Preparation method of ammonium alum by using waste catalyst as raw material

A waste catalyst and ammonium alum technology, applied in chemical instruments and methods, inorganic chemistry, aluminum compounds, etc., can solve the problems of cumbersome process and many operation steps, and achieve the effects of simple process steps, environmental protection and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

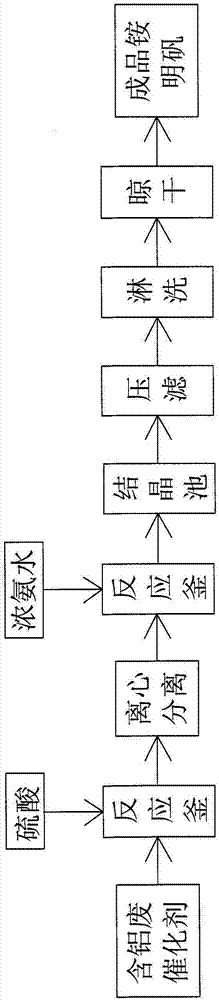

[0024] according to figure 1 Shown flow process is that the step that raw material prepares ammonium alum with spent catalyst is as follows:

[0025] A) prepare aluminum sulfate crude liquid, add the sulfuric acid that mass % ratio concentration is 25% to soak a week in petrochemical industry in the production process such as the mass % content of the aluminum that produces in the catalytic cracking process of petroleum that is 30% aluminum-containing waste catalyst, Specifically, it is advisable to put the aluminum-containing waste catalyst from the aforementioned industries (petrochemical industry) into a immersion pool filled with sulfuric acid and submerge the aluminum-containing waste catalyst with sulfuric acid. (Equipped with) a container with a stirring device and a heating device, such as a reactor, and the stirring reaction is performed with the stirring device and the heating device turned on. The stirring speed of the stirring device is controlled at 2100rpm, and t...

Embodiment 2

[0030] Only change the mass % content of aluminum in the aluminum-containing waste catalyst in step A) to 10%, change the mass % specific concentration of sulfuric acid to 30%, change the stirring speed of the stirring device to 100rpm, and change the stirring reaction time Change it to 6h, change the heating temperature, that is, the reaction temperature to 120°C; change the stirring speed in step B) to 4000rpm, change the heating temperature, that is, the reaction temperature to 80°C, change the reaction time to 35min, and mix concentrated ammonia water and sulfuric acid Change the mass ratio of aluminum crude liquid to 0.05:1, change the mass % ratio concentration of concentrated ammonia water to 27%; change the crystallization reaction temperature in step C) to 15°C, and change the time of crystallization reaction to 40min; The temperature of the cold water in D) was changed to 15°C, and the rest were the same as those described in Example 1.

Embodiment 3

[0032] Only change the mass % content of aluminum in the aluminum-containing waste catalyst in step A) to 50%, change the mass % specific concentration of sulfuric acid to 40%, change the stirring speed of the stirring device to 4000rpm, and change the time of the stirring reaction Change it to 20h, change the heating temperature, that is, the reaction temperature to 110°C; change the stirring speed in step B) to 2000rpm, change the heating temperature, that is, the reaction temperature, to 82°C, change the reaction time to 32min, and mix concentrated ammonia water and sulfuric acid Change the mass ratio of aluminum crude liquid to 0.5:1, change the mass % ratio concentration of concentrated ammonia water to 26%; change the crystallization reaction temperature in step C) to 12°C, and change the time of crystallization reaction to 60min; The temperature of the cold water in D) was changed to 10°C, and the rest were the same as those described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com