Process for preparing alumina powder with high sinter activity

A technology of alumina powder and sintering activity, applied in the field of fine chemical industry, can solve the problems of affecting the microstructure and mechanical properties of sintered porcelain, reducing the sinterability of powder, unfavorable to environmental protection, etc., achieving good market prospects and improving sinterability. , the effect of low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

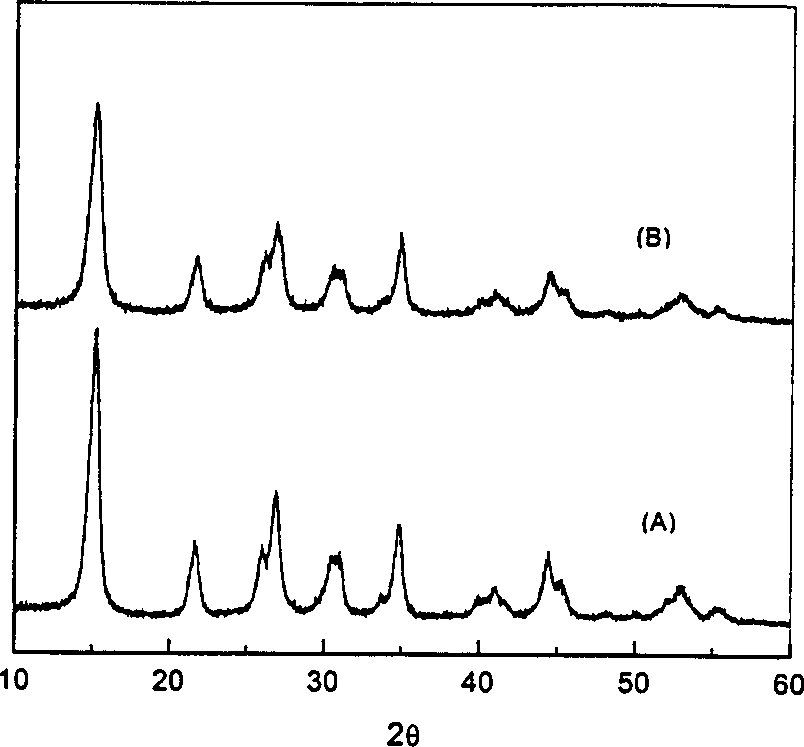

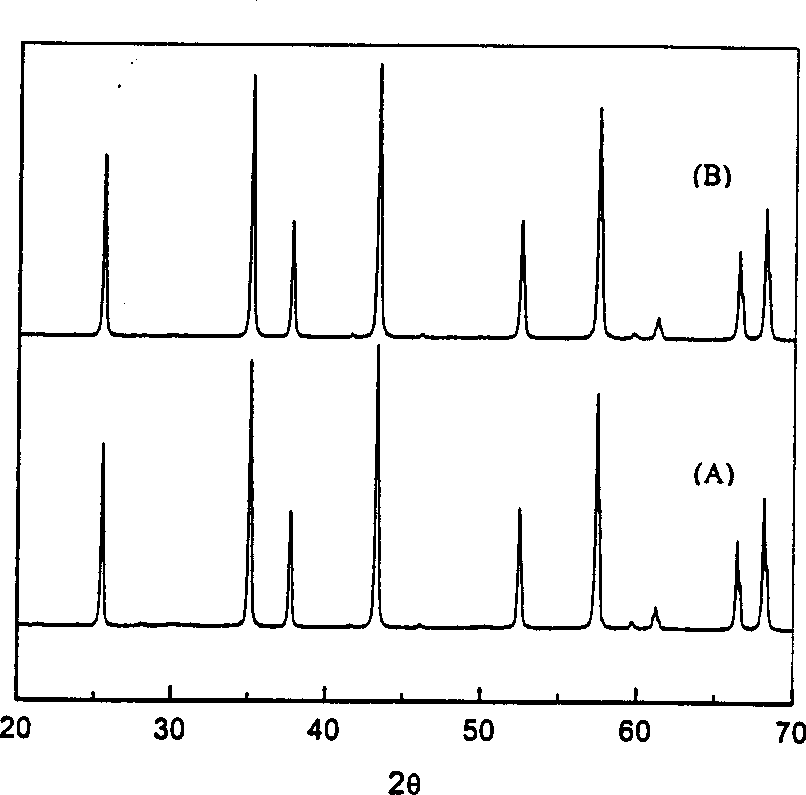

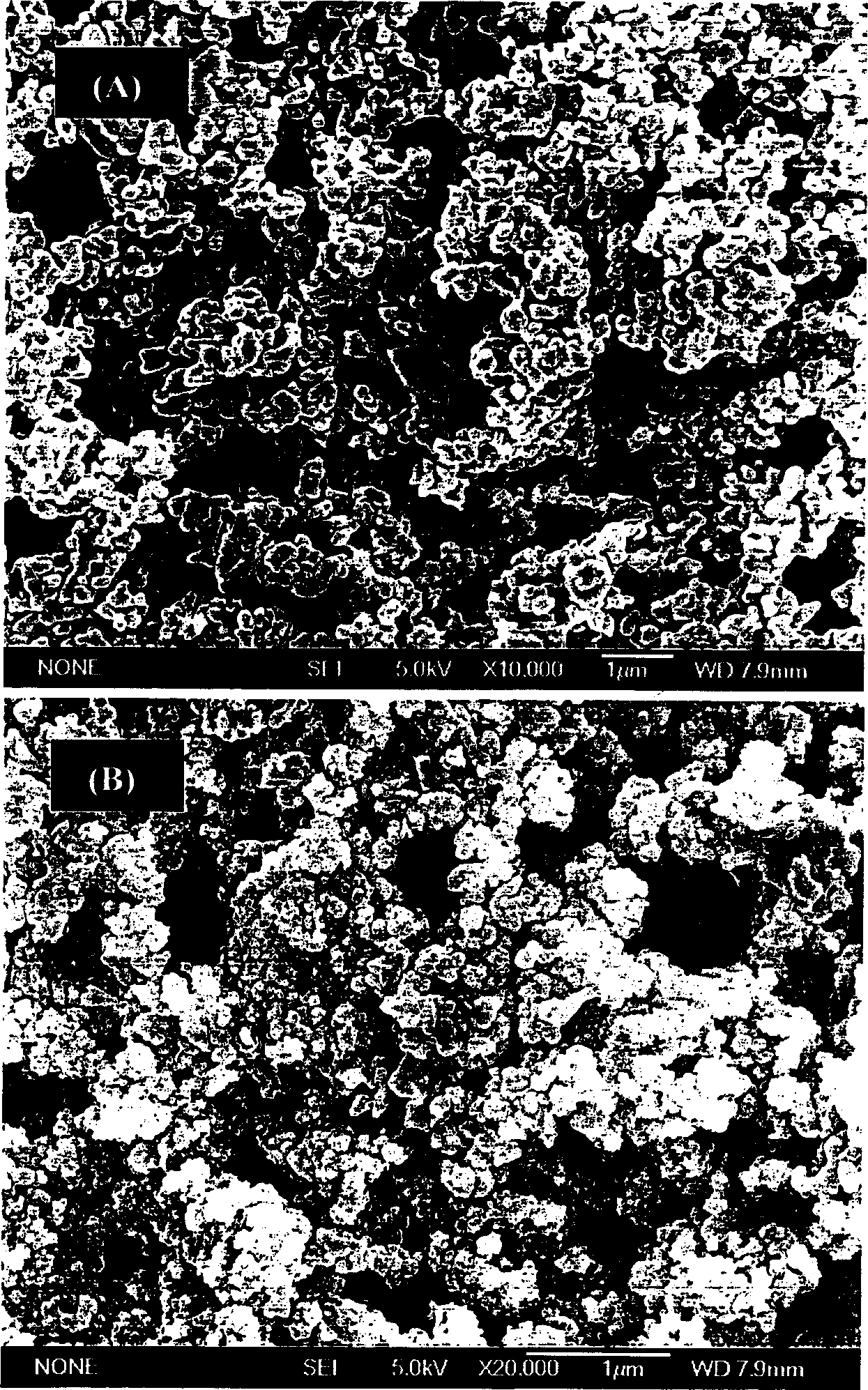

Embodiment 1

[0028] Add 0.4M aluminum nitrate solution (1000ml) dropwise to 4M ammonium bicarbonate solution (1500ml) while stirring at room temperature, and the white precipitate obtained is aged for 12 hours and washed 5 times with deionized water to remove free inorganic ion. The resulting precipitate was semi-dry after long-term suction filtration and dehydration, and then transferred to an oven for drying at 50°C. The obtained dry powder was subjected to XRD characterization before and after calcination at 1200°C for 1 hour, and it was found that the uncalcined powder had completely generated NH 4 Al(OH) 2 CO 3 ( figure 1 A), NH after high temperature calcination 4 Al(OH) 2 CO 3 Decompose into α-Al 2 o 3 ( figure 2 A). generated α-Al 2 o 3 The particle size is around 300nm ( image 3 A), has good sinterability. 96% of the theoretical density can be achieved by pressureless sintering at 1500°C for 2 hours, and it can be completely densified by sintering at 1525°C for 2 h...

Embodiment 2

[0030] Using 2M ammonium bicarbonate and 0.2M aluminum nitrate as raw materials, alumina powder was prepared by aging for 24 hours and calcining at 1200° C. for 1 hour, and the others were the same as in Example 1. figure 1 B and figure 2 B are the resulting NH 4 Al(OH) 2 CO 3 Precipitation and α-Al 2 o 3 XRD pattern of the powder. image 3 B is the resulting α-Al 2 o 3 SEM photo of the powder. The powder exhibits good sinterability, 98% of the theoretical density can be achieved by pressureless sintering at 1500°C for 1 hour, and complete densification can be achieved by sintering at 1525°C for 1 hour ( Figure 4 Curve B).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com