Method for recycling and treating electroplating wastewater

A treatment method and technology for electroplating wastewater, which are applied in the fields of metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of low recycling rate of electroplating wastewater, increased discharge, and large energy consumption, so as to avoid pollution. and harm, realize the effect of energy saving and emission reduction, and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

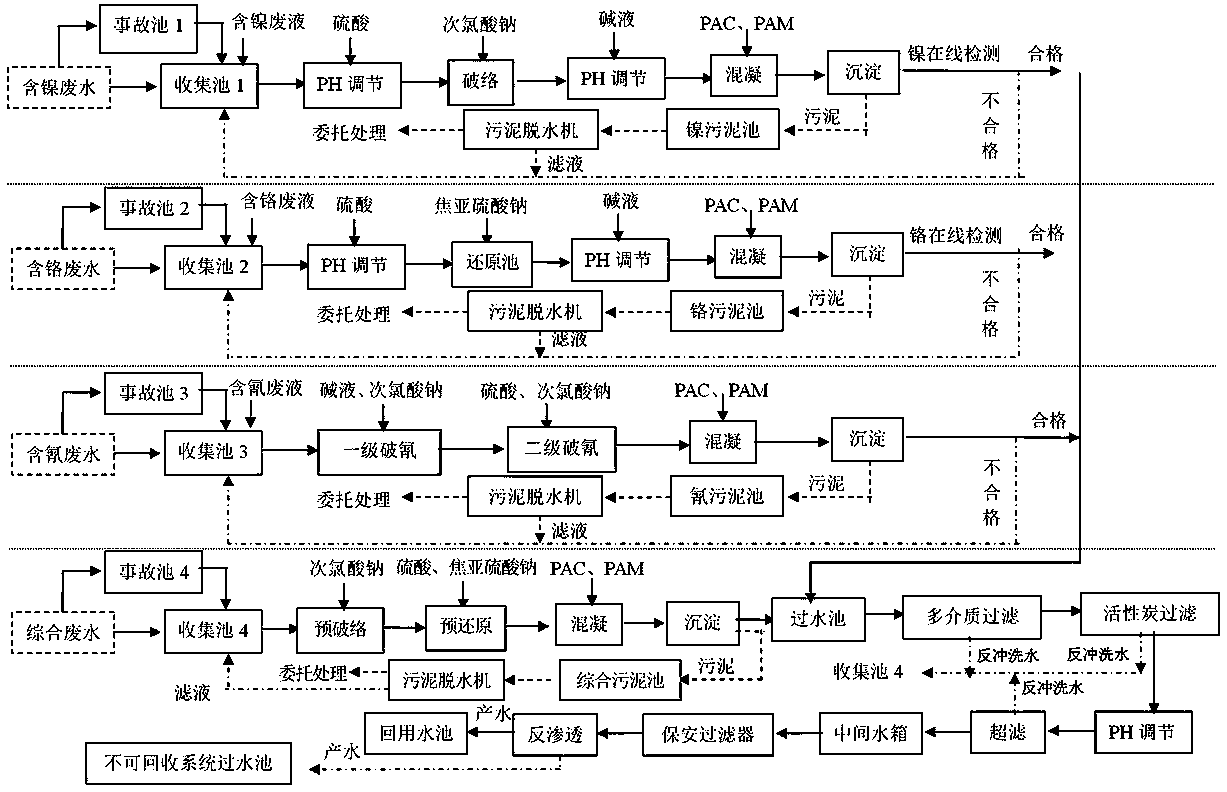

[0032] Such as figure 1 Shown: This embodiment is a recycling treatment method for electroplating wastewater, including: nickel-containing wastewater treatment process, chromium-containing wastewater treatment process, cyanide-containing wastewater treatment process, comprehensive wastewater treatment process and wastewater reuse treatment process.

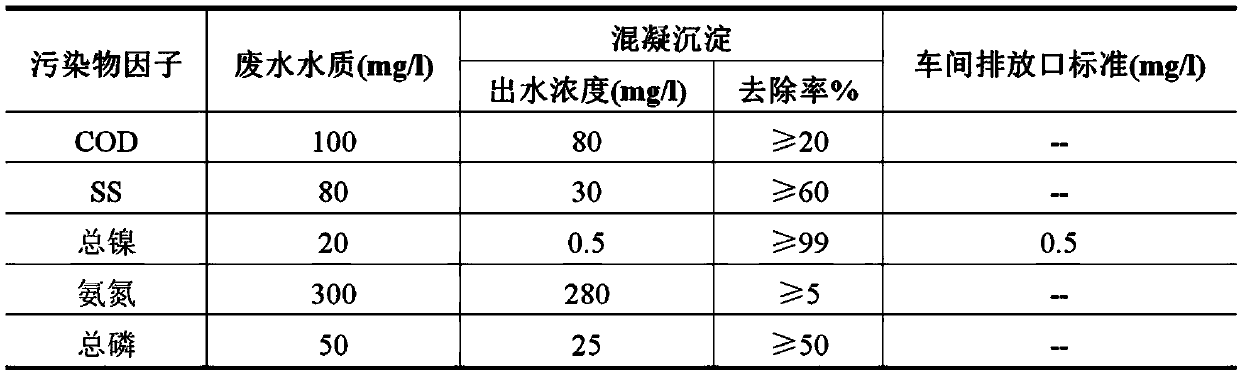

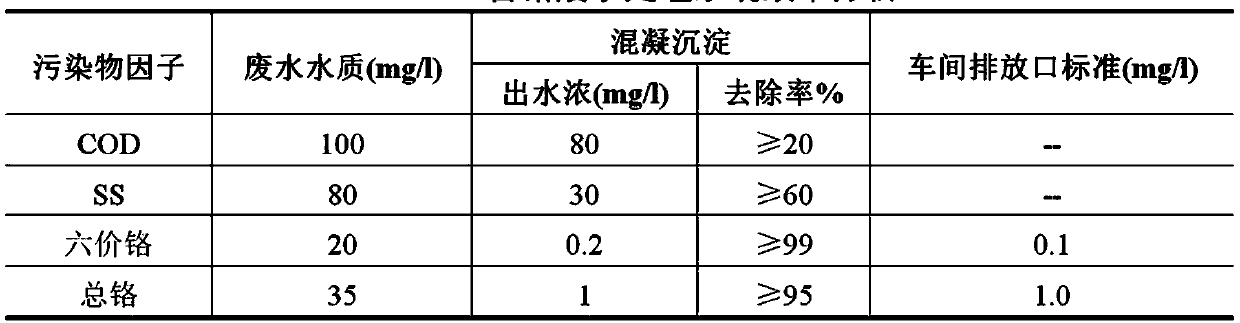

[0033] The nickel-containing wastewater treatment process includes firstly transporting the nickel-containing wastewater to the nickel-containing wastewater collection pool, after uniformly diluting the water quality and quantity, raising the nickel-containing wastewater to the nickel-containing wastewater adjustment pool, adding sulfuric acid to make it acidic, and then adding a strong oxidant sodium hypochlorite Oxidize complex nickel, simultaneously oxidize hypophosphite and phosphite into orthophospha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com