Method for producing metallurgical grade alumina by using fly ash

A technology for the production of metallurgy and fly ash, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of huge investment, doubled discharge of residual slag, and harsh equipment material requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

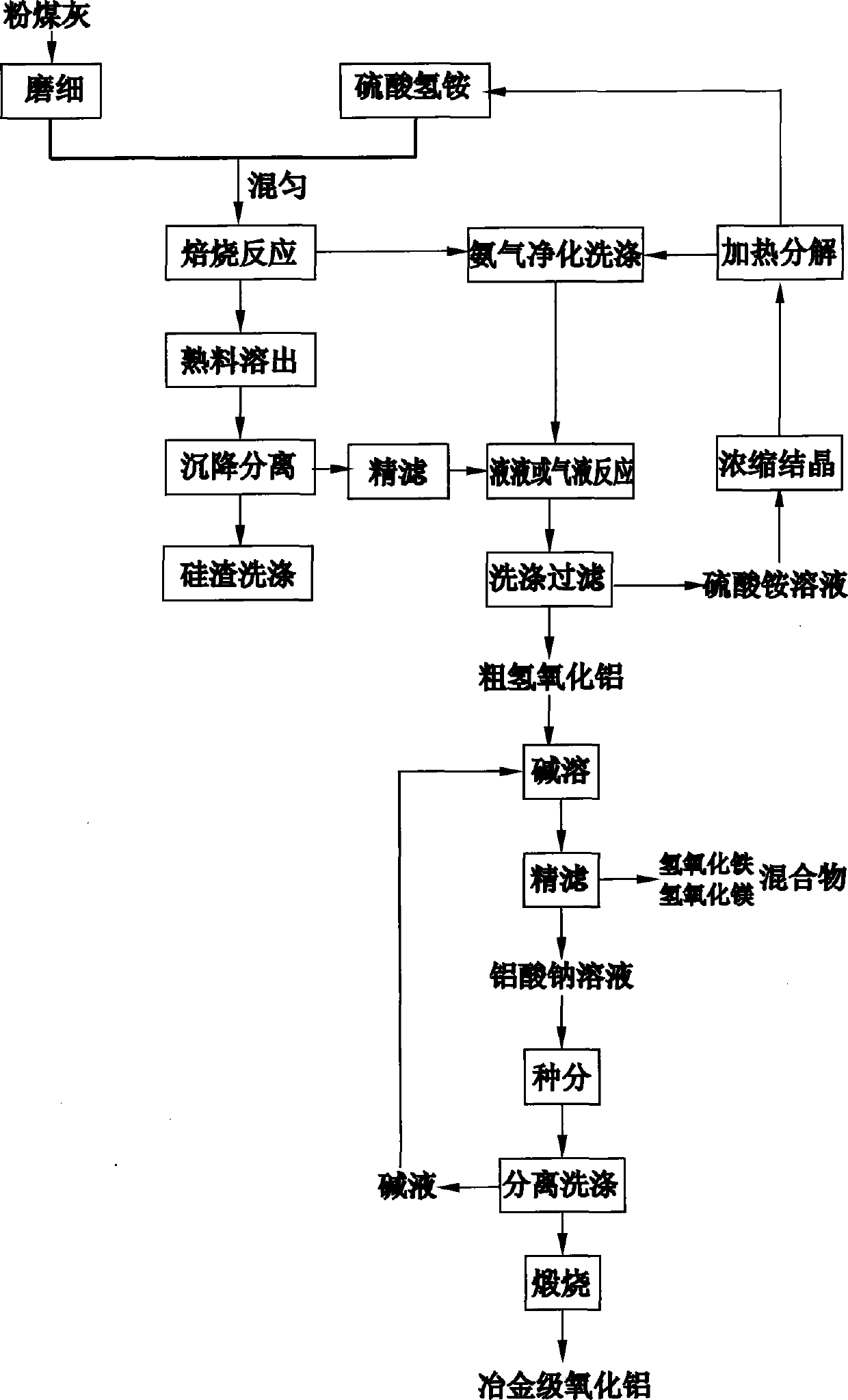

Image

Examples

Embodiment 1

[0035] The fly ash is ground to 325 mesh, and the molar ratio of alumina and ammonium bisulfate contained in the fly ash is Al 2 o 3 : NH 4 HSO 4 =1:5.3 ingredients, 390°C roasting for 2.5h, the calcined clinker is dissolved in a closed autoclave, the amount of water added is 5 times the clinker mass, the dissolution pressure is 0.3Mpa, and the dissolution time is 1h. The ammonium concentration is 0.47mol / L, and the aluminum content in the eluate is 86.7% of the total aluminum contained in the fly ash. After the dissolution, the obtained filtrate was slowly added dropwise to 7.5mol / L ammonia water at 50°C and 100r / min stirring conditions to pH = 8 to obtain aluminum hydroxide precipitate, which was washed and filtered to obtain crude aluminum hydroxide and ammonium sulfate solution, crude hydrogen Alkali-dissolved impurity removal, carbon content, and roasting are used to obtain metallurgical-grade alumina. The ammonium sulfate solution is evaporated and concentrated to obt...

Embodiment 2

[0037] The fly ash is ground to 400 mesh, according to the molar ratio of alumina and ammonium bisulfate in the fly ash 2 o 3 : NH 4 HSO 4 = 1: 6.1 ingredients, 440 ° C roasting 1.5h, the fired clinker is dissolved in a closed autoclave, the amount of water added is 4 times the clinker mass, the dissolution pressure is 0.25Mpa, and the dissolution time is 50min. The ammonium concentration is 0.52mol / L, and the aluminum content in the eluate is 84.7% of the total aluminum contained in the fly ash. In the above examples, the filtrate obtained after the fly ash and ammonium bisulfate roasted clinker was dissolved was slowly added dropwise with 11 mol / L ammonia water to pH=8.5 under 45°C and 260r / min stirring conditions to obtain aluminum hydroxide precipitate, which was washed Filtrate to obtain crude aluminum hydroxide and ammonium sulfate solution. The crude aluminum hydroxide is subjected to alkali dissolution to remove impurities, carbon content, and roasting to obtain met...

Embodiment 3

[0039] The fly ash is ground to 300 mesh, according to the molar ratio of alumina and ammonium bisulfate in the fly ash 2 o 3 : NH 4 HSO 4 = 1:4 ingredients, 420 ° C roasting for 2 hours, the calcined clinker is dissolved in a closed pressure vessel, the amount of water added is 3 times the clinker mass, the dissolution pressure is 1Mpa, and the dissolution time is 0.5h. The measured dissolution filtrate aluminum ammonium sulfate The concentration is 0.92mol / L, and the aluminum content in the stripping solution is 85.2% of the total aluminum content in the fly ash. In the above-mentioned examples, after the fly ash and ammonium bisulfate roasted clinker are dissolved, the filtrate obtained is slowly dripped with 4.5mol / L ammonia water at 55°C under stirring conditions of 350r / min to pH=9 to obtain aluminum hydroxide precipitation, which is passed through Wash and filter to obtain crude aluminum hydroxide and ammonium sulfate solution. The crude aluminum hydroxide is dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com