Roasting filler prepared by recycling carbon product production waste and method

A technology for carbon products and waste production, applied in the field of roasting fillers, can solve the problems of investing in environmental protection purification facilities, hazardous waste, high energy consumption, etc., and achieve the effects of high reuse value, lower production costs, and easy access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

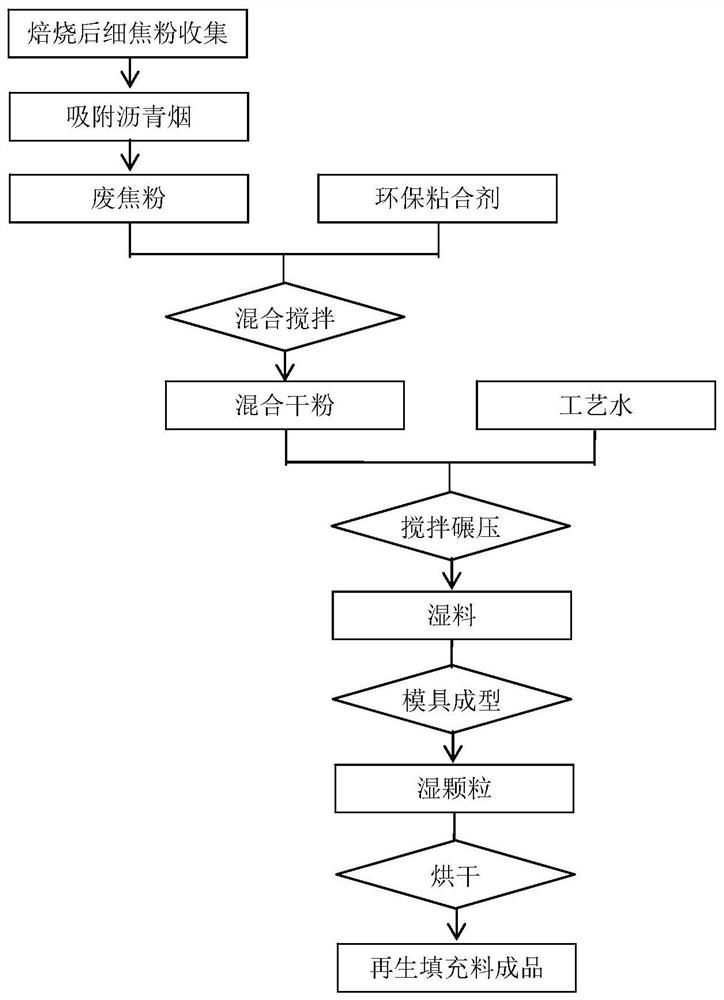

Image

Examples

Embodiment 1

[0030] The fine metallurgical coke powder separated from the filling material collected by the dust collecting crane above the roasting furnace in the roasting workshop is transported to the adsorption purification system by pneumatic conveying to absorb asphalt smoke, and the waste coke powder is separated by a bag filter After testing, the mass content of asphalt smoke solidification in this batch of waste coke powder is 25%. After the waste coke powder is discharged from the adsorption purification system, it is transported to the preparation powder bin of the regeneration preparation workshop by a pneumatic conveying system. Take 200kg of waste coke powder, add 5.2kg of an environmentally friendly adhesive, mix and stir for about 20 minutes, and wait until it is uniform to obtain Mix the dry powder, inject about 40L of process water evenly into it, stir and roll it with a mechanical wheel, so that the mixture of waste coke powder and environmental protection adhesive and pr...

Embodiment 2

[0033] The fine metallurgical coke powder separated from the filling material collected by the dust collecting crane above the roasting furnace in the roasting workshop is transported to the adsorption purification system by pneumatic conveying to absorb asphalt smoke, and the waste coke powder is separated by a bag filter After testing, the mass content of asphalt smoke solidification in this batch of waste coke powder was 13%. After the waste coke powder is discharged from the adsorption purification system, it is transported to the preparation powder silo of the regeneration preparation workshop by a pneumatic conveying system. Take 200kg of waste coke powder, add 5kg of environmentally friendly adhesive, mix and stir for about 20 minutes, and mix after being uniform For dry powder, about 40L of process water is evenly injected into it, stirred and rolled by a mechanical wheel, so that the mixture of waste coke powder and environmental protection adhesive and process water m...

Embodiment 3

[0036] The fine metallurgical coke powder separated from the filling material collected by the dust collecting crane above the roasting furnace in the roasting workshop is transported to the adsorption purification system by pneumatic conveying to absorb asphalt smoke, and the waste coke powder is separated by a bag filter After testing, the mass content of asphalt smoke solidification in this batch of waste coke powder was 50%. After the waste coke powder is discharged from the adsorption purification system, it is transported to the preparation powder silo of the regeneration preparation workshop by a pneumatic conveying system. Take 200kg of waste coke powder, add 6kg of environmentally friendly adhesive, mix and stir for about 20 minutes, and mix after being uniform For dry powder, about 40L of process water is evenly injected into it, stirred and rolled by a mechanical wheel, so that the mixture of waste coke powder and environmental protection adhesive and process water m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com