A kind of preparation method of methyl p-methoxycinnamate

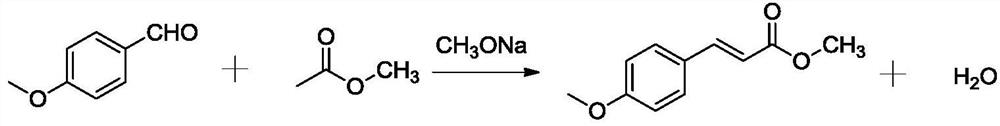

A technology of p-methoxybenzaldehyde and methyl laurate, which is applied in the field of preparation of methyl p-methoxycinnamate, can solve the problems of increasing the amount of saline wastewater and reducing the reaction yield, and achieve the reduction of three wastes treatment Cost, reduction of catalyst usage, and effect of catalyst cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

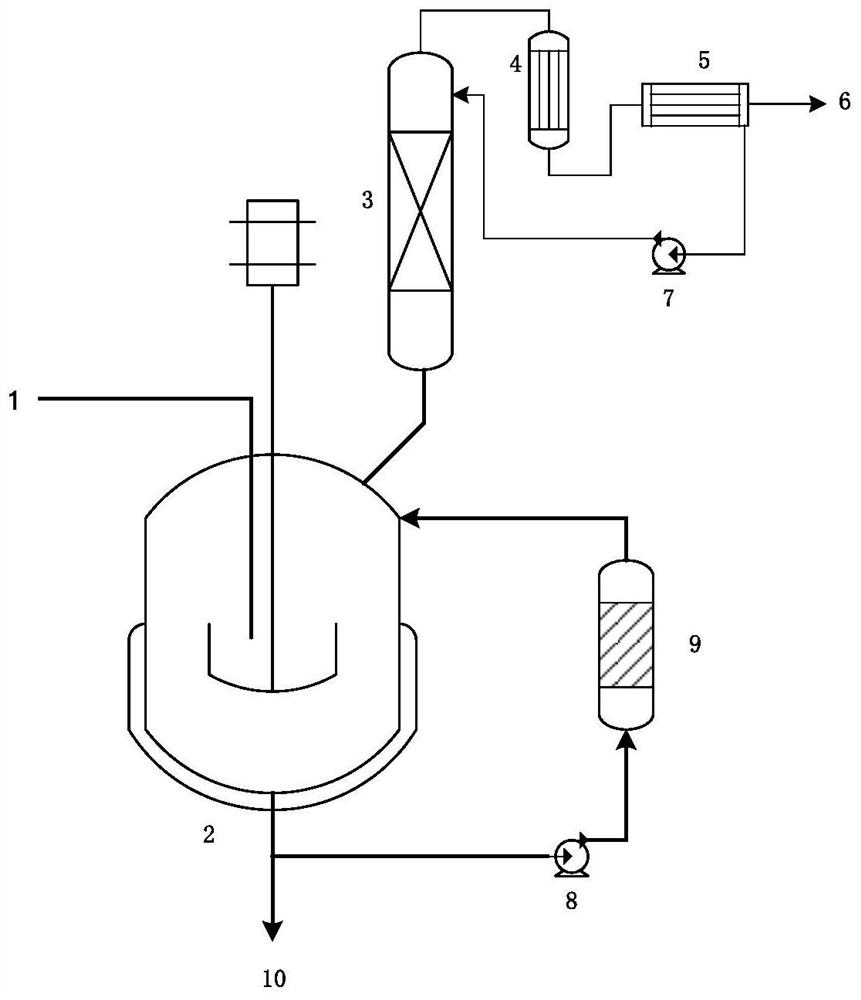

Method used

Image

Examples

Embodiment 1

[0073] Mix 529.7 grams of γ-alumina powder and 70 grams of polyethylene glycol (molecular weight 1000) powder evenly, and then add 30 grams of calcium oxide powder, 60 grams of magnesium oxide powder, 10 grams of cerium oxide, and 100 mg of oxide powder to the mixture of the two. Manganese and 200 mg of rhenium oxide powder were stirred evenly and added to a solution containing 300 g of aluminum sol. The catalyst was molded by extruding, dried at 100° C. for 15 hours, and calcined at 600° C. for 10 hours to obtain catalyst 1.

Embodiment 2

[0075] Mix 769.6 grams of γ-alumina powder with 35 grams of polyethylene glycol (molecular weight 3000) powder, and then add 60 grams of calcium oxide powder, 30 grams of magnesium oxide powder, 5 grams of cerium oxide, and 300 mg of oxide powder to the mixture of the two. Manganese and 100 mg of rhenium oxide powder were stirred evenly and added to a solution containing 100 g of aluminum sol. The catalyst was molded by extruding, dried at 100°C for 15 hours, and calcined at 600°C for 10 hours to obtain catalyst 2.

Embodiment 3

[0077] Mix 500 grams of γ-alumina powder and 60 grams of polyethylene glycol (molecular weight 4000) powder evenly, and then add 60 grams of calcium oxide powder, 60 grams of magnesium oxide powder, 20 grams of cerium oxide, and 200 mg of oxide powder to the mixture of the two. Manganese and 150 mg of rhenium oxide powder were stirred evenly and added to a solution containing 300 g of aluminum sol. The catalyst was molded by extruding, dried at 100°C for 15 hours, and calcined at 600°C for 10 hours to obtain catalyst 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com