Method for extracting aluminium oxide from coal ash

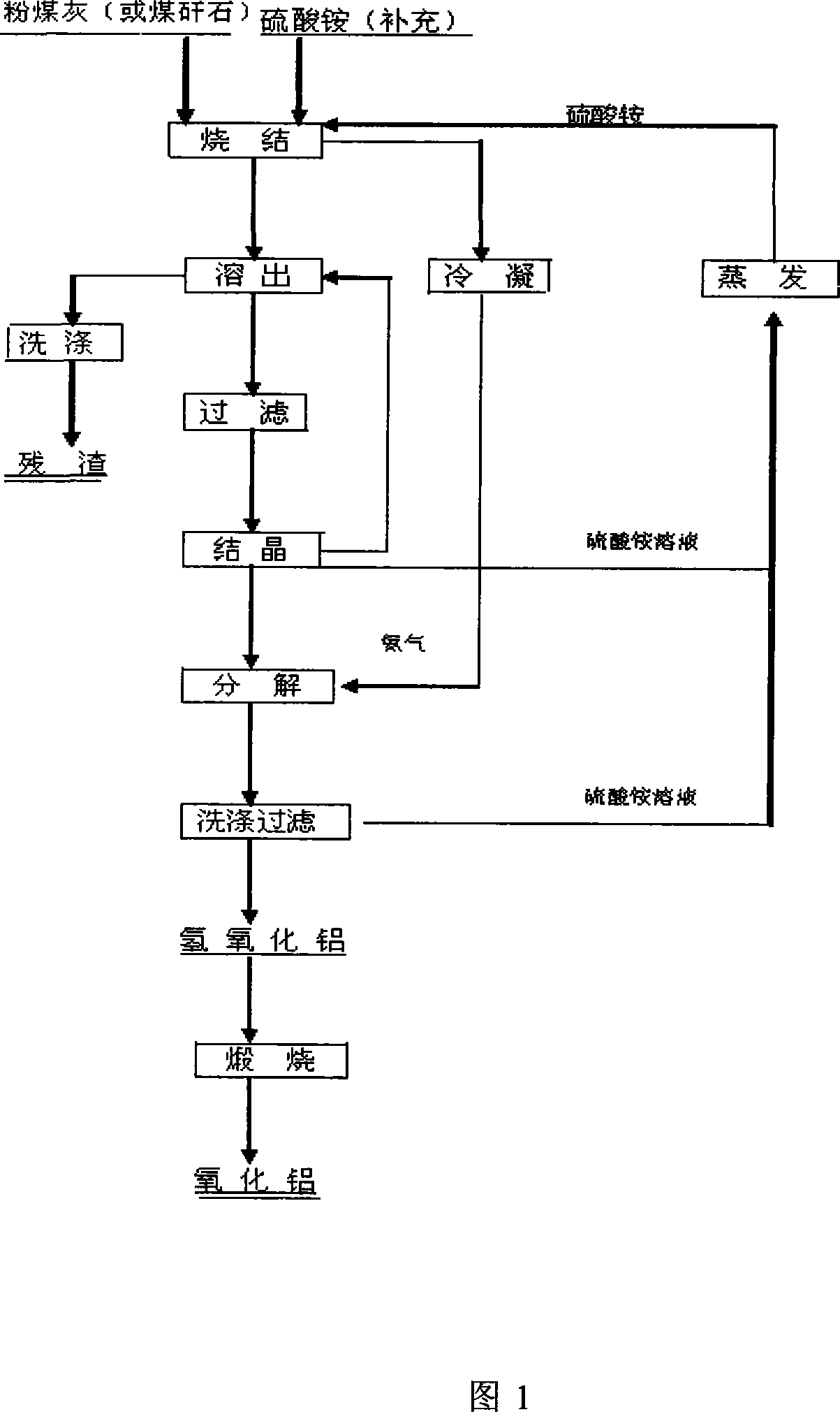

A technology of fly ash and alumina, which is applied in the direction of alumina/hydroxide, alumina/hydroxide preparation, etc., can solve the problems of restricting social and economic benefits, adding treatment procedures, and difficult recovery of waste acid, etc., to achieve durable The effect of low corrosion performance requirements, small amount of residue, and low corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Grind the fly ash containing 33% of alumina and 49% of silica, mix ore according to the molecular ratio of ammonium sulfate / alumina in fly ash to 5, the sintering temperature is 530°C, the reaction time is 2 hours, and sintering The clinker is dissolved under the condition of 98°C, and the aluminum ammonium sulfate solid obtained after the dissolution liquid is crystallized is decomposed with ammonia gas to obtain the aluminum hydroxide solid, which is washed, filtered and roasted to obtain the alumina product, and the obtained alumina product has impurities The chemical composition is: Fe 2 o 3 : 0.02%, SiO 2 : 0.08%.

Embodiment 2

[0026] Grind the fly ash containing 40% of alumina and 48% of silica, mix ore according to the molecular ratio of ammonium sulfate / alumina in fly ash to 4, the sintering reaction temperature is 500°C, and the reaction time is 2 hours. The sintered clinker is dissolved under the condition of 85°C, and the aluminum ammonium sulfate solid obtained after the dissolution liquid is crystallized is decomposed with ammonia gas to obtain the aluminum hydroxide solid, which is washed, filtered and roasted to obtain the alumina product, and the obtained alumina product The chemical composition of impurities is: Fe 2 o 3 : 0.05%, SiO 2 : 0.05%.

Embodiment 3

[0028] Grind the fly ash containing 38% of alumina and 47% of silica, mix the ore according to the molecular ratio of ammonium sulfate / alumina in fly ash to 4.5, sinter the reaction temperature at 460°C, and the reaction time is 3 hours. The sintered clinker is dissolved under the condition of 90°C, and the aluminum ammonium sulfate solid obtained after the dissolution is crystallized is dissolved and then recrystallized, and then decomposed with ammonia gas to obtain aluminum hydroxide solid, which is obtained after washing, filtering and roasting. Alumina product, the impurity chemical composition of gained alumina product is: Fe 2 o 3 : 0.04%, SiO 2 : 0.04%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com