Sulfur dioxide absorbent using secondary salt mud from lime flue gas process as raw material

A lime flue gas and sulfur dioxide technology is applied in the fields of environmental protection and solid waste resource utilization to achieve the effects of high desulfurization efficiency, simplified process and reduced desulfurization cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

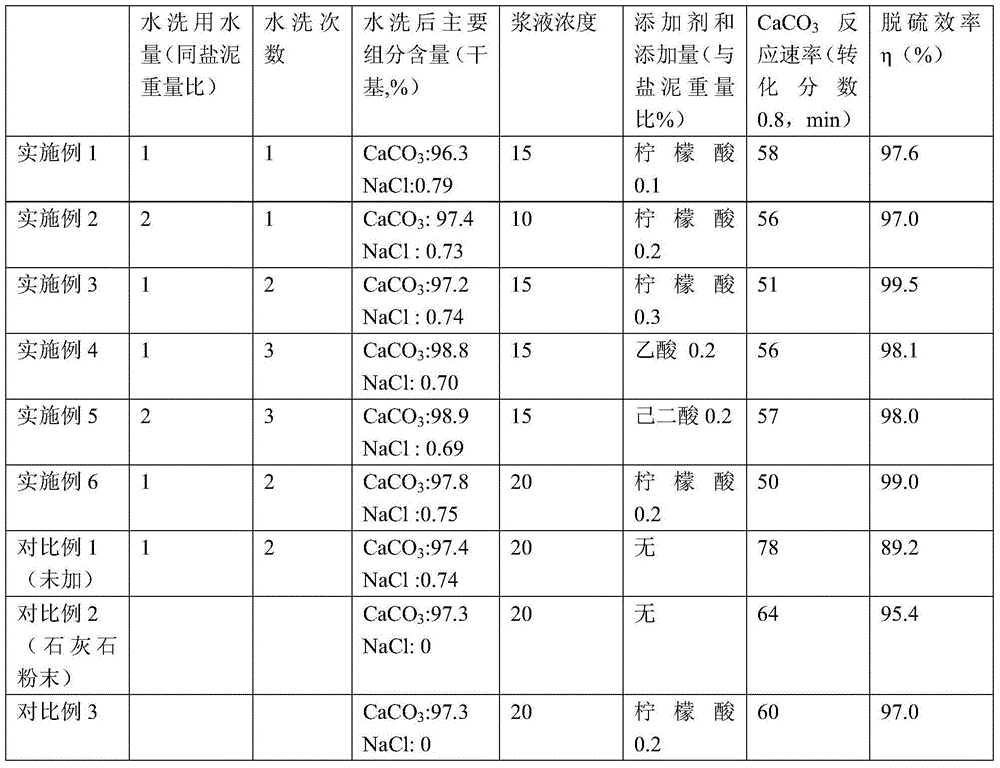

Embodiment 1

[0044] Take the limestone flue gas method secondary salt mud, wash it once with the same weight of water, use a vacuum drum filter to dehydrate, and the CaCO in the dry basis 3 The content is 96.3, and the NaCl content is 0.79. Prepare a slurry with a solid content of 15%, then add citric acid (purity ≥ 97%) with a total weight of 0.1% of salt mud on a dry basis, and mix thoroughly to make a desulfurization absorbent slurry.

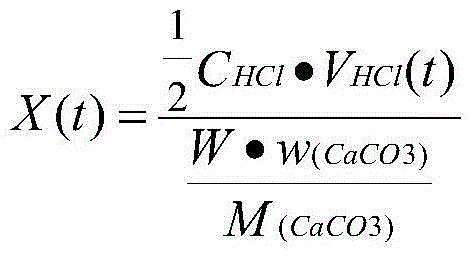

[0045] Using the electric power industry standard of the People's Republic of China ("Determination of the reaction rate of limestone powder for wet flue gas desulfurization" DL / T943-2005), the activity of calcium carbonate in the prepared slurry was tested.

[0046] The test results of this example show that when the conversion rate of calcium carbonate is 0.8, the consumption time is 58 minutes.

[0047] Desulfurize the flue gas produced by three 75t / h circulating fluidized bed boilers in a thermal power plant. The flue gas temperature is controlled a...

Embodiment 2

[0049] Take limestone flue gas method secondary salt mud, wash it once with 2 times the weight of water, use a vacuum drum filter to dehydrate, the dry basis of CaCO 3 The content is 97.4 and the NaCl content is 0.73. Prepare a slurry with a solid content of 10%, then add citric acid (purity ≥ 97%) with a total weight of 0.2% of salt mud on a dry basis, and mix thoroughly to make a desulfurization absorbent slurry.

[0050] Using the electric power industry standard of the People's Republic of China ("Determination of the reaction rate of limestone powder for wet flue gas desulfurization" DL / T943-2005), the activity of calcium carbonate in the prepared slurry was tested. The test results show that when the conversion rate of calcium carbonate is 0.8, the consumption time is 56 minutes.

[0051] Desulfurize the flue gas produced by three 75t / h circulating fluidized bed boilers in a thermal power plant. The flue gas temperature is controlled at 145°C and the flow rate is contro...

Embodiment 3

[0053] Take the limestone flue gas method secondary salt mud, wash it twice with the same weight of water, use a vacuum drum filter to dehydrate, and the CaCO in the dry basis 3 The content is 97.2, and the NaCl content is 0.74. Prepare a slurry with a solid content of 15%, then add 0.2% citric acid (purity ≥ 97%) in total dry weight of salt mud, and mix thoroughly to make a desulfurization absorbent slurry.

[0054] Using the electric power industry standard of the People's Republic of China ("Determination of the reaction rate of limestone powder for wet flue gas desulfurization" DL / T943-2005), the activity of calcium carbonate in the prepared slurry was tested. The test results show that when the conversion rate of calcium carbonate is 0.8, the consumption time is 51 minutes.

[0055] Desulfurize the flue gas produced by three 75t / h circulating fluidized bed boilers in a thermal power plant. The flue gas temperature is controlled at 145°C and the flow rate is controlled at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com