparation:

[0050] 201 g V 2 o 5 Add it into a solution at a temperature of 80-90° C. consisting of 440 milliliters of water and 420 grams of oxalic acid, stir well, and react to obtain a vanadium oxalate solution.

[0051] 40% (weight) SiO 2 1250 grams of silica sol was slowly added to the above solution under stirring, and then 505 grams of antimony ammonium oxalate [2(NH 4 ) 3 Sb(C 2 o 4 ) 3 2H 2 O] and 300 milliliters of water solution, 68.6 grams of H 3 BO 3 and 560 ml of water and 117.6 g (NH 4 ) 6 Mo 7 o 24 4H 2 A solution consisting of O and 50 ml of water, 0.11 molar phosphoric acid solution, and finally 9.4 g of NaNO 3 A solution composed of 20 ml of water was stirred and mixed, heated and evaporated to a solid content of 42% by weight to obtain a thick slurry.

[0052] The above slurry is sprayed and formed, the gas inlet temperature of the sprayer is 250°C, the outlet temperature is 130°C, the formed catalyst is dried at 130°C for...

Embodiment 2~14

[0060] Catalyst preparation method is the same as embodiment 1, changes the composition or proportioning of catalyst, by catalyst evaluation condition in embodiment 1, evaluation result is listed in following table 1.

[0061] Table 1

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com