Method for separating triterpene alcohols and sterols from rice bran crude sterols

A technology of triterpene alcohols and sterols, which is applied in the field of rice bran crude sterols, can solve the problems of rice bran crude sterol resources such as idleness, discarding, and environmental pollution, and achieve the effects of realizing waste recycling, solving solid waste treatment problems, and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

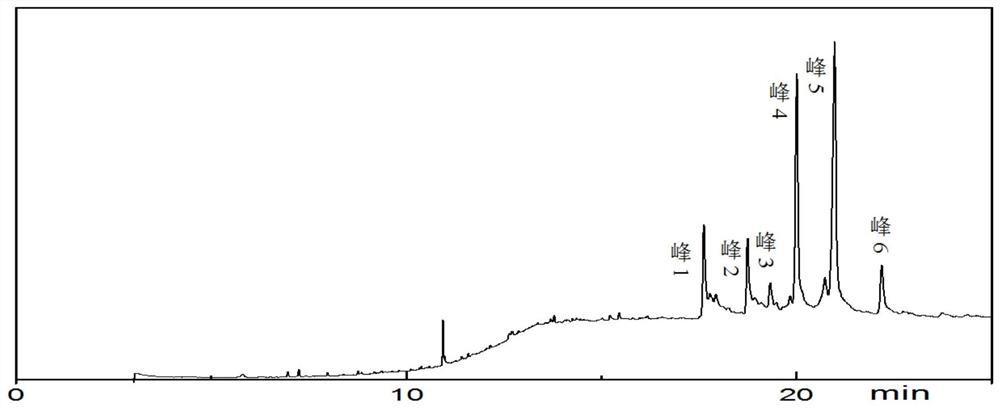

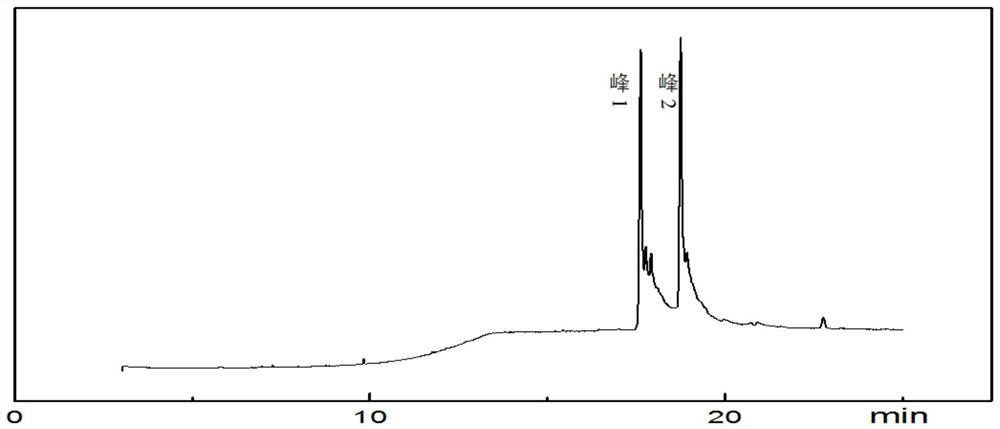

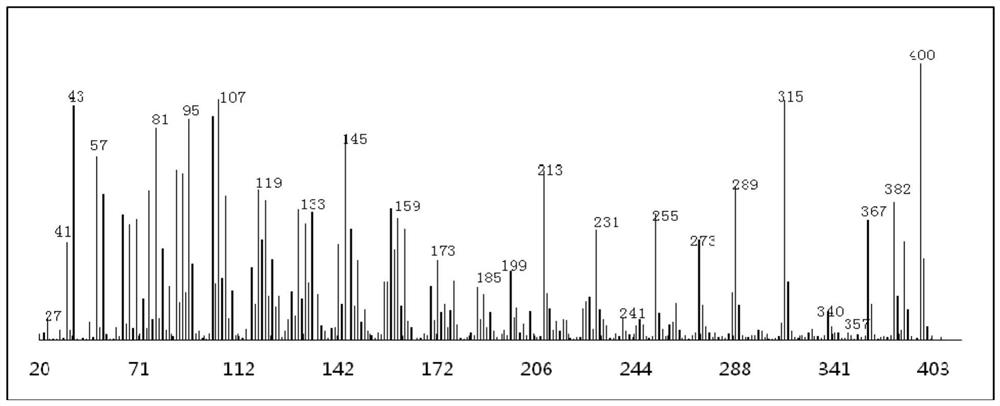

Image

Examples

Embodiment 1

[0041] Embodiment 1: a kind of method for separating sterol and triterpene alcohol from rice bran crude sterol, comprises the following steps:

[0042] 1) Saponification: Mix 1g of rice bran crude sterol with 100ml of ethanol and 1.4g of potassium hydroxide, ultrasonically decompose it at 40KHZ for 10min, put it into a flask and heat it to reflux for about 6h under the protection of nitrogen to obtain a saponified solution.

[0043] 2) Extraction: Open the reflux device immediately after saponification, continue heating, and evaporate about half of the ethanol. After evaporating and concentrating, 100ml of water was added, and then extracted several times with diethyl ether, and the organic solvent layers were combined to obtain the extract.

[0044] 3) Neutralization and evaporation: adding 25% dilute hydrochloric acid to the extract to make the pH after neutralization 7, then washing with water to separate the liquid, evaporating and spin-drying to obtain unsaponifiable prod...

Embodiment 2

[0068] Embodiment 2: a kind of method for separating sterol and triterpene alcohol from rice bran crude sterol, comprises the following steps:

[0069] 1) Saponification: Mix 1 g of rice bran crude sterol with 100 ml of ethanol and 1.4 g of potassium hydroxide, ultrasonically decompose it at 40 KHz for 10 min, and leave it at room temperature for about 24 h to obtain a saponified solution.

[0070] 2) Extraction: After saponification, heat the saponified solution to evaporate about half of the ethanol. After evaporating and concentrating, 100 ml of water was added, followed by repeated extraction with ethyl acetate, and the ethyl acetate layers were combined to obtain an extract.

[0071] 3) Neutralization and evaporation: adding 25% dilute hydrochloric acid to the extract to make the pH after neutralization 7, then washing with water to separate the liquid, evaporating and spin-drying to obtain unsaponifiable product C.

[0072] 4) Column separation: the unsaponifiable matte...

Embodiment 3

[0078] Embodiment 3: a kind of method for separating sterol and triterpene alcohol from rice bran crude sterol, comprises the following steps:

[0079] 1) Saponification: Mix 5 g of rice bran crude sterol with 500 ml of ethanol and 9 g of potassium hydroxide, ultrasonically decompose it at 40 KHz for 30 min, and leave it at room temperature for about 24 h to obtain a saponified solution.

[0080] 2) Extraction: After saponification, heat the saponified solution to evaporate about half of the ethanol. After evaporating and concentrating, 300ml of water was added, and then extracted several times with ethyl acetate, and the ethyl acetate layers were combined to obtain an extract.

[0081] 3) Neutralization and evaporation: adding 25% dilute hydrochloric acid to the extract to make the pH after neutralization 7, then washing with water to separate the liquid, evaporating and spin-drying to obtain unsaponifiable product C.

[0082] 4) Column separation: the unsaponifiable matter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com