Method for extracting vanadium by stone coal through acid leaching

A technology of stone coal acid and stone coal, which is applied in the field of vanadium extraction from stone coal acid leaching, can solve the problems of difficult extraction phase separation, high solution viscosity, and large reagent consumption, and achieve high comprehensive utilization of resources, high grade, and high processing efficiency. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

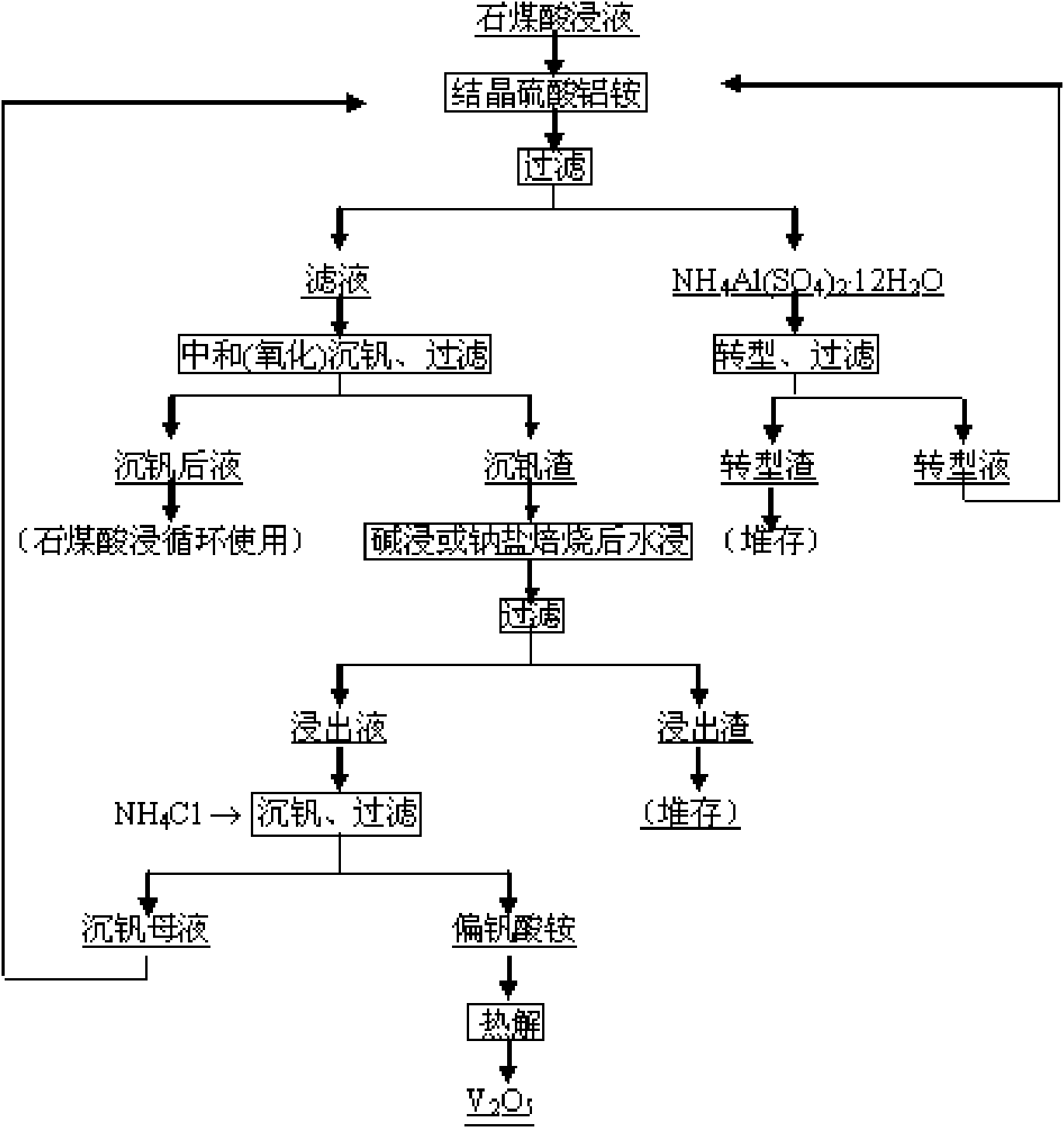

Image

Examples

Embodiment 1

[0023] 2500g contains vanadium (V 2 o 5 ) 1.08% stone coal is crushed and then stirred with water at a solid-to-liquid ratio of 1: 1.2g / ml, then added 270ml of concentrated sulfuric acid at 95°C for leaching for 36 hours and filtered to obtain vanadium-containing (V 2 o 5 ) 3000ml of leaching solution of 6.12g / L, add ammonia water to the leaching solution to adjust the pH value to 0.5, crystallize and separate out aluminum ammonium sulfate NH 4 Al(SO 4 ) 2 12H 2 O crystals, after crystallization, add NaOH to the liquid to neutralize until the pH value reaches 4.5, precipitate and precipitate vanadium-containing slag and filter, and the vanadium-precipitated slag is formed according to the formation of NaVO 3 Add NaCl and Na to twice the stoichiometric number of roasting reactions 2 CO 3 Mix the mixture with a molar ratio of 1:1, mix well and roast at 800°C for 1.5 hours, add water to the calcined sand at a solid-to-liquid ratio of 1:2g / ml and stir at 80°C for 1 hour, ad...

Embodiment 2

[0025] 2500g contains vanadium (V 2 o 5 ) 1.08% stone coal is crushed and then added 270ml of concentrated sulfuric acid and mixed thoroughly and roasted at 250°C for 2 hours, and the calcined sand is added in Example 1 at a solid-to-liquid ratio of 1: 1.2g / ml to neutralize the vanadium-precipitated liquid at 95°C for 1.5 hours and filter. Get vanadium (V 2 o 5 ) 6.79g / L leach solution 3100ml, the leach solution is NH 4 Al(SO 4 ) 2 12H 2 Adding 1.5 times the stoichiometric number of O crystal precipitation (NH 4 ) SO 4 , to remove aluminum by crystallization, and add CaCO to the liquid after crystallization 3 Neutralize until the pH value reaches 2.5 and filter, add hydrogen peroxide to the filtrate to oxidize and precipitate, and filter the vanadium residue according to the formation of NaVO 3 NaOH was added to twice the stoichiometric number, the solid-to-liquid ratio was 1:2g / ml, stirred and leached at 80°C for 2.0 hours, and NH was added to the leach solution at 1...

Embodiment 3

[0027] 1000g contains vanadium (V 2 o 5 ) 1.08% of the stone coal is crushed and press solid-liquid ratio 1: 1.2g / ml embodiment 2 to neutralize the liquid after vanadium precipitation, add 110ml concentrated sulfuric acid oxygen pressure 165 ℃ of leaching for 3 hours and filter again, obtain vanadium-containing (V 2 o 5 ) 8.61g / L leachate 985ml, the leachate adds NaOH and the NH that embodiment 2 obtains 4 Al(SO 4 ) 2 12H 2 After the transformation of O, the pH value of the liquid is adjusted to 1.5, and aluminum ammonium sulfate NH is crystallized. 4 Al(SO 4 ) 2 12H 2 O crystal, add Na to the liquid after crystallization 2 CO 3 Neutralize until the pH value reaches 3.5, blow air, oxidize, precipitate, precipitate vanadium-containing slag, filter, and form NaVO 3 Add Na to 1.5 times the stoichiometric number of roasting reactions 2 CO 3 After mixing well, roast at 750°C for 3 hours, add water to the calcined sand at a solid-to-liquid ratio of 1:3g / ml and stir at 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com