Water purifier and preparation method thereof

A technology of water purifying agent and ammonium aluminum sulfate, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., to achieve the effect of avoiding pollution and solving solid waste treatment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

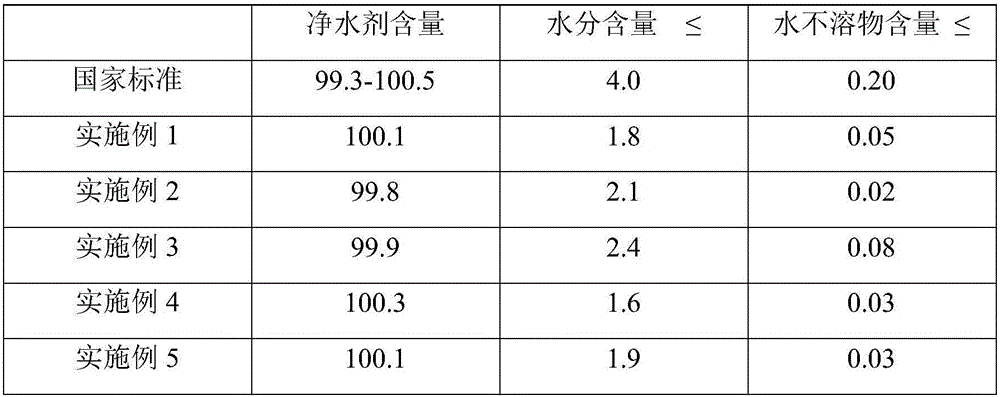

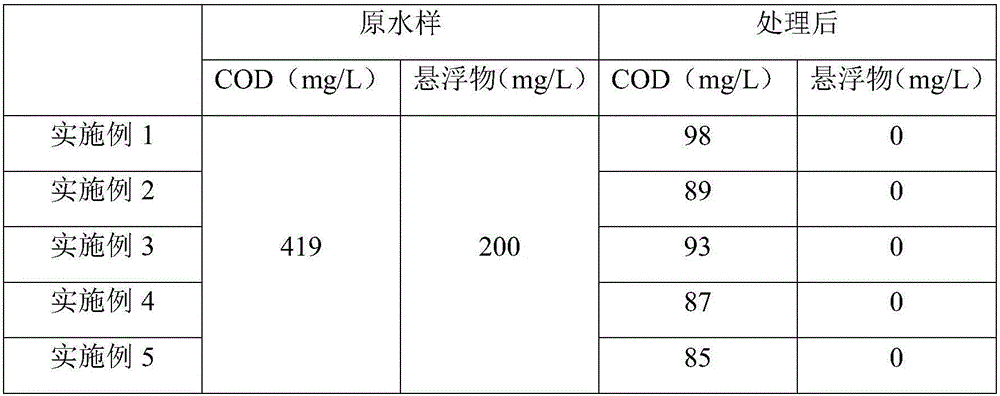

Examples

Embodiment 1

[0020] The preparation process of water purifying agent is as follows:

[0021] (1) Weighing 100g of microspherical catalytic cracking waste catalyst with a particle size<200 μm, beating it with water, and stirring for 30 minutes;

[0022] (2) According to the acid concentration in the reaction process, it is 20%, and the ratio of solid to liquid is 1:6 to add sulfuric acid, and the acid addition speed can be controlled for safety reasons;

[0023] (3) After adding acid, adjust the reaction temperature to be 140° C., and react at this temperature for 4 hours;

[0024] (4) Add water to dilute to 2 times of the original volume after the reaction is finished, and centrifuge while hot to obtain the filtrate;

[0025] (5) Pass ammonia water into the filtrate, cool to 10°C, filter, wash, and dry to obtain the crude product of granular water purifying agent aluminum ammonium sulfate;

[0026] (6) The aluminum ammonium sulfate crude product is recrystallized to obtain the industrial...

Embodiment 2

[0029] The preparation process of water purifying agent is as follows:

[0030] (1) Weighing 100g of microspherical catalytic cracking waste catalyst with a particle size<40 μm, beating it with water, and stirring for 30 minutes;

[0031] (2) According to the acid concentration in the reaction process, the acid concentration is 30%, and the solid-liquid ratio is 1:5 to add sulfuric acid, and the acid addition speed can be controlled for the sake of safety;

[0032] (3) After adding acid, adjust the reaction temperature to be 130° C., and react at this temperature for 4 hours;

[0033] (4) Add water to dilute to 2 times of the original volume after the reaction is finished, and centrifuge while hot to obtain the filtrate;

[0034] (5) Pass through ammoniacal liquor in filtrate, cool down to 50 ℃, filter, wash, dry to obtain granular water purifying agent aluminum ammonium sulfate crude product;

[0035] (6) The aluminum ammonium sulfate crude product is recrystallized to obta...

Embodiment 3

[0038] The preparation process of water purifying agent is as follows:

[0039] (1) Weighing 100g of microspherical catalytic cracking waste catalyst with a particle size<20 μm, beating it with water, and stirring for 30 minutes;

[0040] (2) According to the acid concentration in the reaction process, the acid concentration is 40%, and the solid-liquid ratio is 1:4 to add sulfuric acid, and the acid addition speed can be controlled for the sake of safety;

[0041] (3) After adding acid, adjust the reaction temperature to be 140° C., and react at this temperature for 4 hours;

[0042] (4) Add water to dilute to 2 times of the original volume after the reaction is finished, and centrifuge while hot to obtain the filtrate;

[0043] (5) Ammonia water is passed into the filtrate, cooled to 20°C, filtered, washed, and dried to obtain the crude product of granular water purifying agent aluminum ammonium sulfate;

[0044] (6) The aluminum ammonium sulfate crude product is recrystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com