Method for preparing alumina from fly ash

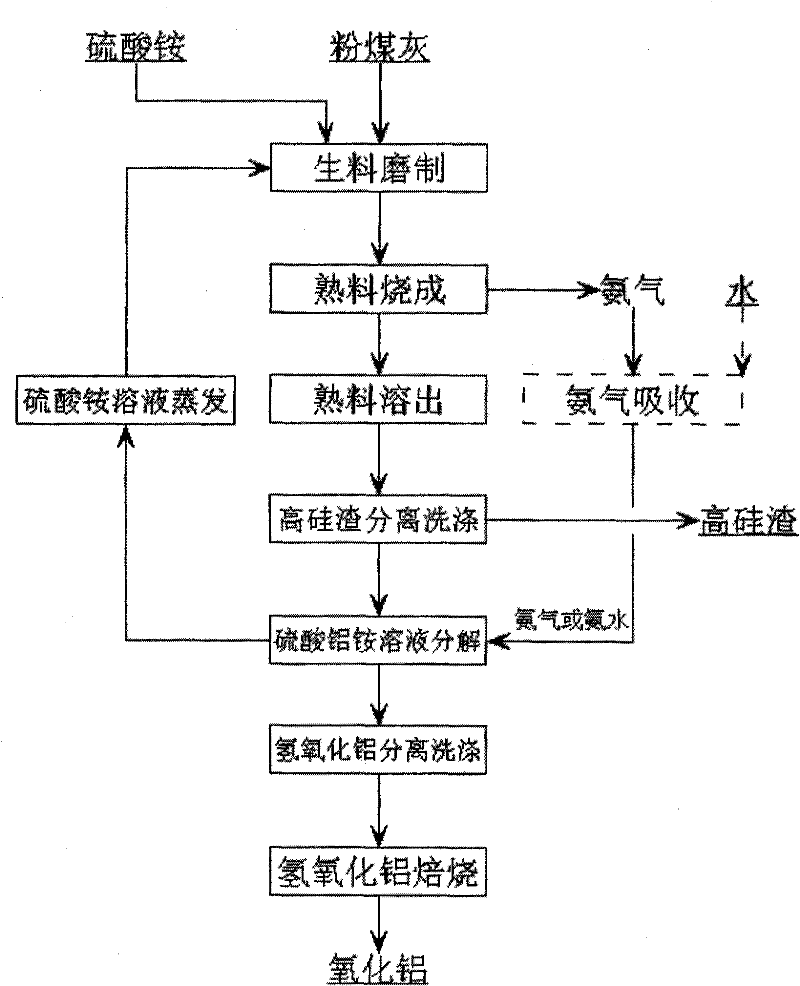

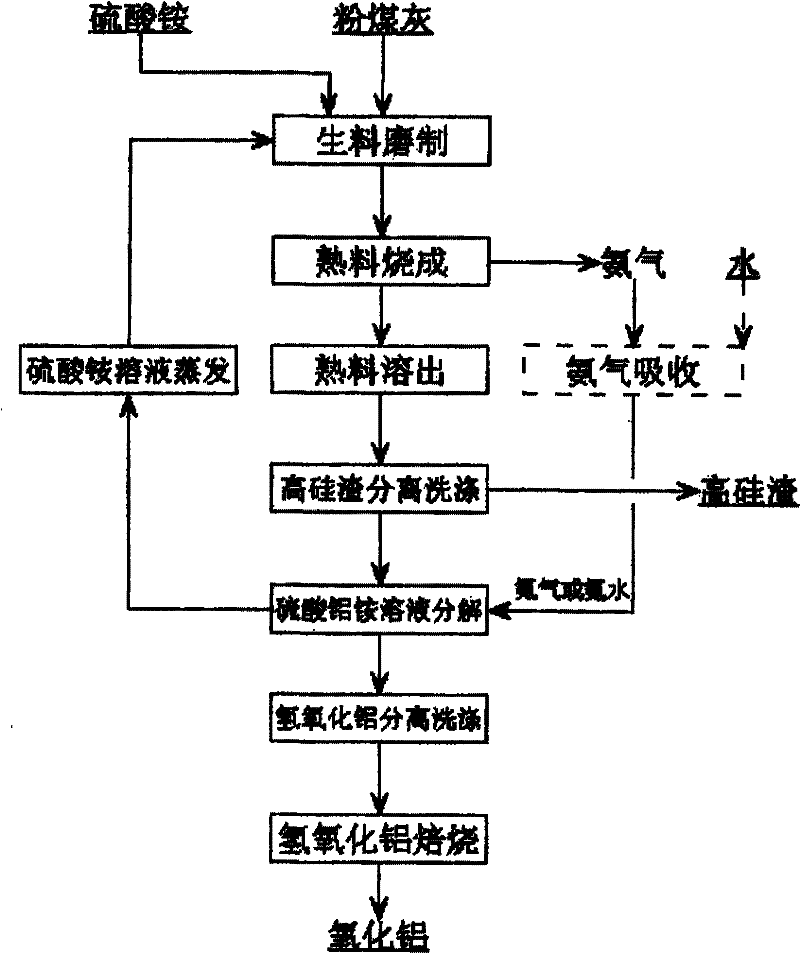

A technology for alumina and fly ash is applied in the field of preparing alumina by using fly ash, which can solve the problems of secondary pollution, high cost and high energy consumption, and achieve the effects of being beneficial to industrialization, utilization and easy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Raw fly ash is mainly composed of the following components: Al 2 o 3 : 41%, SiO 2 : 48%, Fe 2 o 3 : 3.3%, CaO: 3.3%, TiO 2 : 1.3%, MgO: 0.2%. The composition of the raw fly ash can also use other components, which cannot be used to limit the protection scope of the present invention.

[0020] Mix fly ash and ammonium sulfate solution and wet grind to obtain raw meal, wherein the weight ratio of ammonium sulfate and alumina in fly ash is 5:1; heat the raw meal to 450°C and keep it warm for 1 hour to make clinker. The discharged ammonia gas is used for the decomposition of aluminum ammonium sulfate; the clinker is dissolved in hot water with a mill for 0.5h, aluminum enters the solution in the form of aluminum ammonium sulfate, and silicon remains in the solid to form high-silicon slag; after dissolution, the slurry passes through the settling tank Separation and three-stage countercurrent washing, the liquid is aluminum ammonium sulfate solution, and the solid slag...

Embodiment 2

[0022] The raw material fly ash and ammonium sulfate crystals in Example 1 were mixed and dry-milled to obtain a raw meal, wherein the weight ratio of ammonium sulfate to alumina in the fly ash was 4.5:1; the raw meal was heated to 230°C and kept at 0.5 h, making clinker, the discharged ammonia gas is used for the decomposition of aluminum ammonium sulfate; the clinker is dissolved in hot water for 0.1h with stirring, aluminum enters the solution in the form of aluminum ammonium sulfate, and silicon remains in the solid to form high-silicon slag; After dissolution, the slurry is separated by a filter and washed in two countercurrents. The liquid is aluminum ammonium sulfate solution, and the solid slag is high-silicon slag; ammonia water is passed into the aluminum ammonium sulfate solution, and ammonia water is made by adding water to ammonia gas produced by clinker firing. , so that the solution is decomposed into aluminum hydroxide solid, and the liquid is ammonium sulfate s...

Embodiment 3

[0024] The raw material fly ash in Example 1 is mixed and dry-milled with ammonium sulfate crystals to obtain a raw meal, wherein the weight ratio of ammonium sulfate and alumina in the fly ash is 7:1; the raw meal is heated to 300° C. and kept for 3 hours , to make clinker, and the discharged ammonia gas is used for the decomposition of aluminum ammonium sulfate; the clinker is dissolved in hot water for 1.3h with stirring, aluminum enters the solution in the form of aluminum ammonium sulfate, and silicon remains in the solid to form high-silicon slag; After the slurry is separated by a filter and washed in the first stage of countercurrent, the liquid is ammonium aluminum sulfate solution, and the solid slag is high-silicon slag; ammonia water is passed into the ammonium aluminum sulfate solution, and ammonia water is made by adding water to ammonia gas produced by clinker burning. The solution is decomposed into solid aluminum hydroxide, and the liquid is ammonium sulfate so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com