Comprehensive utilization method of ammonium sulfate and pulverized coal ash produced by thermal power plant ammonia process

A technology of ammonia desulfurization and fly ash, which is applied in the direction of preparation/separation of aluminum sulfate, aluminum sulfur compounds, ammonia, etc., can solve the problems of excrement waste polluting the environment, achieve reduction of harmful emissions, obvious economic benefits and The effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

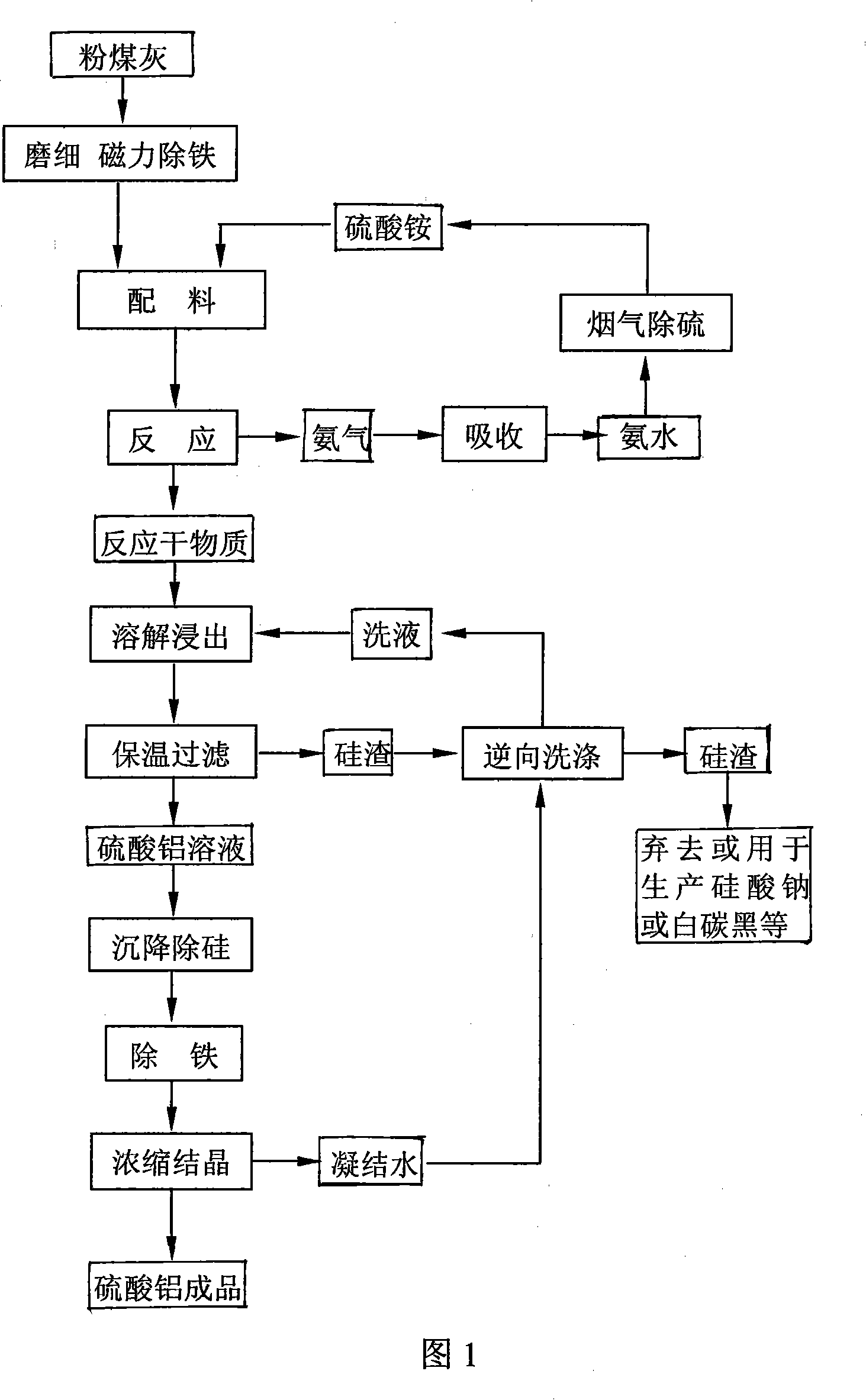

Image

Examples

Embodiment 1

[0021] Embodiment 1: a comprehensive utilization method of ammonium sulfate and fly ash produced by ammonia desulfurization in a thermal power plant,

[0022] 1. Grinding and activating the fly ash. Grind the fly ash to 200 mesh, remove iron by magnetic force, and then roast and activate at 500°C for 0.5 hours. If you use electric dust removal fine ash, you don’t need to grind it, and you can directly remove iron and activate it;

[0023] 2. Batching, the activated fly ash fine ash is mixed evenly according to the ratio of ammonium sulfate and the aluminum oxide contained in the fly ash with a weight ratio of 4.5: 1;

[0024] 3. React. The mixture of ammonium sulfate and fly ash was subjected to solid phase reaction at 300°C for 2 hours to generate ammonia gas, aluminum sulfate and ammonium aluminum sulfate. The reaction equations involved are:

[0025] al 2 o 3 +3(NH 4 ) 2 SO 4 =Al 2 (SO 4 ) 3 +6NH 3 ↑+3H 2 O……………①

[0026] Fe 2 o 3 +3(NH 4 ) 2 SO 4 = Fe 2...

Embodiment 2

[0039] Example 2, the steps are the same as in Example 1, the difference is that in step 1, the fly ash is ground to 400 mesh, iron is removed by magnetic force, and then activated by roasting at 600° C. for 1 hour.

[0040] In step 2, the alumina contained in the ammonium sulfate and the fly ash is mixed in a ratio of 6:1 by weight,

[0041] In step 3, the mixture of ammonium sulfate and fly ash is subjected to solid phase reaction at 380°C,

[0042] In step 5, the dry reacted substance enters the leaching tank while it is hot, and is stirred and leached at 100° C. for 60 minutes.

Embodiment 3

[0043] Example 3, the steps are the same as in Example 1, the difference is that in step 1, the fly ash is ground to 300 mesh, iron is removed by magnetic force, and then activated by roasting at 550° C. for 0.8 hours.

[0044] In step 2, the aluminum oxide contained in the ammonium sulfate and the fly ash is mixed in a ratio of 5:1 by weight,

[0045] In step 3, the mixture of ammonium sulfate and fly ash is subjected to solid phase reaction at 340°C,

[0046] In step 5, the dry reacted substance enters the leaching tank while it is hot, and is stirred and leached at 90° C. for 45 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com