Patents

Literature

72results about How to "Desired thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

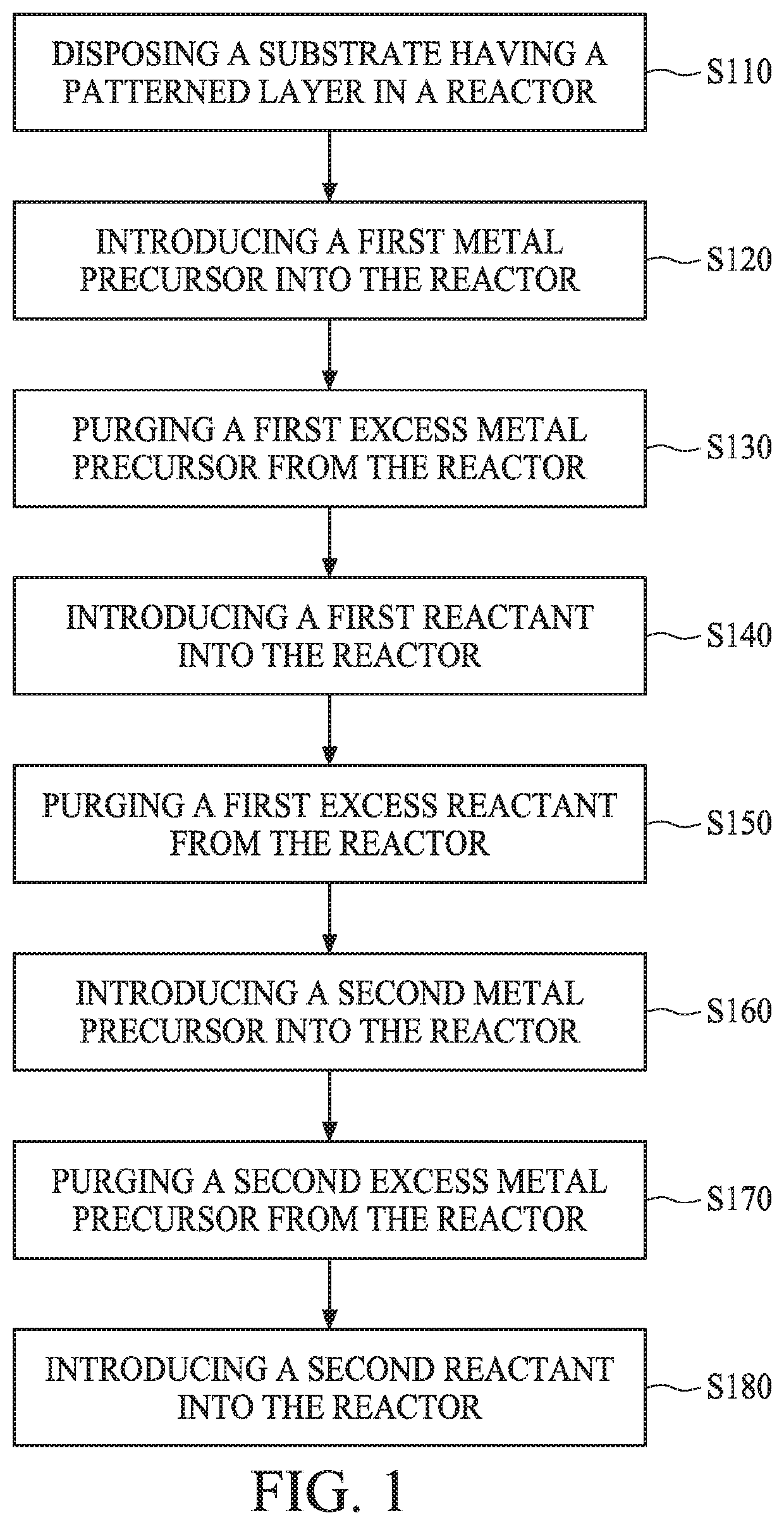

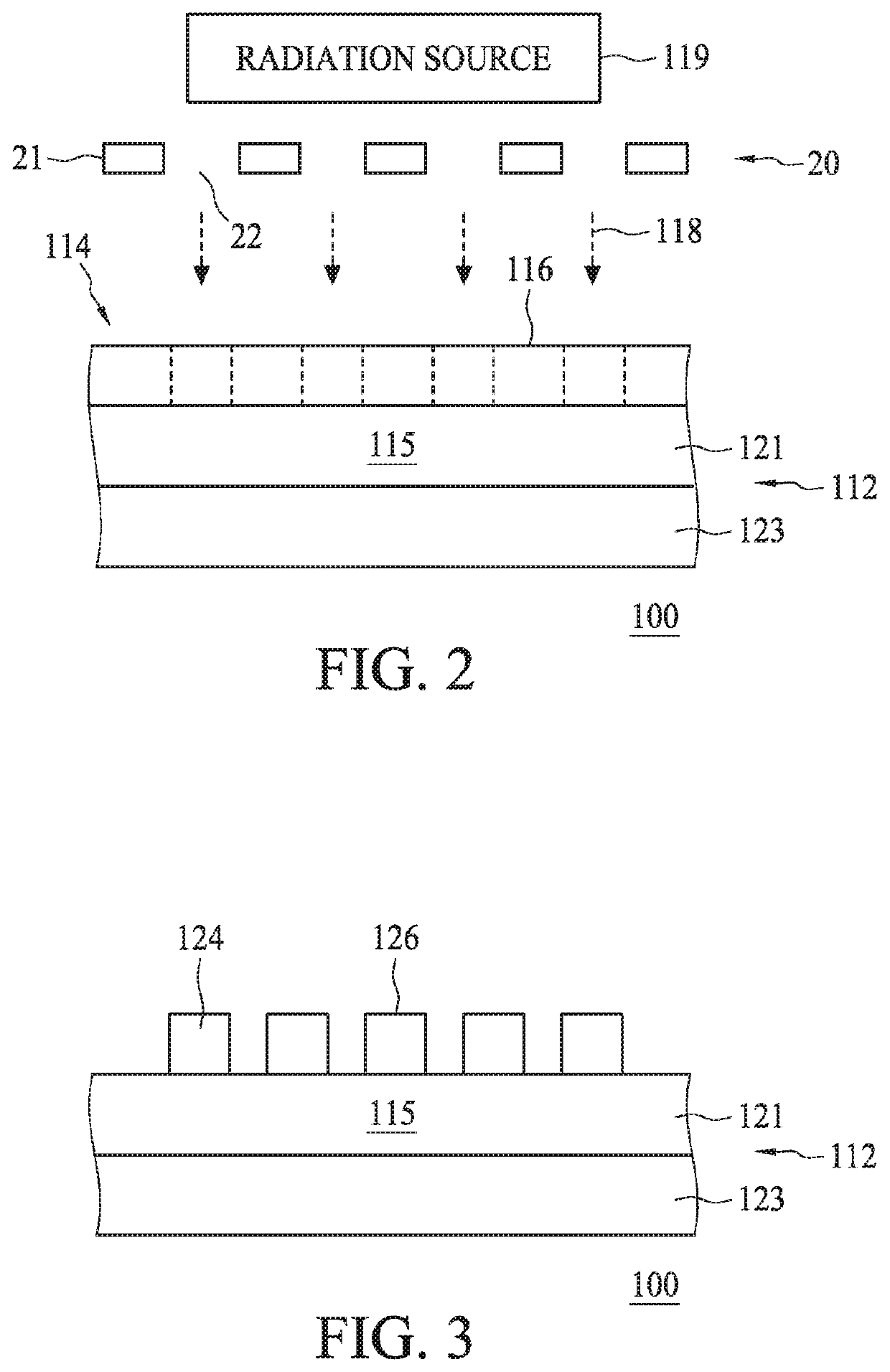

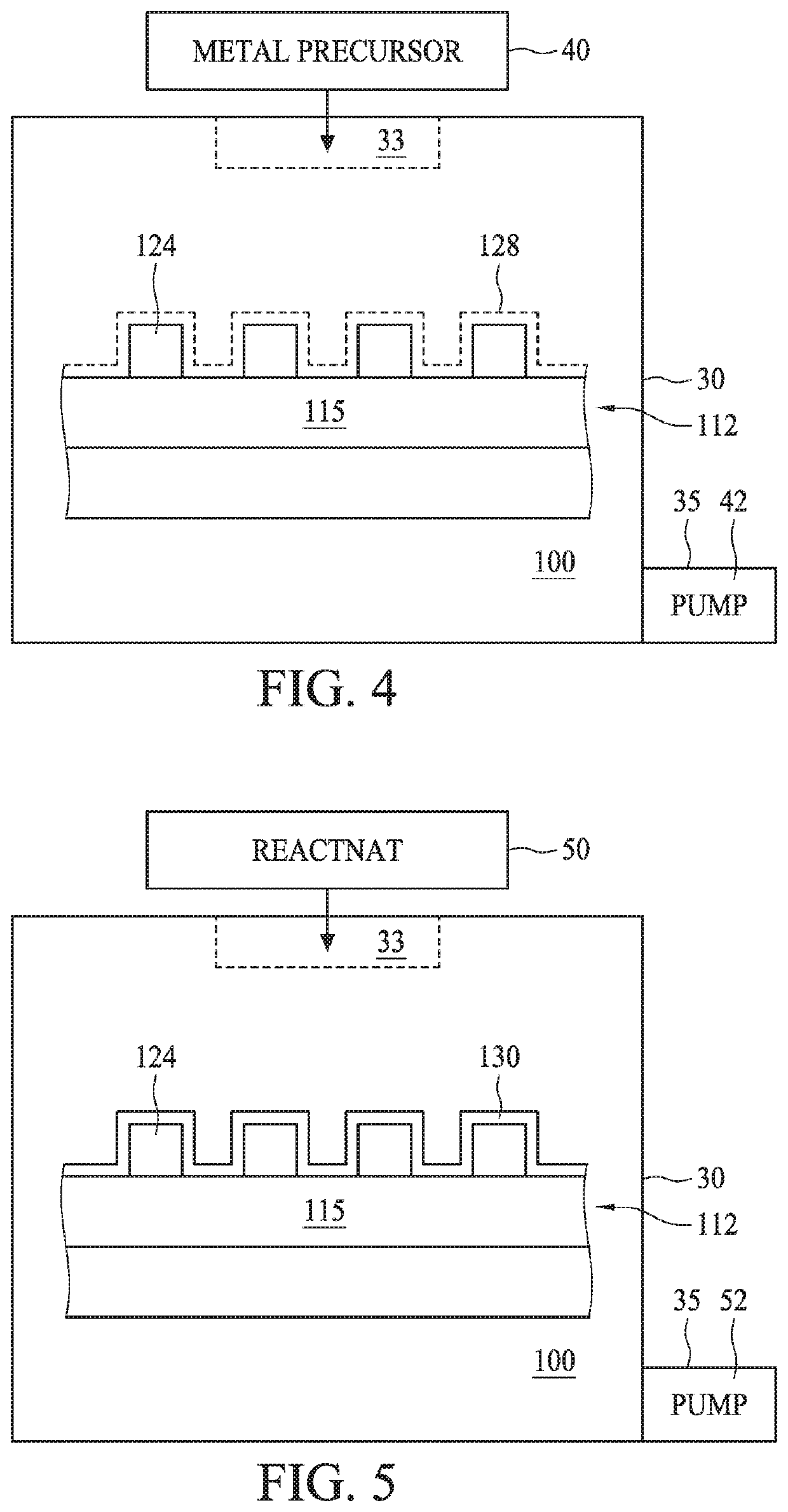

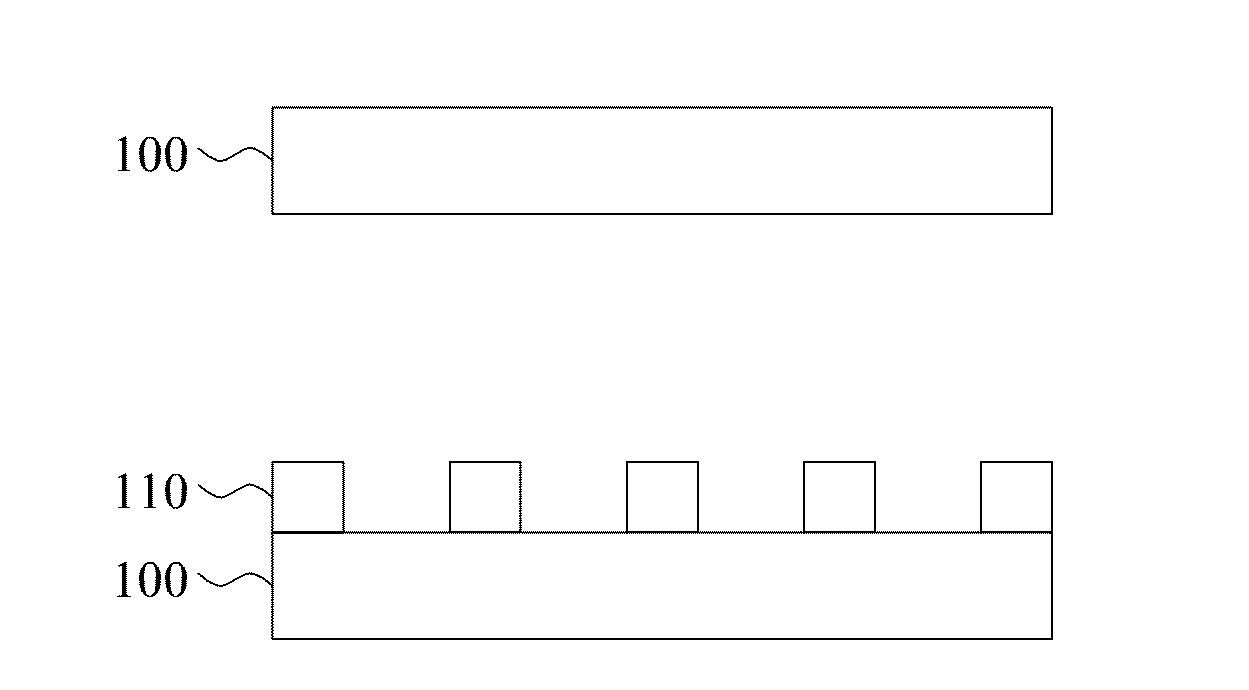

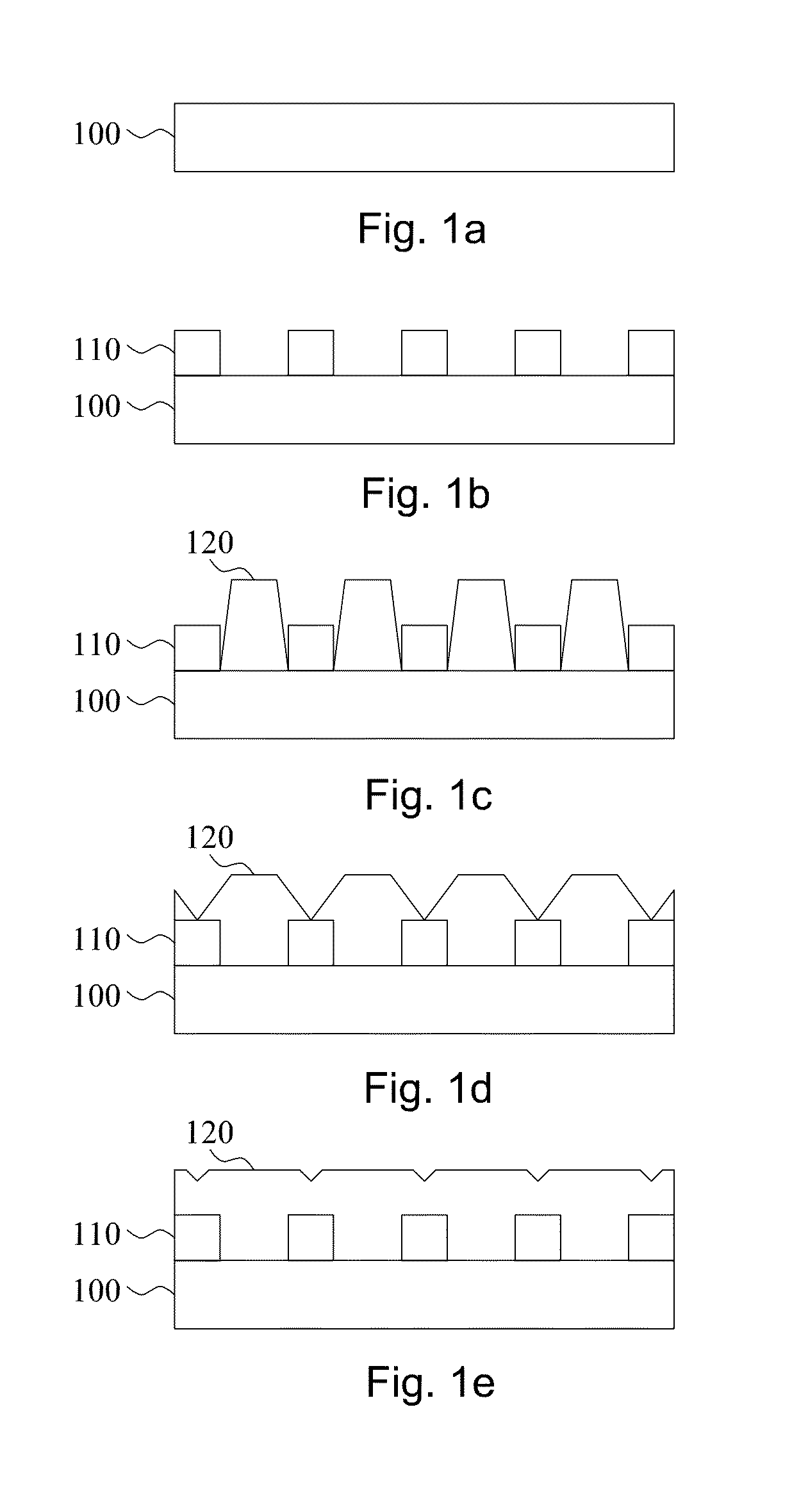

Method for preparing multiplayer structure

InactiveUS20200203157A1Desired thicknessImprove adsorption capacitySemiconductor/solid-state device manufacturingPhotomechanical coating apparatusReagentMetal

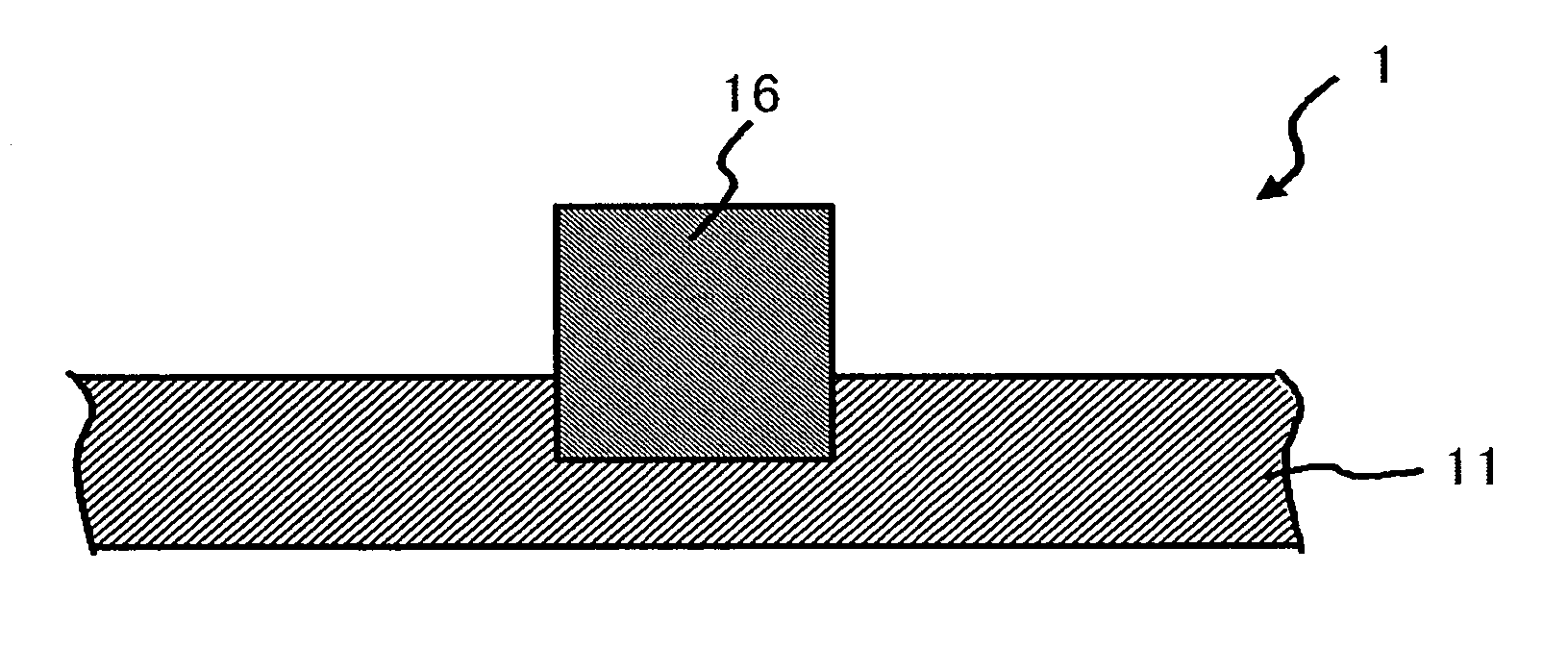

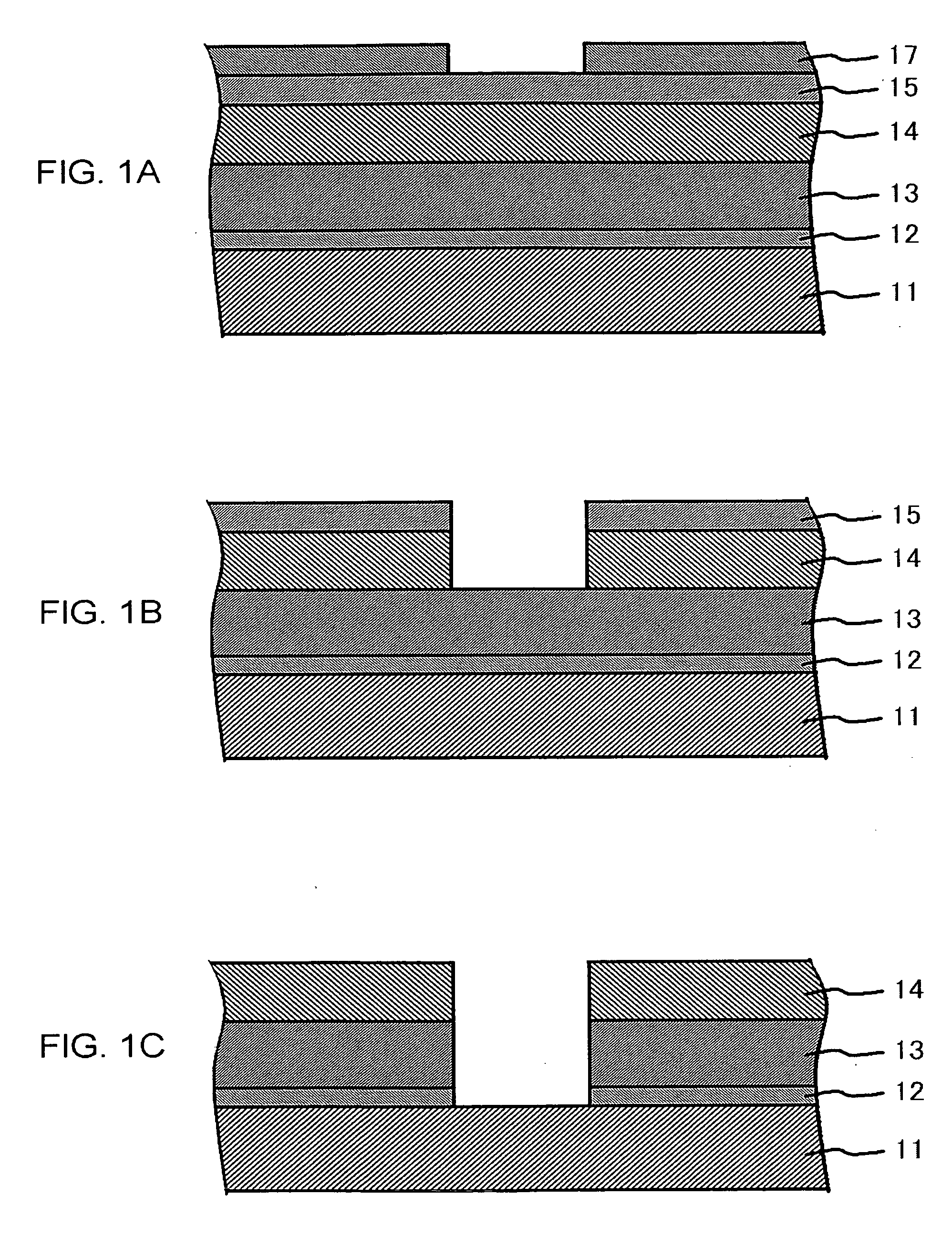

A method for preparing a multilayer structure includes the following steps. A substrate having a patterned layer is disposed in a reactor. A first metal precursor is introduced into the reactor. A first excess metal precursor is purged from the reactor by pumping out the first excess metal precursor. A first reactant is introduced into the reactor, wherein the first reactant reacts with the first metal precursor to form a first metal-containing layer on the patterned layer. A first excess reactant is purged from the reactor by pumping out the first to excess reactant. A second metal precursor is introduced into the reactor, wherein the second metal precursor is adsorbed on the first metal-containing layer. A second excess metal precursor is purged from the reactor by pumping out the second excess metal precursor. A second reactant is introduced into the reactor, wherein the second reactant reacts with the second metal precursor to form a second metal-containing layer on the first metal-containing layer.

Owner:NAN YA TECH

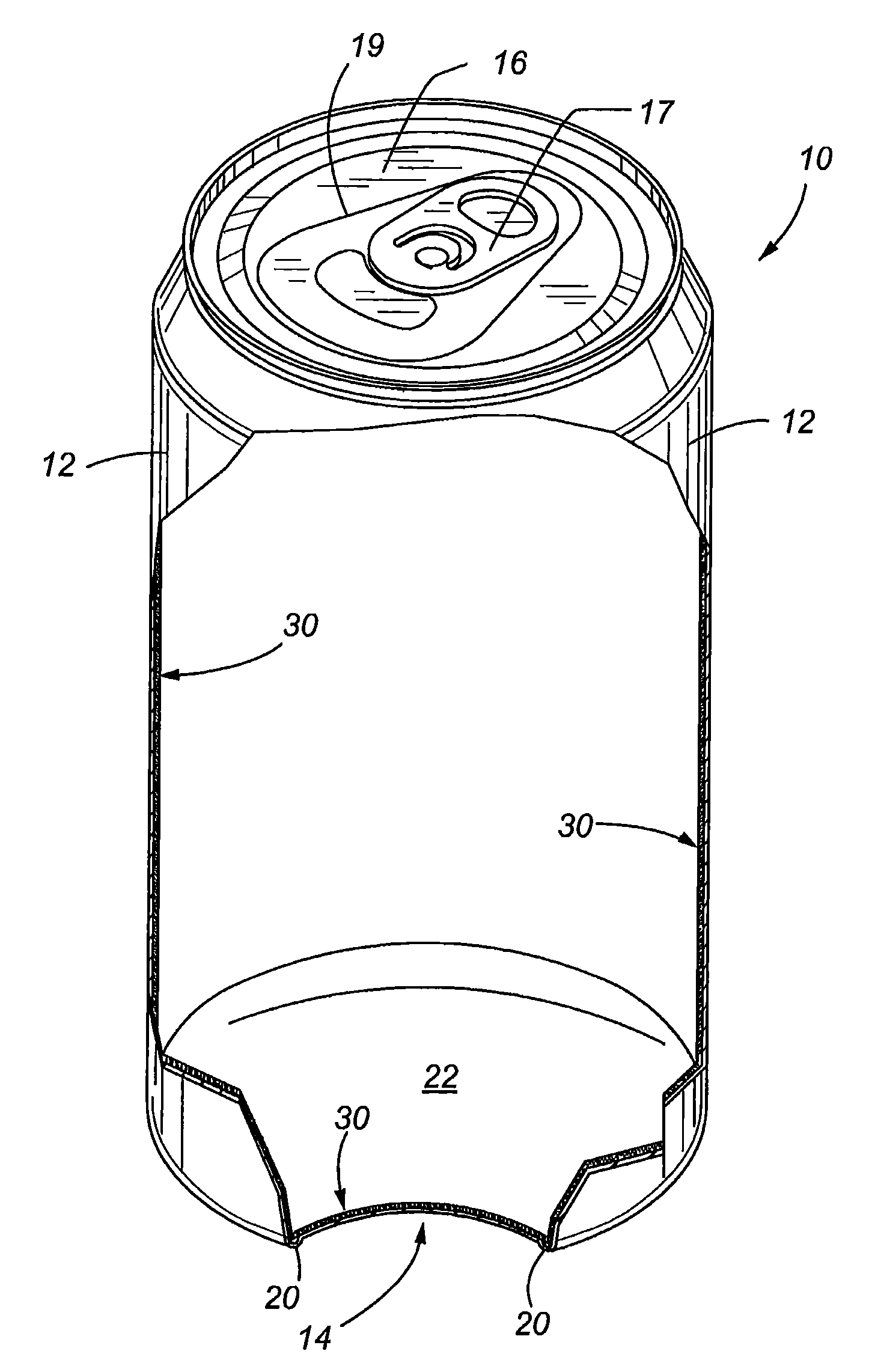

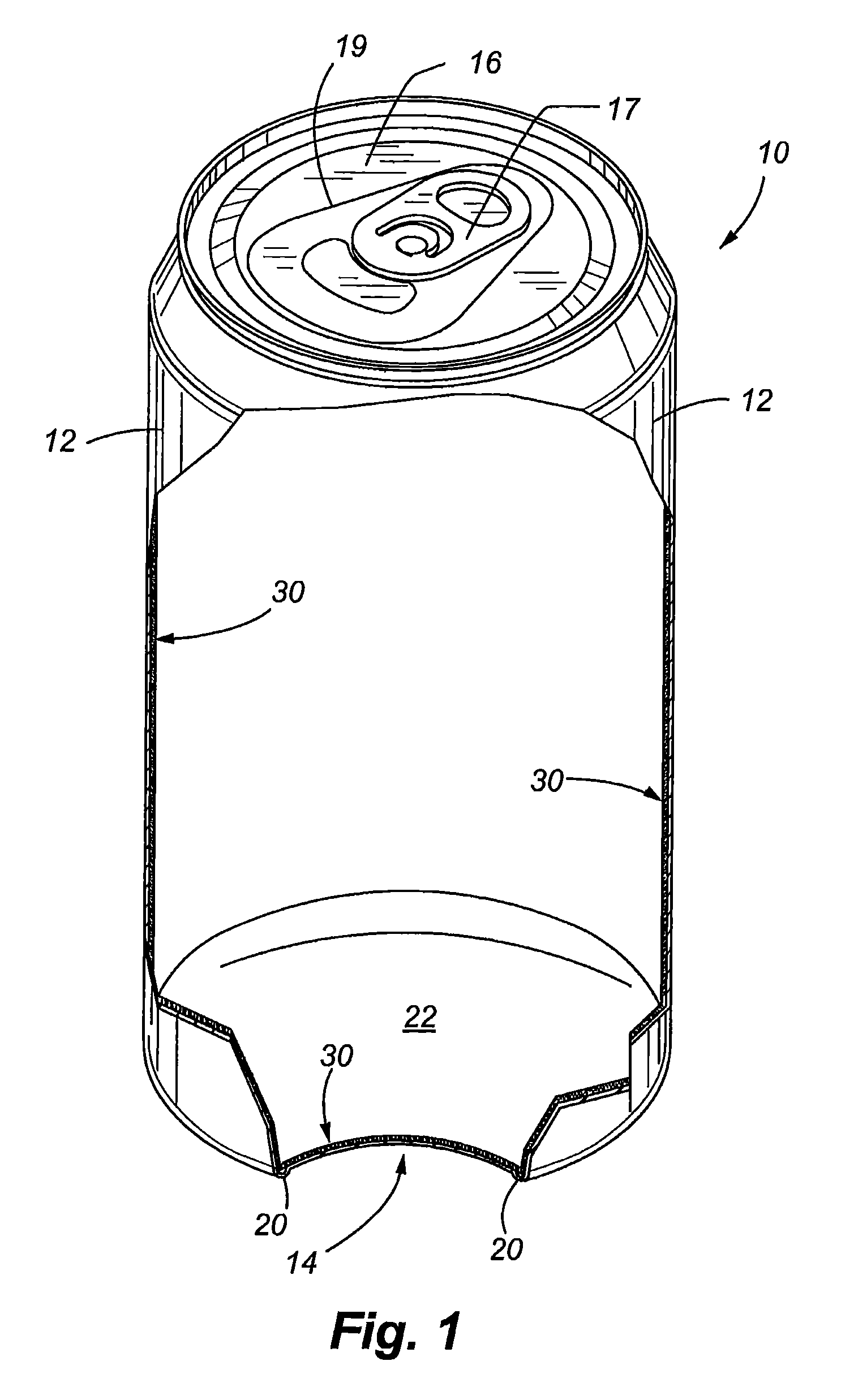

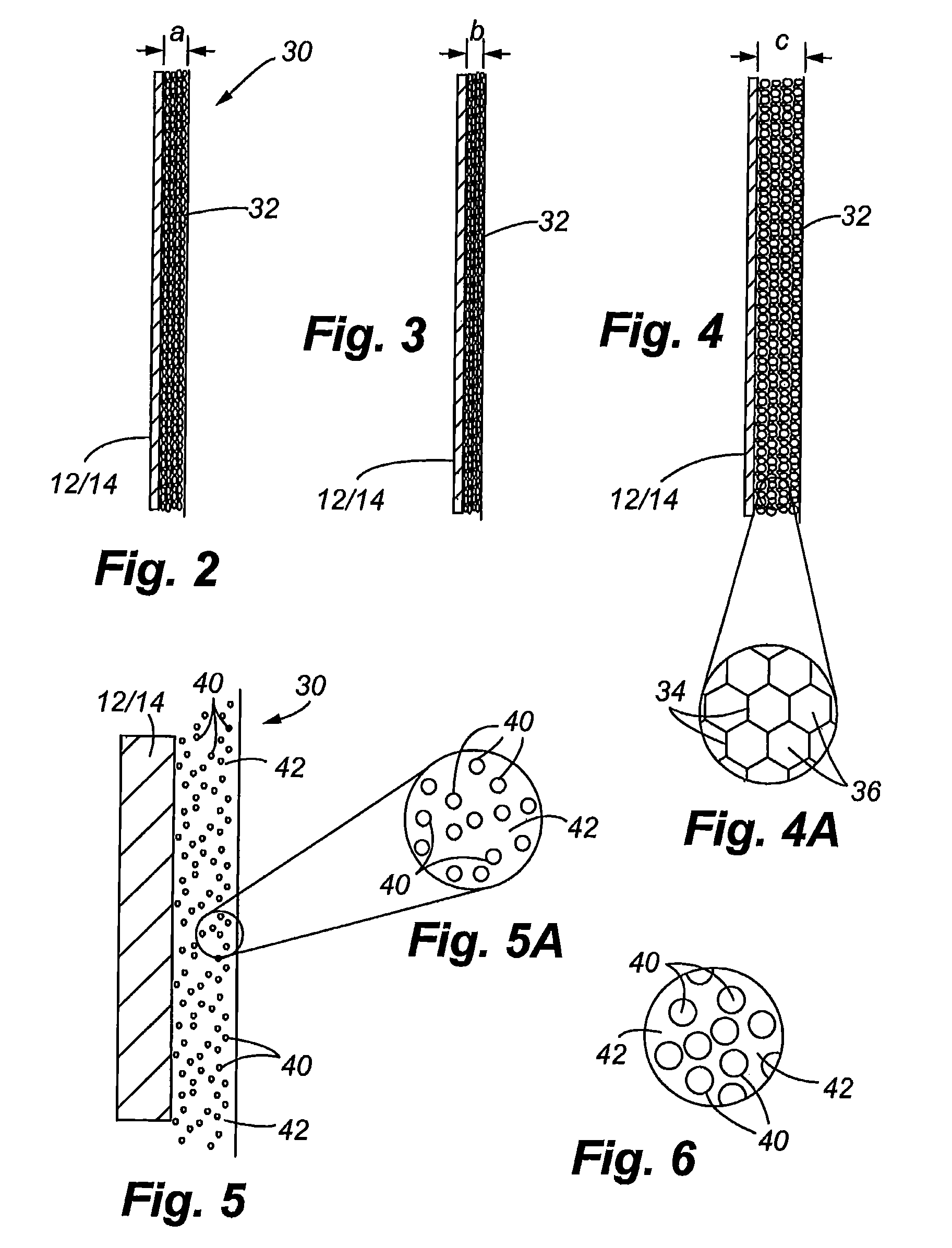

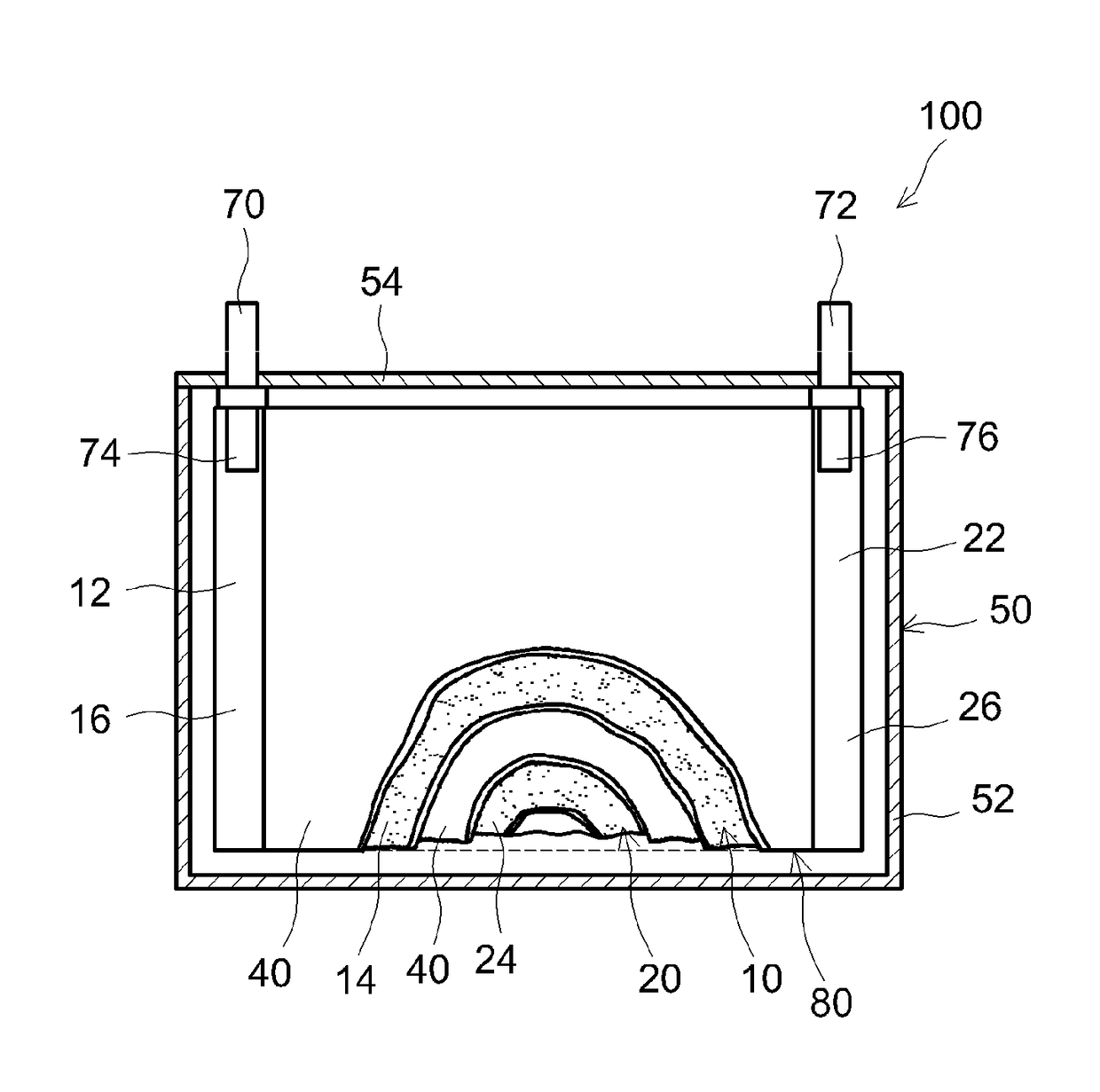

Thermal barrier liner for containers

ActiveUS8336729B2Effectively and safely keep beverages at a desired temperatureIncreased physical sizeDomestic cooling apparatusHeat storage plantsFoaming agentLiquid state

A thermal barrier liner is preferably spray coated onto the internal surface of a container. The liner is provided in embodiments including a closed cell substrate, a base layer having gas or liquid filled microcapsules, a base layer having microencapsulated solid-liquid phase change material, or combinations thereof. For the closed cell substrate embodiment, when the liner is under pressure within the container prior to the container being opened, the liner maintains a minimum thickness. When the container is opened and as pressure is released within the container, the liner expands to achieve equilibrium. The liner can be supplemented with a foaming agent to create cellular structures. Voids created by the microcapsules enhance the thermal barrier characteristics of the liner. The phase change material changes phase from a solid to a liquid state upon absorbing heat.

Owner:MILLERCOORS

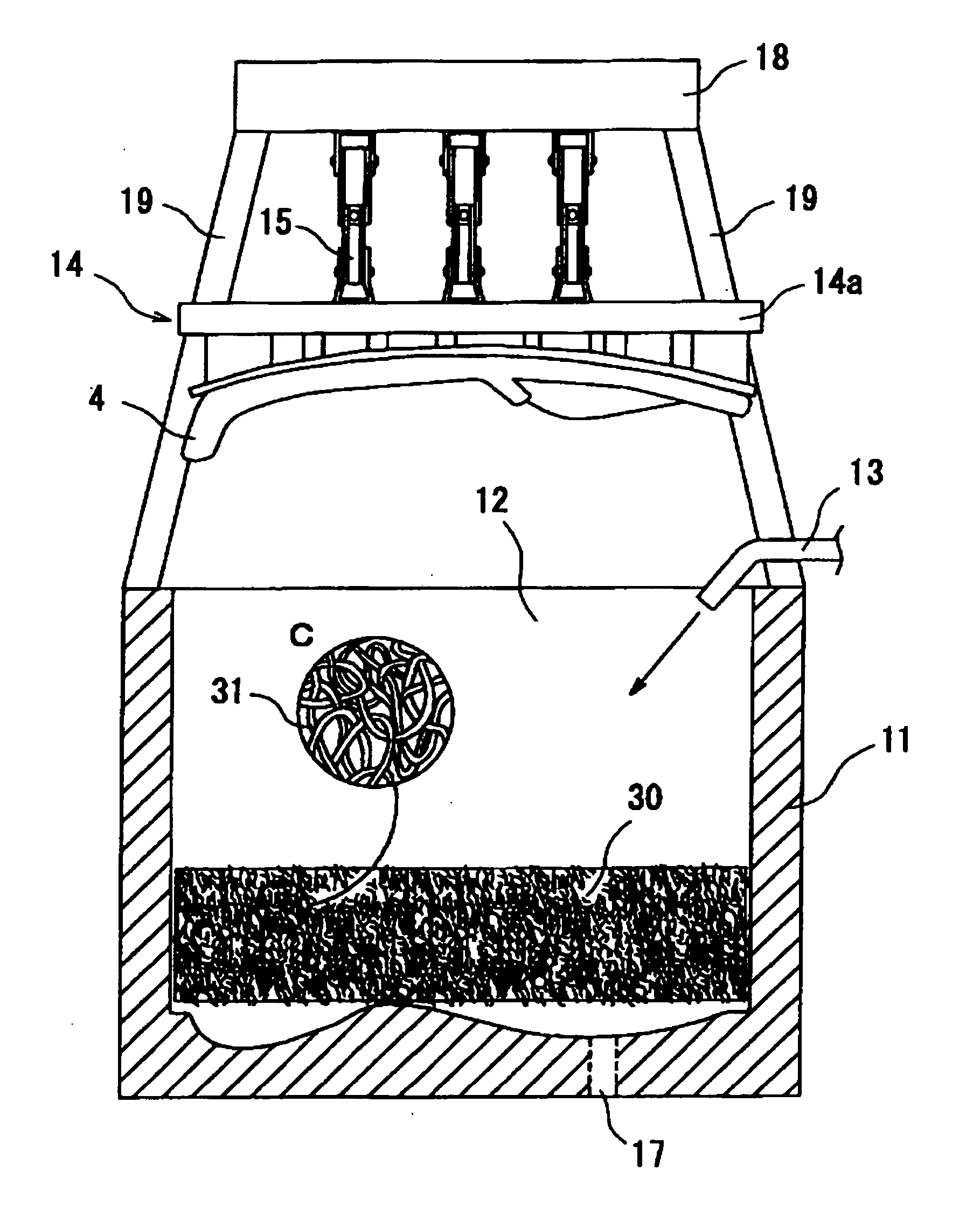

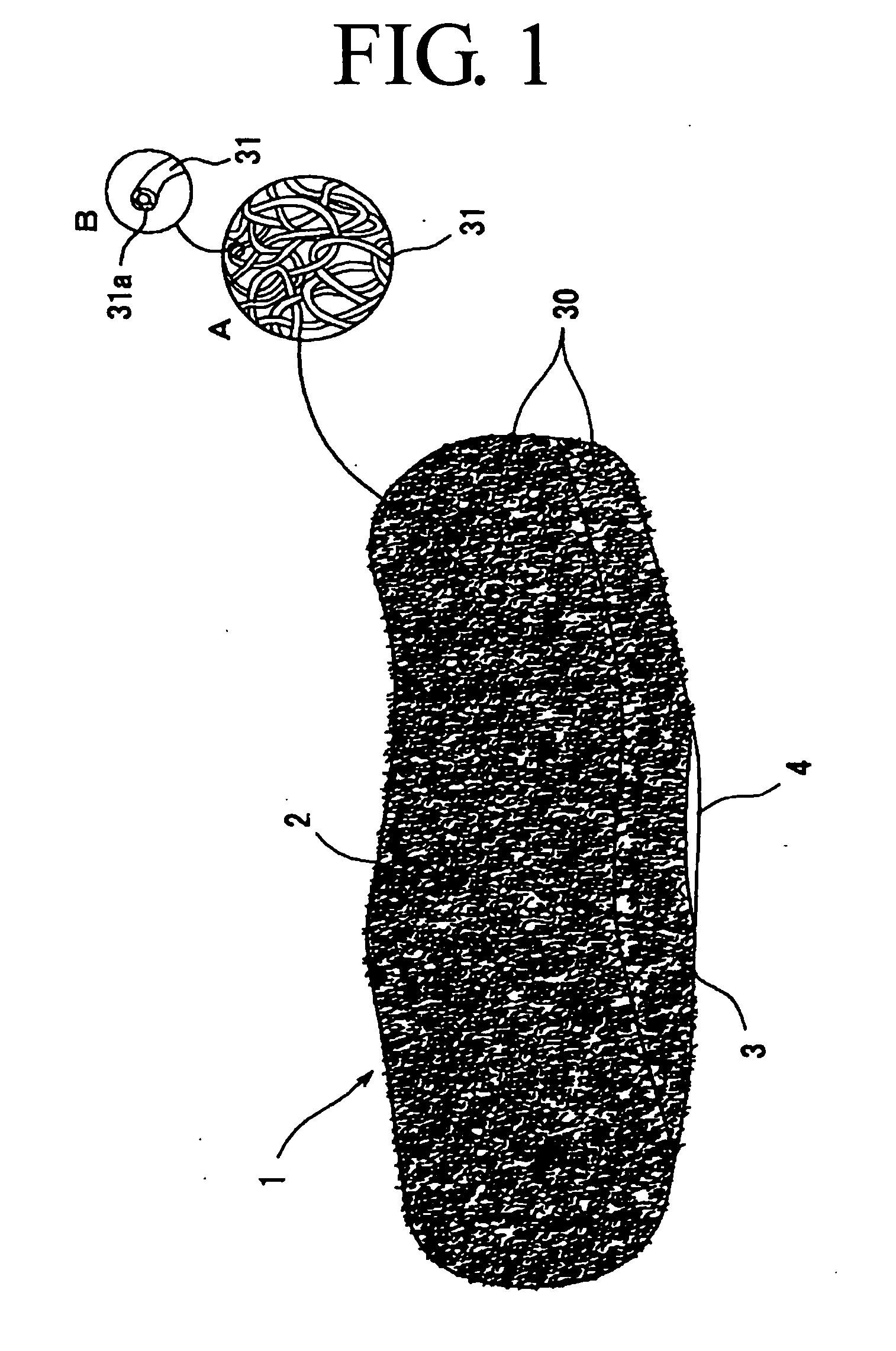

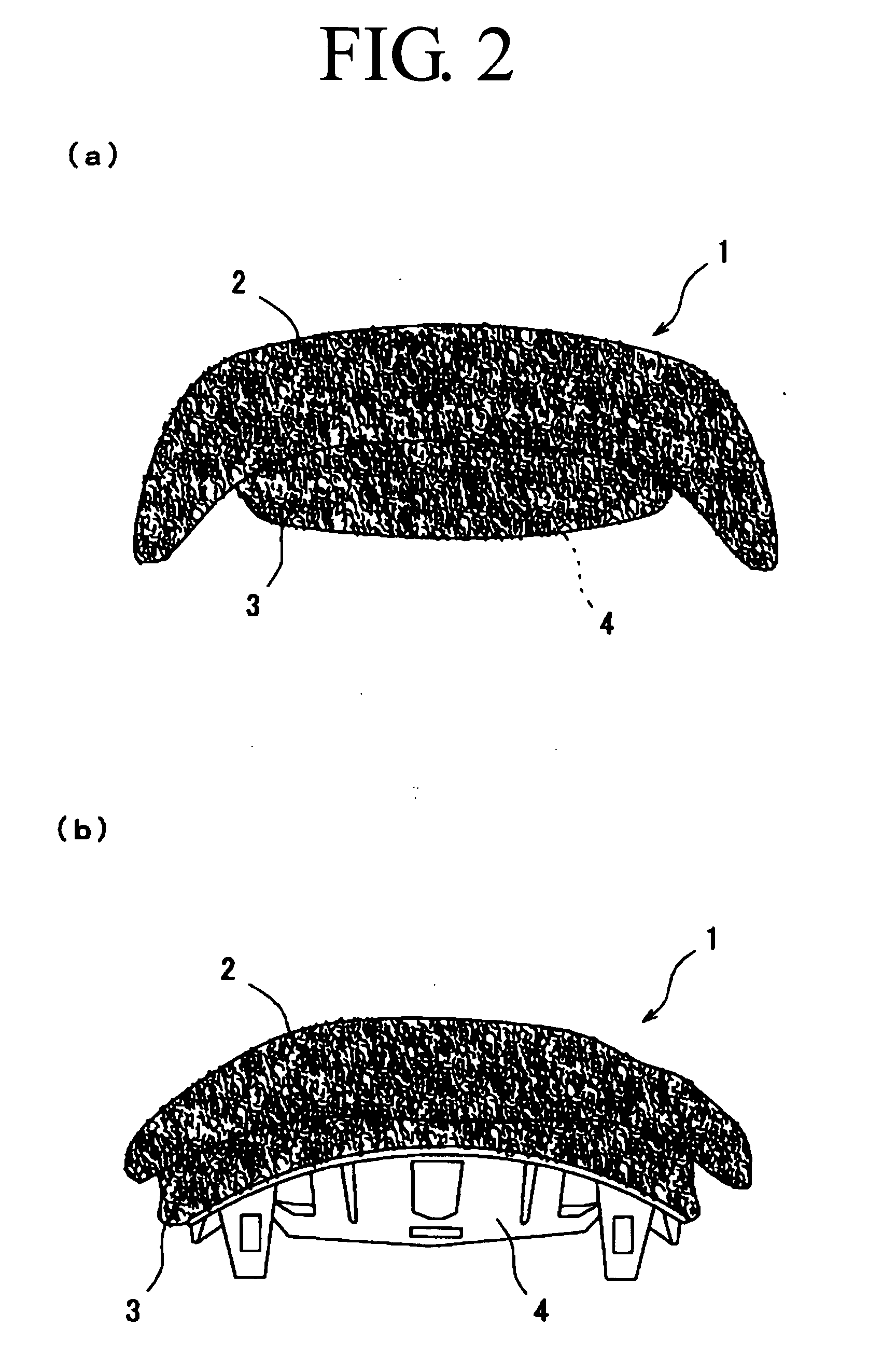

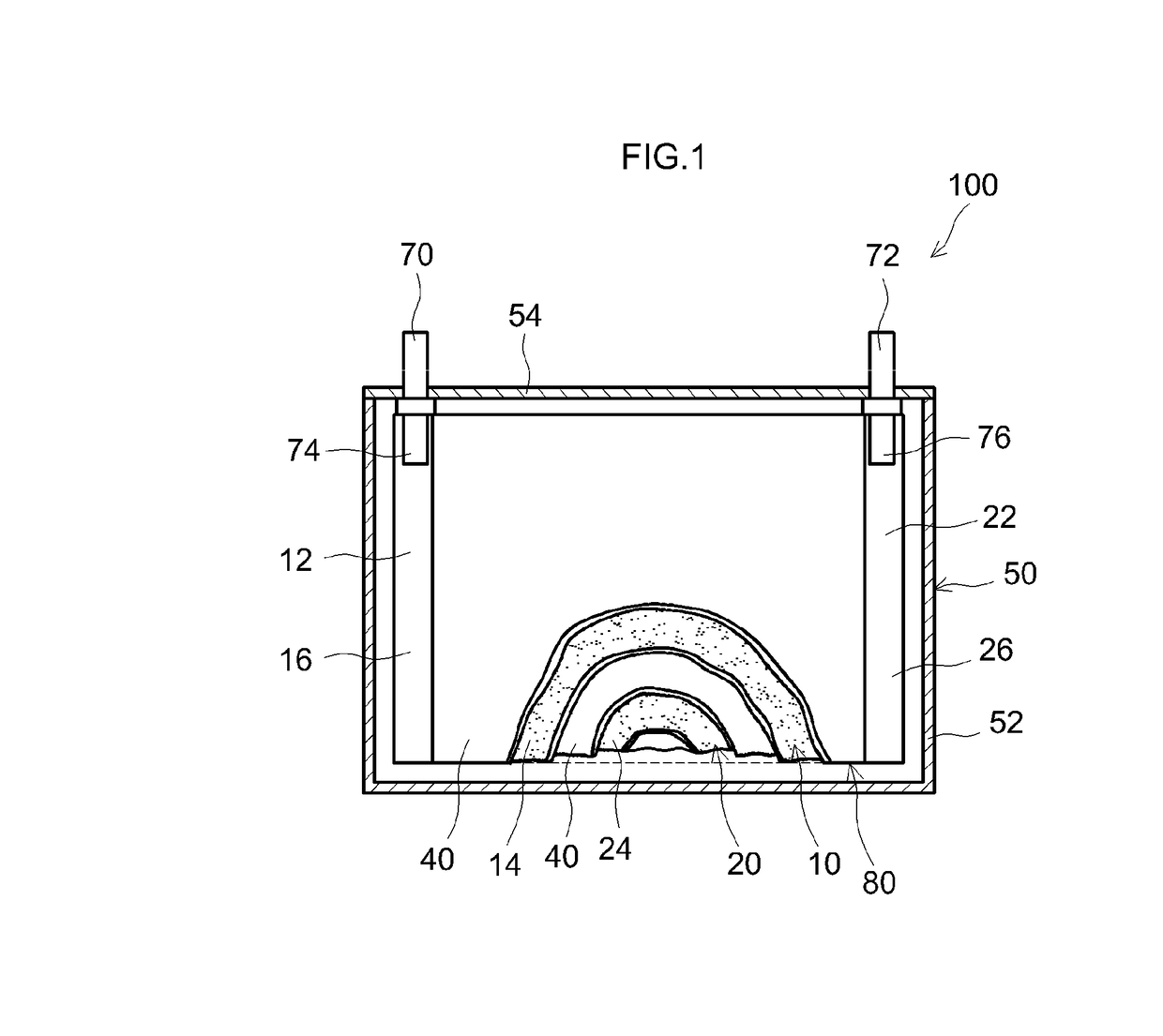

Cushion material formed of spring-structured resin-molded product, manufacturing method for the cushion material, and mold used for the manufacturing method

InactiveUS20070001336A1Desirable tactile impressionTendency to collapseStuffed mattressesMouldsProduct formationEngineering

There is provided a method for producing a cushion material composed of a resin molded article with a spring structure which is so moldable as to allow the mold take any shape and size, is cheap, and resistant to collapsing, does not cause fatigue even after prolonged use, and has high shock absorbing capability and load capacity, and thus suitably used as a material of any supports on which one can sit, rest or mount such as seats of automotive vehicles, motor cycles, bicycles, electric trains, and aircraft, saddles for horse riding, chairs, sofas and beds, and a method for producing a cushion material requiring only a low cost for its disposal.

Owner:AIN ENJINIARINGU

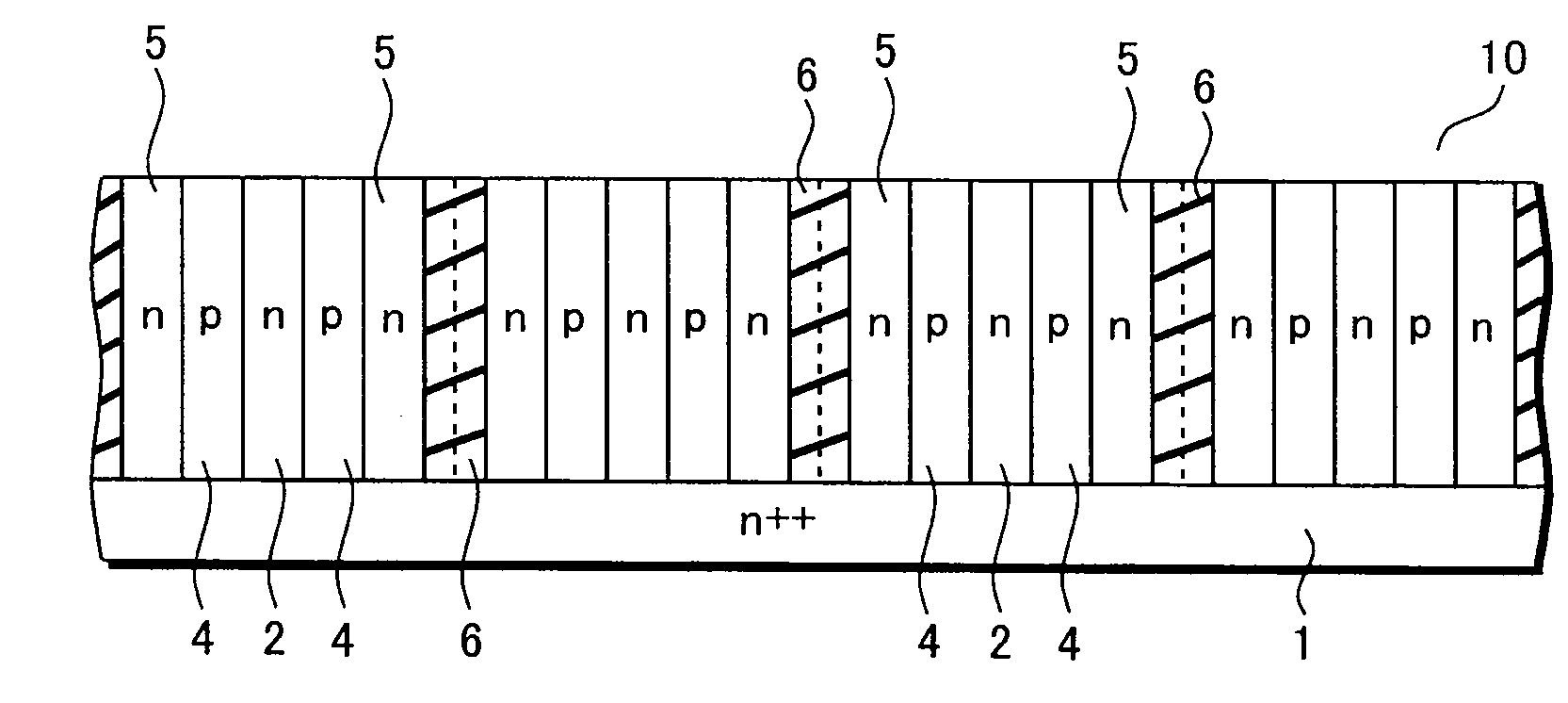

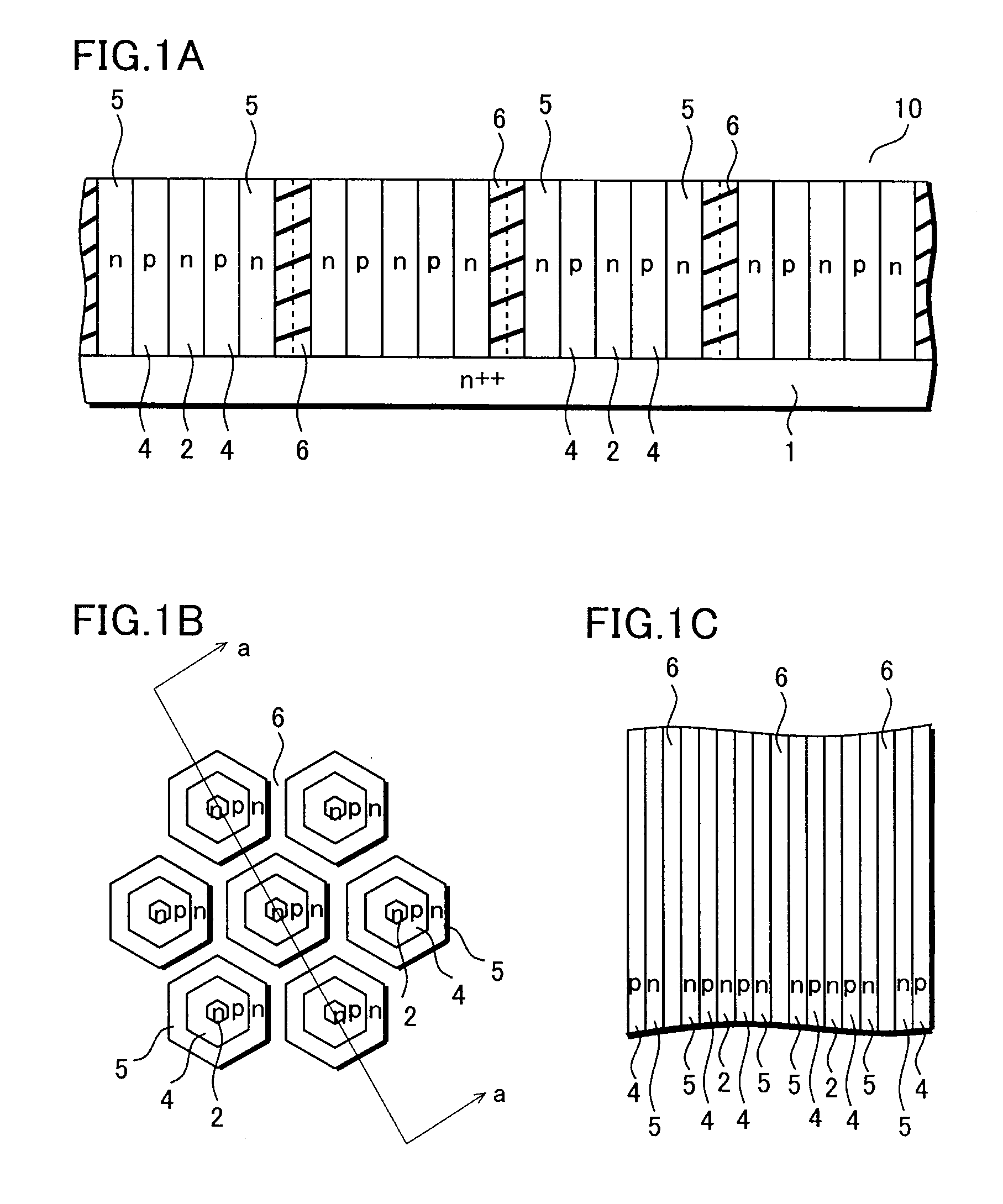

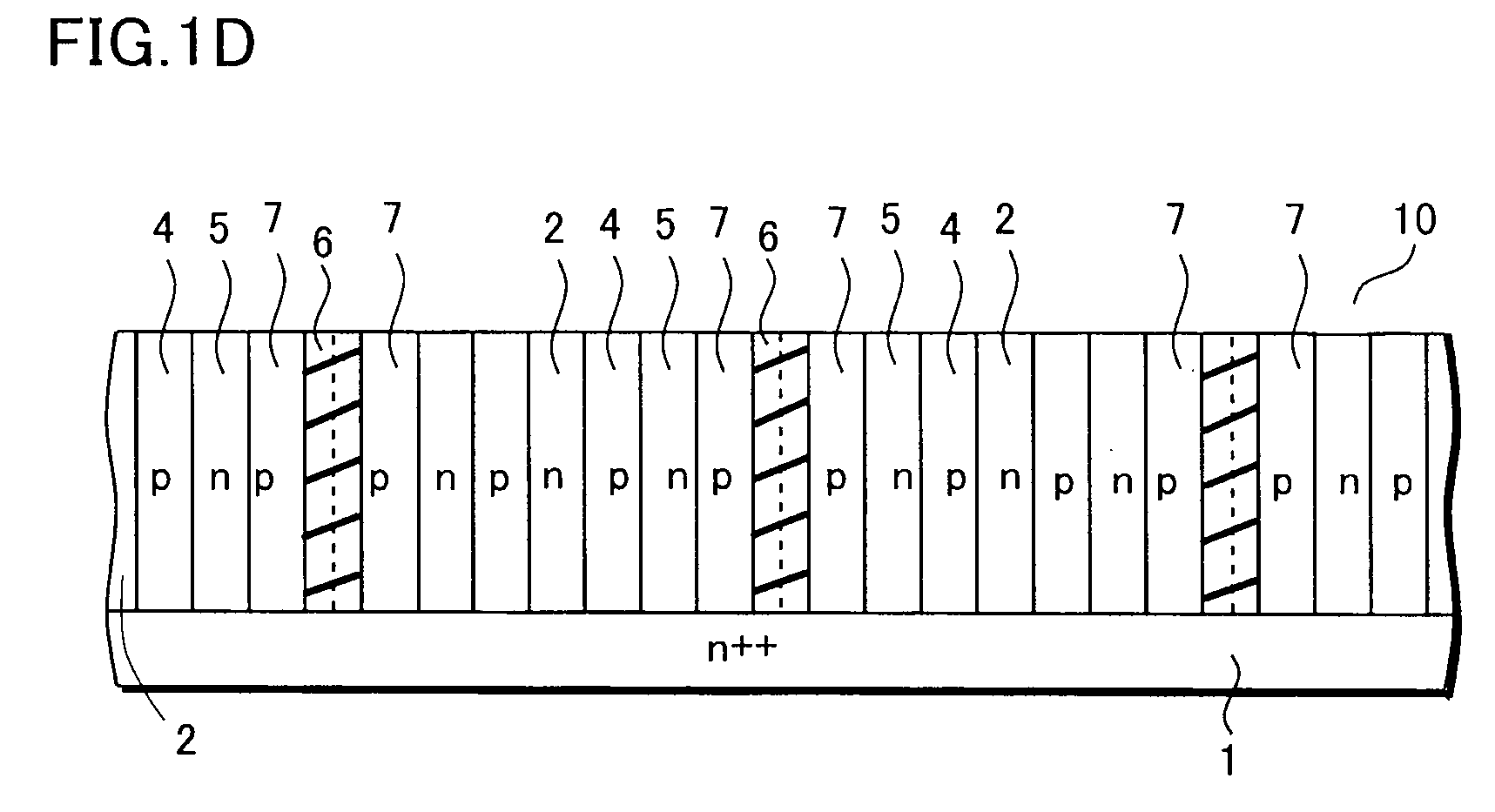

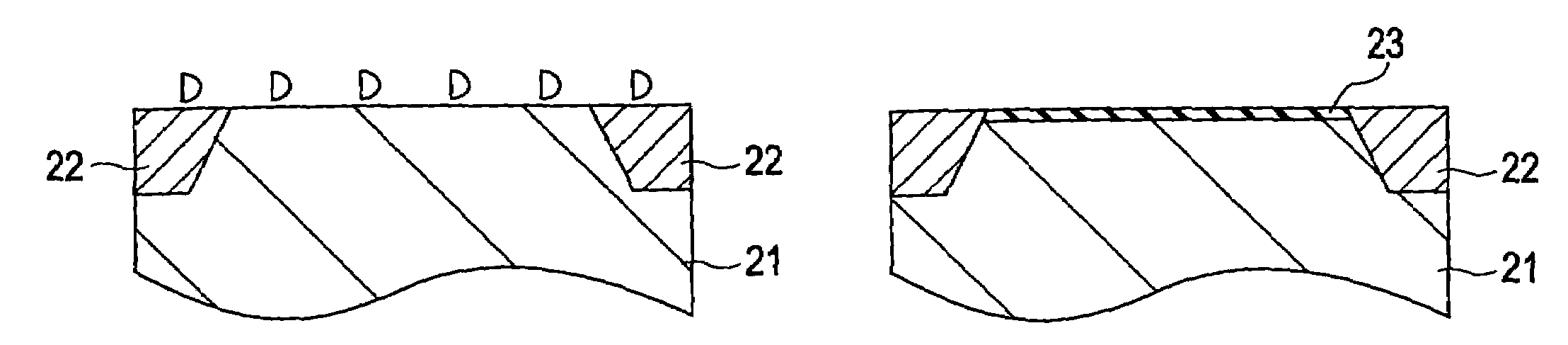

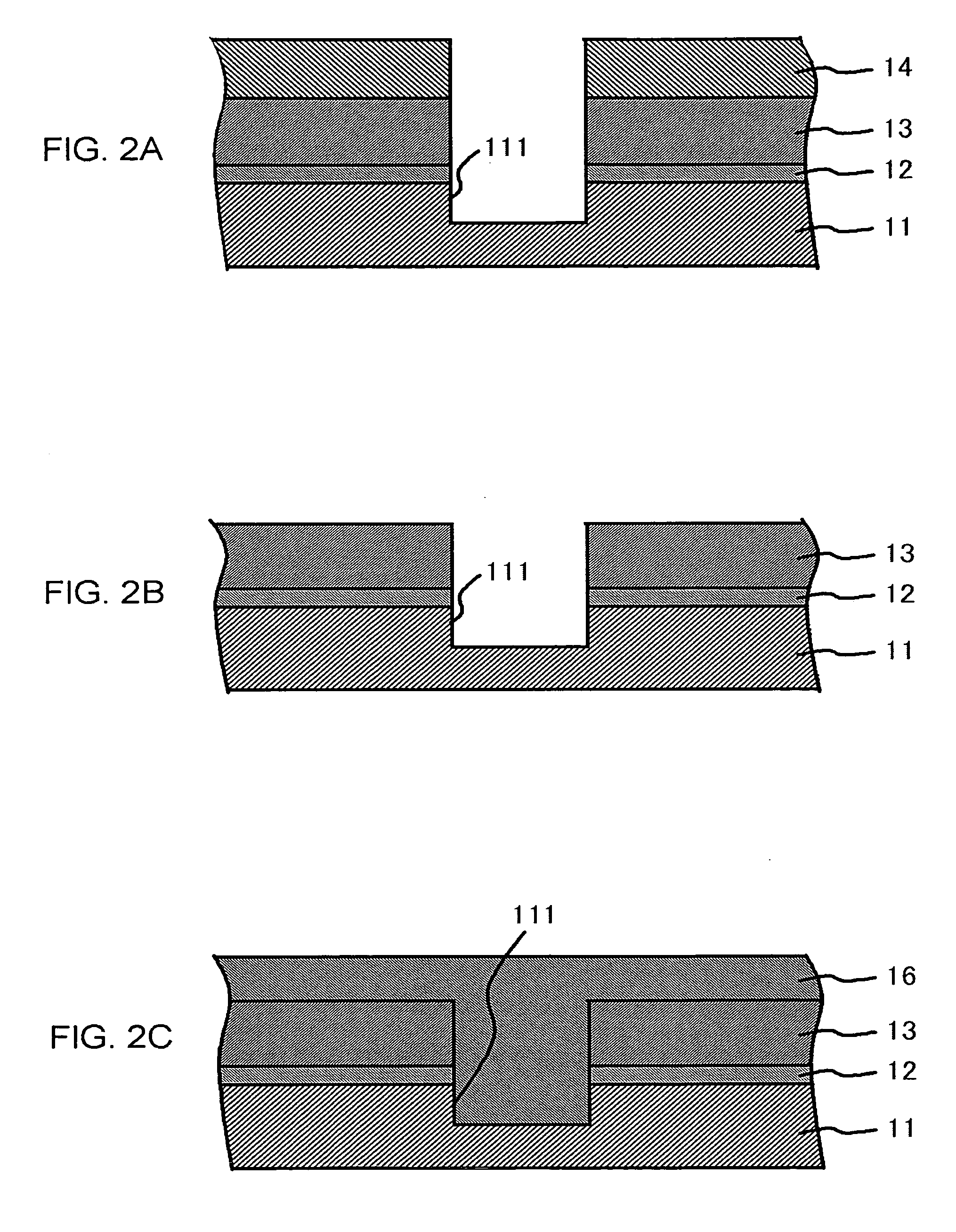

Semiconductor device and method of processing the same

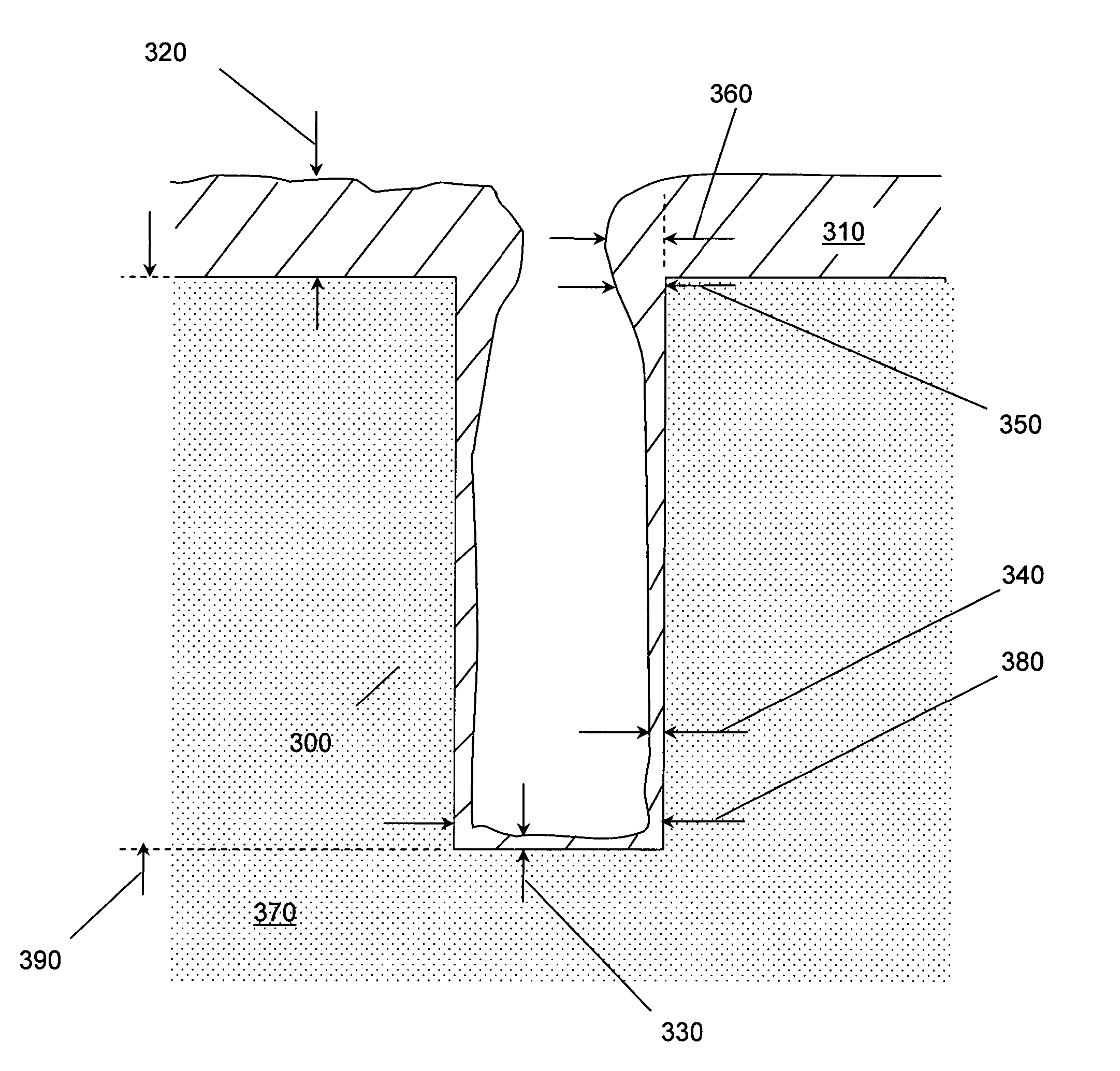

ActiveUS20090085149A1Desired thicknessSolid-state devicesSemiconductor/solid-state device manufacturingEtchingSemiconductor

Provided is a semiconductor wafer. In the semiconductor wafer, formation and etching of an n type epitaxial layer and formation and etching of a p type epitaxial layer are alternately performed for at least three times, so that all semiconductor layers are formed of epitaxial layers on a semiconductor substrate. Thereby, the respective semiconductor layers can be formed to have reduced widths. Thus, if a required breakdown voltage is the same, dopant concentrations of the respective semiconductor layers can be increased and a resistance value of the wafer can be reduced. In addition, a space portion remaining in the end is buried with an insulating layer, so that a defect can be avoided in a junction surface of the epitaxial layers.

Owner:SEMICON COMPONENTS IND LLC

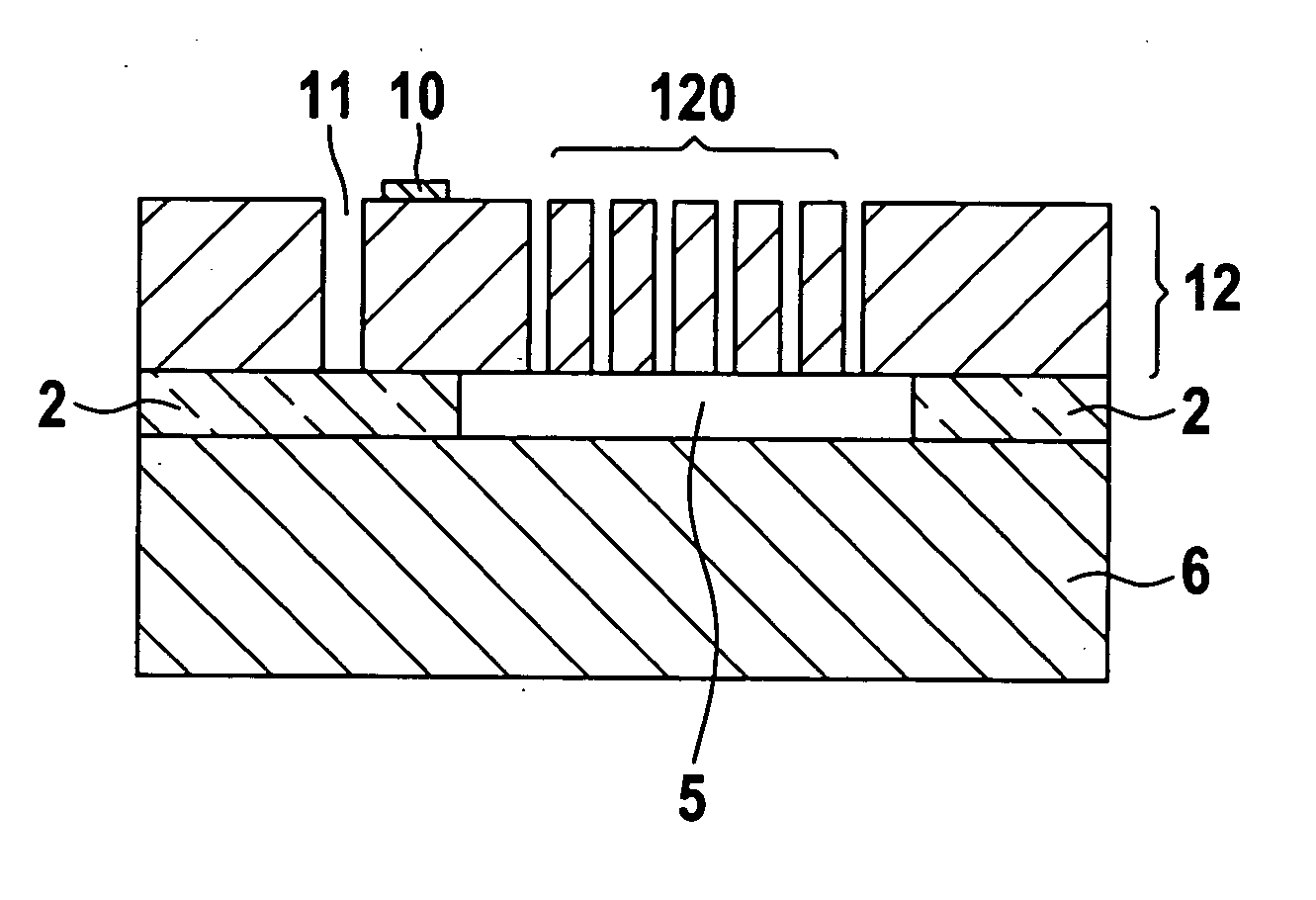

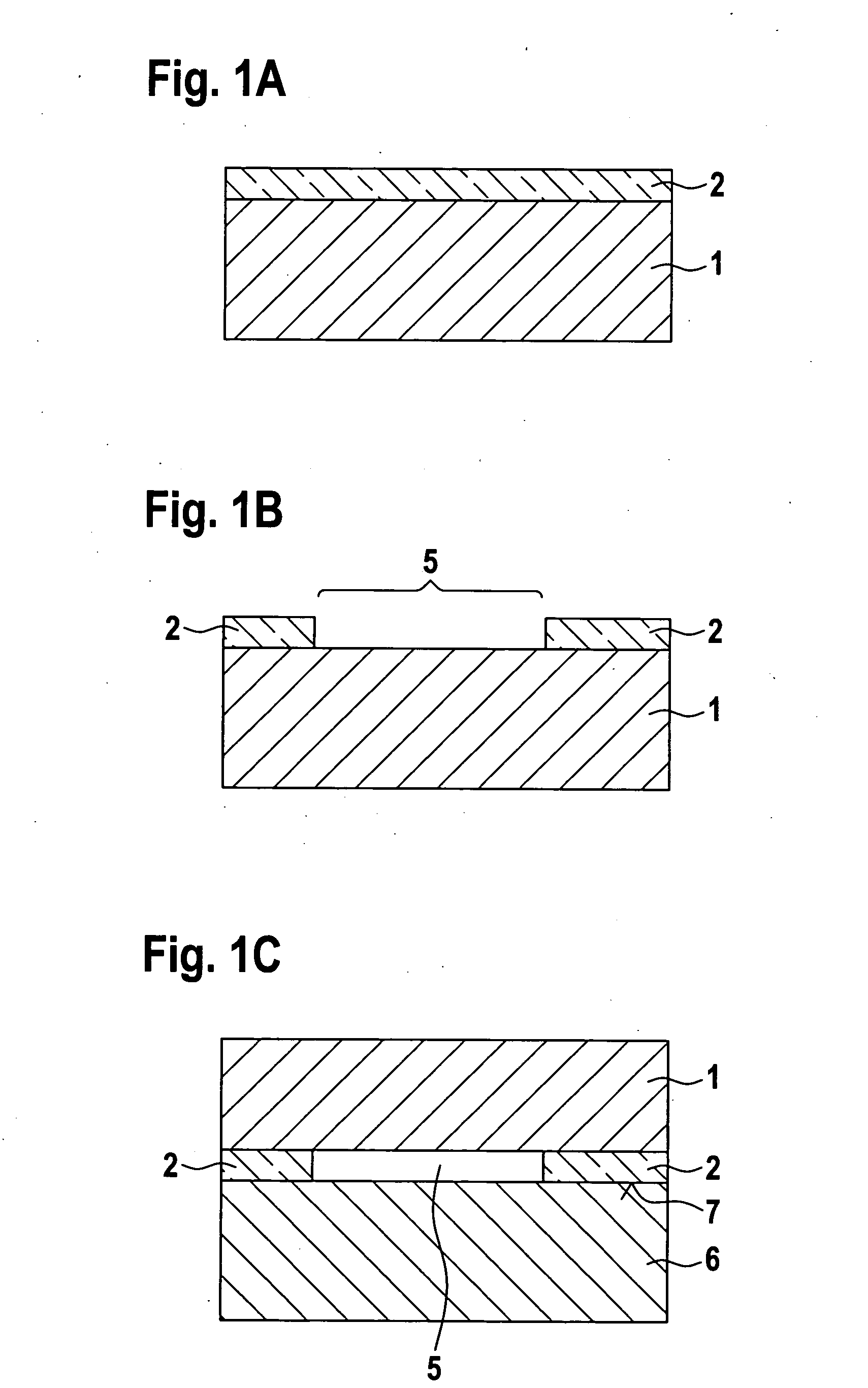

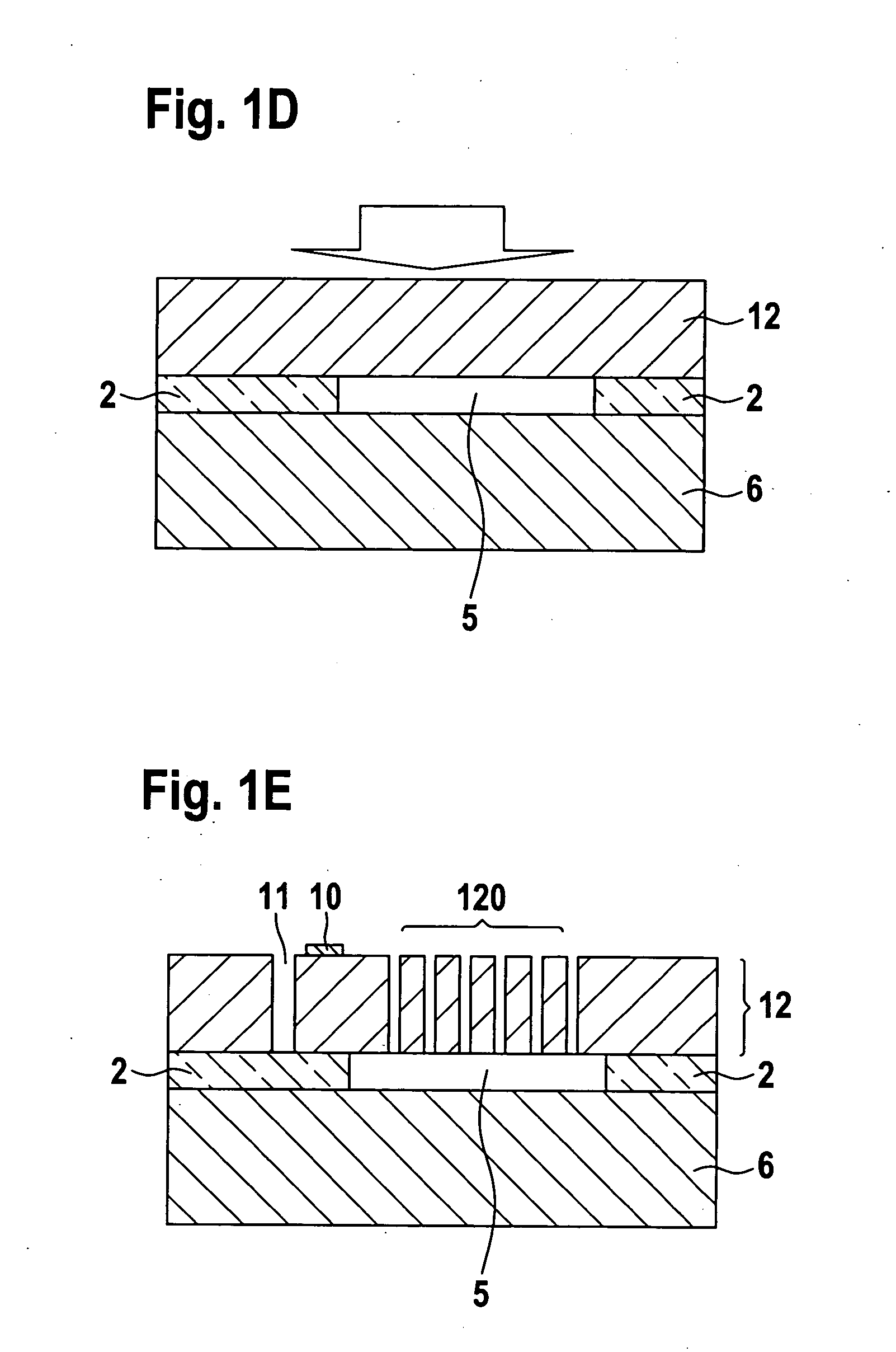

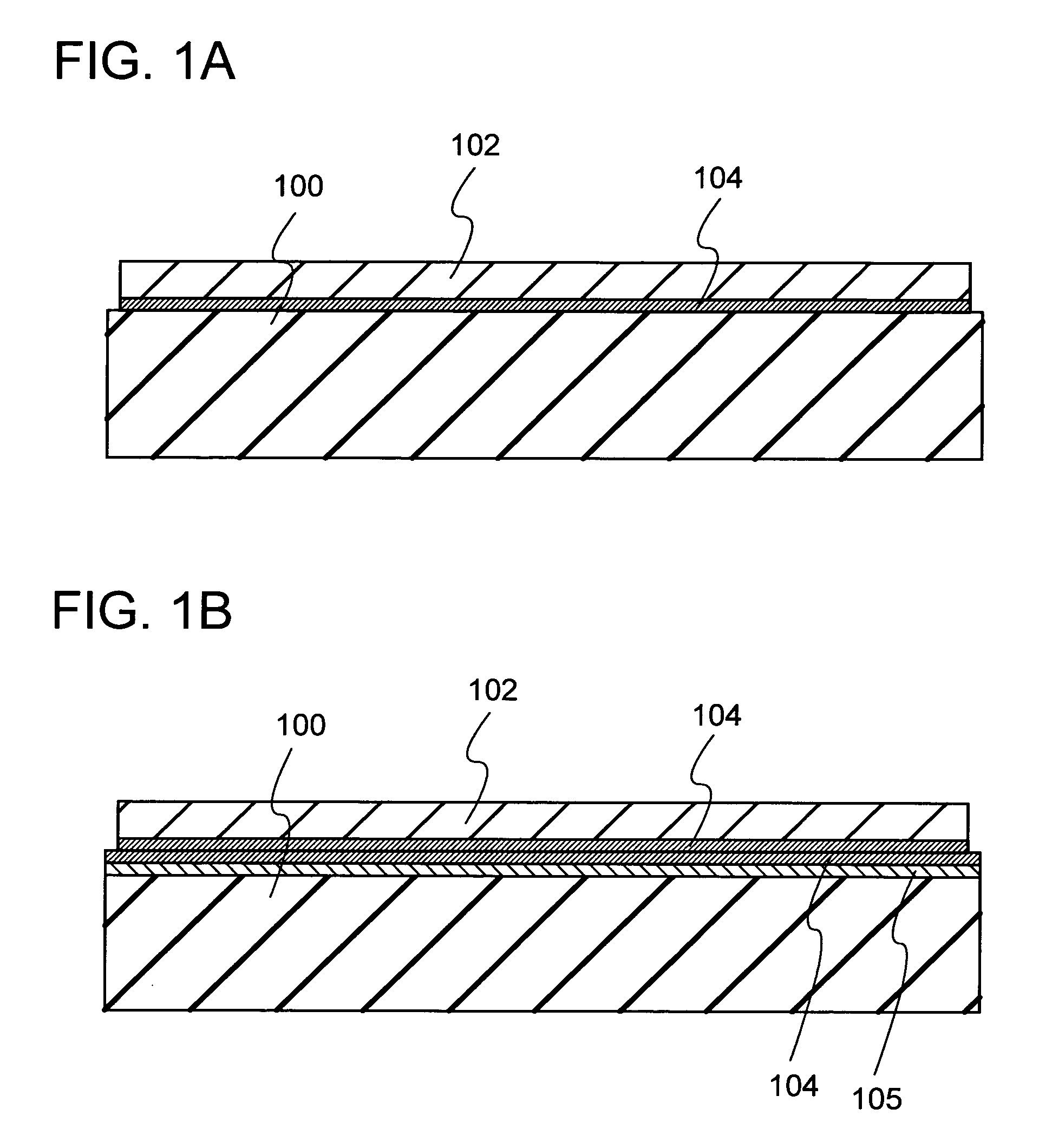

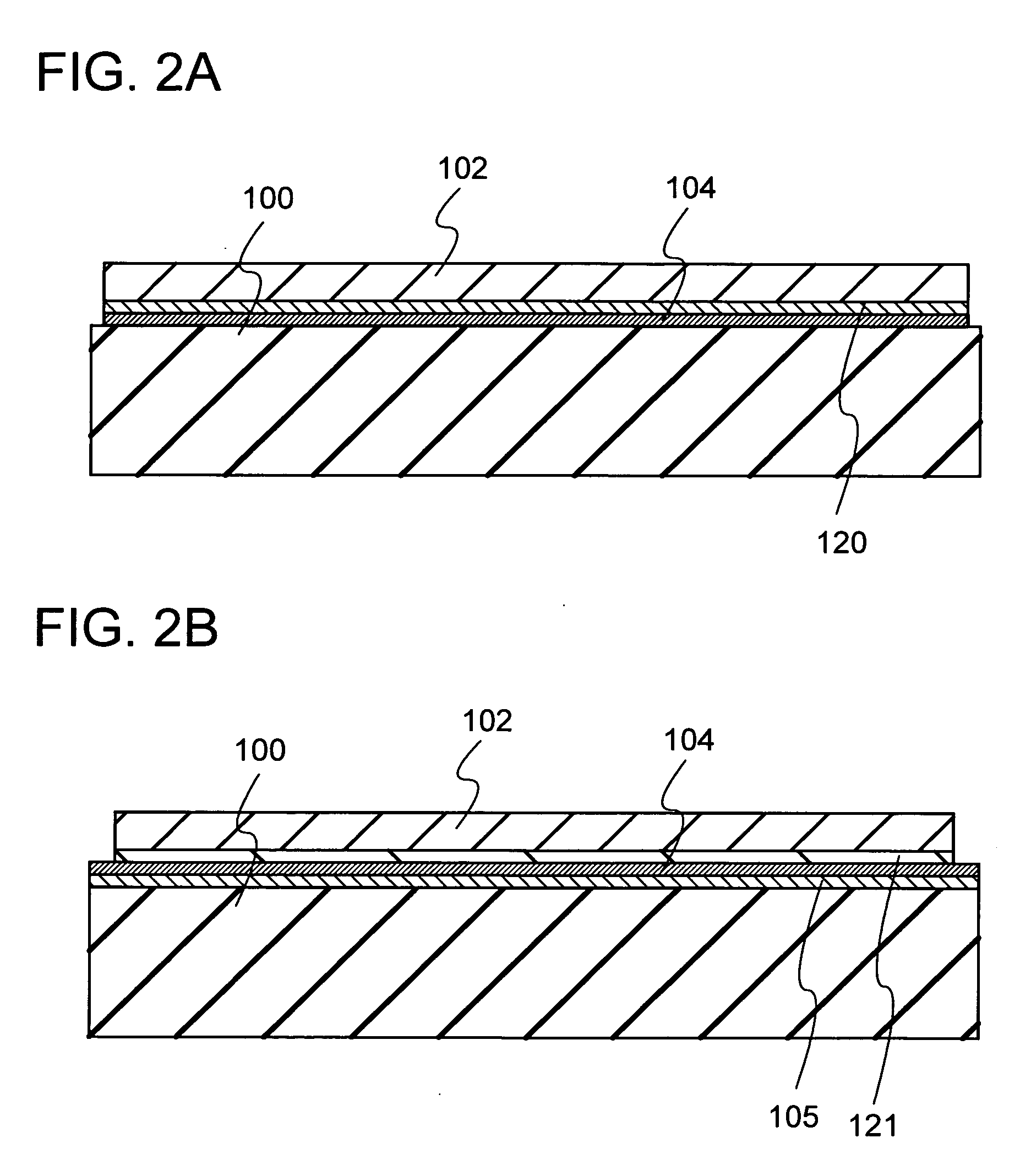

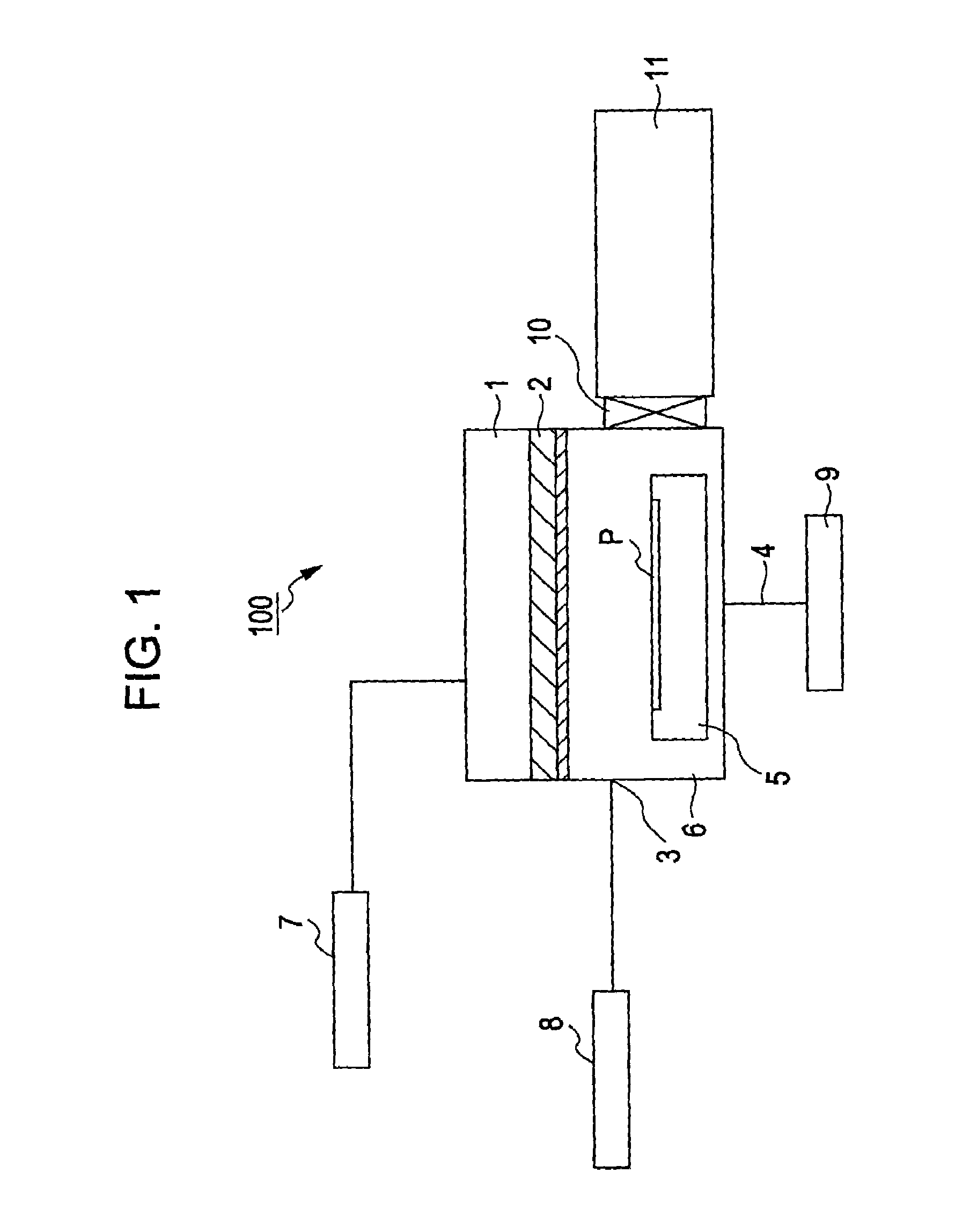

Method for anodic bonding of wafers and device

InactiveUS20050112843A1Avoid Bonding DefectsCost-effectiveSolid-state devicesSemiconductor/solid-state device manufacturingInter layerEngineering

A method for anodic bonding of wafers and a device essentially composed of such bonded wafers. An intermediate layer is placed between two wafers, after which the two wafers are anodically bonded. The method and the device have the advantage of being implementable and manufacturable, respectively, in a particularly cost-effective manner. The anodically bonded intermediate layer plastically encloses any possible particles present or evens out differences in height of the wafer surfaces to be bonded and thus prevents any extensive bond defects from occurring.

Owner:ROBERT BOSCH GMBH

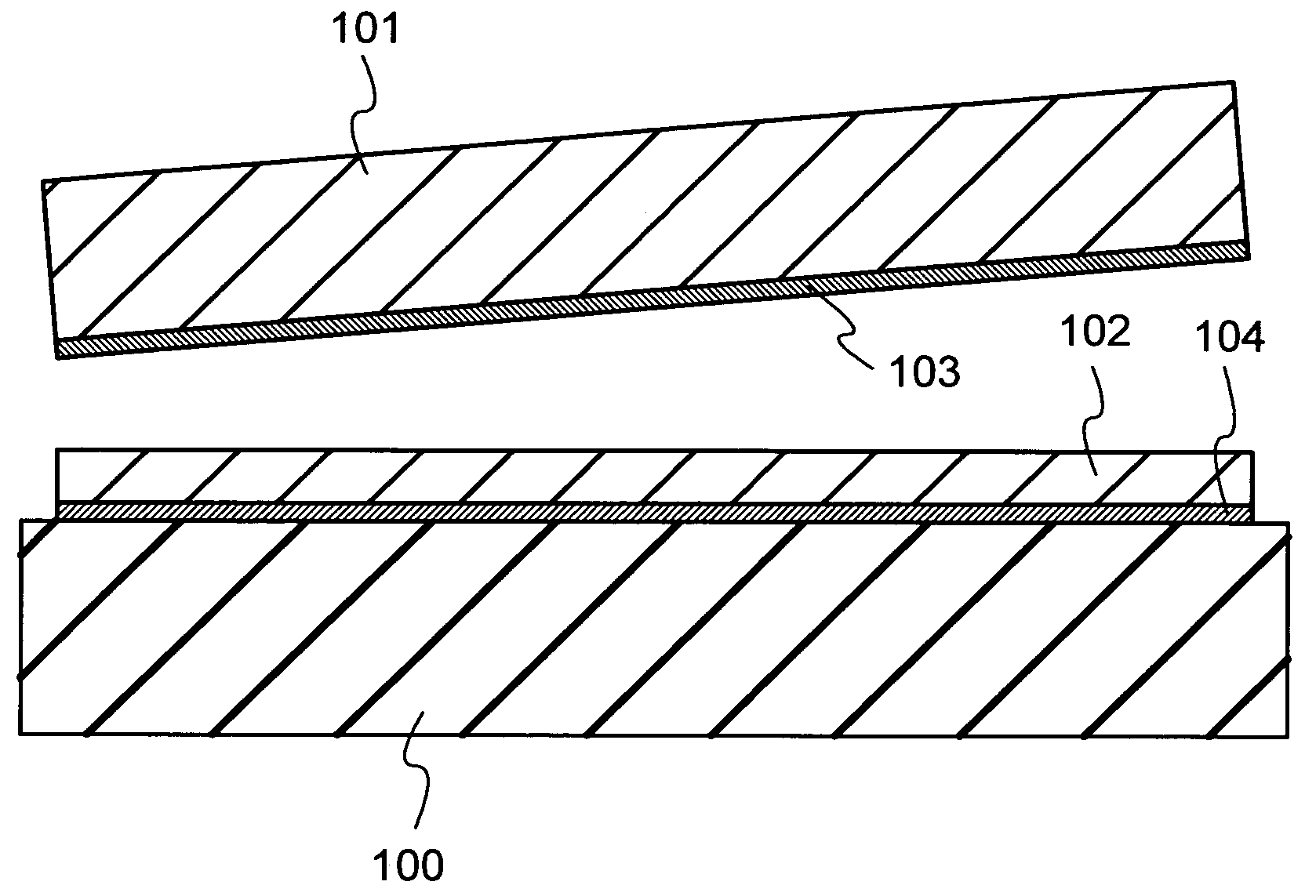

Method for manufacturing semiconductor substrate

InactiveUS20080248629A1Avoid pollutionVariation of depth is reducedSemiconductor/solid-state device manufacturingSingle crystalSilicon oxide

A method for manufacturing a semiconductor substrate is provided, which comprises a step of irradiating a single crystal semiconductor substrate with ions to form an embrittlement layer in the single crystal semiconductor substrate, a step of forming a silicon oxide film over the single crystal semiconductor substrate, a step of bonding the single crystal semiconductor substrate and a substrate having an insulating surface with the silicon oxide film interposed therebetween, a step of performing a thermal treatment, and a step of separating the single crystal semiconductor substrate with a single crystal semiconductor layer left over the substrate having the insulating surface.

Owner:SEMICON ENERGY LAB CO LTD

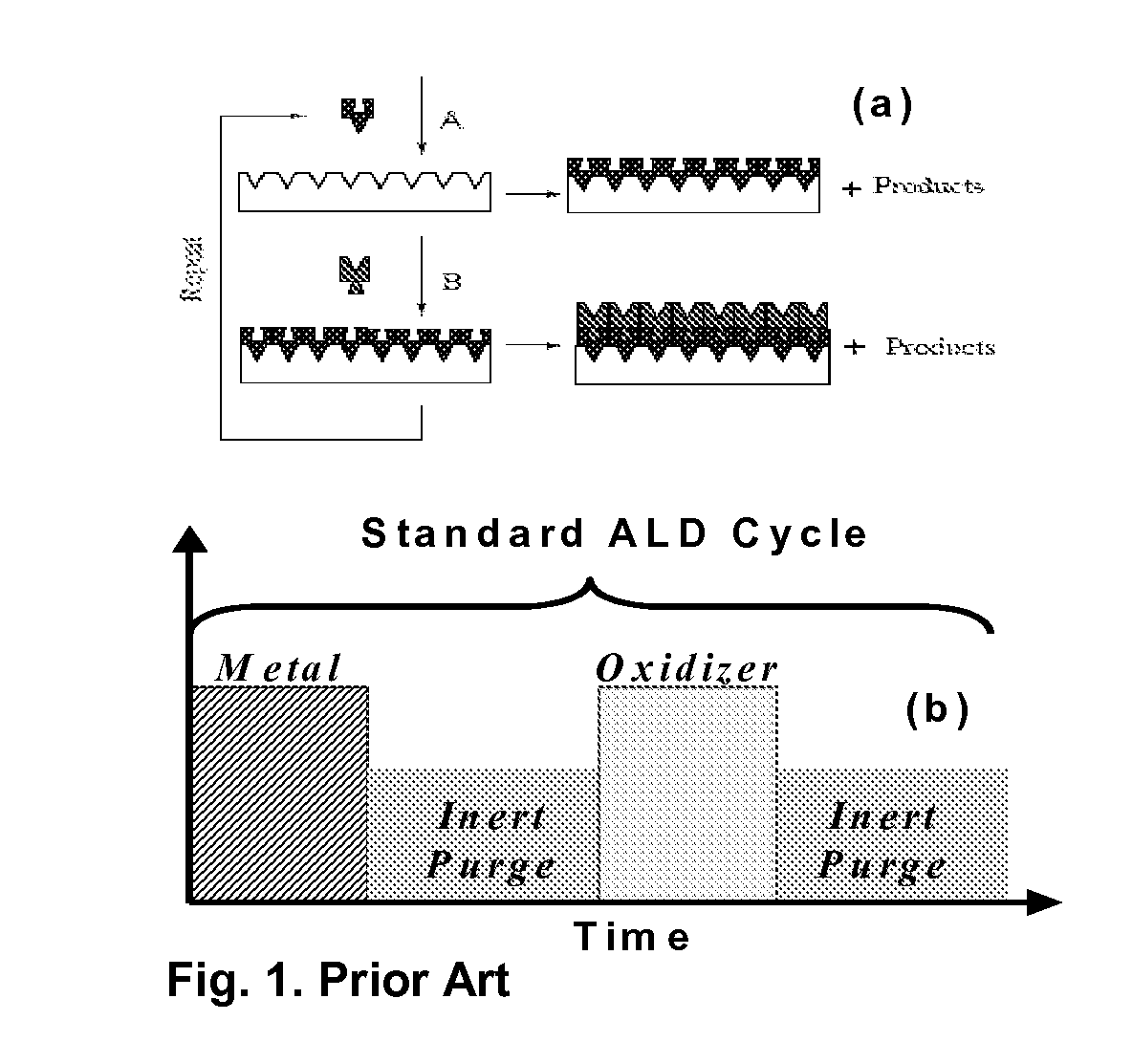

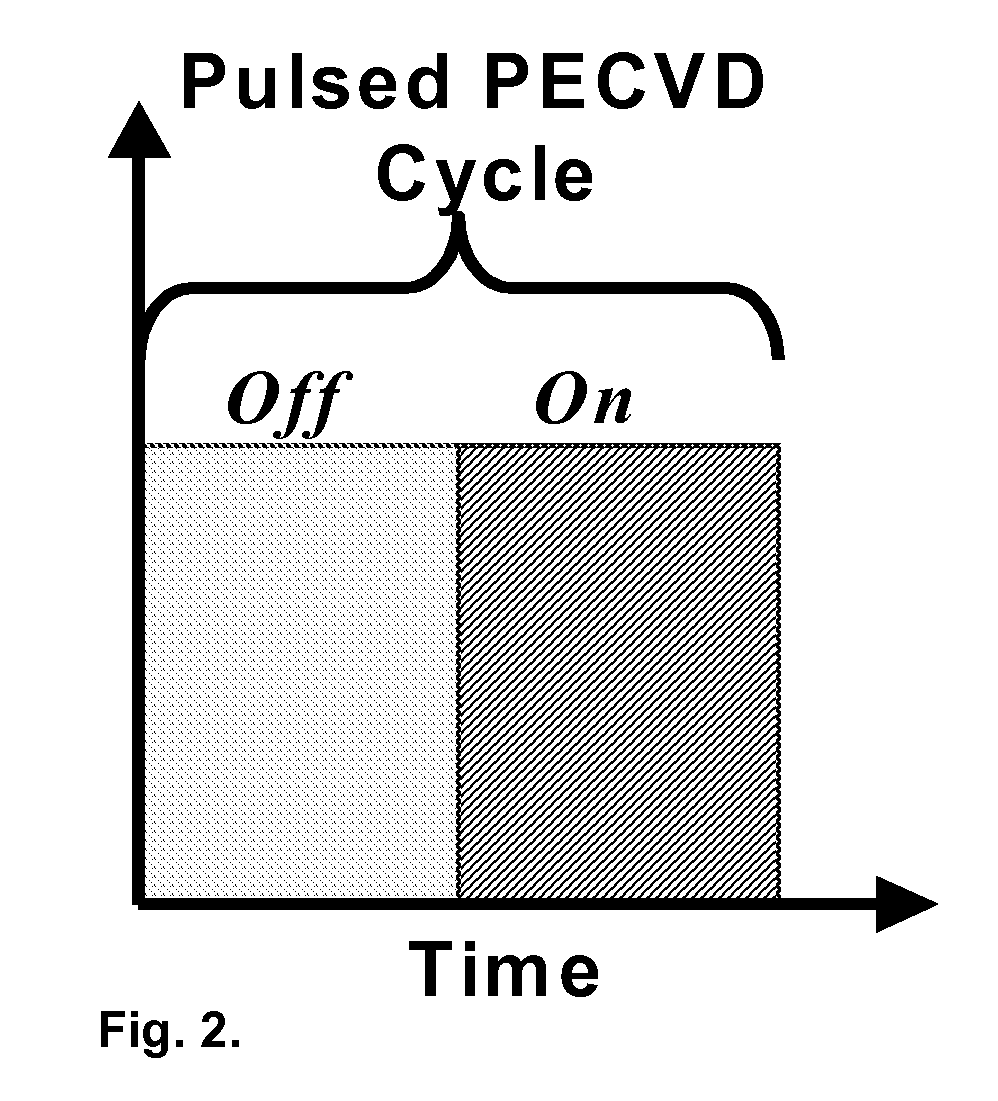

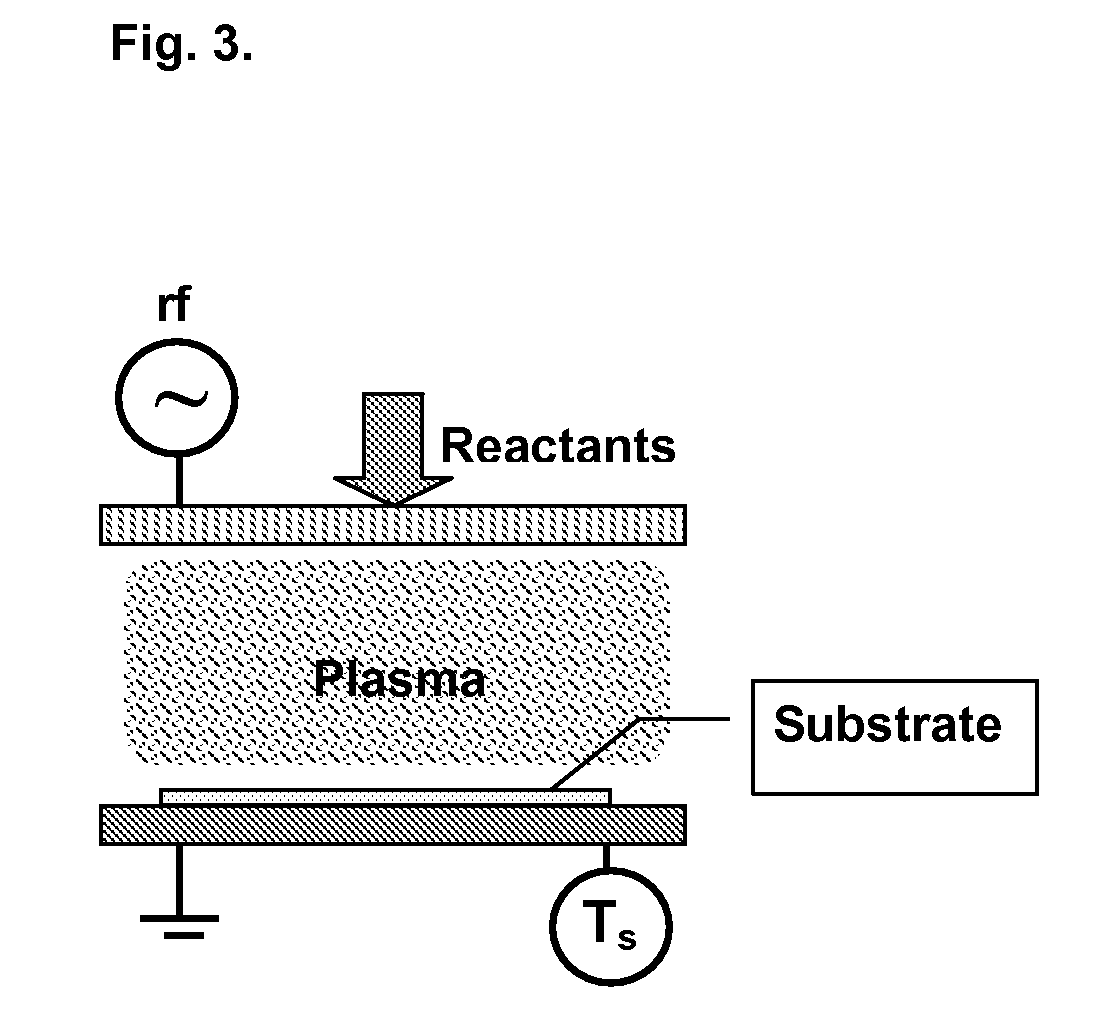

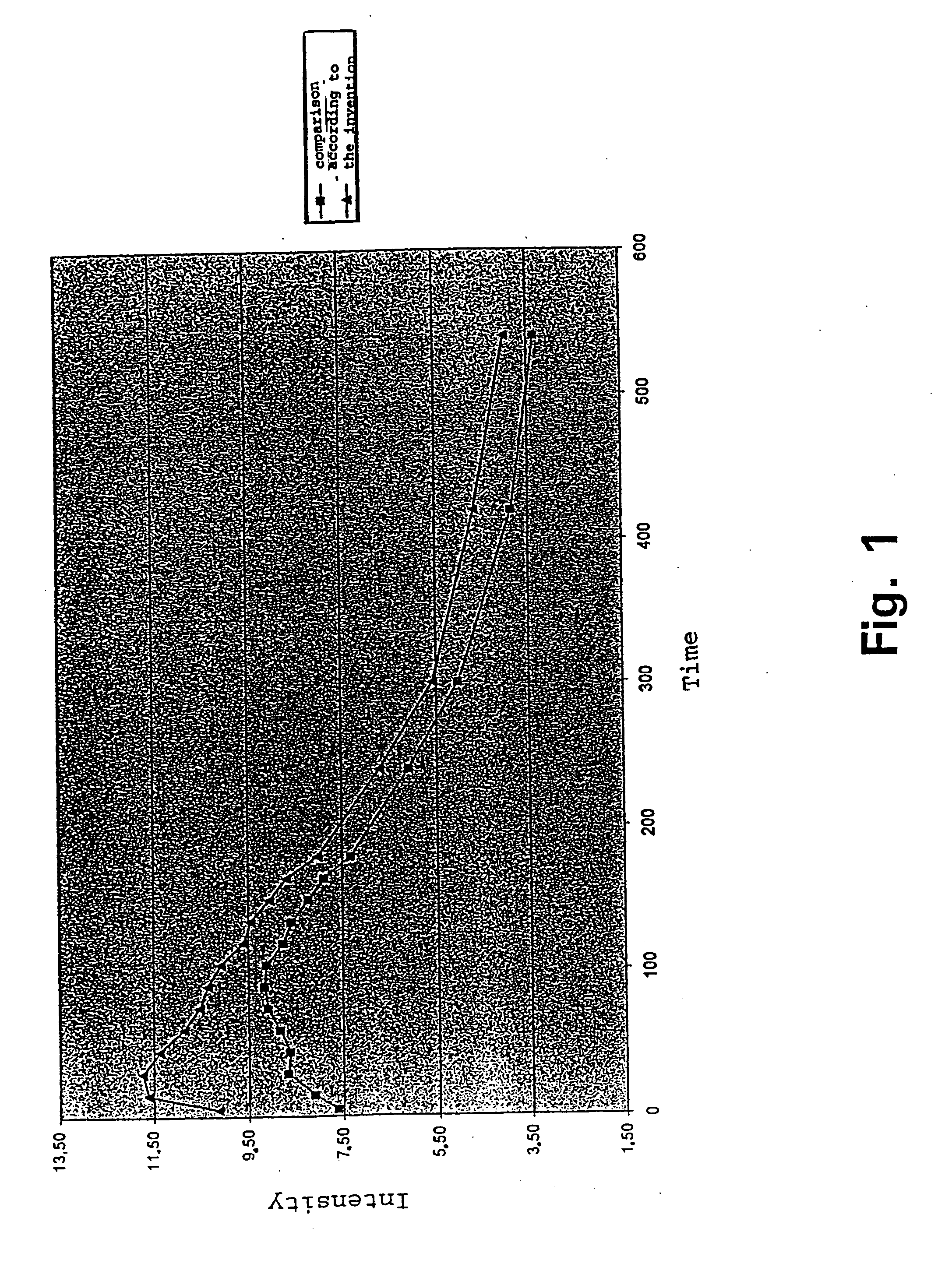

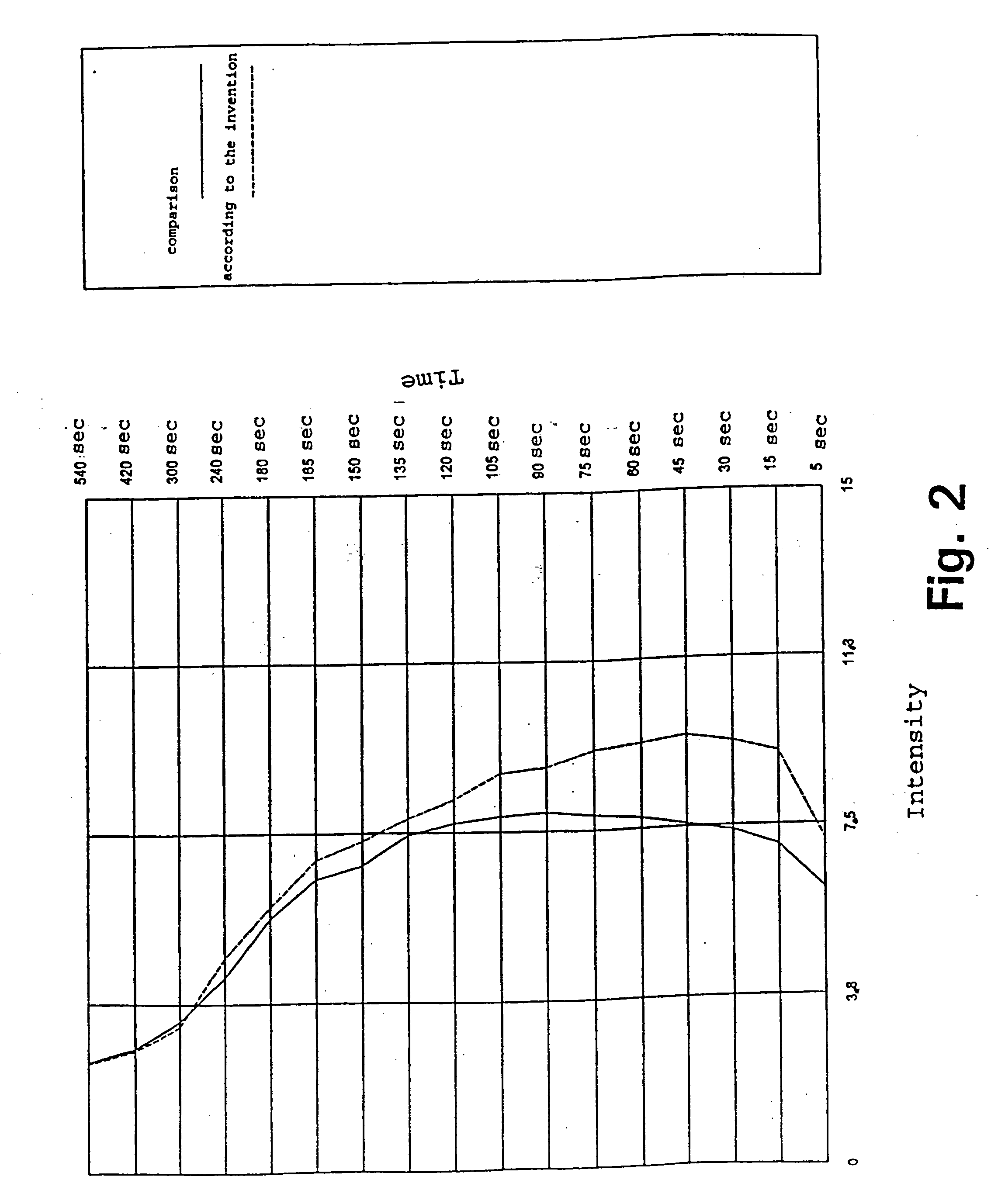

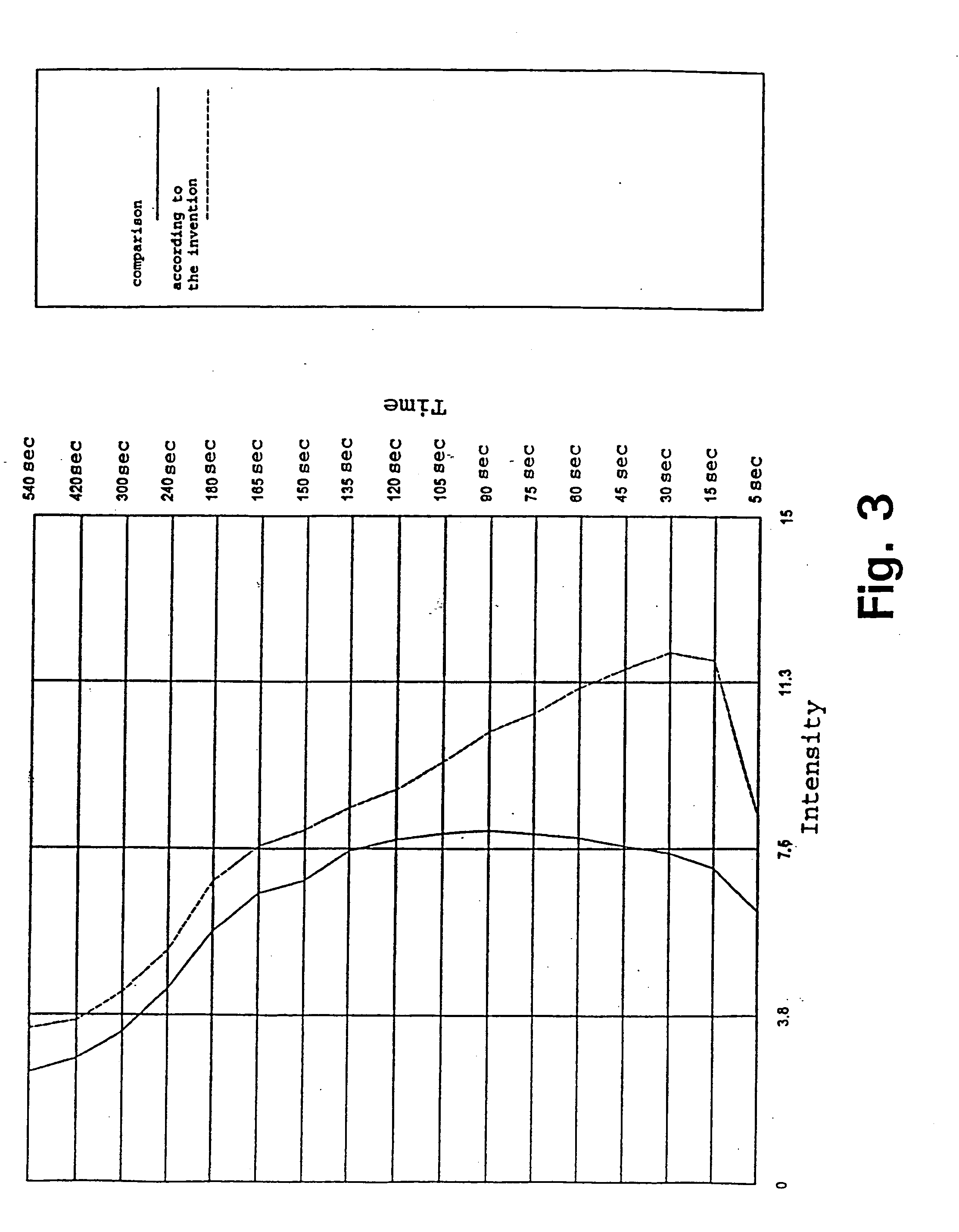

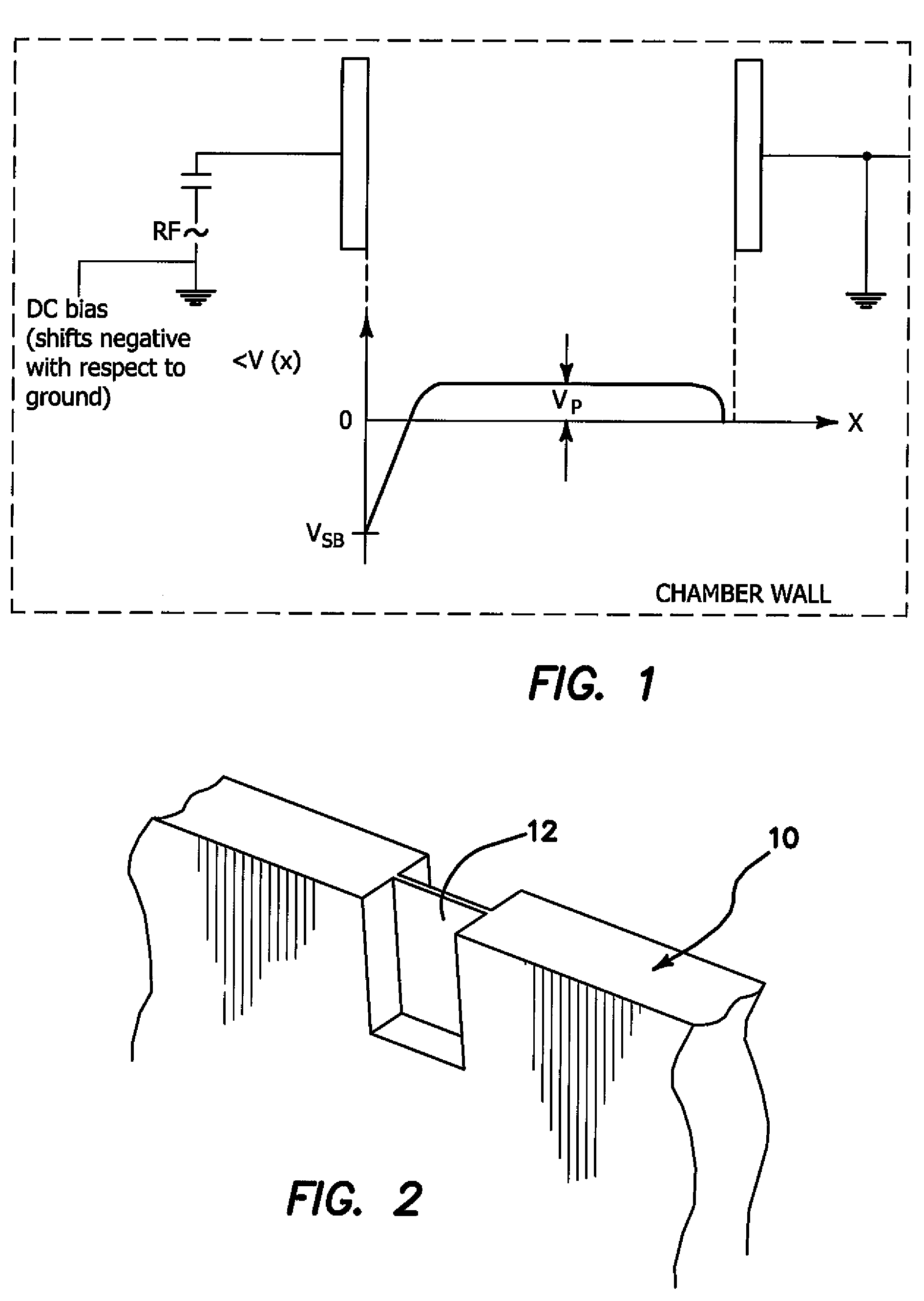

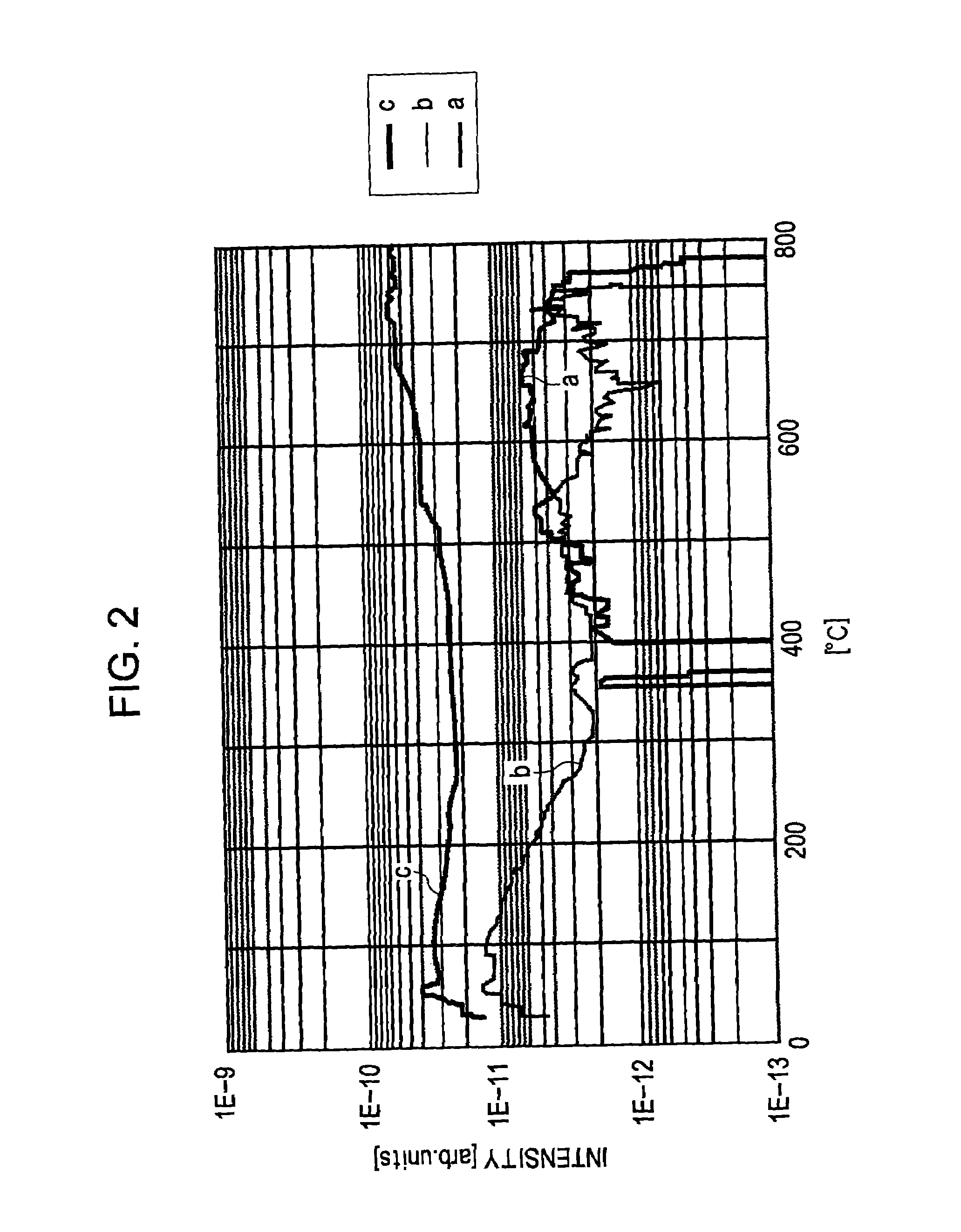

Self-Limiting Thin Film Synthesis Achieved by Pulsed Plasma-Enhanced Chemical Vapor Deposition

InactiveUS20080199632A1Improve throughputIncrease deposition rateChemical vapor deposition coatingPlasma techniqueSelf limitingFourier transform infrared spectroscopy

Ta2O5 and Al2O3 thin films were fabricated by pulsed plasma-enhanced chemical vapor deposition (PECVD) with simultaneous delivery of O2 and the metal precursor. By appropriately controlling the gas-phase environment self-limiting deposition at controllable rates (˜1 Å / pulse) was obtained. The process was insensitive to substrate temperature, with a constant deposition rate observed from 90-350° C. As-deposited Ta2O5 films under these conditions displayed good dielectric properties. Performance improvements correlate strongly with film density and composition as measured by spectroscopic ellipsometry and Fourier transform infrared spectroscopy. Pulsed PECVD eliminates the need for gas actuation and inert purge steps required by atomic layer deposition.

Owner:COLORADO SCHOOL OF MINES

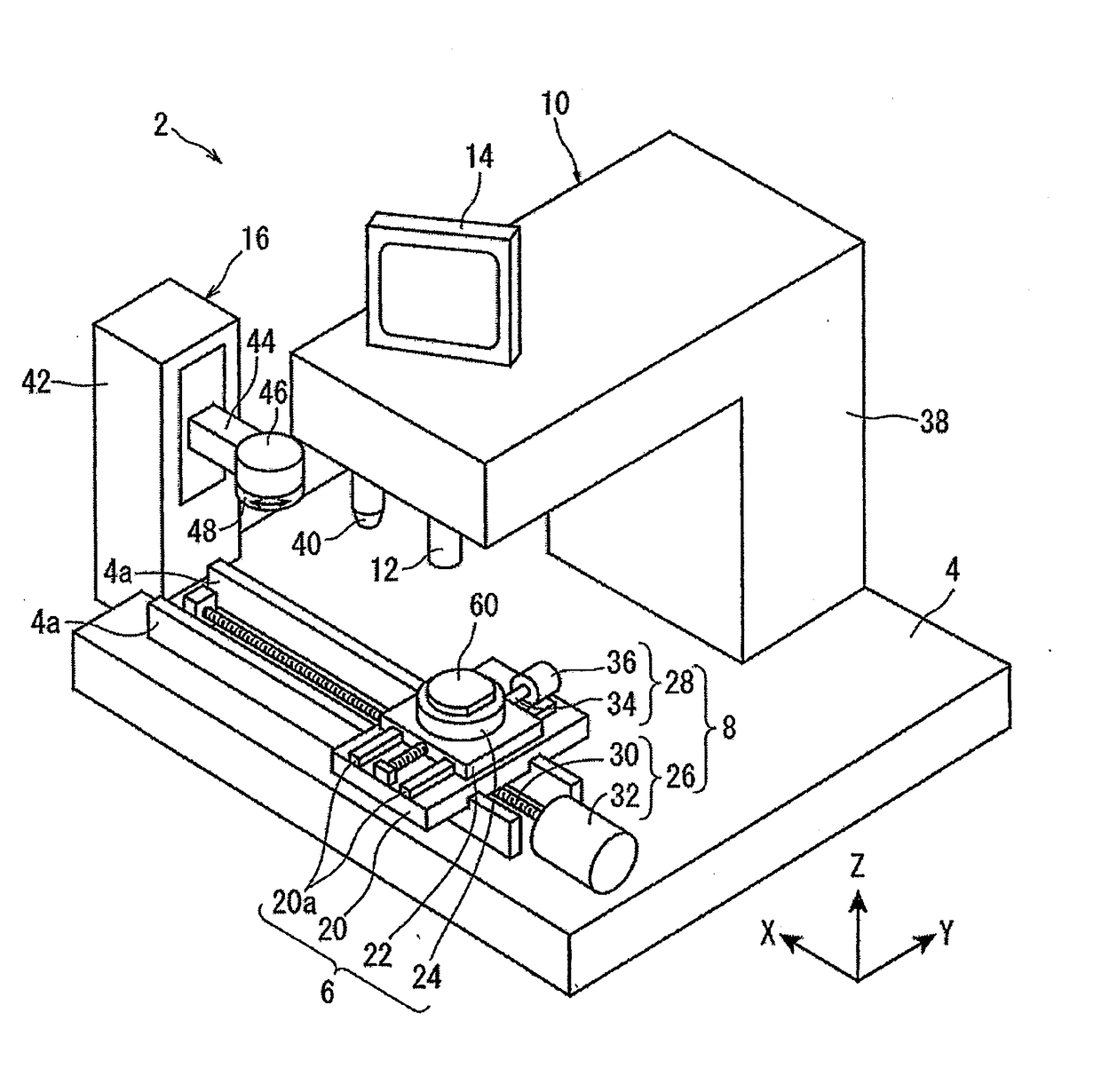

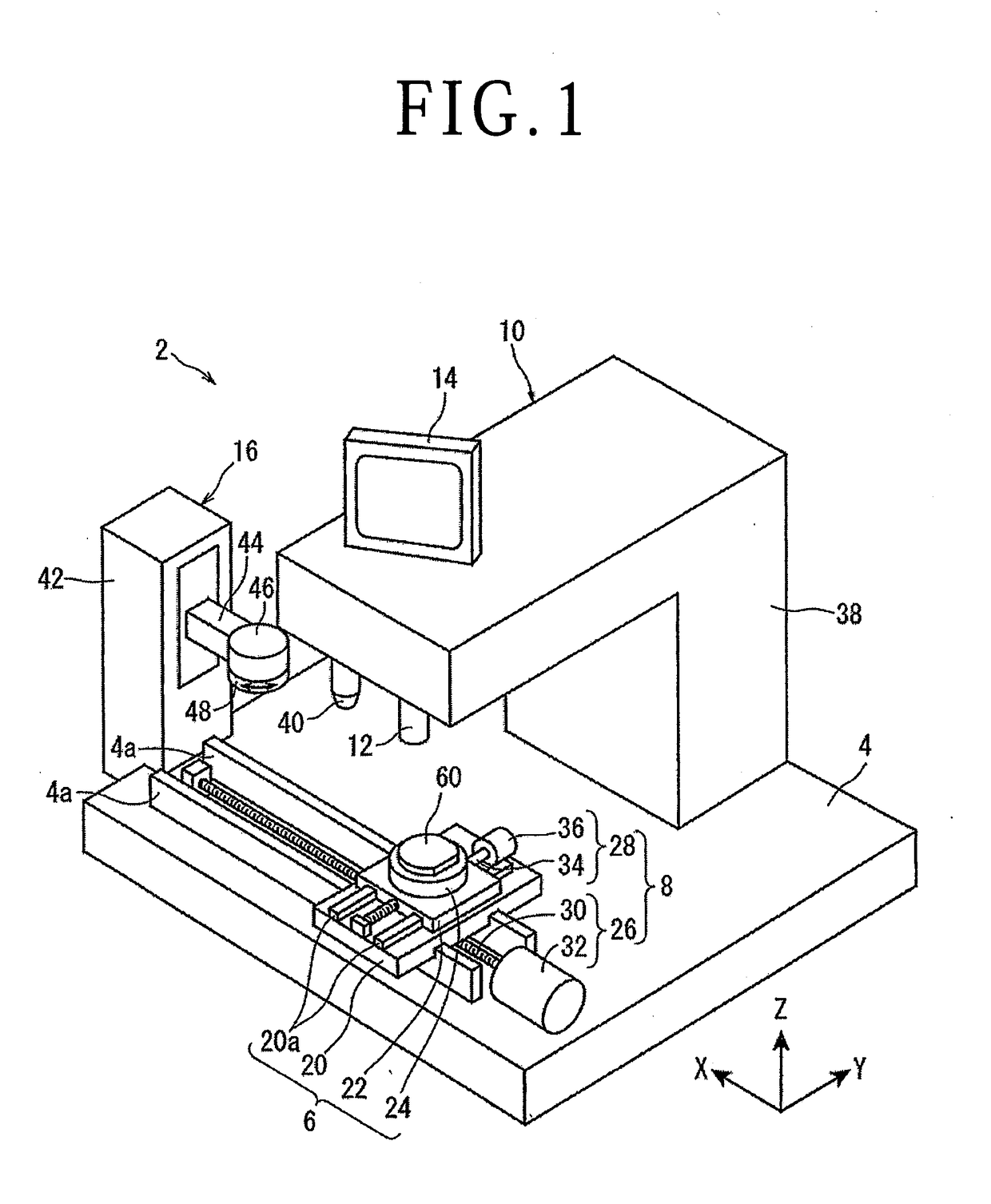

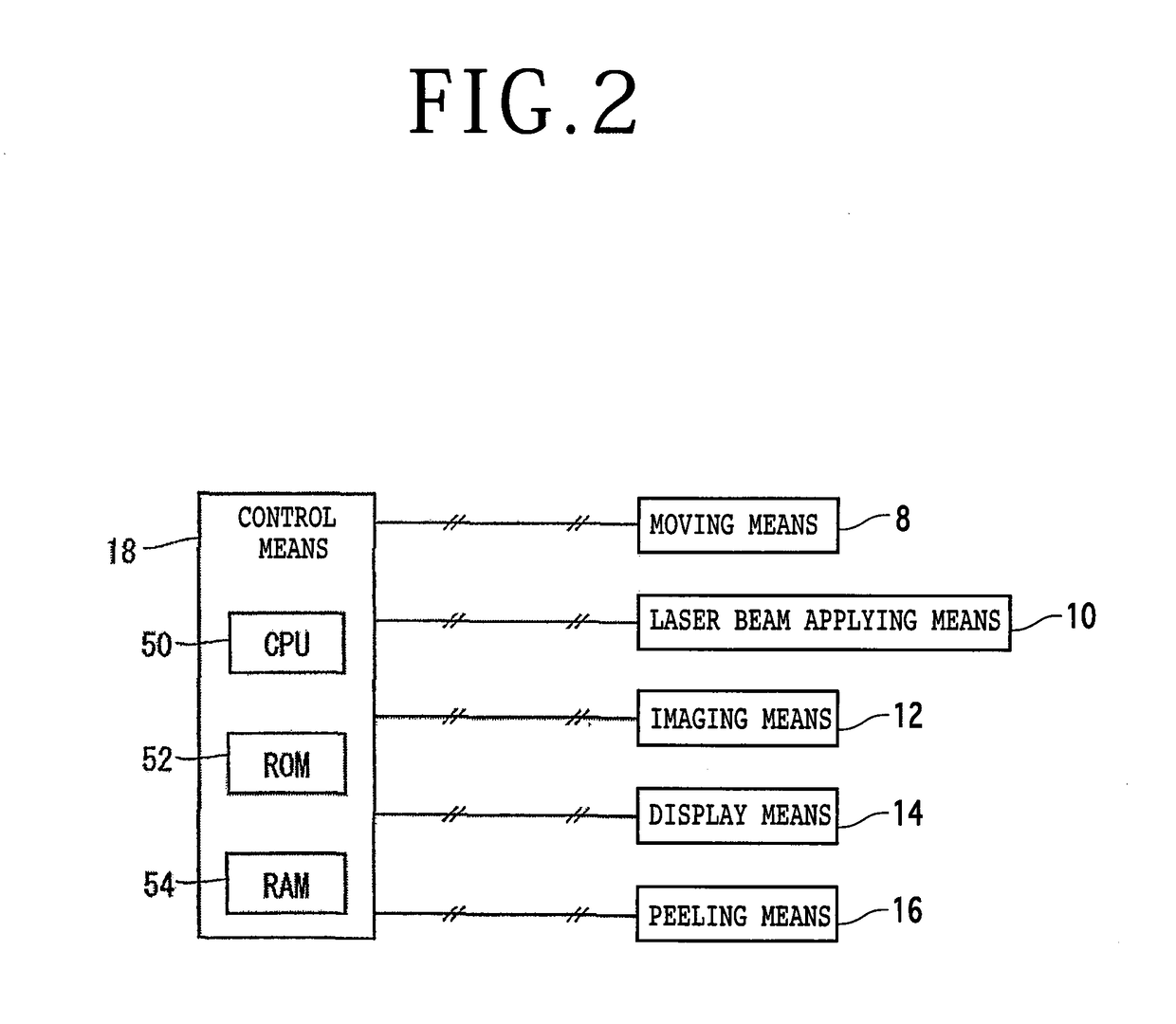

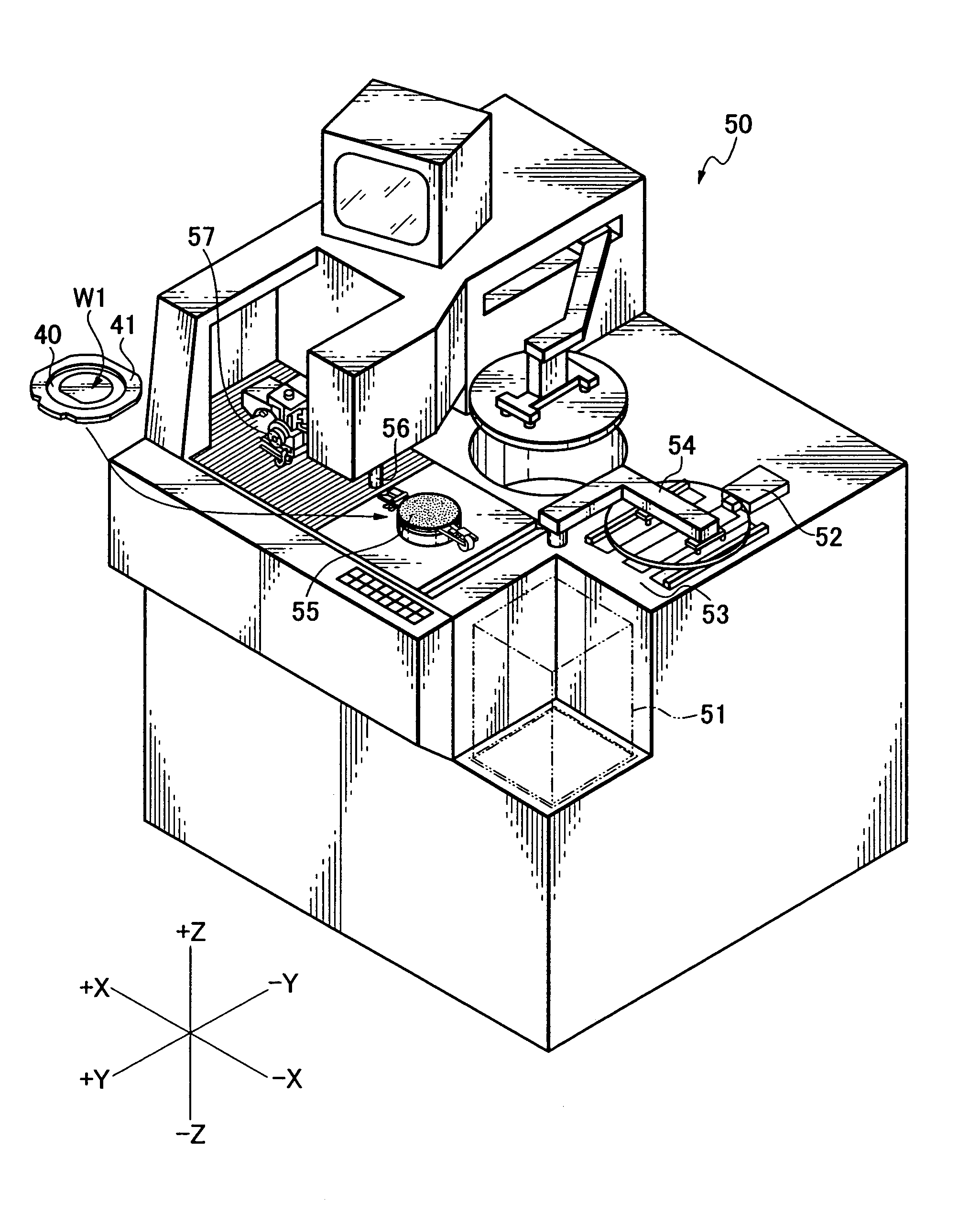

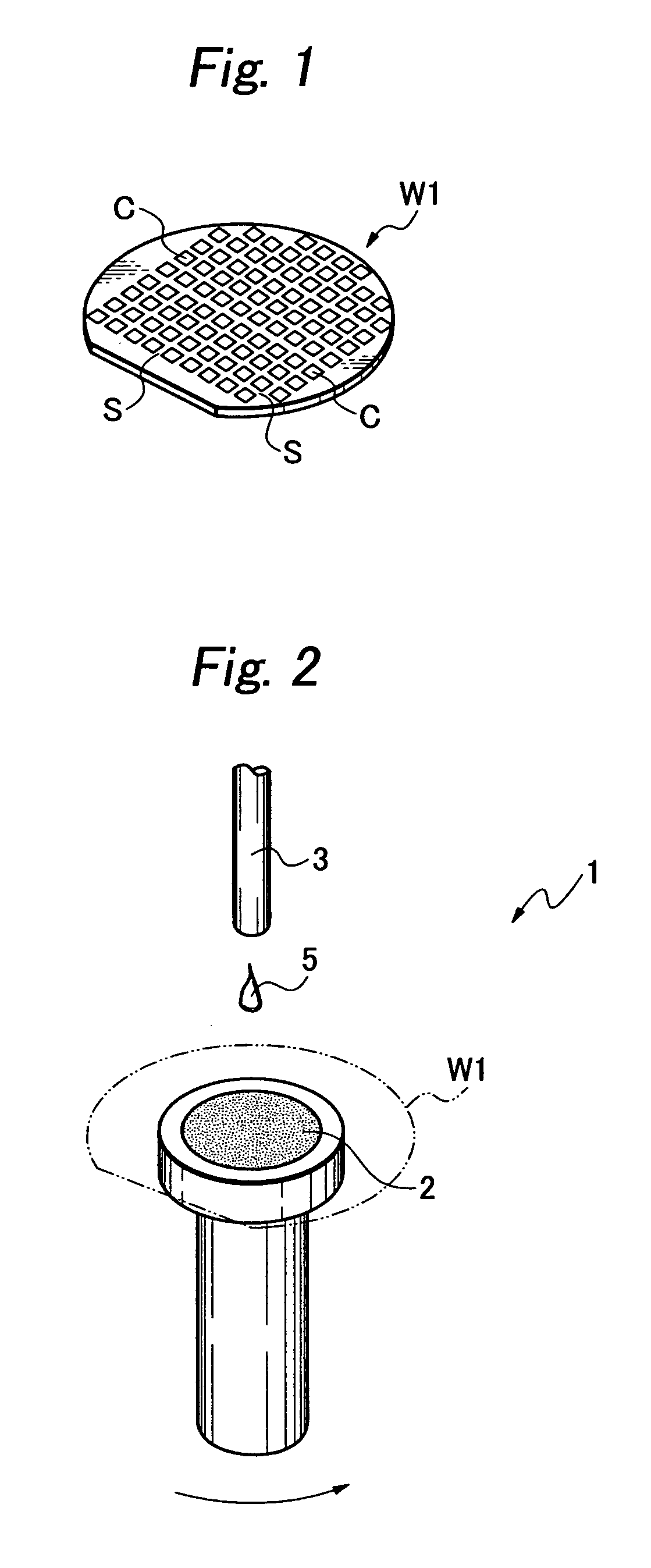

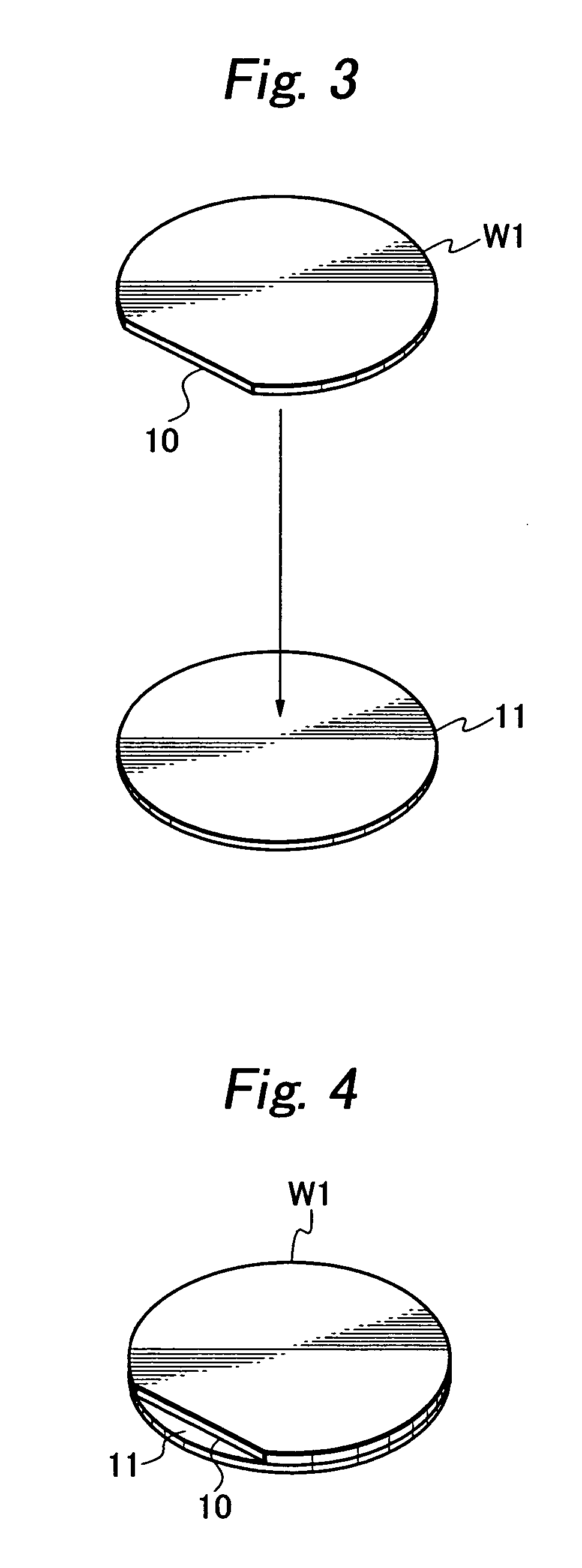

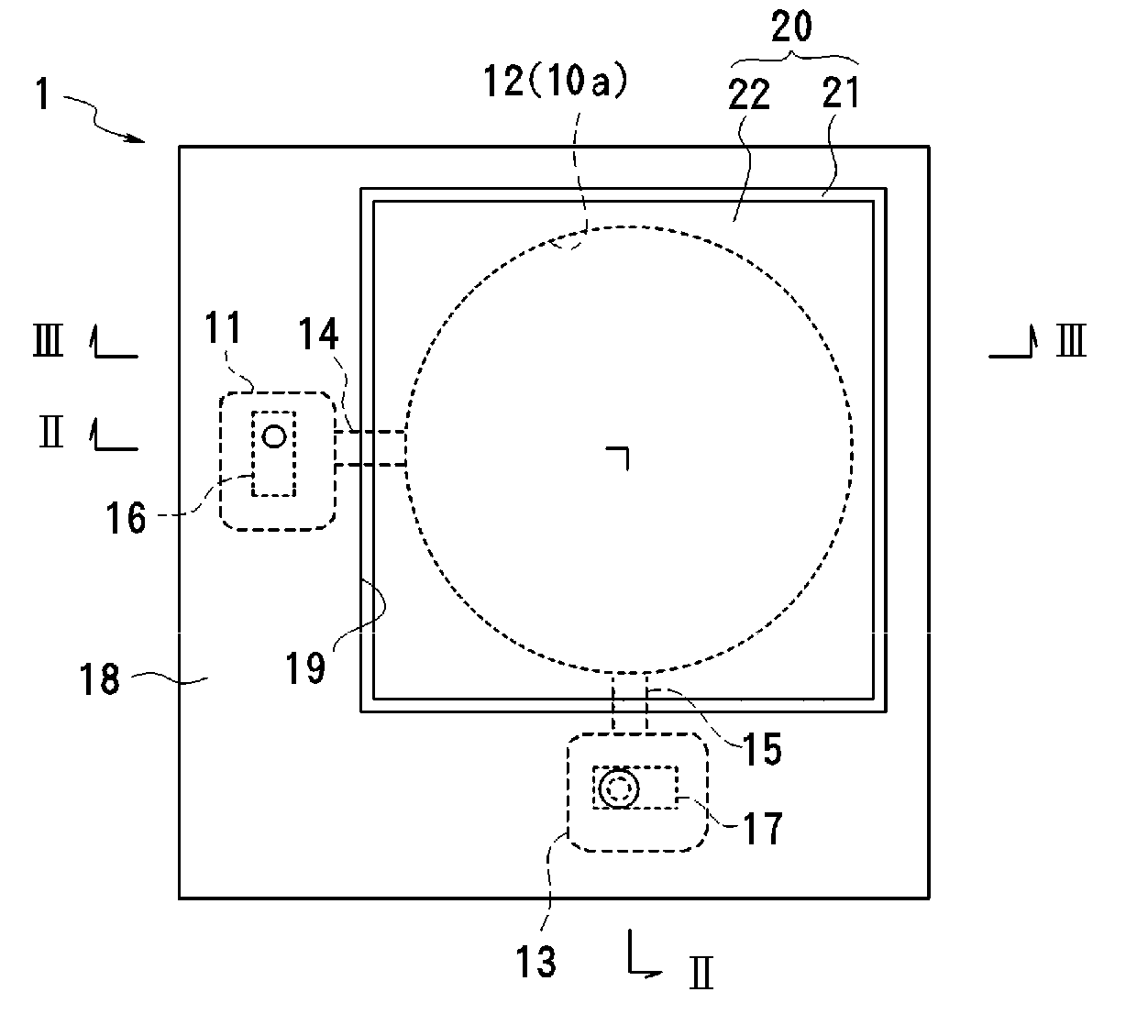

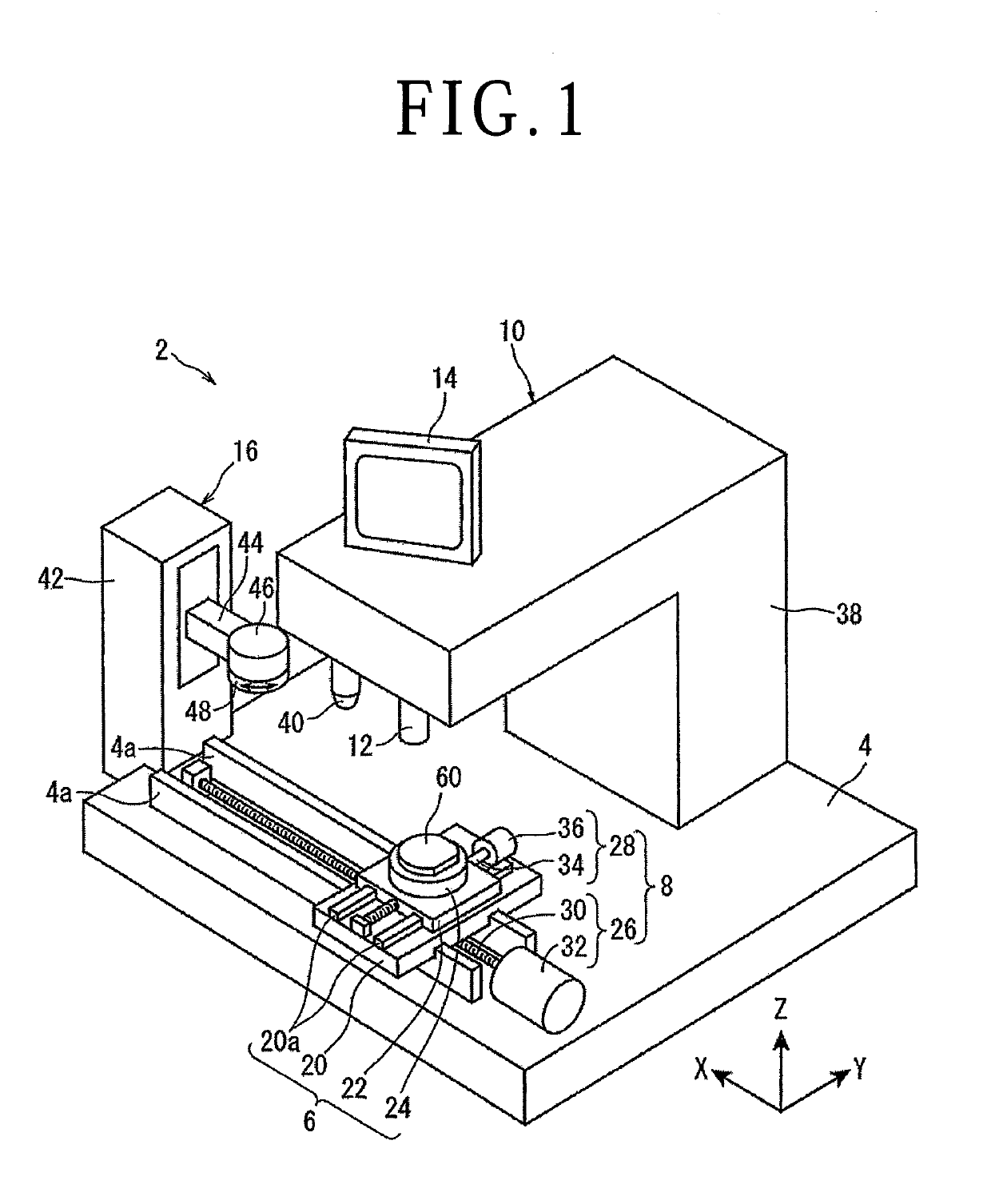

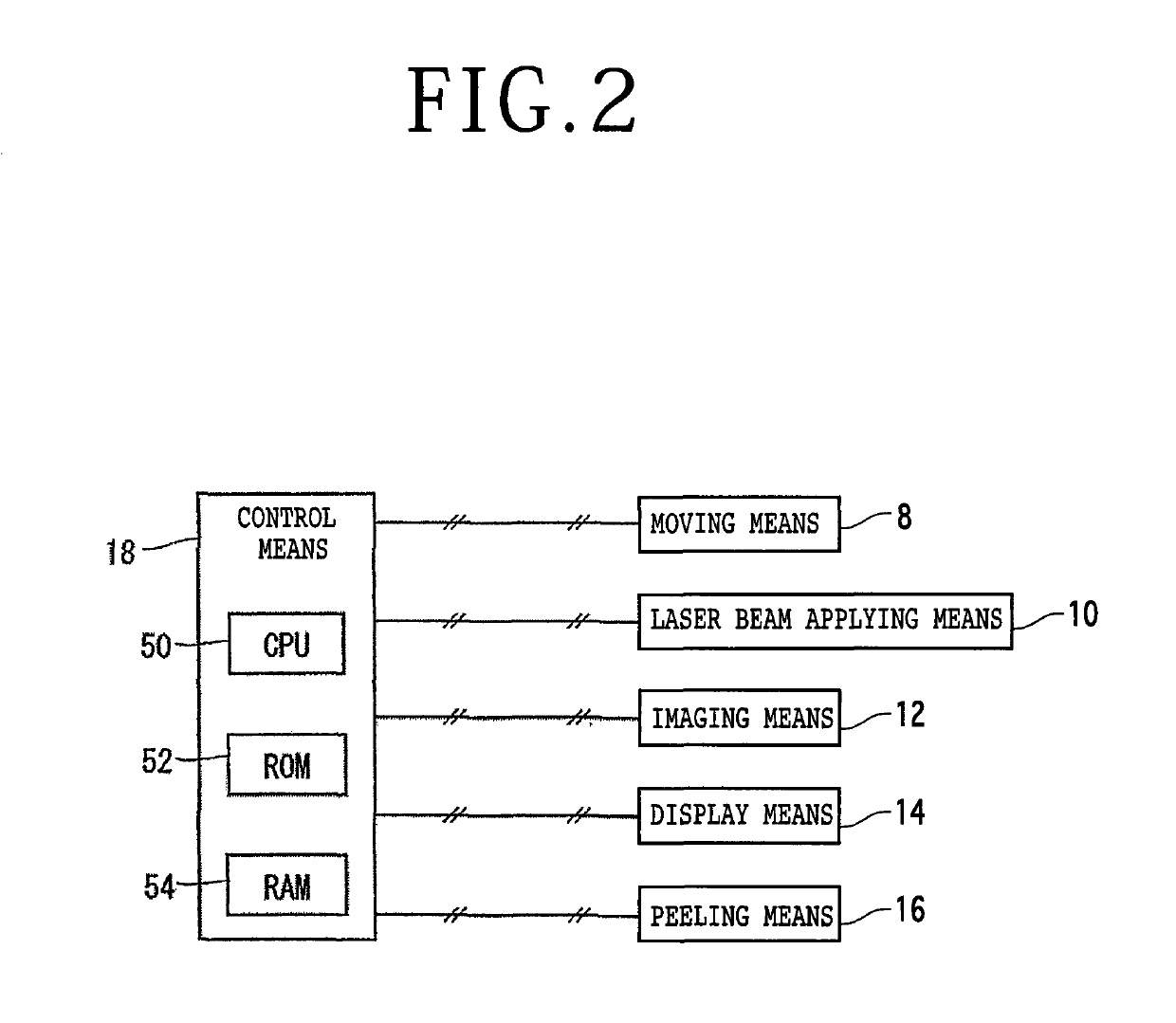

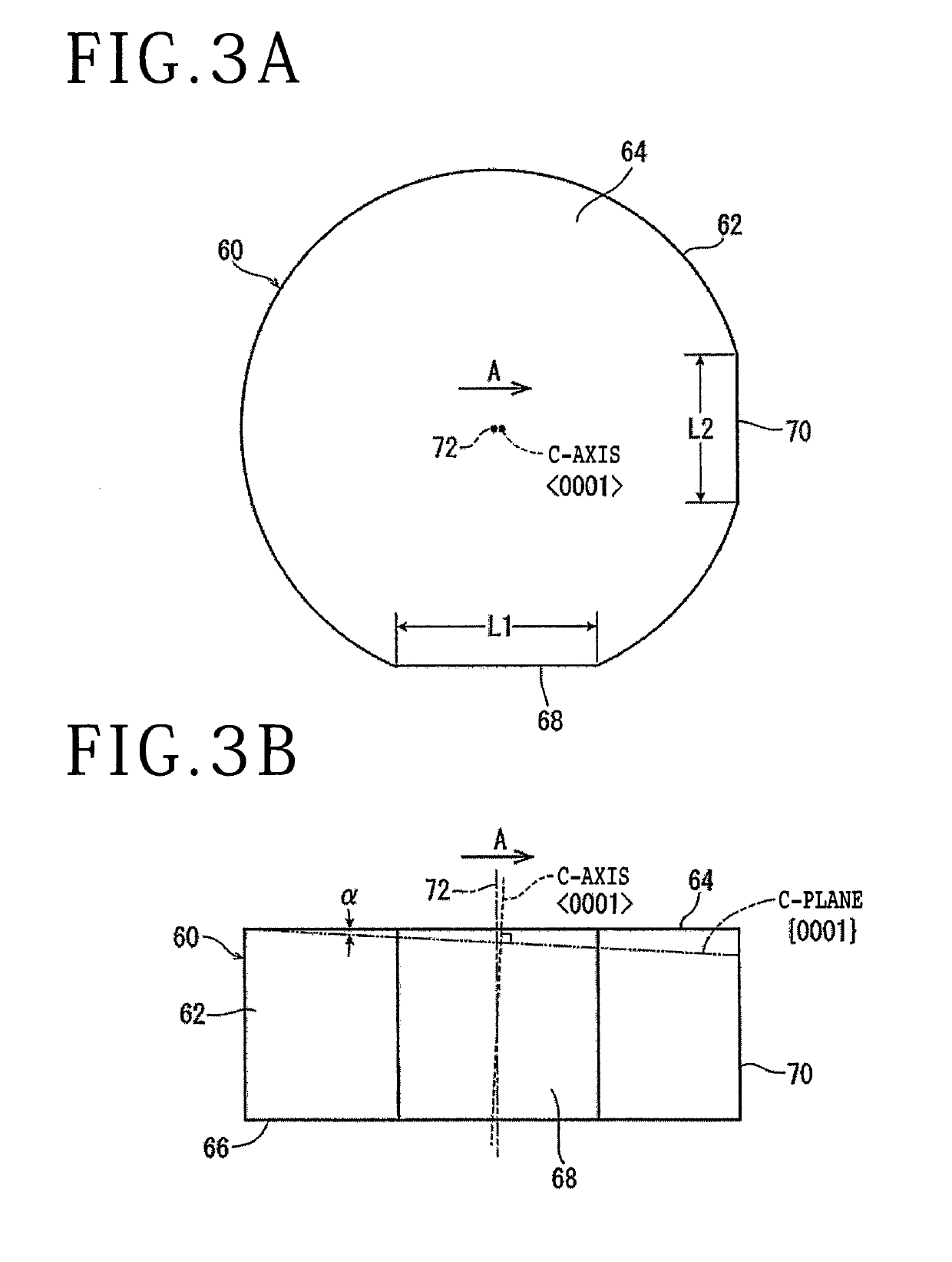

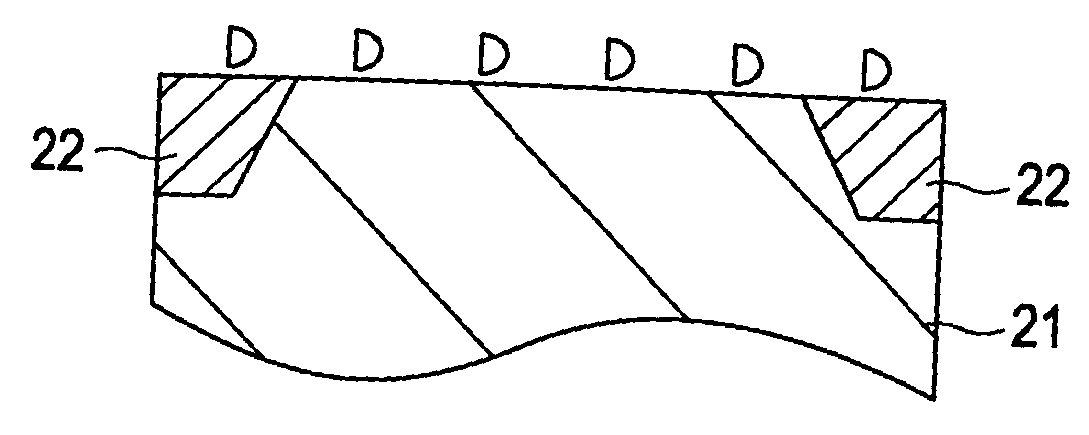

Wafer producing method and processing feed direction detecting method

ActiveUS20170291255A1Improve productivityEfficient productionPolycrystalline material growthAfter-treatment detailsAngular degreesIngot

A wafer is produced from an ingot by confirming whether or not an inclined c-axis of the ingot and a second orientation flat of the ingot are perpendicular to each other, and detecting a processing feed direction perpendicular to the direction in which the c-axis is inclined. The method includes performing sampling irradiation of the ingot with a laser beam, along a direction parallel to the second orientation flat and a plurality of directions inclined clockwise and counterclockwise by respective predetermined angles from the second orientation flat, thereby forming a plurality of sampled reduced strength areas in the ingot; measuring the number of nodes which exist per unit length on each of the sampled reduced strength areas, and determining a direction in which the sampled reduced strength area where the measured number of nodes is zero extends as a processing feed direction.

Owner:DISCO CORP

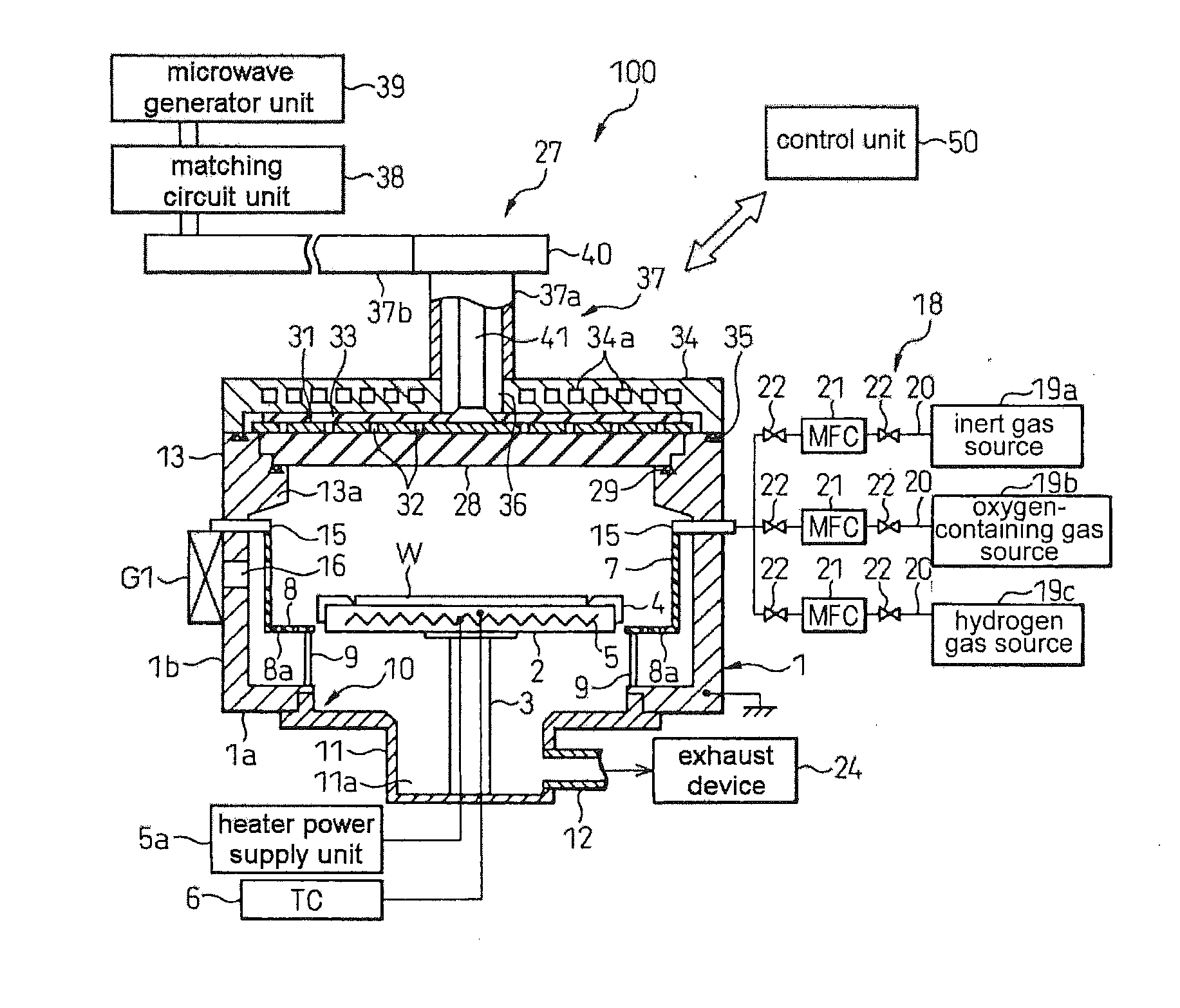

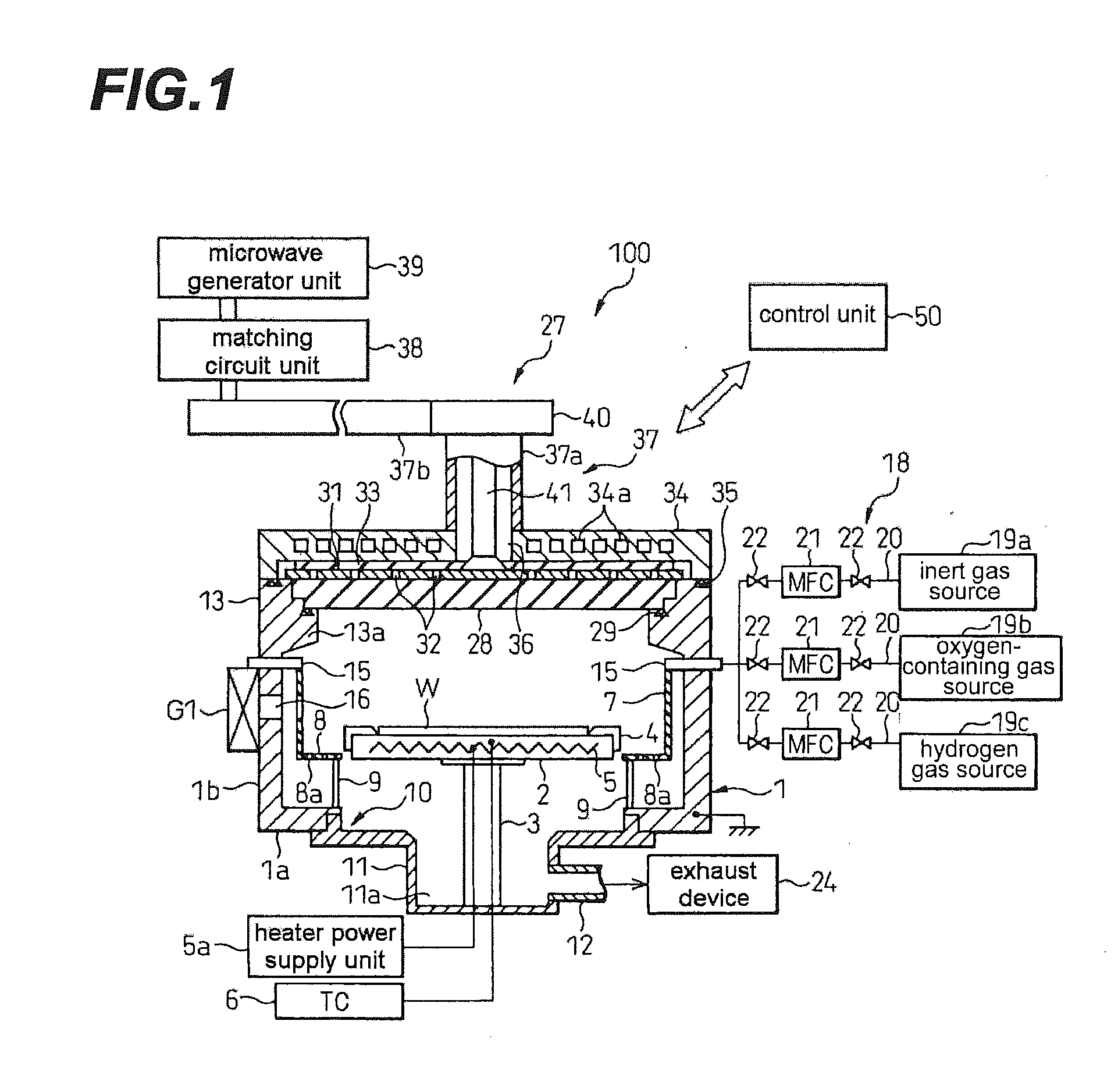

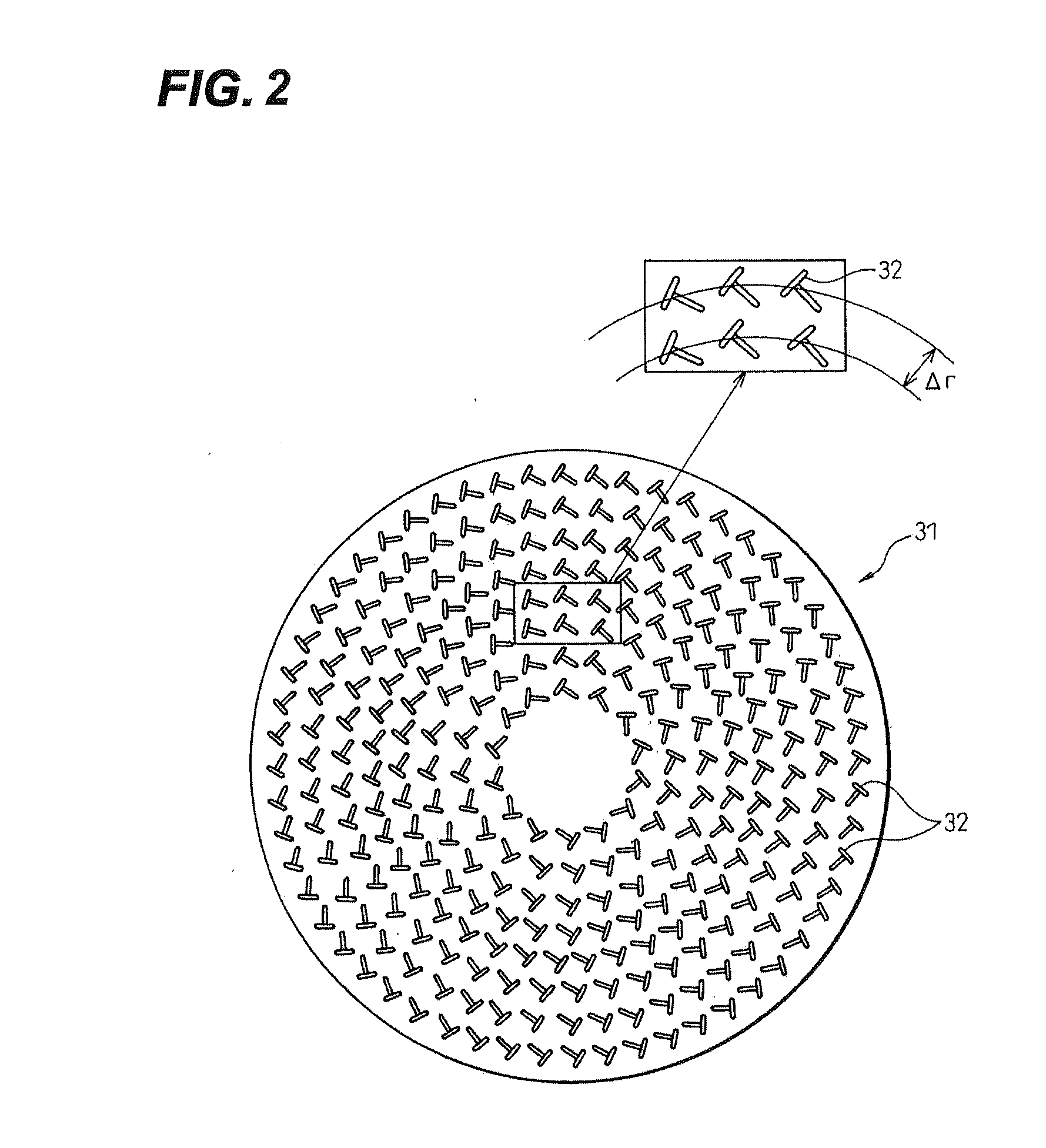

Method for modifying insulating film with plasma

InactiveUS20110053381A1Minimizing increase of amountAccurate shapeElectric discharge tubesSolid-state devicesMicrowaveNoble gas

Disclosed is a method for modifying an insulating film with plasma using a plasma processing apparatus which introduces a microwave into a processing chamber through a plane antenna having a plurality of holes. Processing gas containing a noble gas and oxygen is introduced into the processing chamber and microwave is introduced into the processing chamber through the plane antenna. Plasma composed mainly of O2+ ions and O(1D2) radicals is generated in a pressure condition within a range of 6.7 Pa to 267 Pa to modify the insulating film with the plasma.

Owner:TOKYO ELECTRON LTD

Coated chewing gum, a method for preparation thereof and the use of one or more active substance(s) in solid form

InactiveUS7056541B1Reduce bad tasteDesired thicknessContainers for annular articlesChewing gumPolymer scienceOrganic chemistry

A coated chewing gum comprising a core of chewing gum and a coating comprising a coating material and one or more active substances in solid form. The use of an active substance in solid form in the coating of a coated chewing gum provides a fast onset of the effect, a better stability of the active substance, and an increased effect thereof in al chewing phases.

Owner:KRAFT FOODS DANMARK INTPROP APS

Chip microphone and method of making same

InactiveUS7298856B2Strong heat-resistant characteristicSmall sizeSemiconductor electrostatic transducersMicrophone structural associationEngineeringSound pressure

A chip microphone implemented as a single silicon-based chip includes a diaphragm which includes a vibration portion that vibrates in response to sound pressures, a support block which is formed on the diaphragm, excluding at least the vibration portion to provide a vibration space, and a back plate which is formed on the support block and over the vibration space, thereby facing the vibration portion of the diaphragm across the vibration space.

Owner:NIPPON HOSO KYOKAI

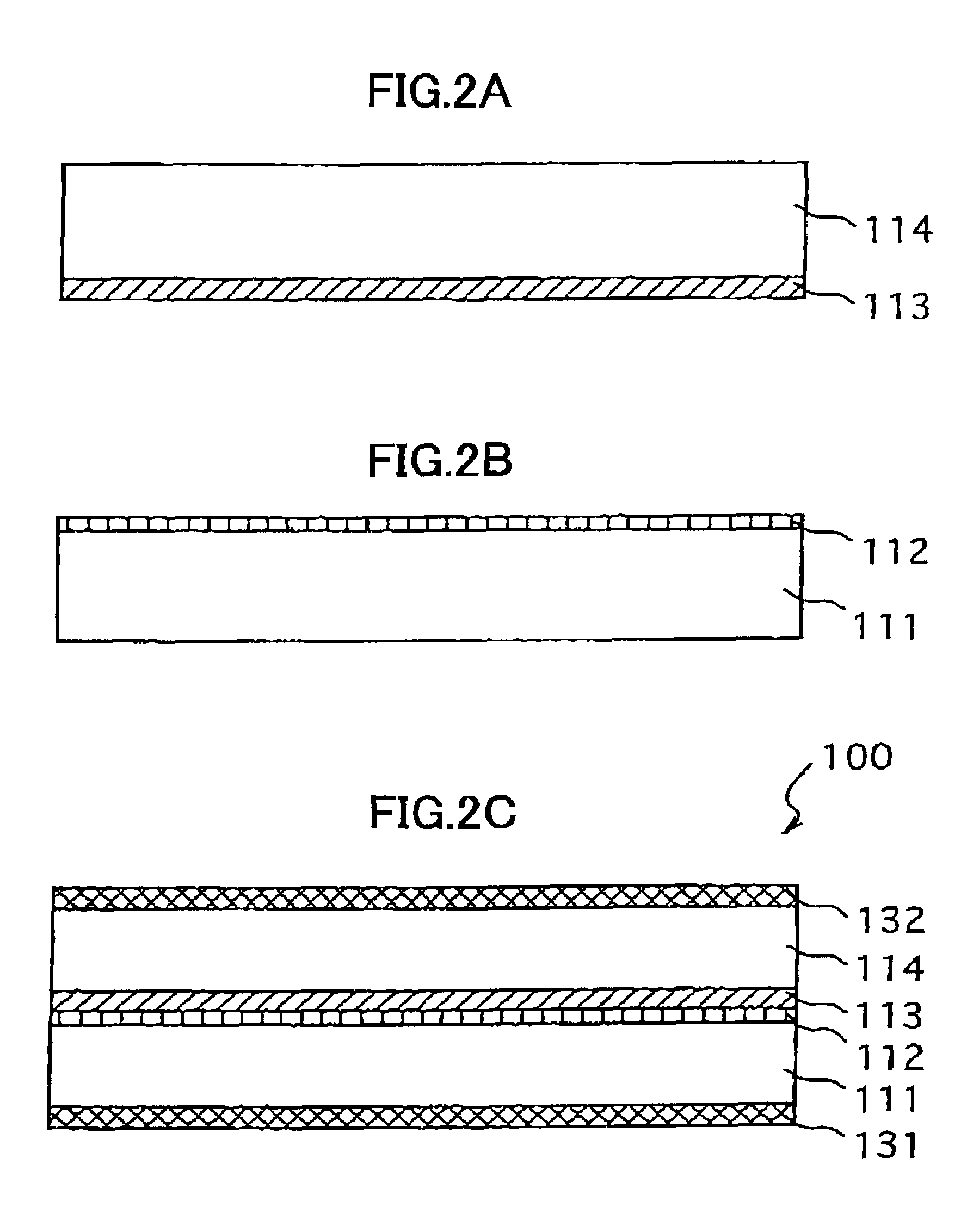

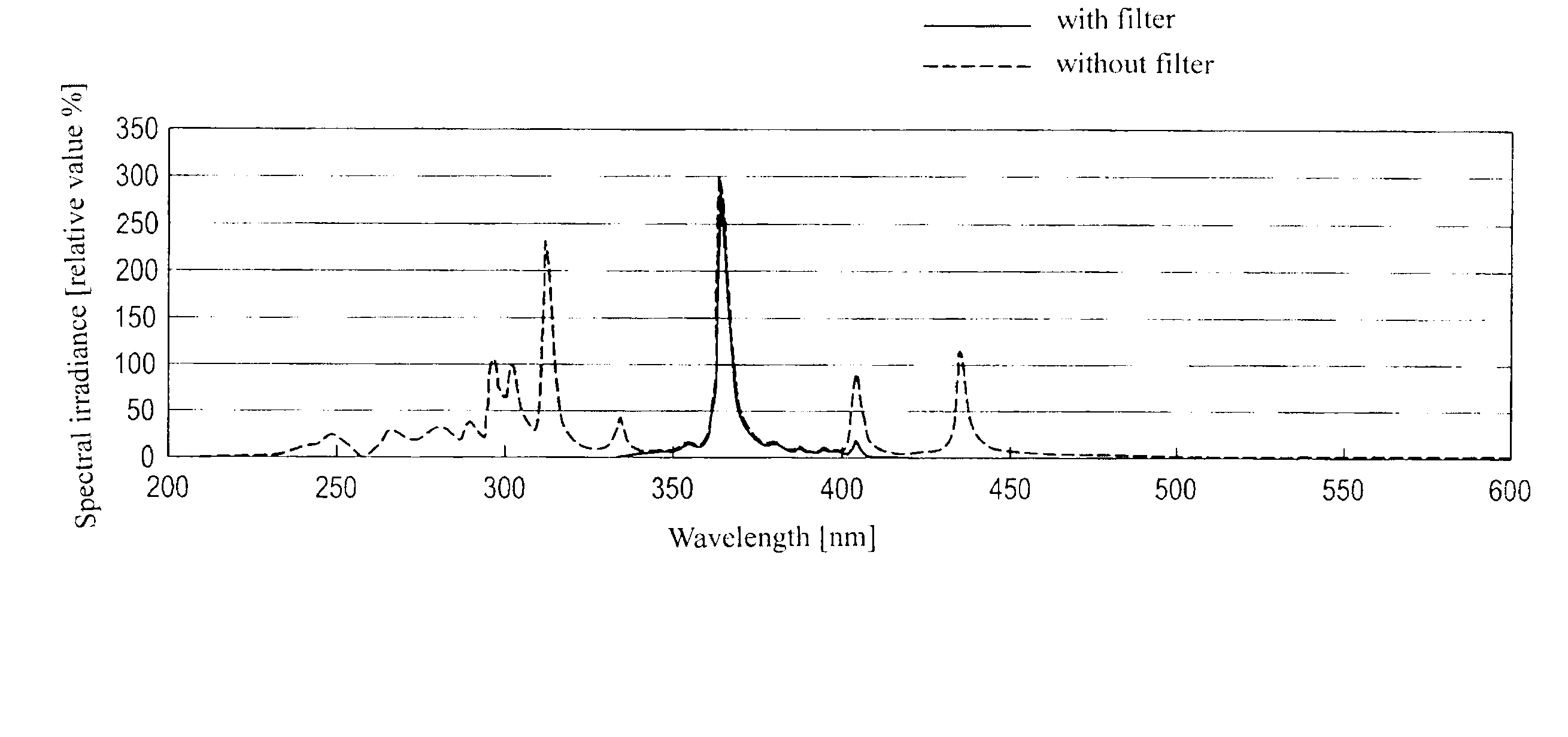

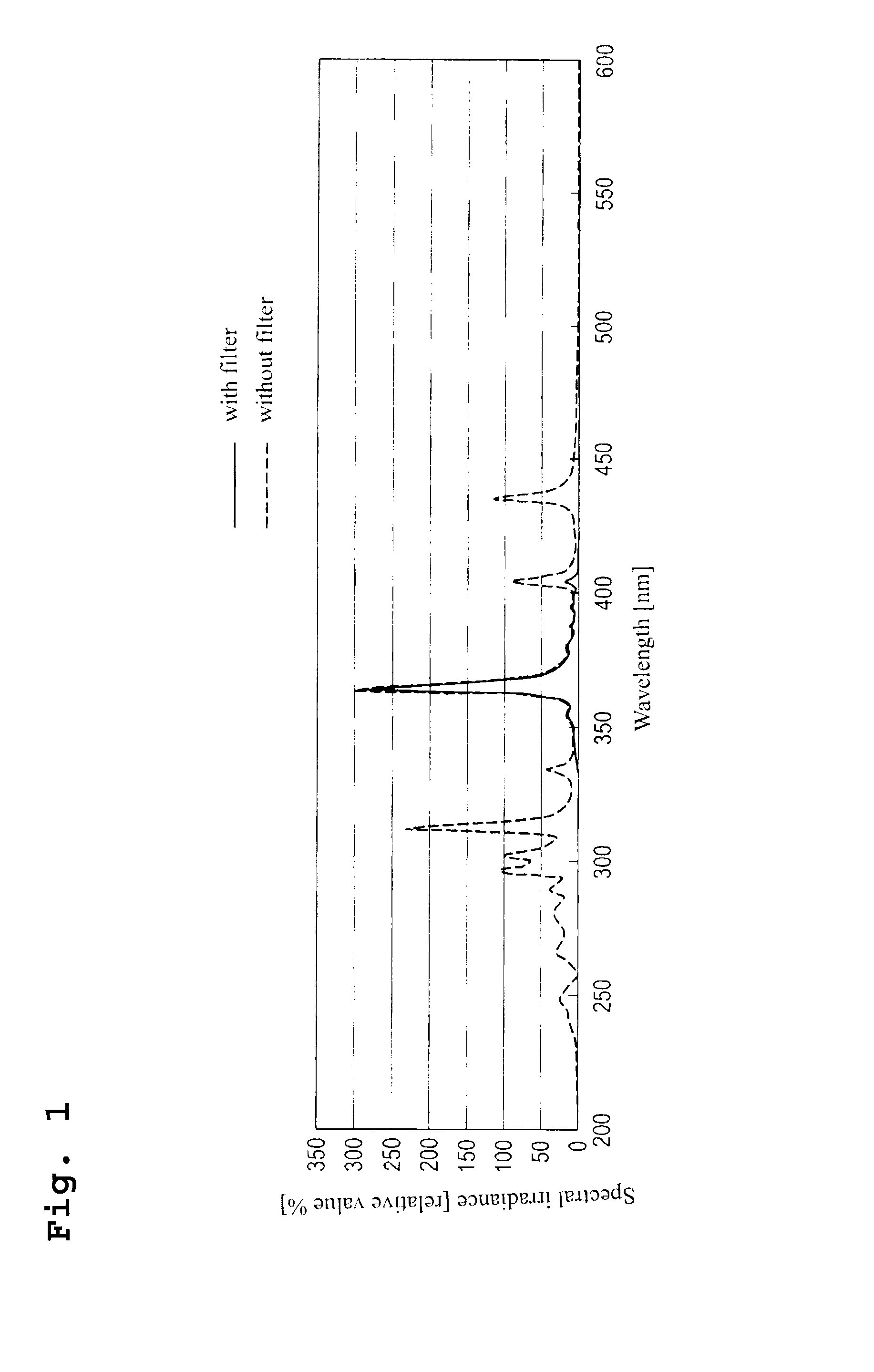

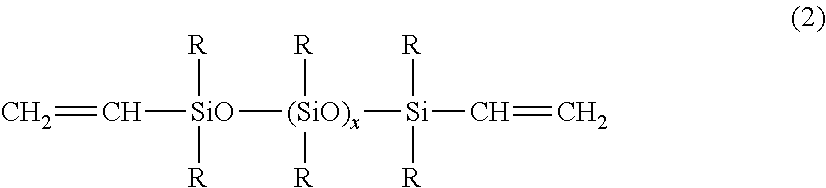

Method of producing cured thin film using photocurable silicone resin composition

A cured thin film may be easily prepared, by curing a photocurable silicone resin composition containing: (A) an organopolysiloxane having two or more alkenyl groups within each molecule, (B) an organohydrogenpolysiloxane having two or more hydrogen atoms bonded to silicon atoms within each molecule, and (C) a photoactive catalyst, by: (i) applying the composition to a substrate, (ii) obtaining a thin film in a semi-cured state by irradiating the applied coating with light, and (iii) heating the thin film in a semi-cured state to achieve complete curing, wherein the spectrum of the light irradiated in step (ii) has a maximum peak in a wavelength region from 300 nm to 400 nm, and the spectral irradiance of light of any wavelength within the wavelength region shorter than 300 nm is not more than 5% of the spectral irradiance of light of the maximum peak wavelength.

Owner:SHIN ETSU CHEM IND CO LTD

Liquid crystalline coating solution and polarizing film

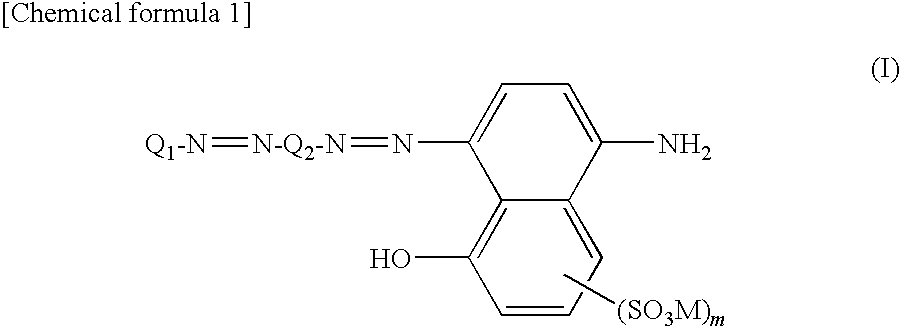

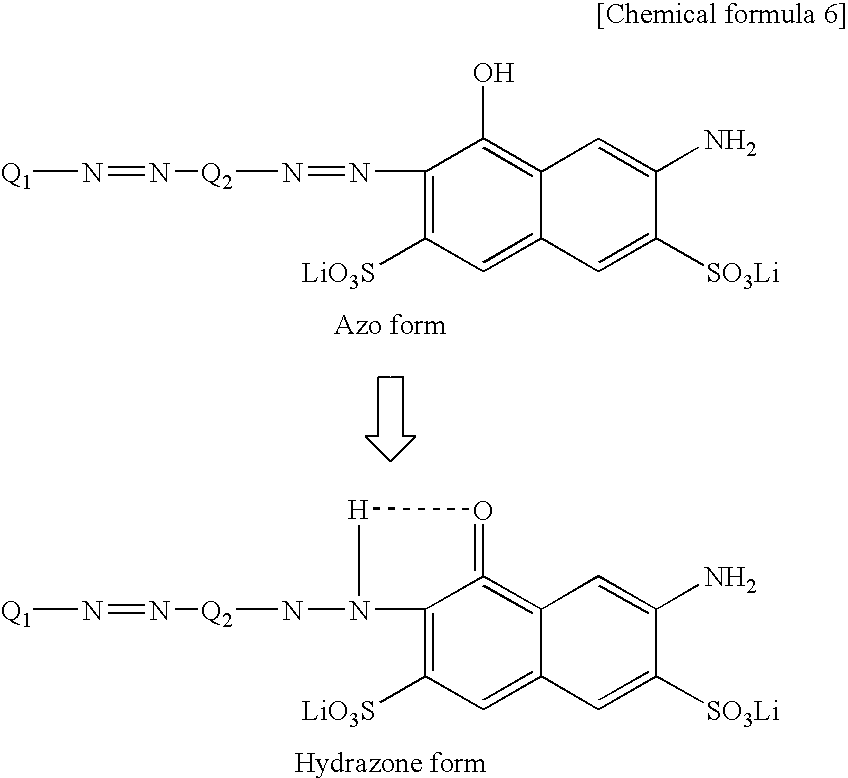

InactiveUS20100110361A1Improve visibilityLarge absorption dichroismLiquid crystal compositionsMonoazo dyesLiquid crystallineSolvent

A liquid crystalline coating solution which comprises: an azo compound represented by the following general formula (I); and a solvent to dissolve the azo compound:wherein Q1 is a phenyl group or a naphthyl group (these groups may have any substituent groups); Q2 is a pheylene group or a naphtylene group (these groups may have any substituent groups); m is an integer from 1 to 5; and M is a counter ion.

Owner:NITTO DENKO CORP

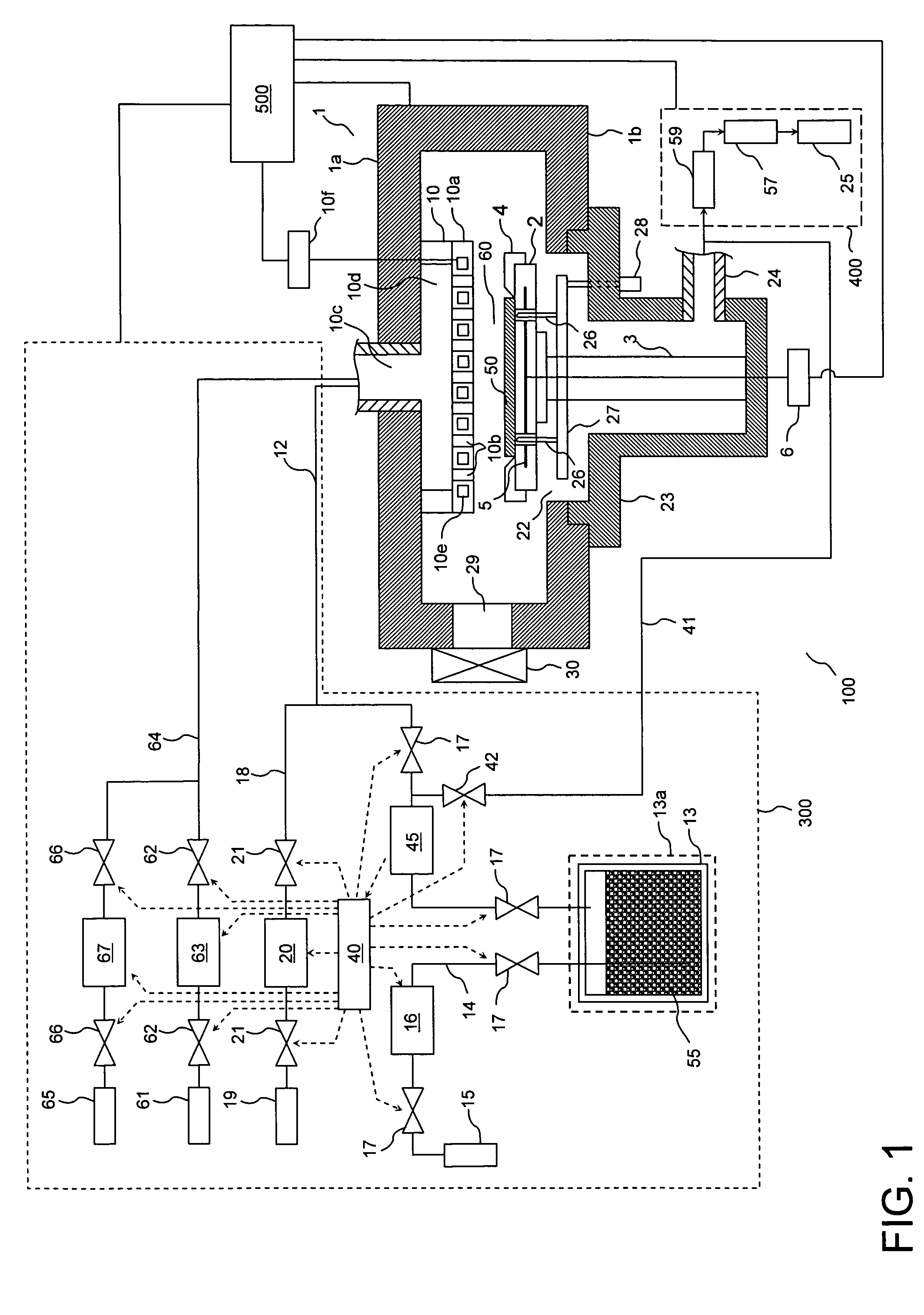

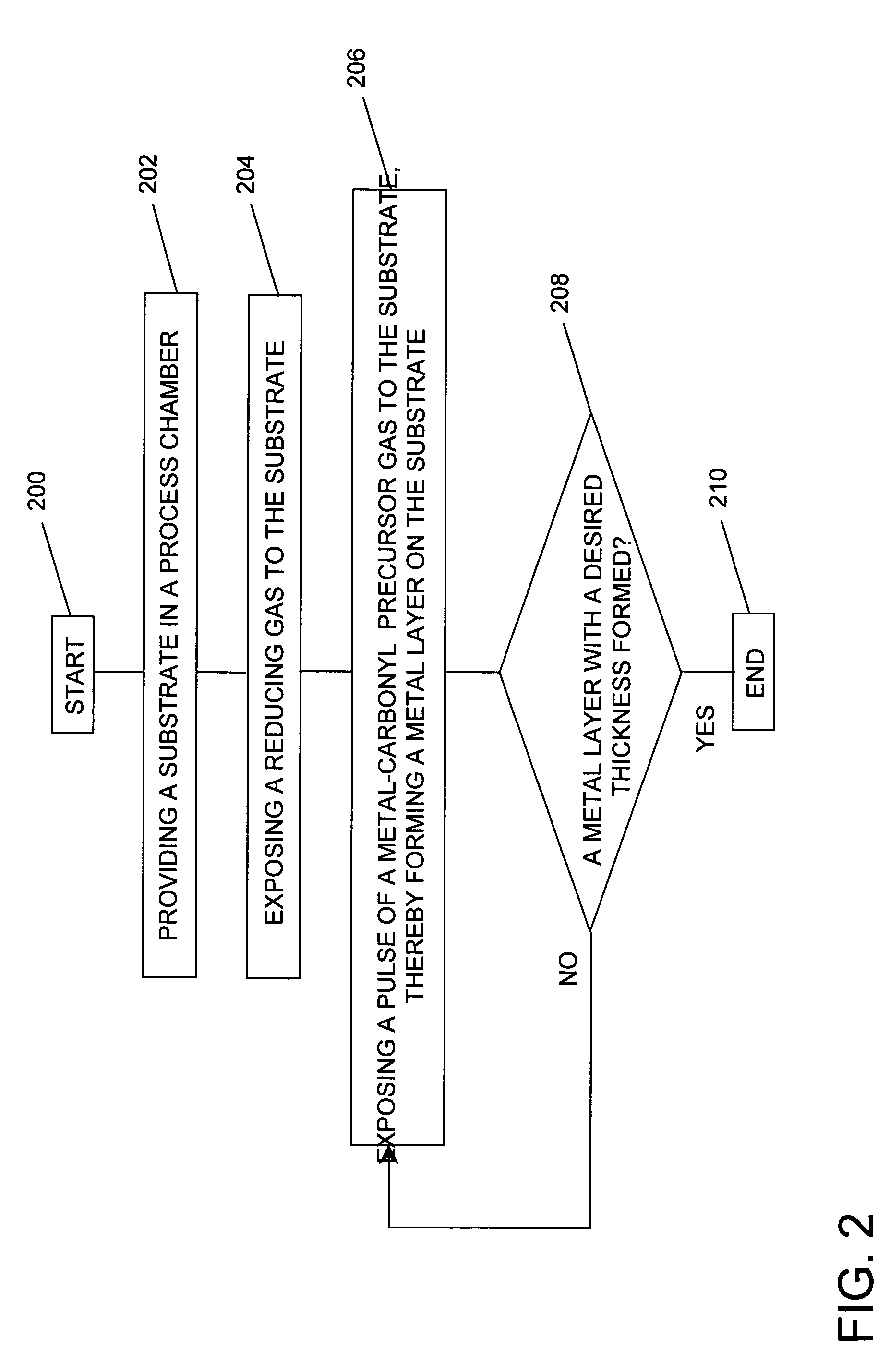

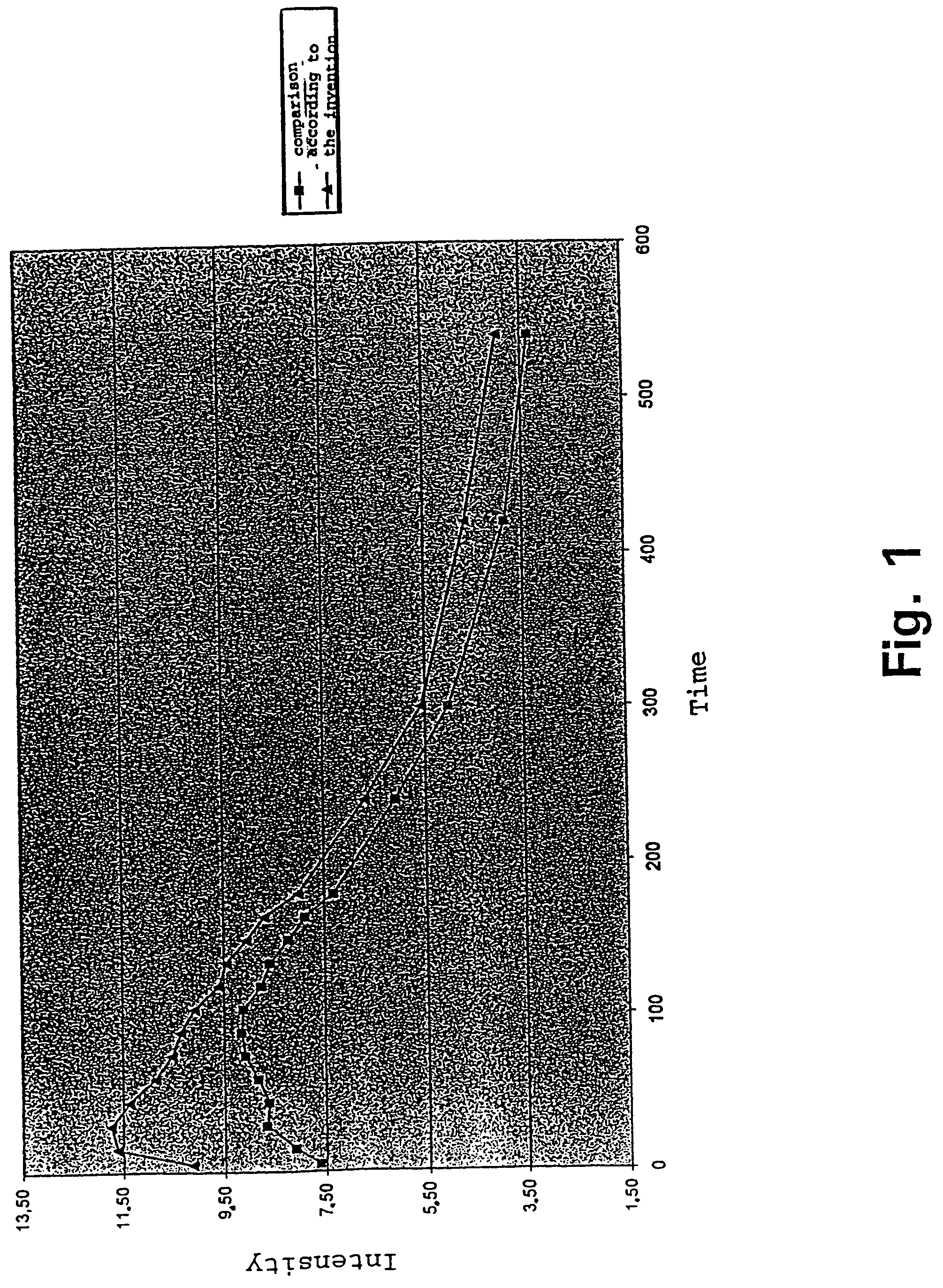

Method of forming a metal layer using an intermittent precursor gas flow process

ActiveUS20050069632A1Desired thicknessSemiconductor/solid-state device manufacturingSpecial surfacesProduct gasMetallurgy

A method is provided for forming a metal layer on a substrate using an intermittent precursor gas flow process. The method includes exposing the substrate to a reducing gas while exposing the substrate to pulses of a metal-carbonyl precursor gas. The process is carried out until a metal layer with desired thickness is formed on the substrate. The metal layer can be formed on a substrate, or alternately, the metal layer can be formed on a metal nucleation layer.

Owner:IBM CORP +1

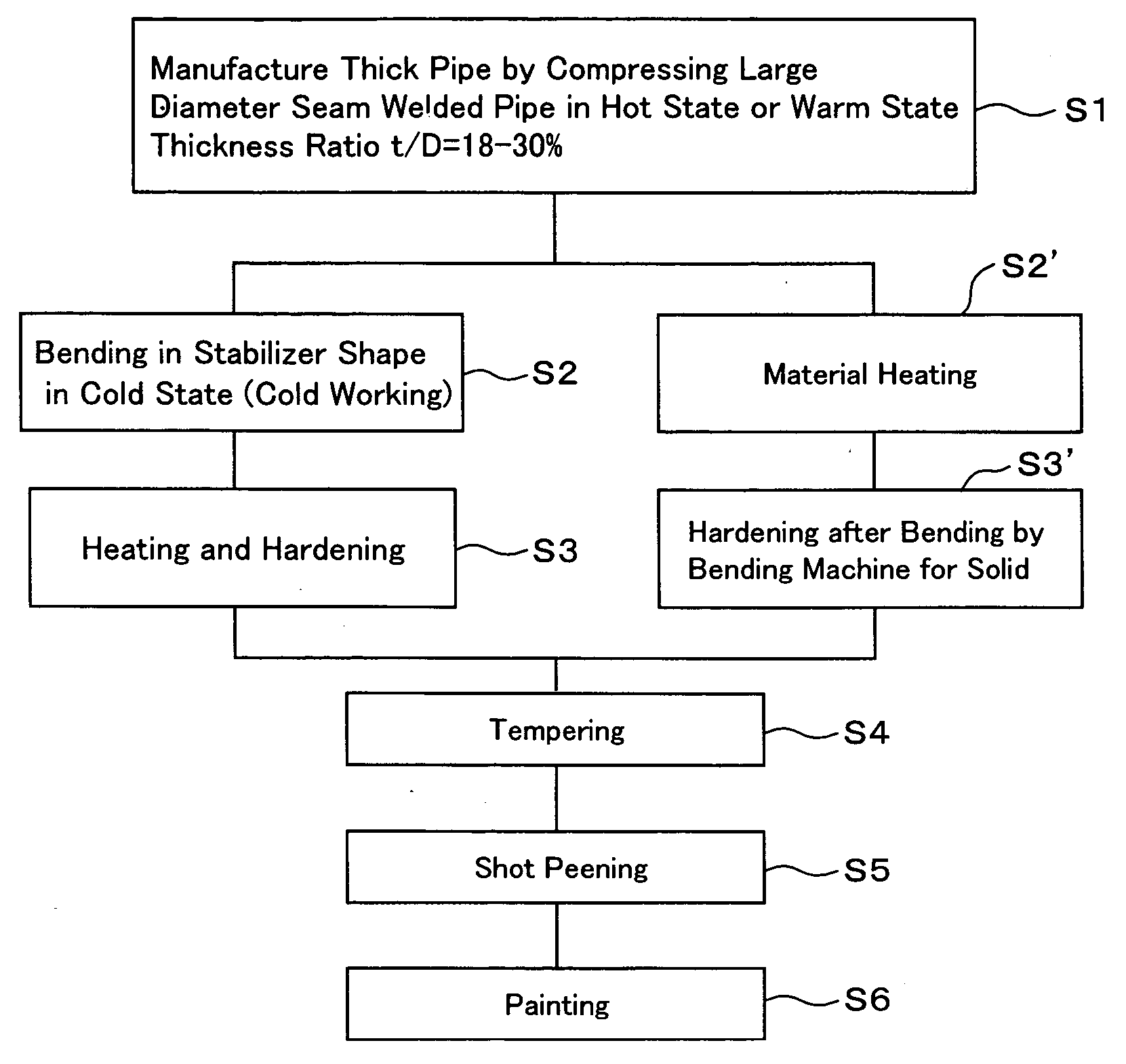

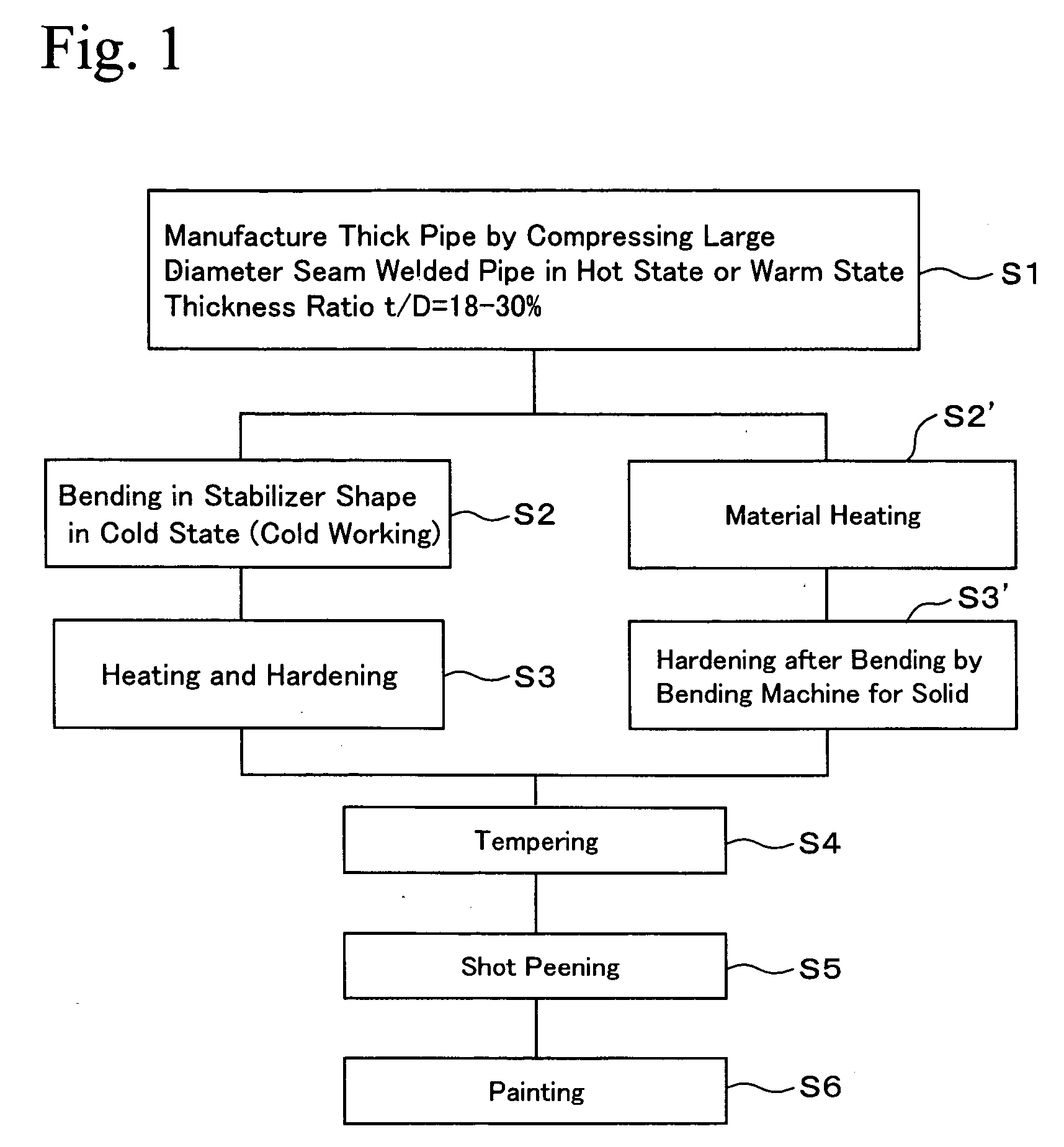

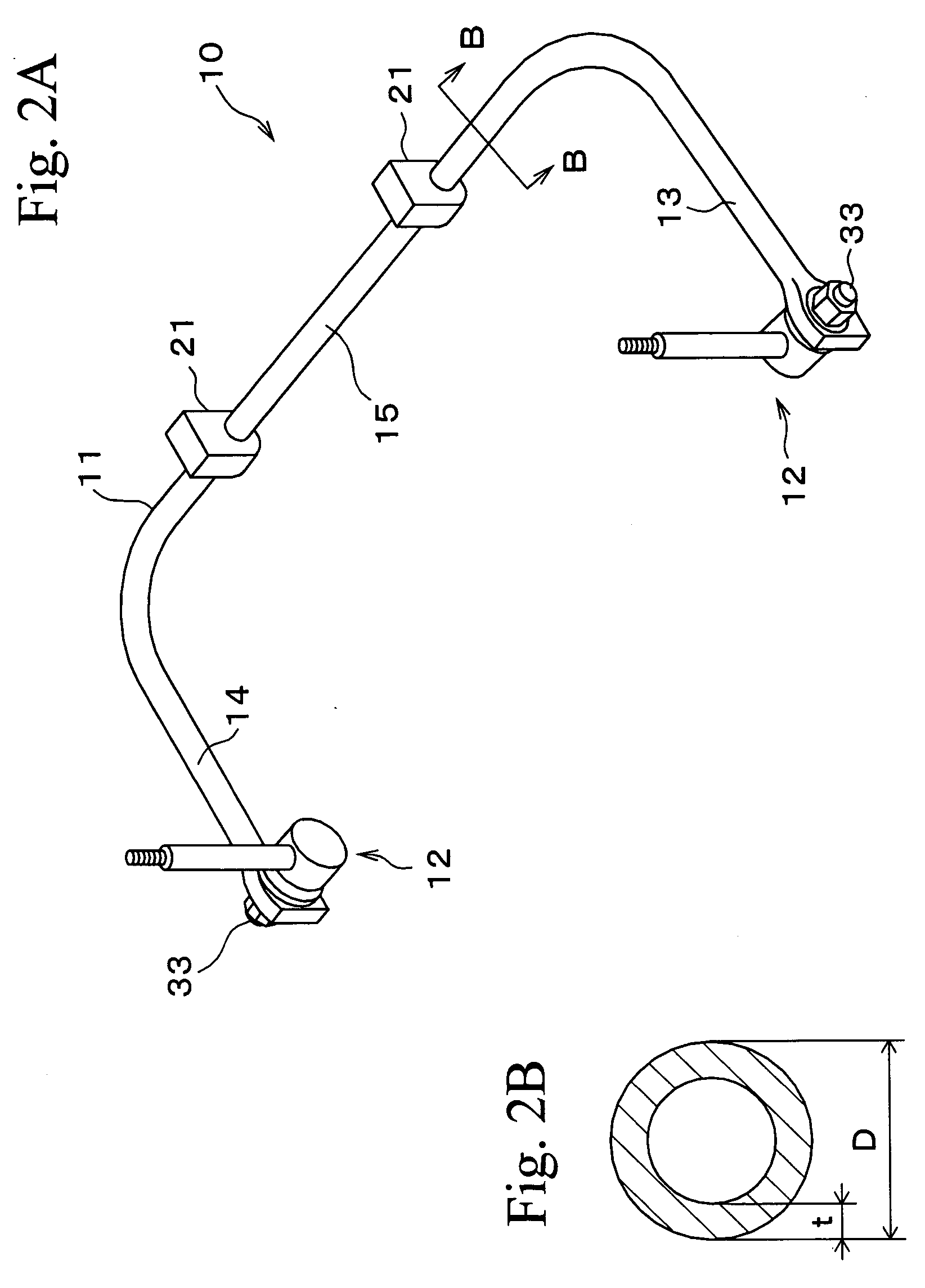

Hollow stabilizer and method of manufacturing the same

InactiveUS20060200990A1Wide range of choicesEasily correspondMetal-working apparatusFurnace typesBiomedical engineeringPeening

In a method of manufacturing a hollow stabilizer, a pipe compressing step of compressing an electroseamed pipe in a temperature range of a hot state or a warm state so as to make a rate of a thickness with respect to an outer diameter between 18 and 35% is performed, and a forming step of forming the compressed electroseamed pipe in a stabilizer shape in a cold state is executed. Next, a step of applying a heat treatment to a half-finished stabilizer is performed, a shot peening step of impacting a shot on the half-finished stabilizer is performed, and a step of coating the half-finished stabilizer is performed.

Owner:NHK SPRING CO LTD

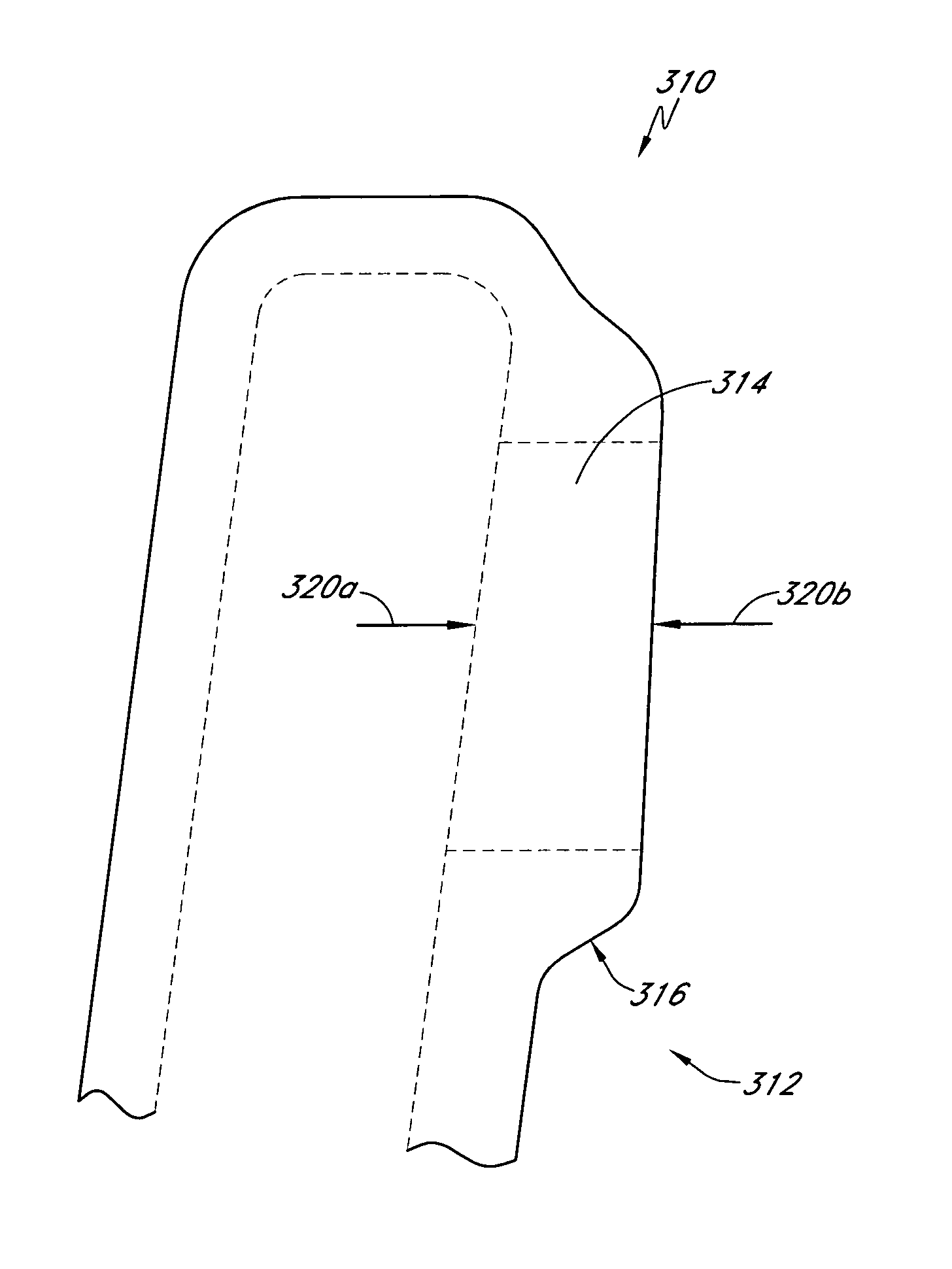

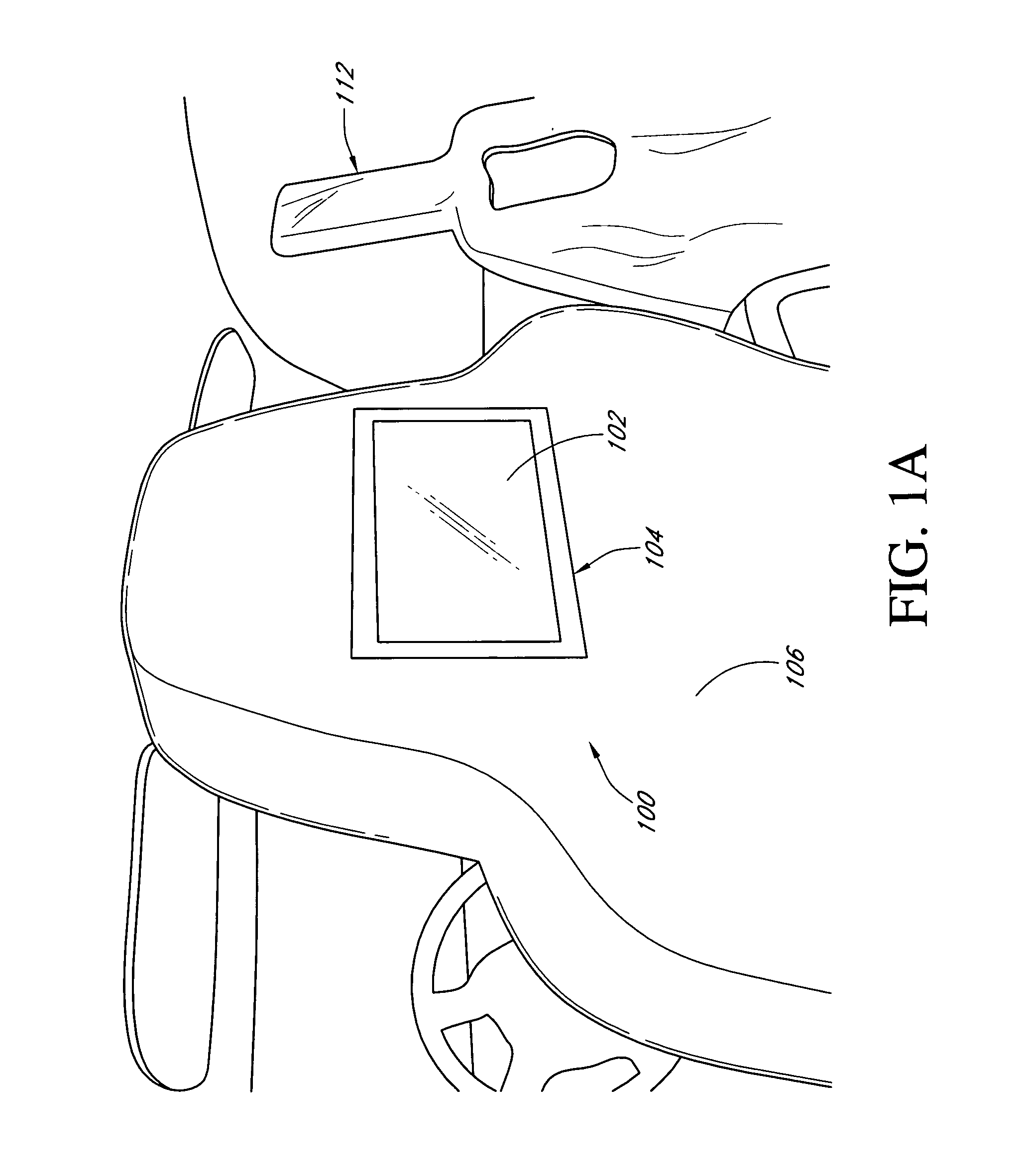

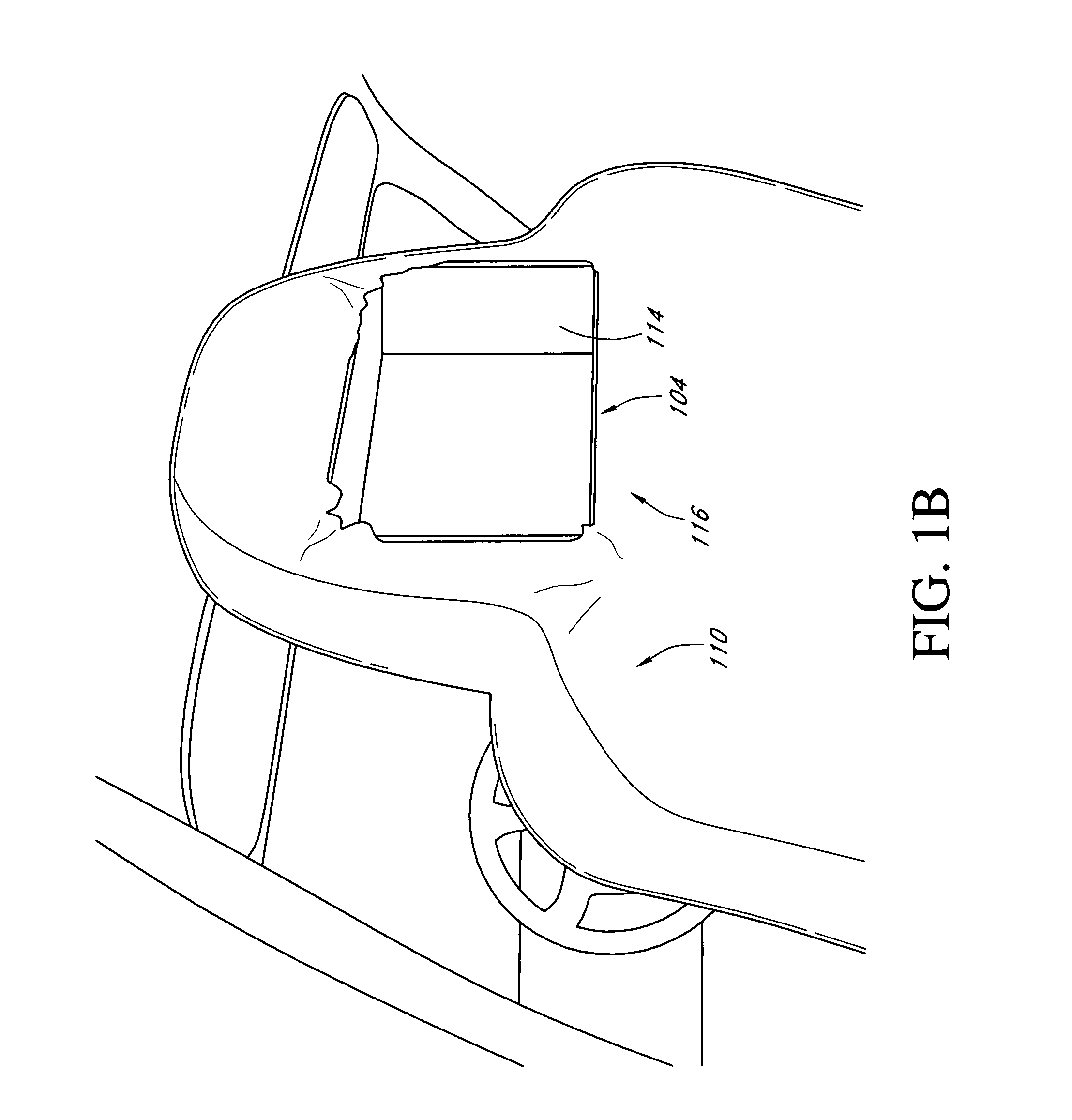

Preformed foam seatback with integral opening

A high-back automobile seat having an opening defined by the seat's rear surface. The opening allows mounting of utility or entertainment components for use by a passenger behind the high-back seat. Entertainment components such as a video screen or an integrated DVD player / screen may be mounted for viewing enjoyment. A formed seat bun with the opening provides the space for mounting of such components. The formed seat bun may be prewired to allow easier installation of electronic components. An area about the opening may be contoured to provide sufficient depth for flush mounting of components.

Owner:TIMELY INNOVATIONS

Coated chewing gum comprising an active substance having systemic activity

InactiveUS20050048164A1Reduce bad tasteDesired thicknessContainers for annular articlesConfectioneryWhole bodyChewing gum

A coated chewing gum comprising a core of chewing gum and a coating comprising a coating material and one or more active substance(s) in solid form. The use of an active substance in solid form in the coating of a coated chewing gum provides a fast onset of the effect, a better stability of the active substance, and an increased effect thereof in al chewing phases.

Owner:STAHL BRONISLAW JAN

Method for growing epitaxial diamond

ActiveUS20140137795A1Desired thicknessQuality improvementPolycrystalline material growthFrom chemically reactive gasesDiamond thin filmMaterials science

A method for growing epitaxial diamond is provided here. A metallic layer is deposited on a diamond substrate and is followed by an epitaxial diamond film deposited on top of the metallic layer. As a buffer layer, the metallic layer relieves stress accumulated in the thin film of the epitaxial diamond to prevent cracks. In consequence, diamond epitaxial layers with desired thickness and good quality can be obtained.

Owner:NAT CHIAO TUNG UNIV

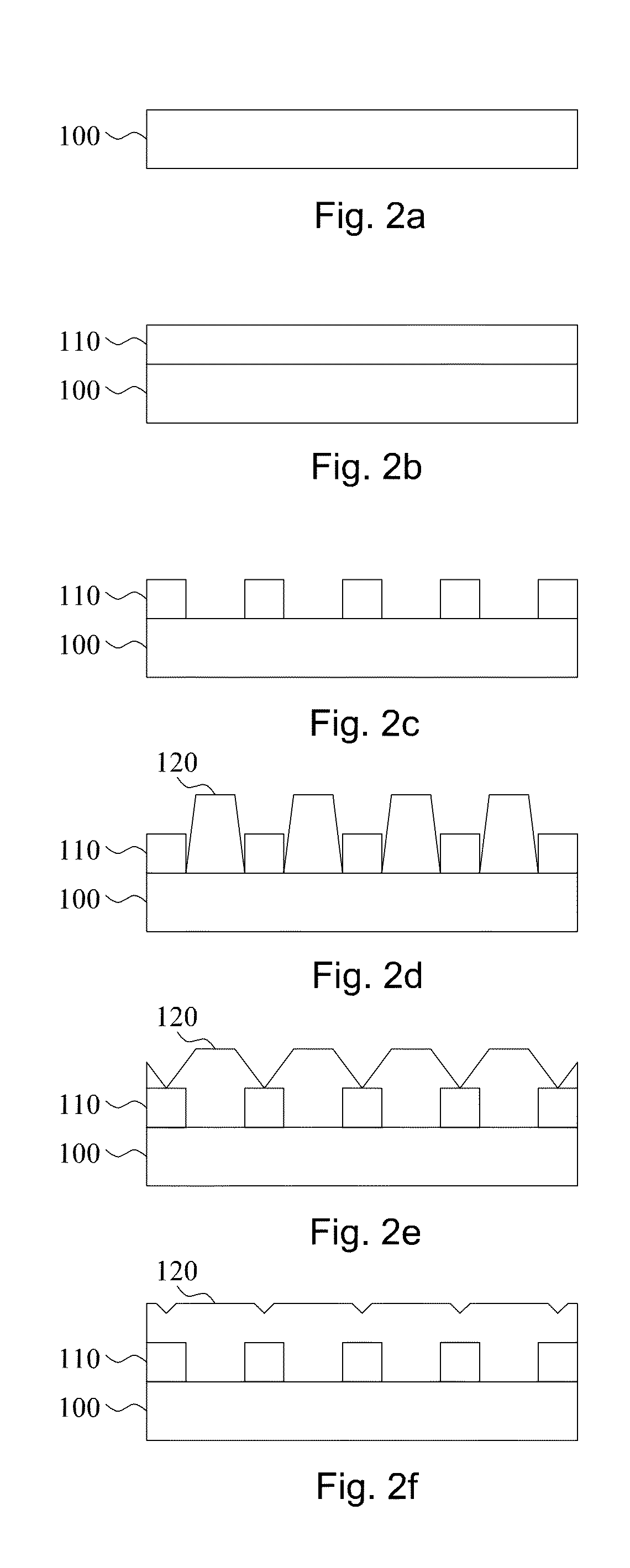

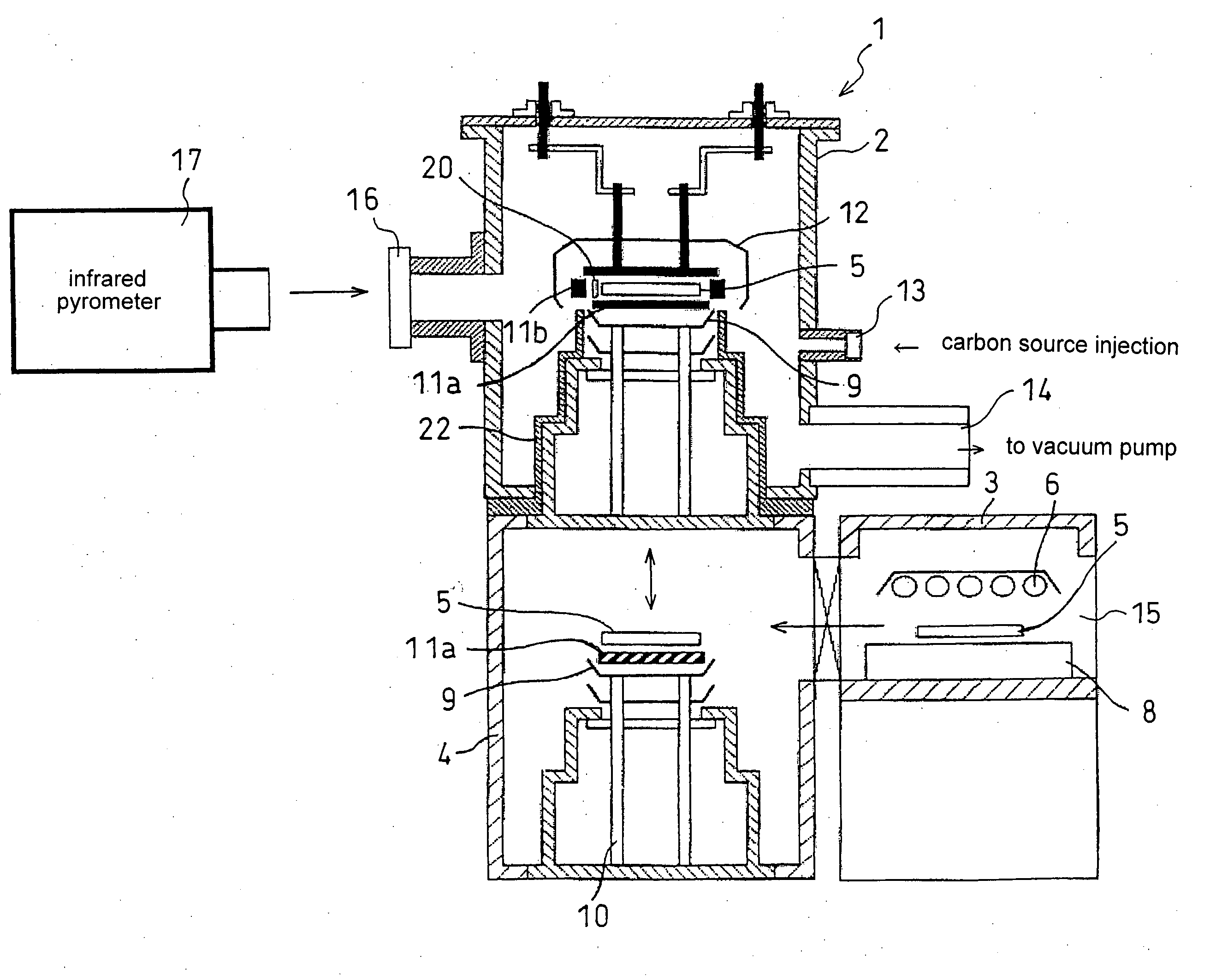

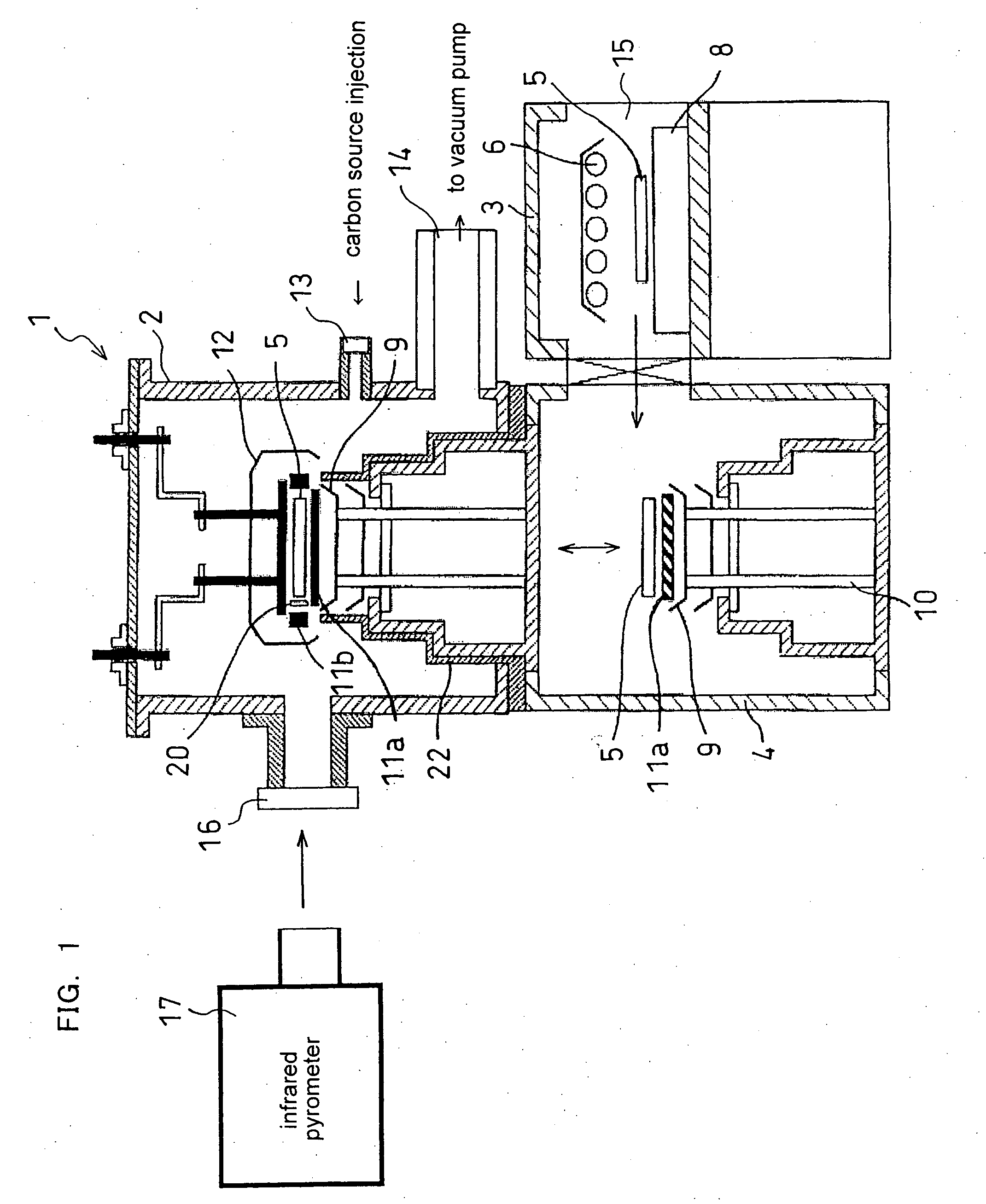

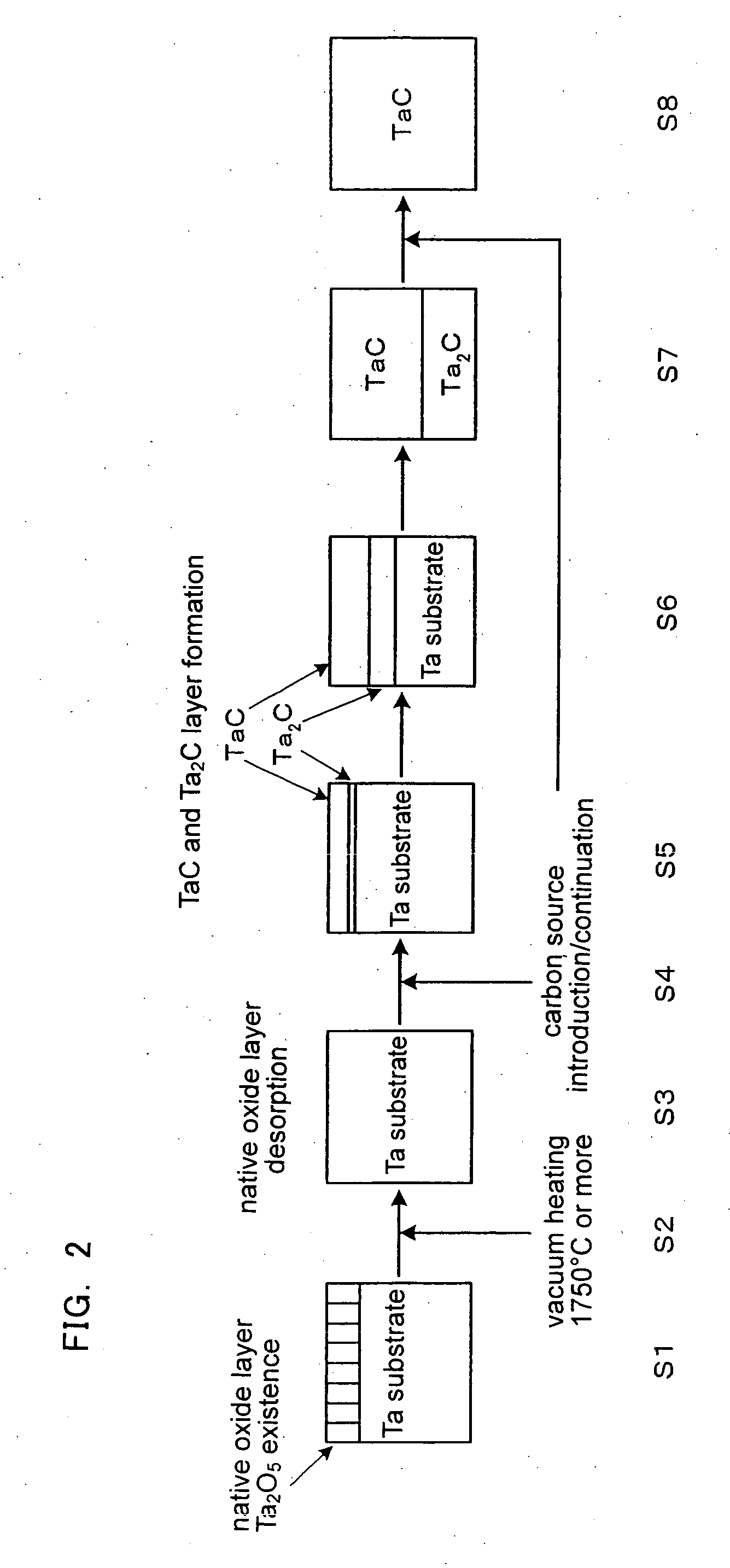

Tantalum carbide, method for producing tantalum carbide, tantalum carbide wiring and tantalum carbide electrode

InactiveUS20070059501A1High melting pointHigh hardness propertiesSolid state diffusion coatingCeramic layered productsTantalum carbideCarbon source

It is an object of the present invention to provide a method for manufacturing tantalum carbide which can form tantalum carbide having a prescribed shape using a simple method, can form the tantalum carbide having a uniform thickness even when the tantalum carbide is coated on the surface of an article and is not peeled off by a thermal history, tantalum carbide obtained by the manufacturing method, wiring of tantalum carbide, and electrodes of tantalum carbide. The tantalum carbide is formed on the surface of tantalum or a tantalum alloy by placing the tantalum or tantalum alloy in a vacuum heat treatment furnace, heat-treating the tantalum or tantalum alloy under a condition where a native oxide layer of Ta2O5 formed on the surface of tantalum or tantalum alloy is sublimated to remove the Ta205, introducing a carbon source into the vacuum heat treatment furnace, and then heat-treating.

Owner:TOYO TANSO KK

Method for manufacturing semiconductor chip

InactiveUS7172950B2Reduce adhesionEasy to disassembleSolid-state devicesSemiconductor/solid-state device manufacturingAdhesion forceSemiconductor chip

In manufacturing thinned semiconductor chips by grinding a semiconductor wafer supported on a rigid support substrate, in order to remove the semiconductor wafer or semiconductor chips from the support substrate without damage to the semiconductor wafer or semiconductor chips, a semiconductor wafer at its surface is bonded on a light-transmissive support substrate through an adhesive layer having an adhesion force that is reduced upon exposure to light radiation, thereby exposing the back surface of the semiconductor wafer. A tape is bonded to the backside of the semiconductor wafer integrated with the support substrate after grinding, wherein the tape is supported at the periphery. Before or after bonding of the tape, light radiation is applied to the adhesive layer at a side close to the support substrate to reduce the adhesion force in the adhesion layer. Thereafter, the support substrate and adhesive layer is removed from the surface of the semiconductor wafer, leaving the semiconductor wafer held by the tape and frame. The semiconductor wafer supported by the tape and frame is cut at streets into individual semiconductor chips.

Owner:KANSAI PAINT CO LTD +1

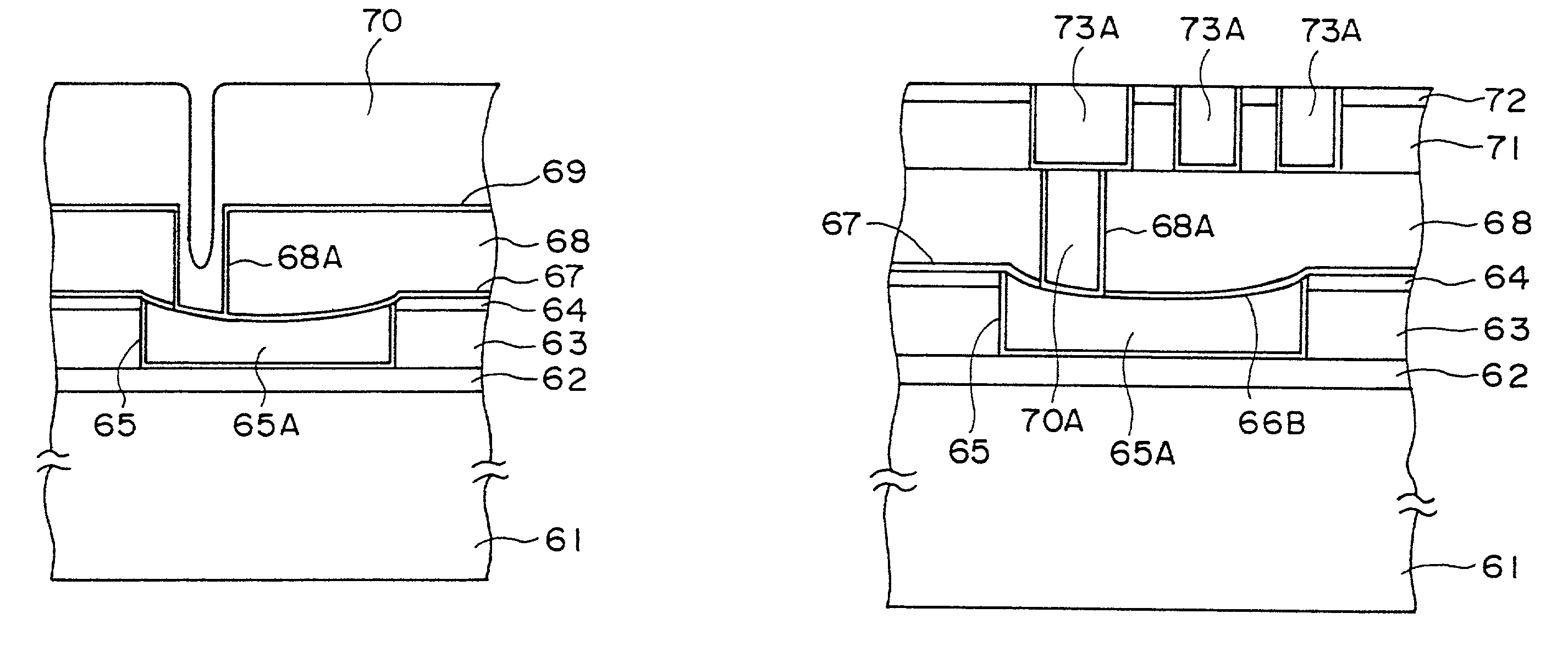

Semiconductor device having a multilayer interconnection structure

InactiveUS7041586B2Desired thicknessLow dielectric constantSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInterconnection

A semiconductor device includes a multilayer interconnection structure including an organic interlayer insulation film in which a conductor pattern is formed by a damascene process, wherein the organic interlayer insulation film carries thereon an organic spin-on-glass film.

Owner:FUJITSU SEMICON LTD

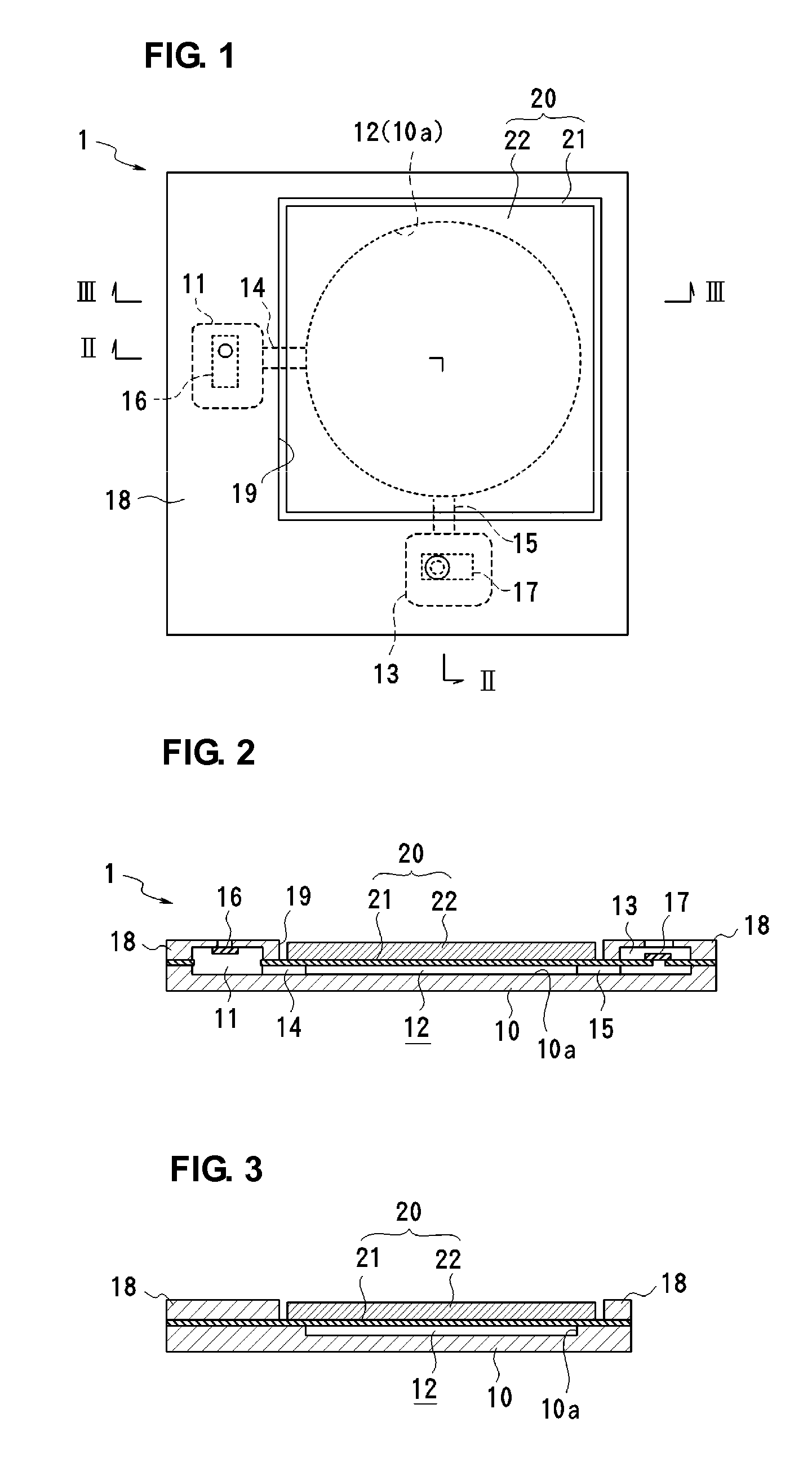

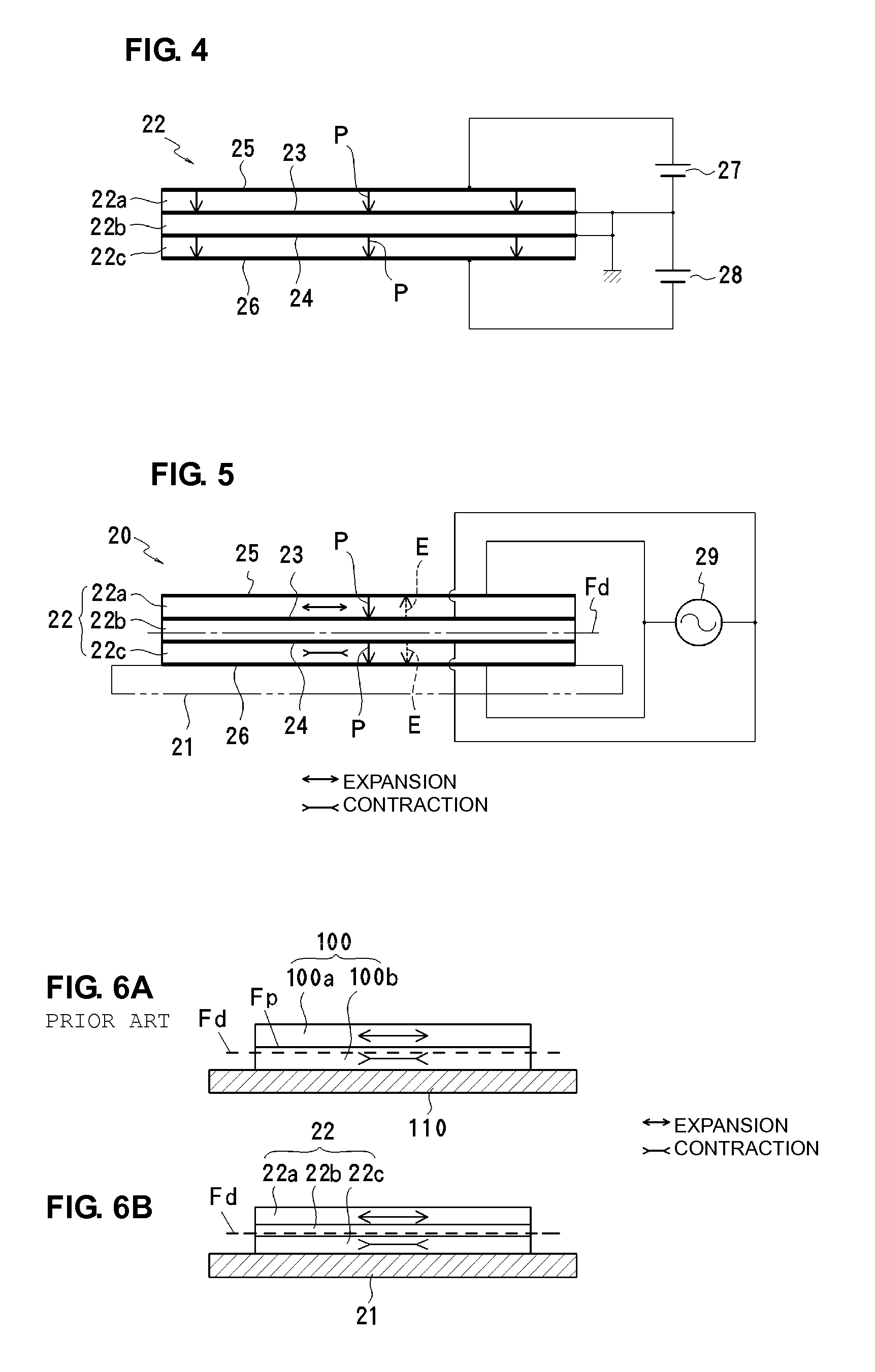

Piezoelectric pump

ActiveUS20090214362A1Efficient processHinder displacement of piezoelectricFlexible member pumpsPiezoelectric/electrostrictive/magnetostrictive devicesPump chamberEngineering

A piezoelectric pump includes a diaphragm that defines a pump chamber between the diaphragm and a pump body, and a piezoelectric element bonded to a surface of the diaphragm. The piezoelectric element is a bimorph piezoelectric element in which a plurality of piezoelectric layers are stacked, including a neutral layer disposed in the approximate middle of the piezoelectric element in the thickness direction and that is not displaced. The piezoelectric element can be efficiently displaced because a neutral plane of the diaphragm and the piezoelectric element bonded therein is located in the neutral layer.

Owner:MURATA MFG CO LTD

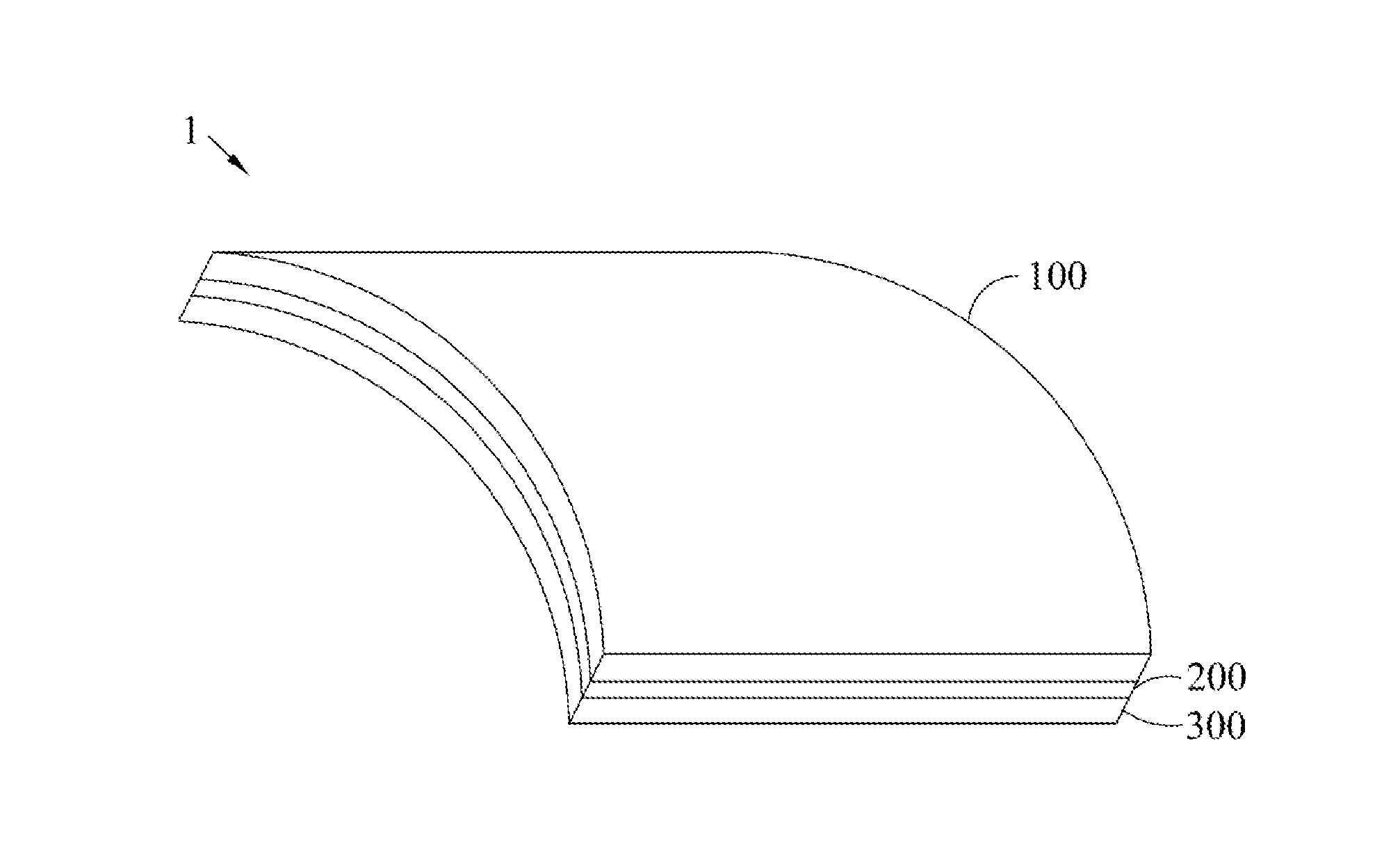

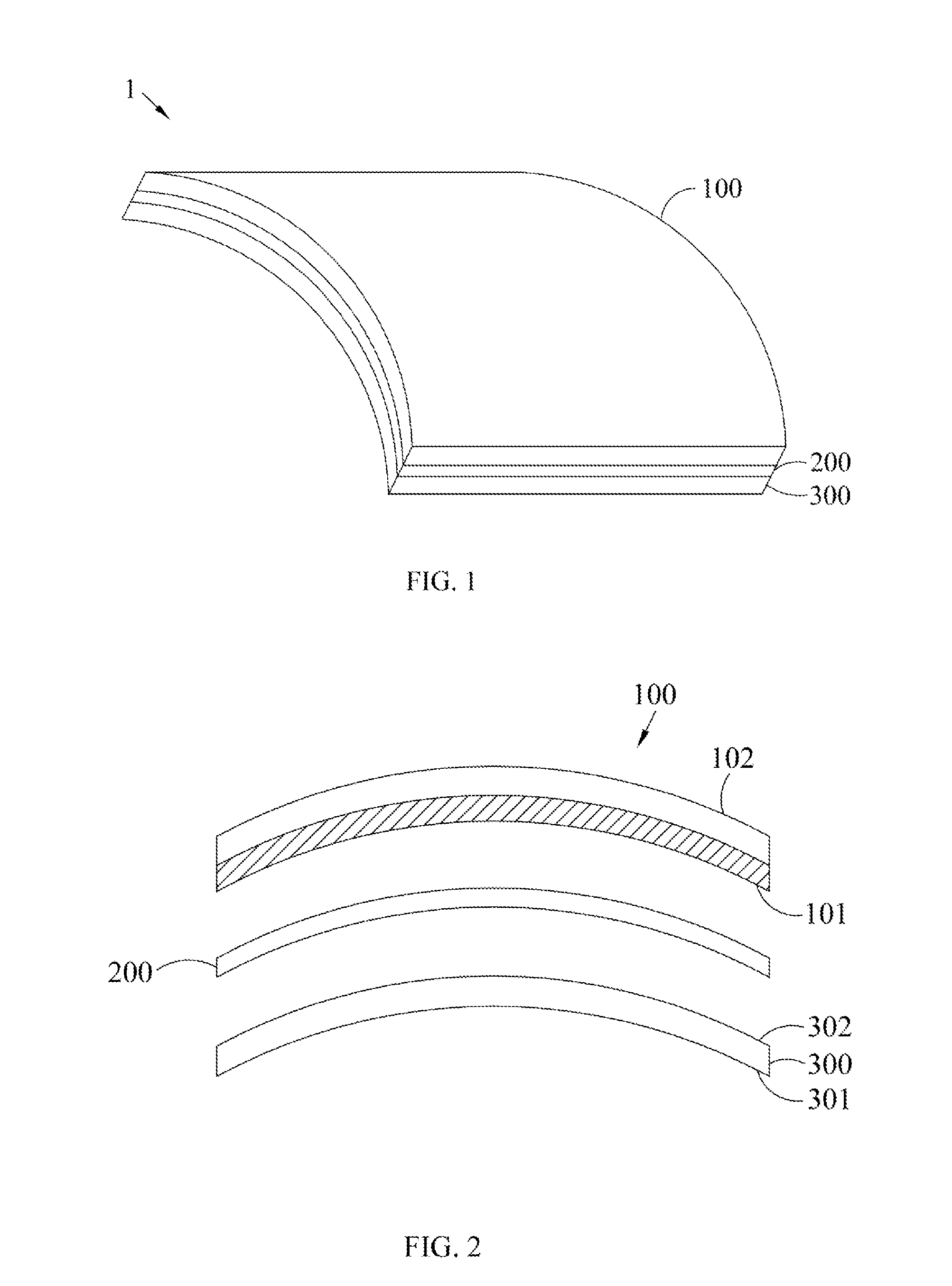

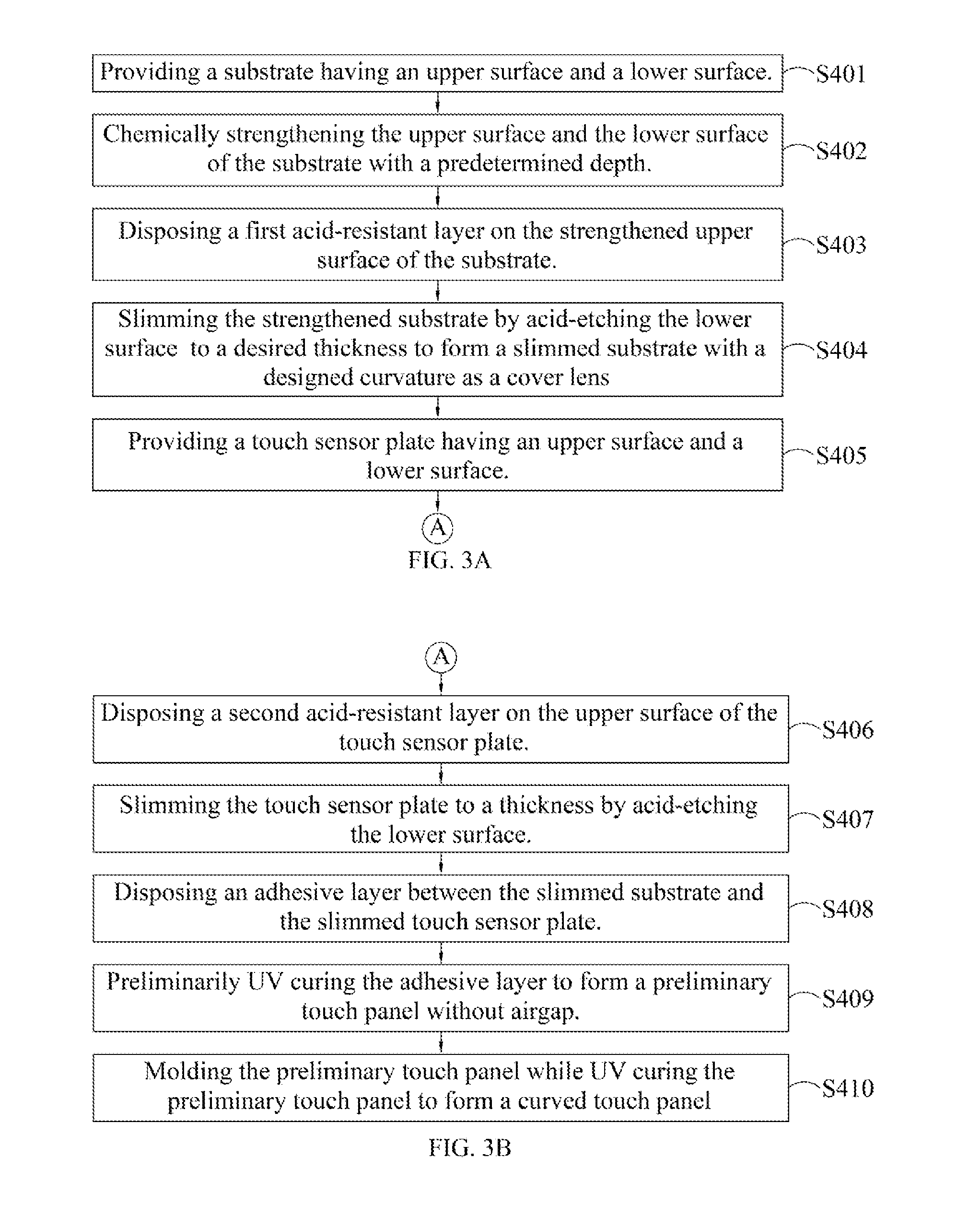

Curved touch panel and method for fabricating the same

ActiveUS20160124534A1Achieve curvature of glassRemoving stress of eitherElectric switchesElectrical equipmentEngineeringTouch panel

A curved touch panel and a method for fabricating the same are disclosed. The curved touch panel with a predetermined curvature, includes a curved substrate having a curved upper surface and a curved lower surface, the upper surface being chemically strengthened and the lower surface being acid-etched, an adhesive layer disposed on one of the curved upper surface and the curved upper surface of the curved substrate, and a curved touch sensor plate with flexibility having a curved upper surface and curved lower surface disposed on the adhesive layer opposite to the curved substrate, wherein the curved upper surface and the curved lower surface are acid-etched, and the curved substrate, the adhesive layer, and the curved touch sensor plate are attached together.

Owner:BUWON PRECISION SCI

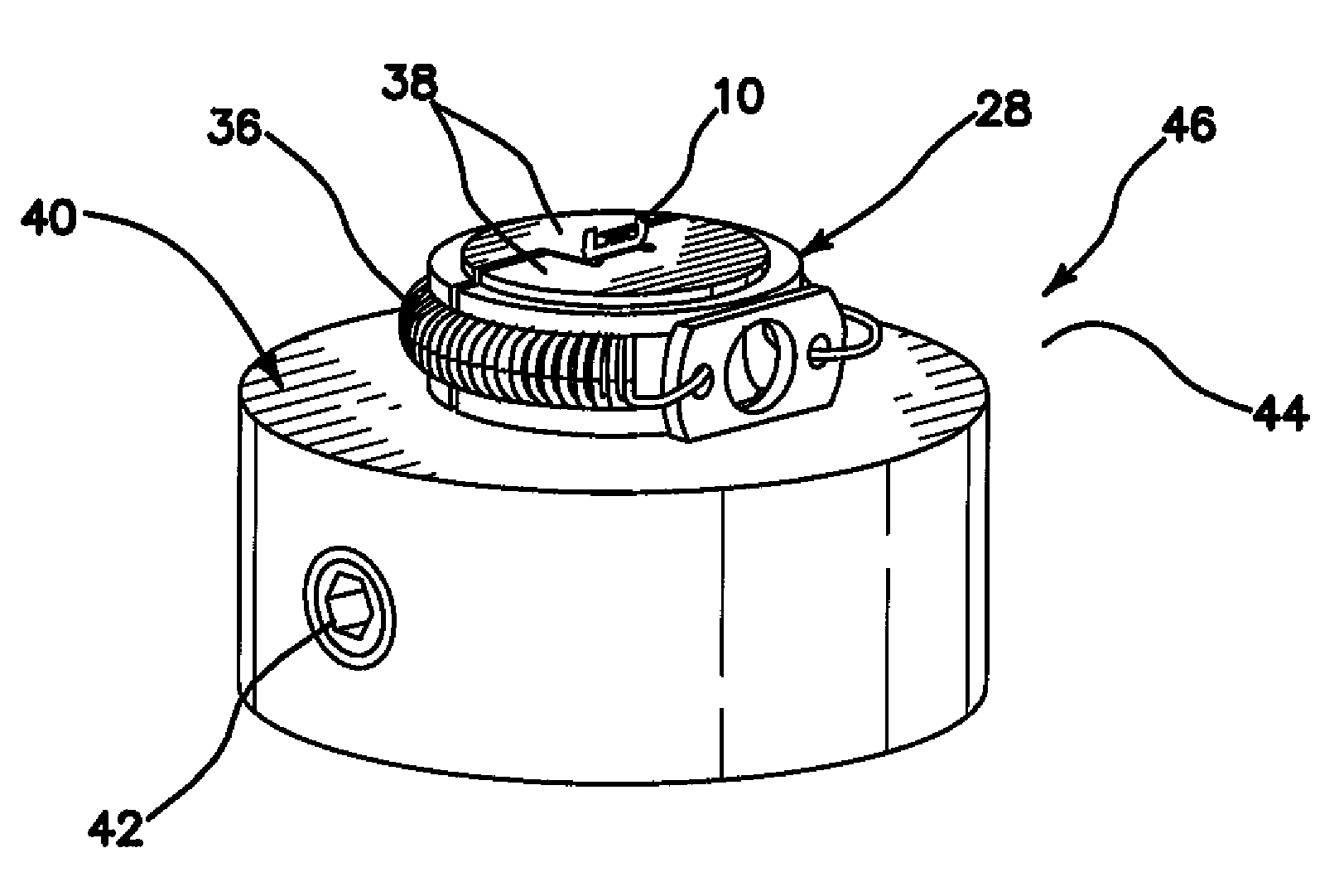

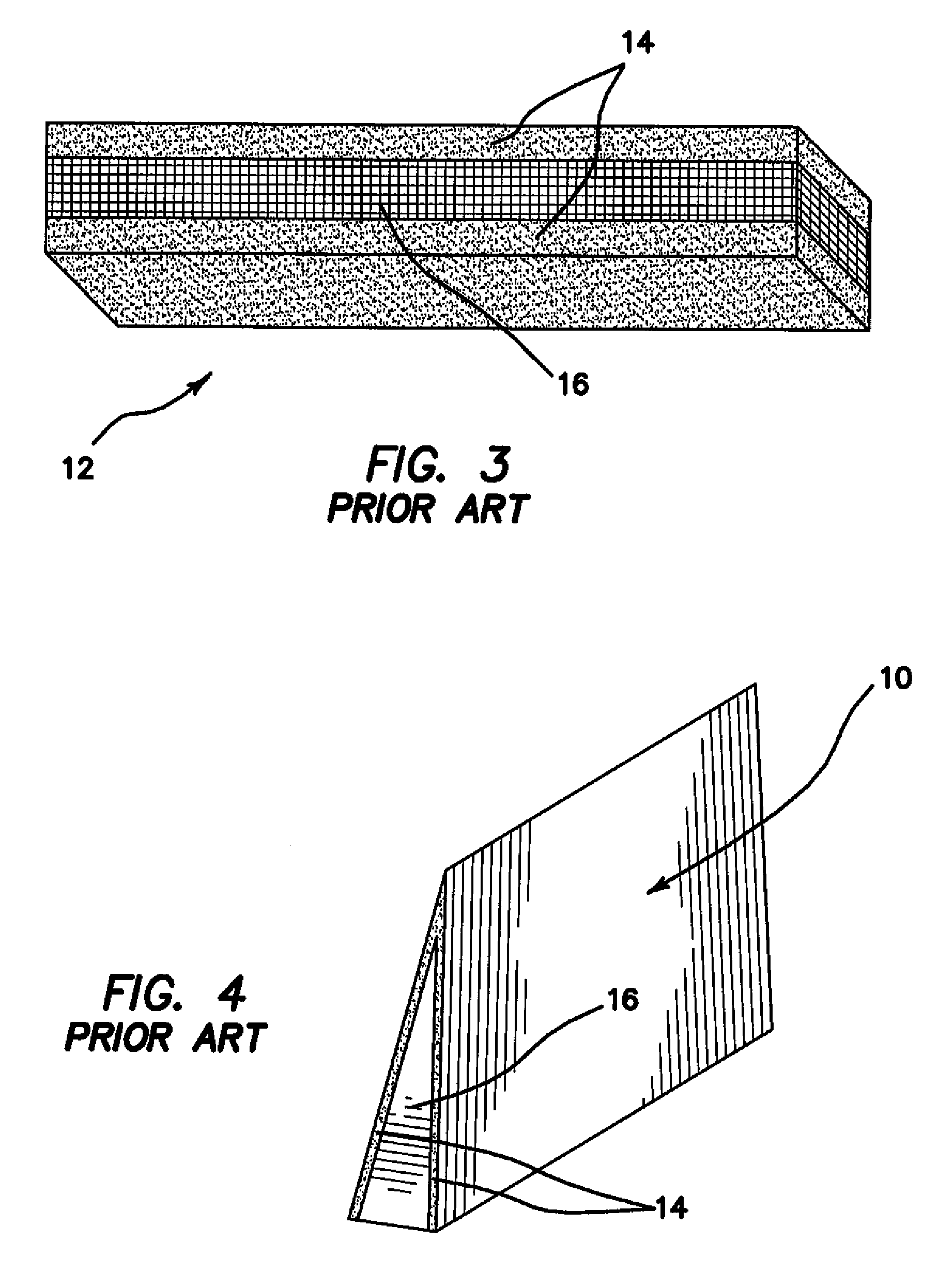

Ion sputter removal from thin microscopy samples with ions extracted from an RF generated plasma

ActiveUS8288737B1Enhance sputter removal rateMinimize and eliminate sputter deposition of materialMaterial analysis using wave/particle radiationElectric discharge tubesCarbon coatingGraphite

A plasma system for changing a microscopy material sample comprises a microscopy material sample holder for holding a microscopy material sample in place in a desired orientation, and a receptacle holder for receiving the sample holder and an RF antenna. The microscopy sample is positioned relative to the antenna so that no point on the antenna is in direct line-of-sight contact with the microscopy sample. This feature of avoiding direct line-of-sight contact between the antenna and the sample assists in preventing, or at least minimizing, ion sputtering of system component material onto the specimen or sample 10 that is being trimmed. Moreover, portions of the system which are in direct line-of-sight contact with the sample are comprised of material having a low sputtering yield, preferably carbon. The material may comprise graphite, and may be in the form of a carbon coating or a carbon paint.

Owner:TED PELLA

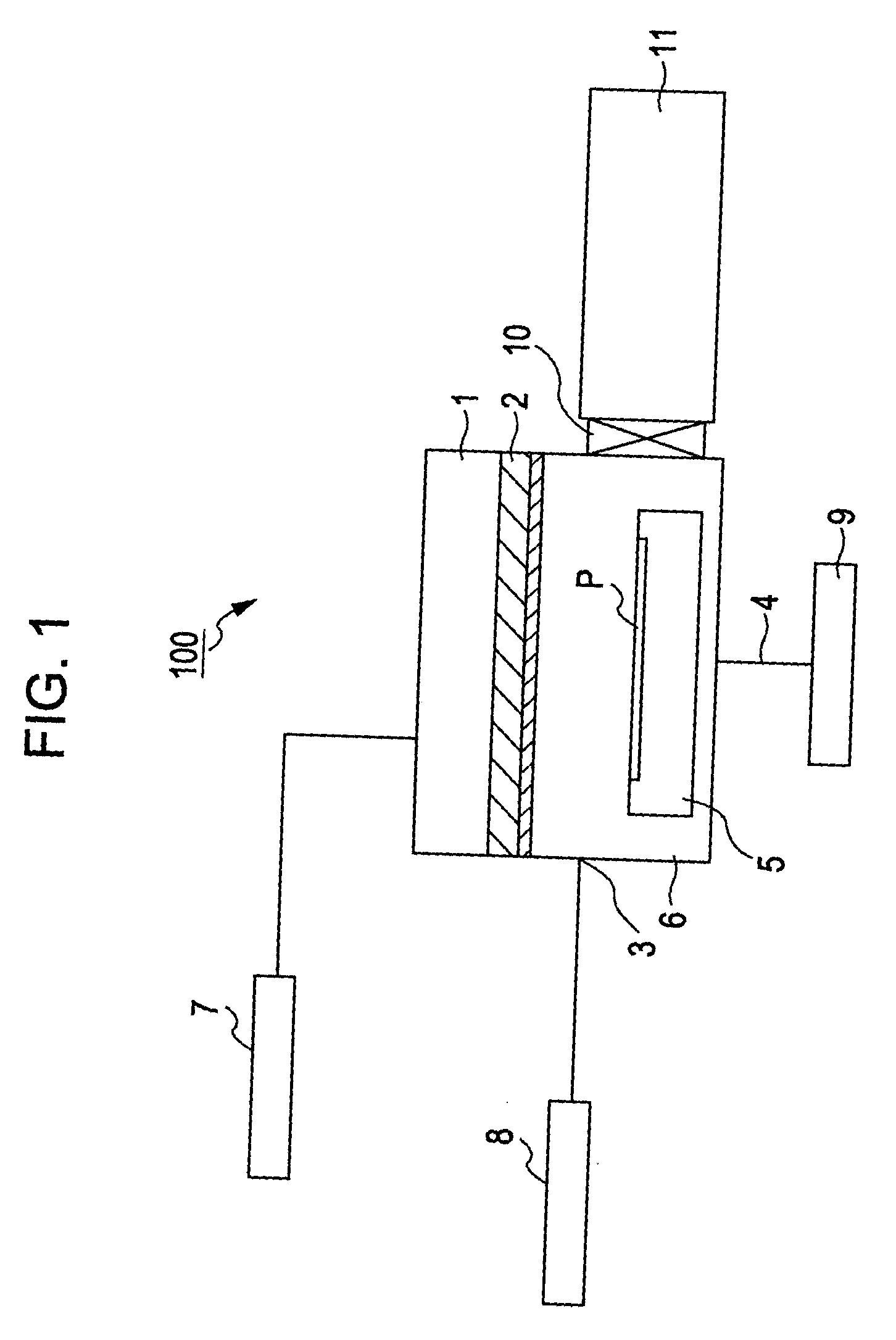

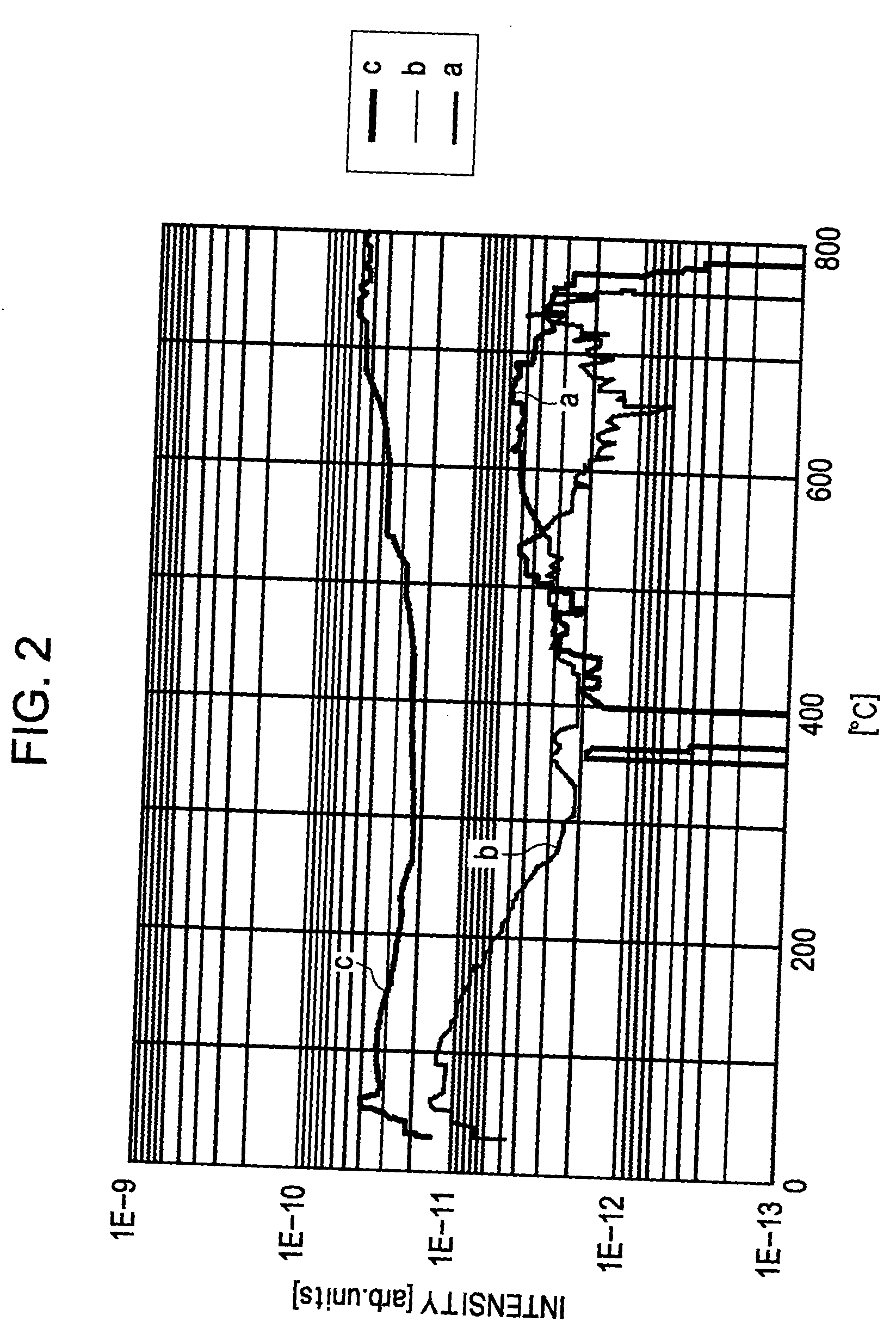

Surface treatment method, manufacturing method of semiconductor device, and manufacturing method of capacitive element

InactiveUS7579287B2Efficient removalInhibition of resorptionTransistorSemiconductor/solid-state device manufacturingCapacitanceMoisture

A method for processing an object containing moisture is provided to efficiently remove the moisture and to prevent re-adsorption of the moisture. In particular, the method has a step of removing the moisture contained in the object in an atmosphere containing excited hydrogen, deuterium, deuterated hydrogen, or tritium.

Owner:CANON KK

Coated chewing gum comprising an active substance having local activity

InactiveUS20050100632A1Reduce bad tasteDesired thicknessConfectioneryChewing gumChewing gumINCREASED EFFECT

A coated chewing gum comprising a core of chewing gum and a coating comprising a coating material and one or more active substance(s) in solid form. The use of an active substance in solid form in the coating of a coated chewing gum provides a fast onset of the effect, a better stability of the active substance, and an increased effect thereof in al chewing phases.

Owner:STAHL BRONISLAW JAN

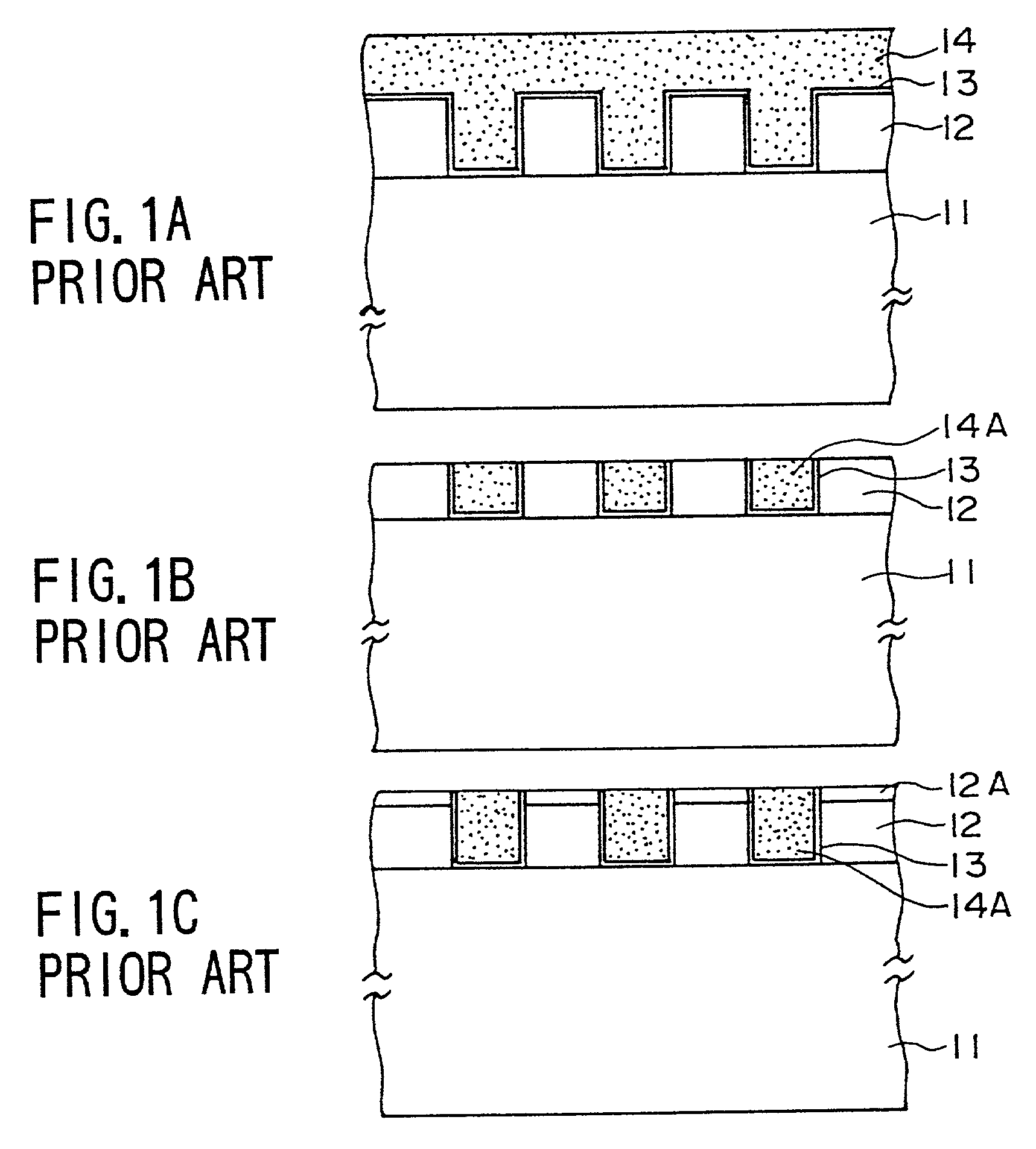

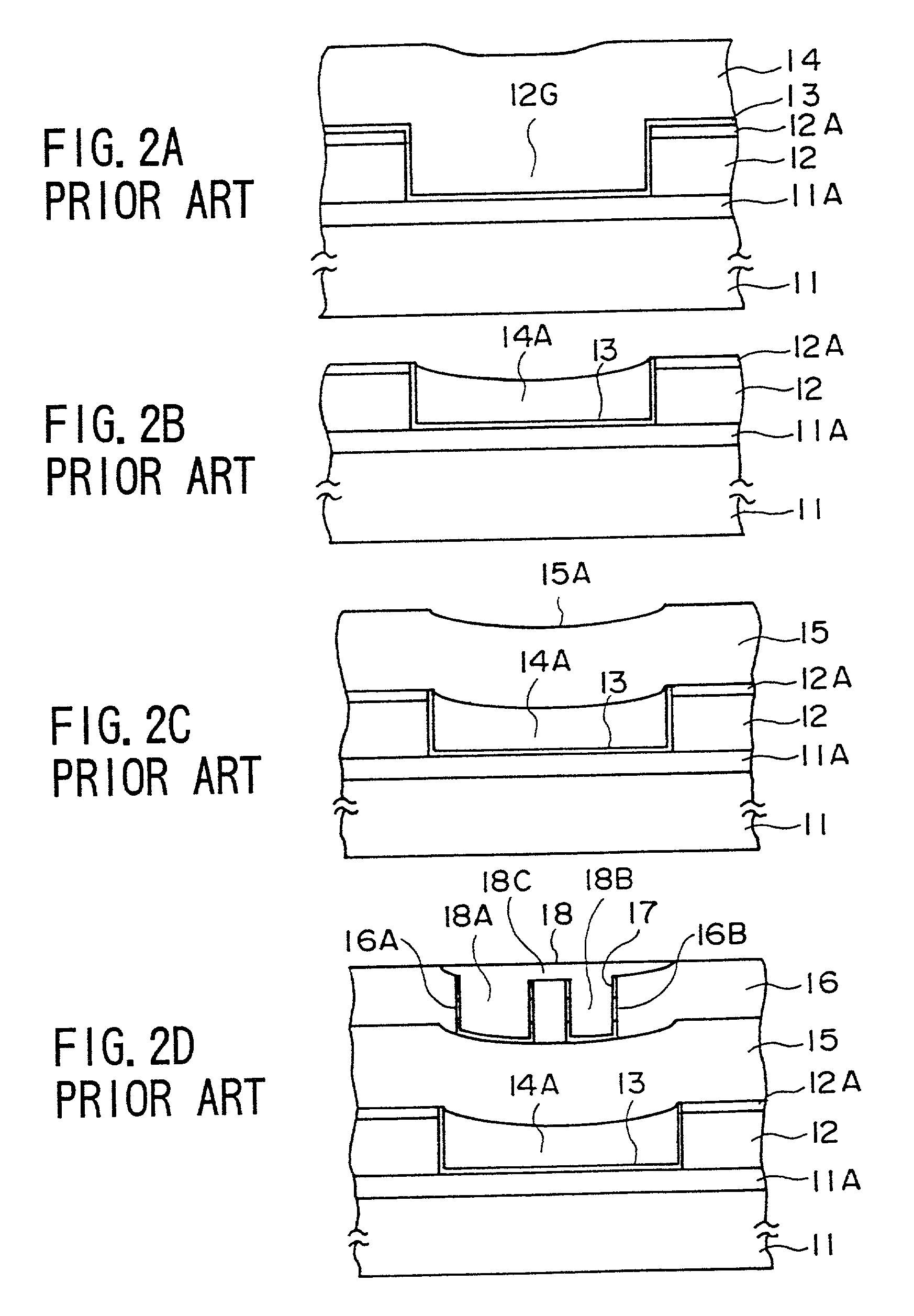

Method for manufacturing semiconductor device

InactiveUS20070087520A1Desired thicknessLess variationSemiconductor/solid-state device manufacturingDevice materialSemiconductor

A semiconductor device includes an element isolation film, which exhibits less variations in the height dimension from the surface of the substrate and has a desired height dimension from the surface of the substrate. A process for manufacturing a semiconductor device includes: providing a predetermined pattern of a silicon nitride film and a protective film which covers the silicon nitride film, on a semiconductor substrate; selectively etching the semiconductor substrate using the protective film as a mask to form a trenched portion; removing the protective film to expose the silicon nitride film; depositing an element isolation film, so as to fill the trenched portion therewith and cover the silicon nitride film; removing the element isolation film formed on the silicon nitride film by polishing thereof until the silicon nitride film is exposed; and removing the silicon nitride film.

Owner:RENESAS ELECTRONICS CORP

Wafer producing method and processing feed direction detecting method

ActiveUS10406635B2Improve productivityEfficient productionPolycrystalline material growthAfter-treatment detailsIngotUltimate tensile strength

A wafer is produced from an ingot by confirming whether or not an inclined c-axis of the ingot and a second orientation flat of the ingot are perpendicular to each other, and detecting a processing feed direction perpendicular to the direction in which the c-axis is inclined. The method includes performing sampling irradiation of the ingot with a laser beam, along a direction parallel to the second orientation flat and a plurality of directions inclined clockwise and counterclockwise by respective predetermined angles from the second orientation flat, thereby forming a plurality of sampled reduced strength areas in the ingot; measuring the number of nodes which exist per unit length on each of the sampled reduced strength areas, and determining a direction in which the sampled reduced strength area where the measured number of nodes is zero extends as a processing feed direction.

Owner:DISCO CORP

Surface treatment method, manufacturing method of semiconductor device, and manufacturing method of capacitive element

InactiveUS20070037413A1Efficient removalInhibition of resorptionTransistorSemiconductor/solid-state device manufacturingCapacitanceDevice material

A method for processing an object containing moisture is provided to efficiently remove the moisture and to prevent re-adsorption of the moisture. In particular, the method has a step of removing the moisture contained in the object in an atmosphere containing excited hydrogen, deuterium, deuterated hydrogen, or tritium.

Owner:CANON KK

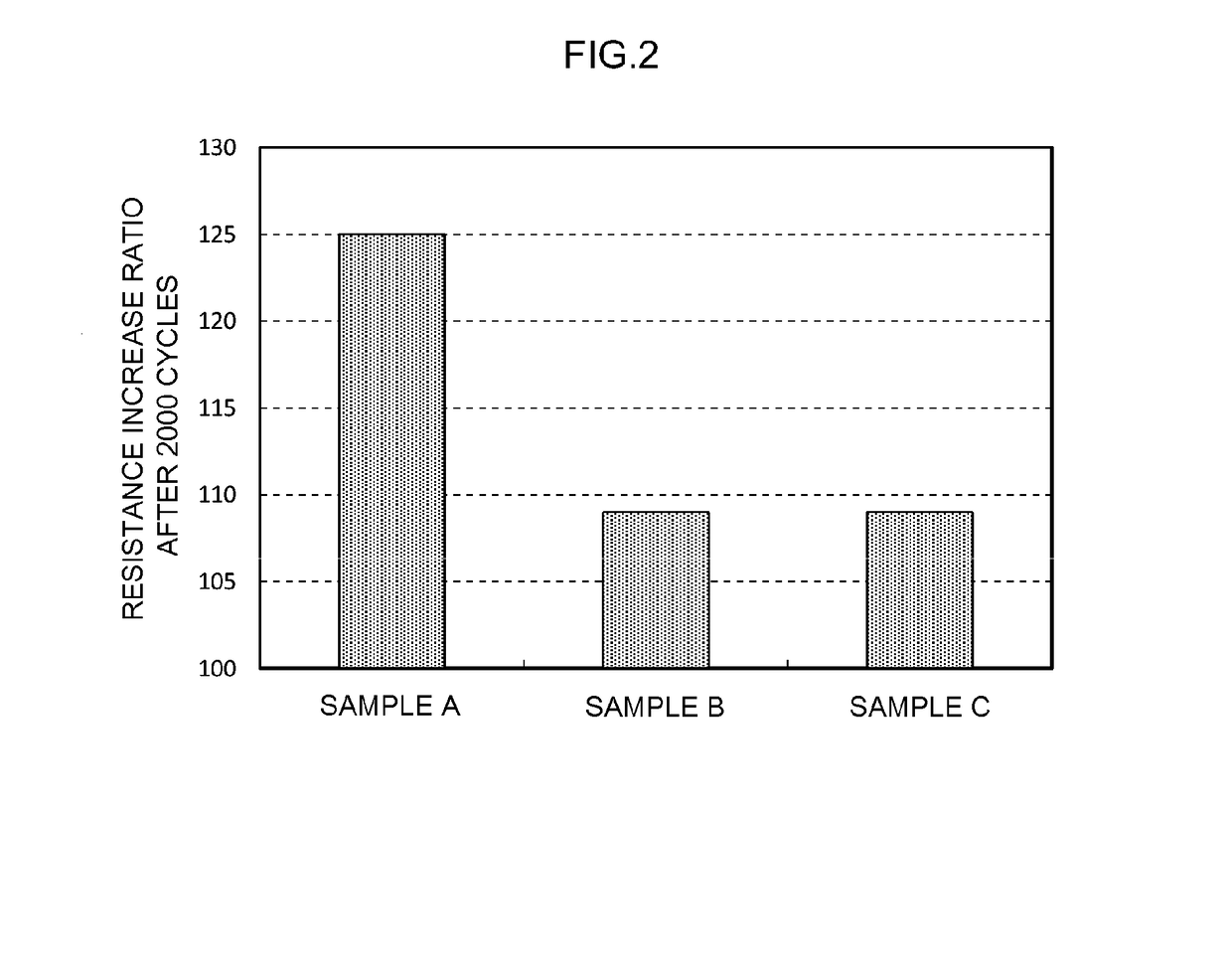

Nonaqueous electrolytic solution secondary battery

ActiveUS20170141386A1Improve performanceInhibition of capacity fadingFinal product manufactureNegative electrodesHigh rateEngineering

The present teaching provides a nonaqueous electrolytic solution secondary battery in which both a satisfactory high-rate characteristic and a high cycle characteristic (prevention of decrease in capacity) are realized. The nonaqueous electrolytic solution secondary battery of the present teaching includes a positive electrode provided with a positive electrode active material layer, a negative electrode provided with a negative electrode active material layer, and a nonaqueous electrolytic solution. The negative electrode active material layer includes a negative electrode active material and carbon black. A coating film made of a lithium transition metal composite oxide having lithium ion conductivity is formed on at least part of a surface of the carbon black.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com