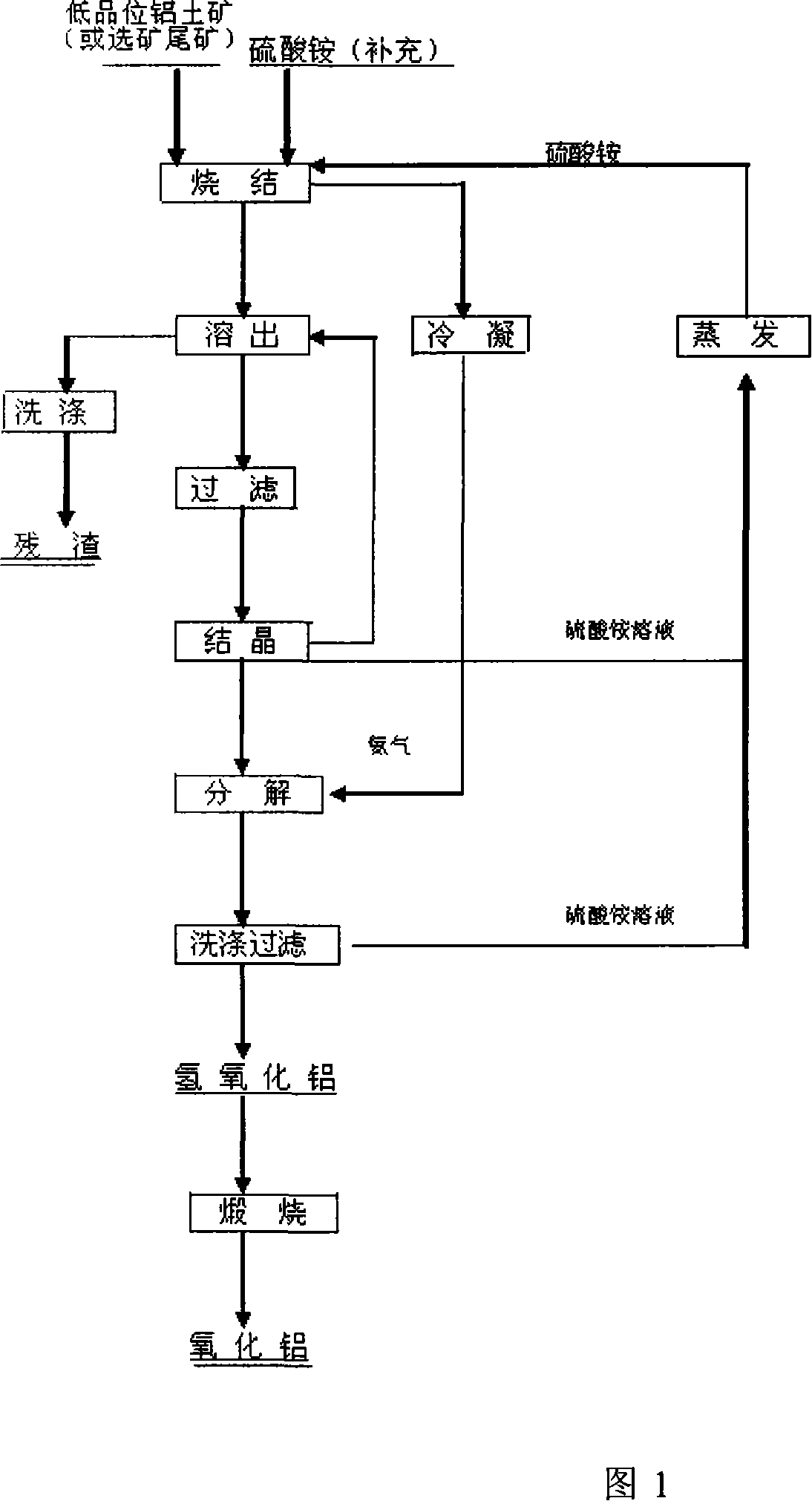

Method for extracting aluminum oxide from low grade bauxite

A low-grade bauxite and alumina technology, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problems of long process and high energy consumption, achieve low corrosion, small residue, and easy industrial application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Low-grade bauxite from a certain area in China is used, and the molecular ratio of ammonium sulfate / alumina in low-grade bauxite is 5. Dissolution under the conditions, the aluminum ammonium sulfate solid obtained after crystallization of the stripping liquid is decomposed by ammonia gas, and the aluminum hydroxide solid is obtained. After washing, filtering and roasting, the alumina product is obtained. The impurity chemical composition of the obtained alumina product is: Fe 2 o 3 : 0.02%, SiO 2 : 0.08%.

Embodiment 2

[0026] Low-grade bauxite from a certain area in China is used, and the molecular ratio of ammonium sulfate / alumina in low-grade bauxite is 4. The sintering reaction temperature is 500 ° C, the reaction time is 2 hours, and the sintering clinker is at 85 ° C. The aluminum ammonium sulfate solid obtained after crystallization of the stripping solution is decomposed by ammonia gas to obtain aluminum hydroxide solid. After washing, filtering and roasting, the alumina product is obtained. The impurity chemical composition of the obtained alumina product is: Fe 2 o 3 : 0.05%, SiO 2 : 0.05%.

Embodiment 3

[0028] Low-grade bauxite from a province in China is used, and the molecular ratio of ammonium sulfate / alumina in low-grade bauxite is 4.5. The sintering reaction temperature is 460°C, the reaction time is 3 hours, and the sintering clinker is 90°C. Dissolution under certain conditions, the aluminum ammonium sulfate solid obtained after crystallization of the dissolution liquid is recrystallized after dissolution, and then decomposed with ammonia gas to obtain aluminum hydroxide solid. After washing, filtering and roasting, the alumina product is obtained. The obtained oxidation The chemical composition of impurities in aluminum products is: Fe 2 o 3 : 0.04%, SiO 2 : 0.04%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com