Patents

Literature

35results about How to "Mass production is possible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formation method of single crystal semiconductor layer, formation method of crystalline semiconductor layer, formation method of polycrystalline layer, and method for manufacturing semiconductor device

InactiveUS7888242B2Increase the areaLittle changeAfter-treatment apparatusPolycrystalline material growthHydrogenPorous layer

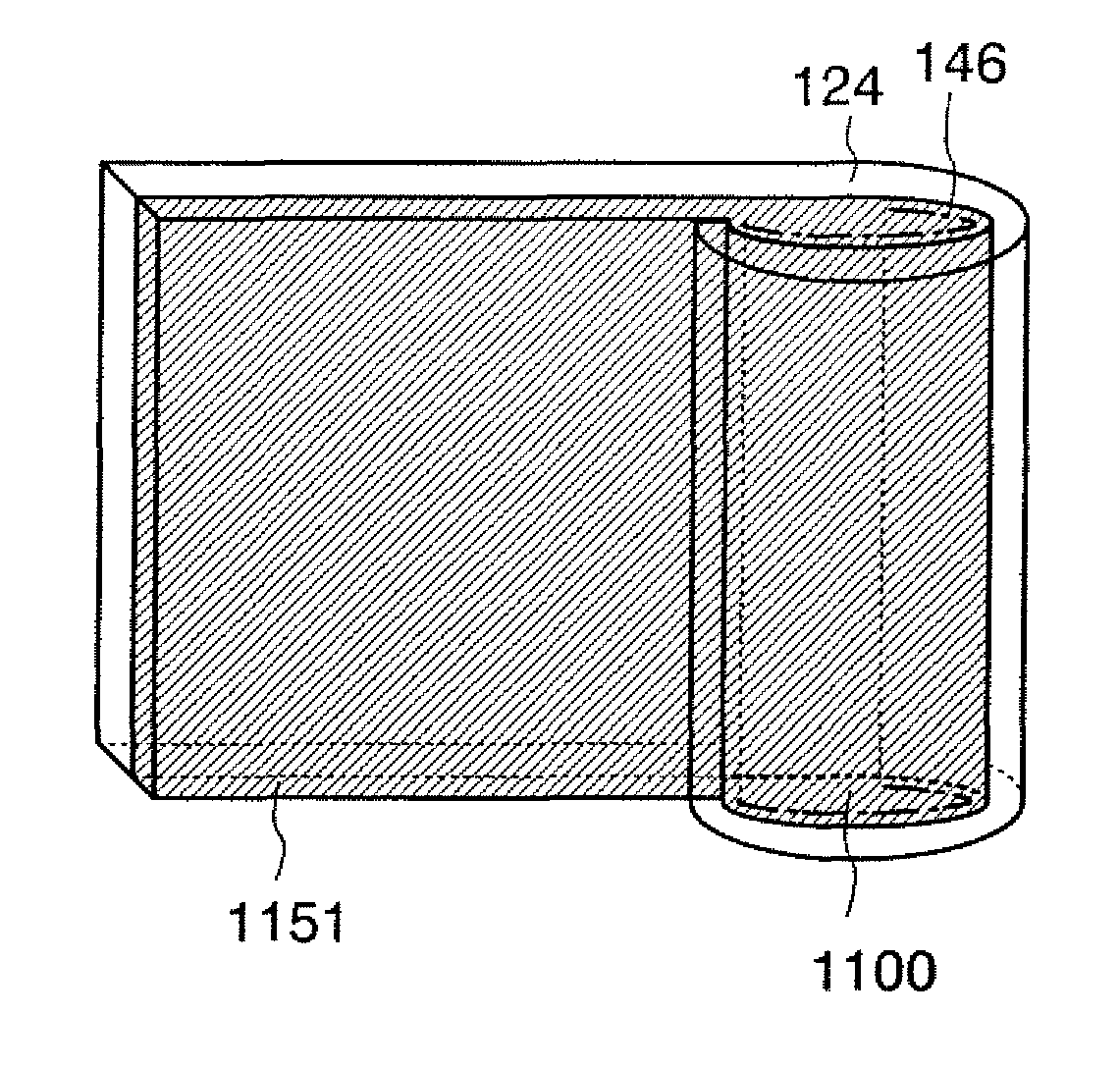

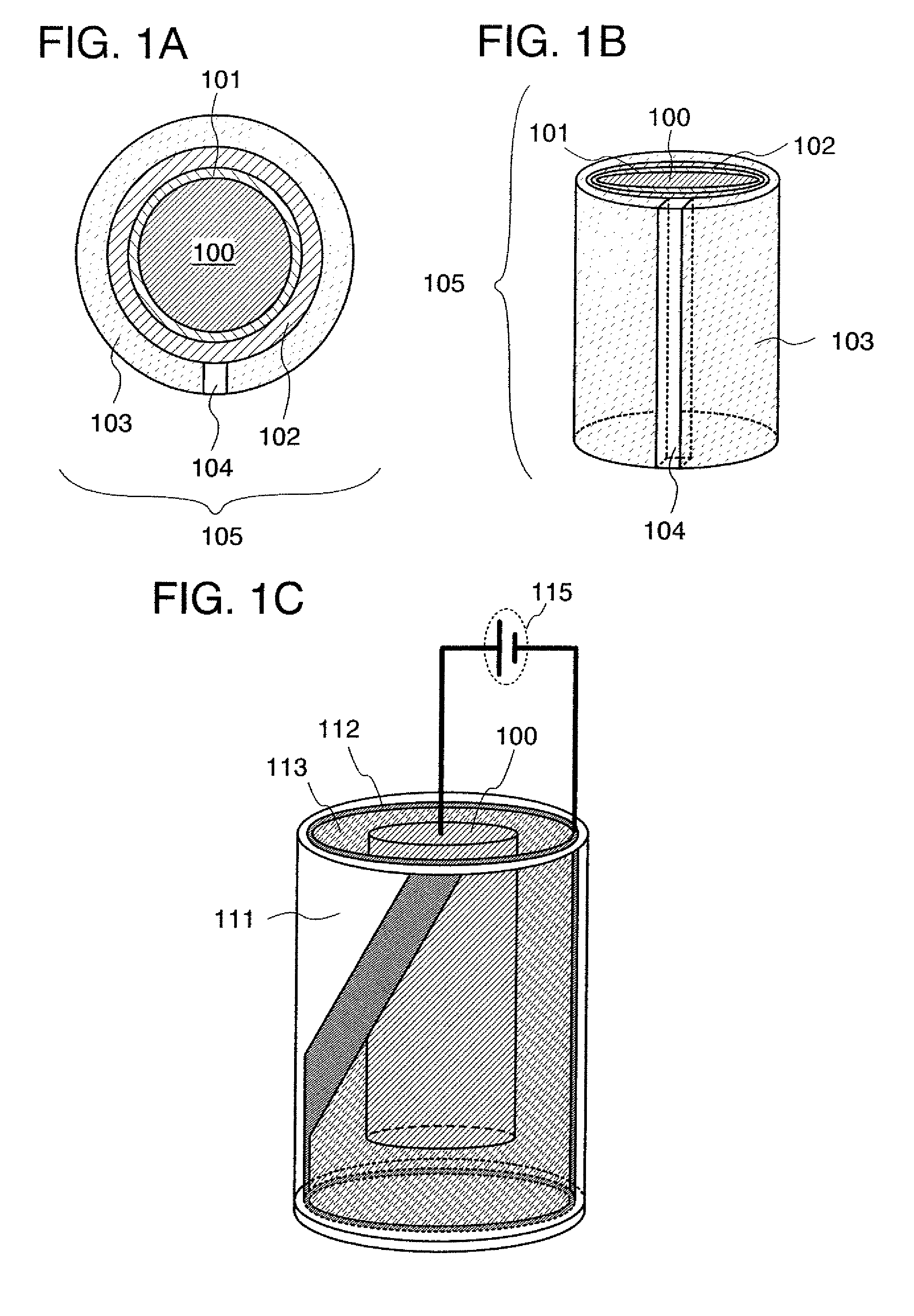

A method for forming a single crystal semiconductor layer in which a first porous layer and a second porous layer are formed over a single crystal semiconductor ingot, a groove is formed in a part of the second porous layer and a single crystal semiconductor layer is formed over the second porous layer, the single crystal semiconductor ingot is attached onto a large insulating substrate, water jet is directed to the interface between the first porous layer and the second porous layer, and the single crystal semiconductor layer is attached to the large insulating substrate, or a method for forming a crystalline semiconductor layer in which a crystalline semiconductor ingot is irradiated with hydrogen ions to form a hydrogen ion irradiation region in the crystalline semiconductor ingot, the crystalline semiconductor ingot is rolled over the large insulating substrate while being heated, the crystalline semiconductor layer is separated from the hydrogen ion irradiation region, and the crystalline semiconductor layer is attached to the large insulating substrate.

Owner:SEMICON ENERGY LAB CO LTD

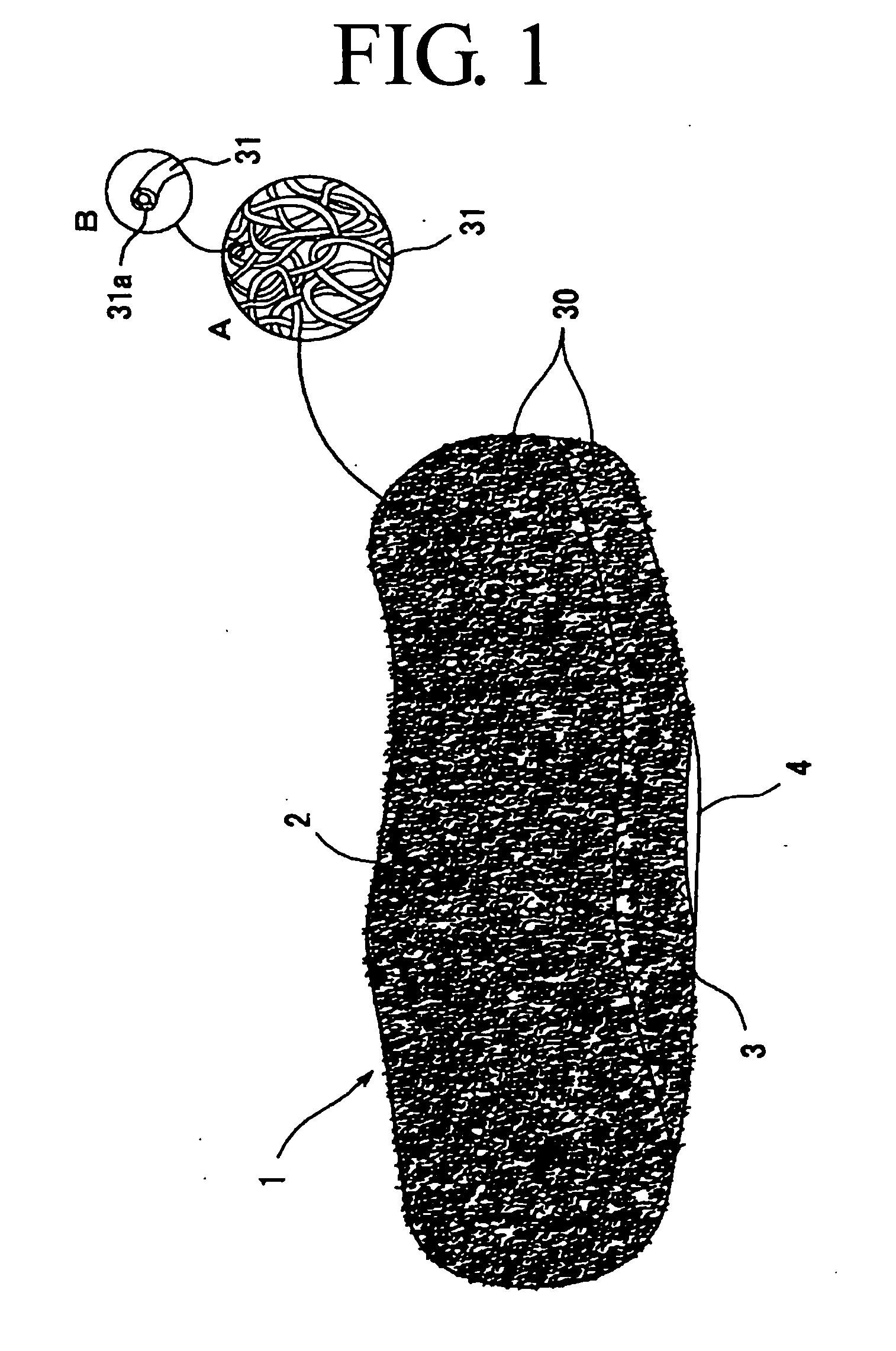

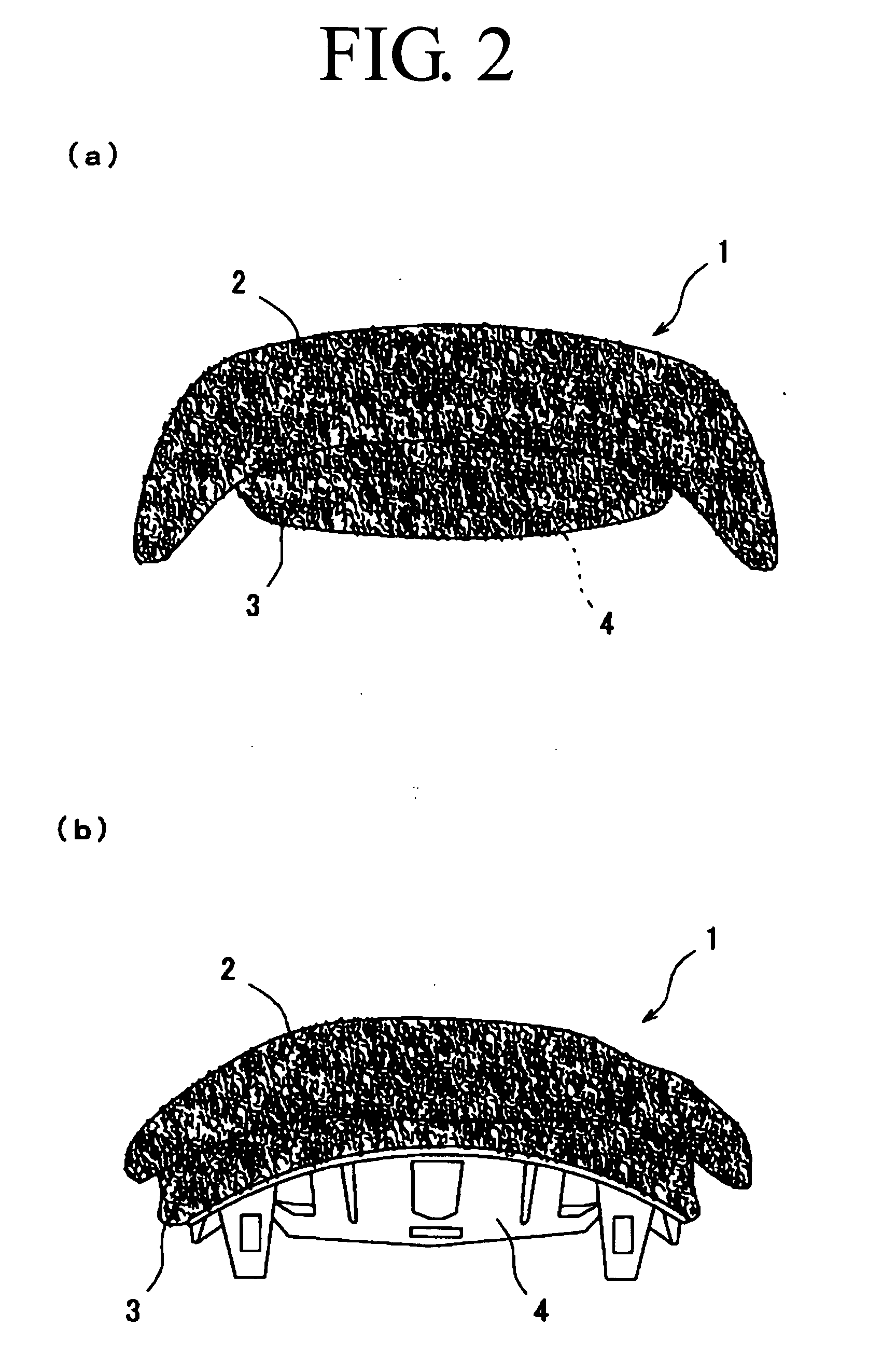

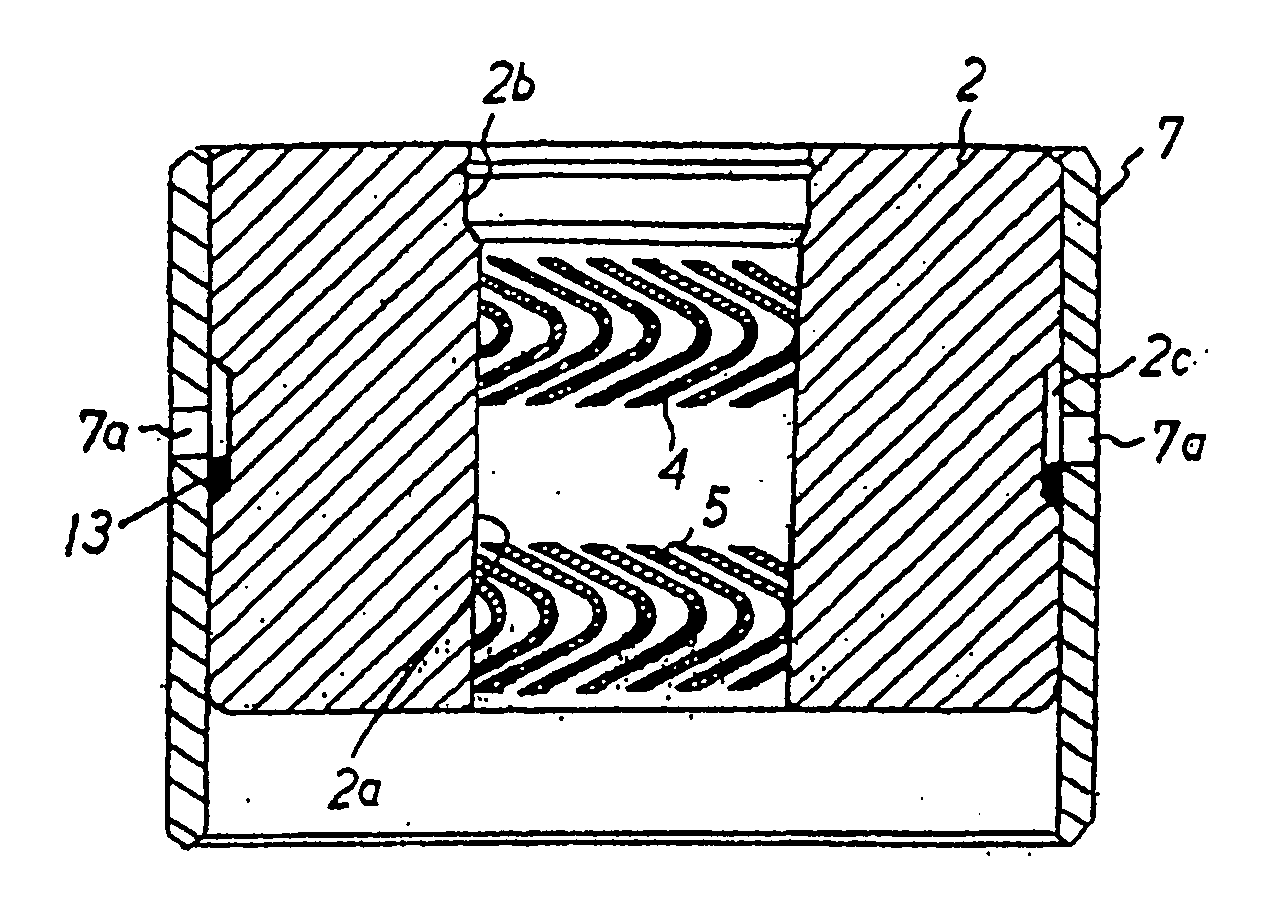

Cushion material formed of spring-structured resin-molded product, manufacturing method for the cushion material, and mold used for the manufacturing method

InactiveUS20070001336A1Desirable tactile impressionTendency to collapseStuffed mattressesMouldsProduct formationEngineering

There is provided a method for producing a cushion material composed of a resin molded article with a spring structure which is so moldable as to allow the mold take any shape and size, is cheap, and resistant to collapsing, does not cause fatigue even after prolonged use, and has high shock absorbing capability and load capacity, and thus suitably used as a material of any supports on which one can sit, rest or mount such as seats of automotive vehicles, motor cycles, bicycles, electric trains, and aircraft, saddles for horse riding, chairs, sofas and beds, and a method for producing a cushion material requiring only a low cost for its disposal.

Owner:AIN ENJINIARINGU

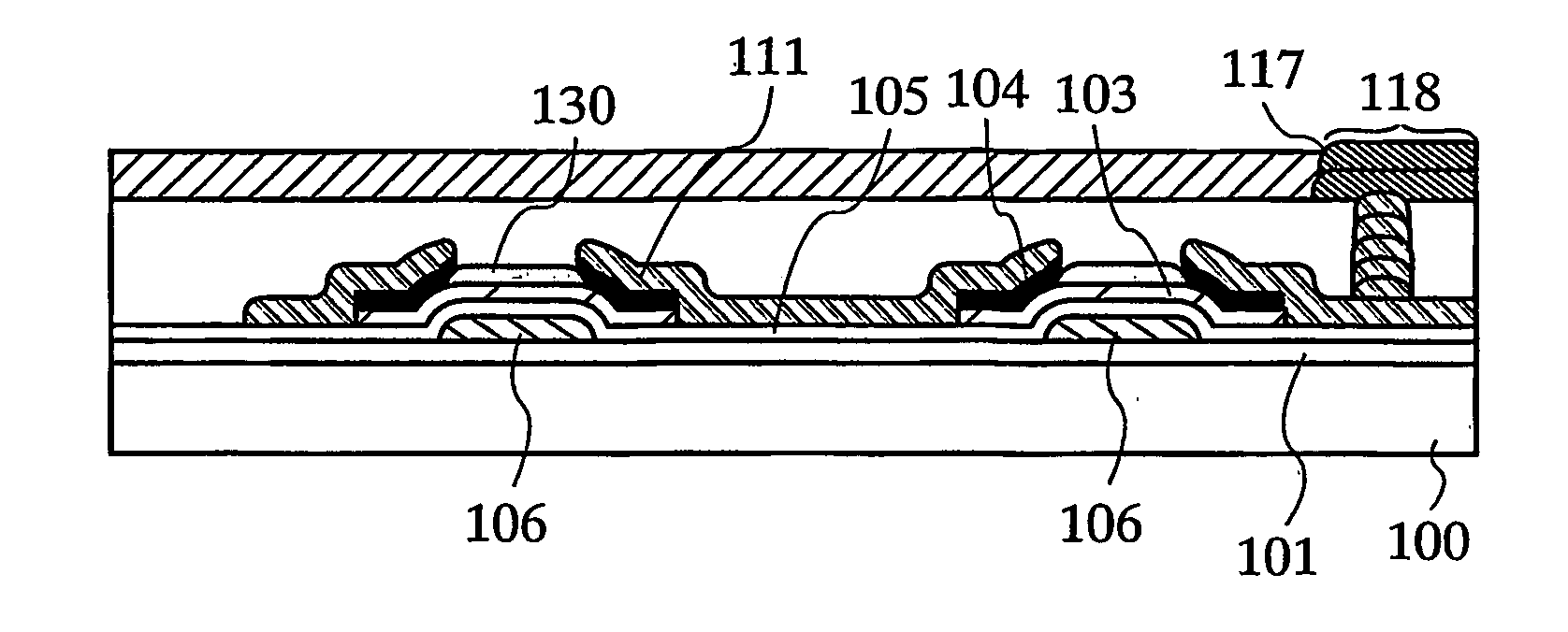

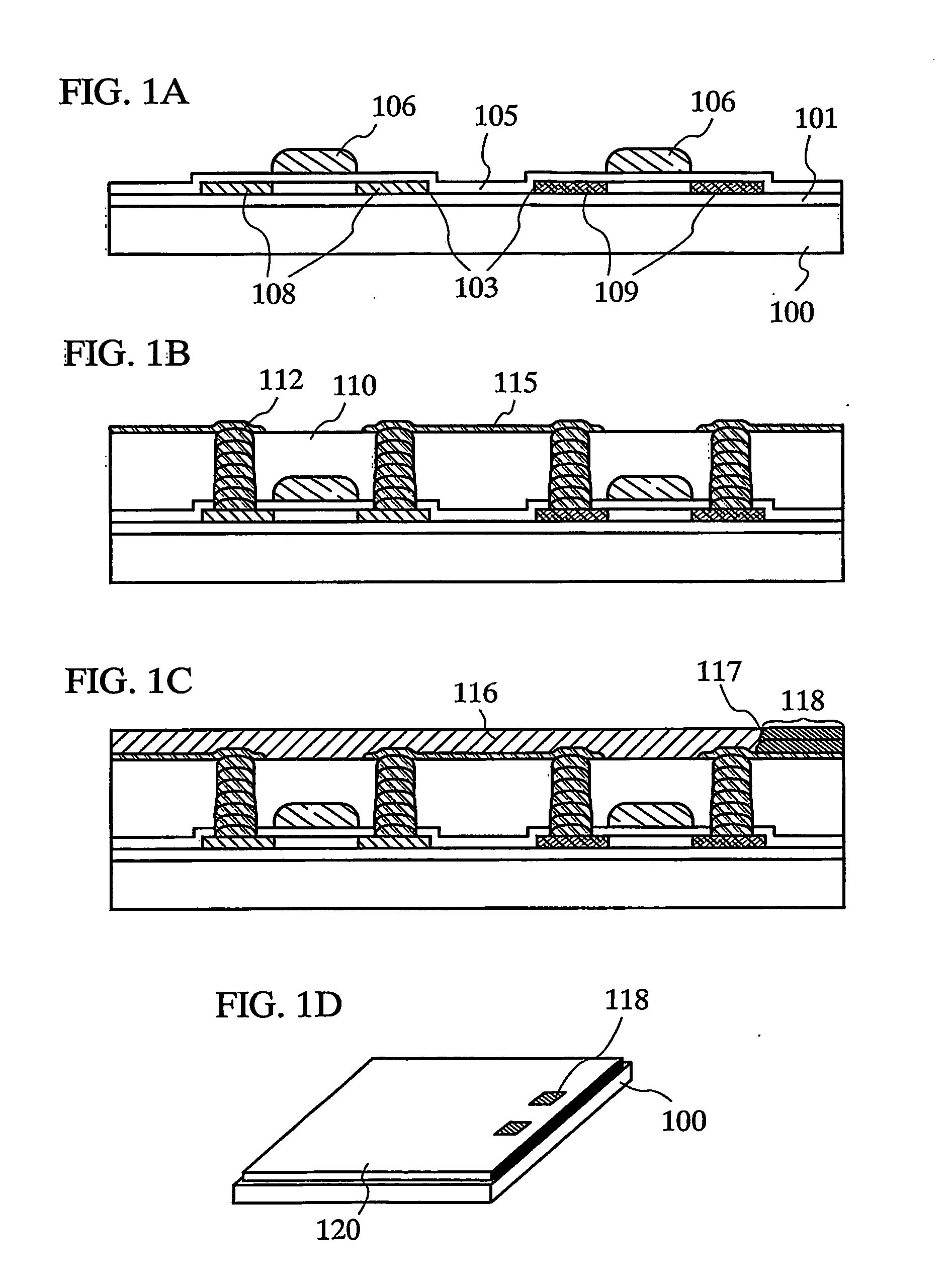

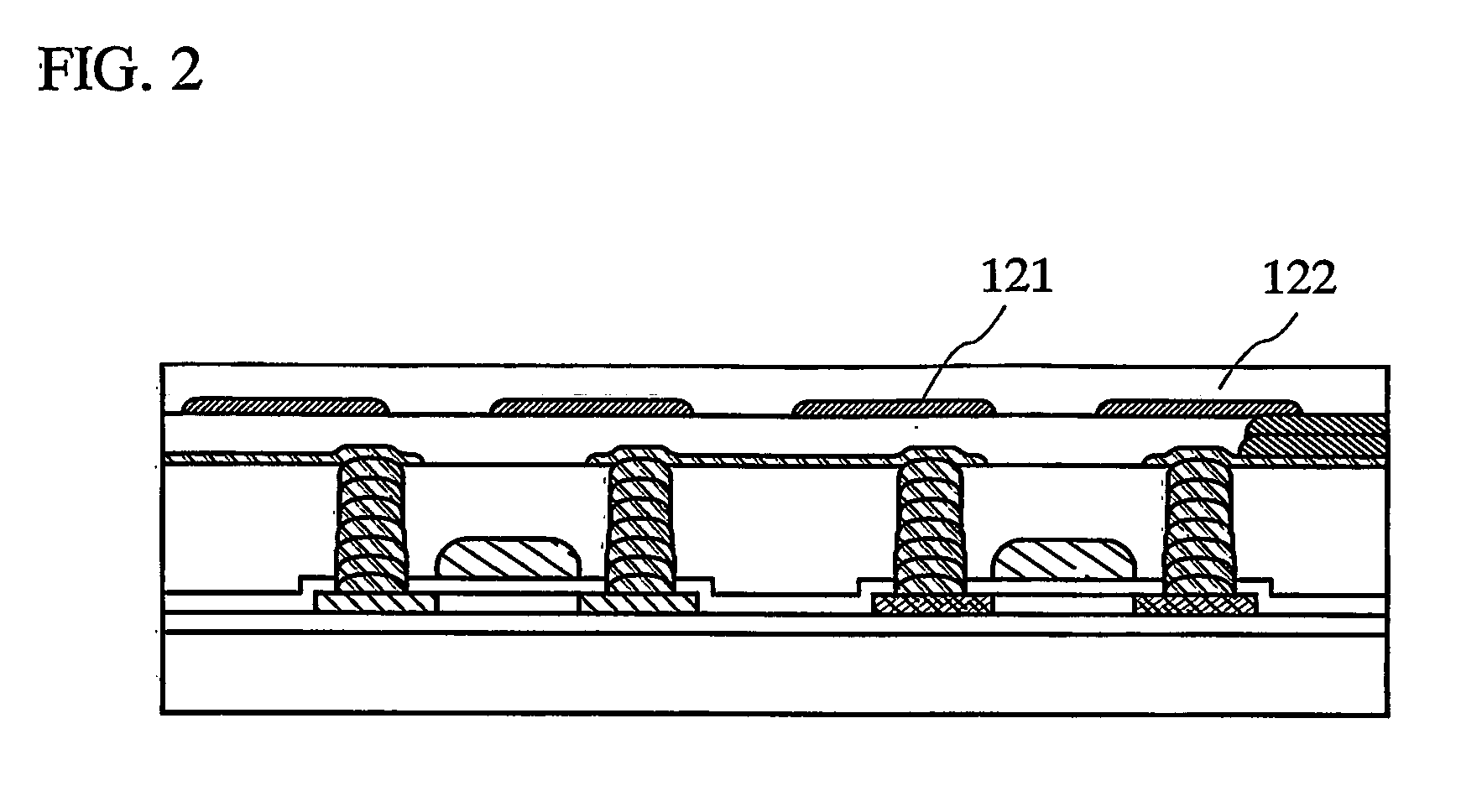

Semiconductor device and method for manufacturing the same

InactiveUS20070004100A1Easy to optimizeShort timeTransistorSolid-state devicesDevice materialEngineering

An IC card is more expensive than a magnetic card, and an electronic tag is also more expensive as a substitute for bar codes. Therefore, the present invention provides an extremely thin integrated circuit that can be mass-produced at low cost unlike a chip of a conventional silicon wafer, and a manufacturing method thereof. One feature of the present invention is that a thin integrated circuit is formed by a formation method that can form a pattern selectively, on a glass substrate, a quartz substrate, a stainless substrate, a substrate made of synthetic resin having flexibility, such as acryl, or the like except for a bulk substrate. Further, another feature of the present invention is that an ID chip in which a thin film integrated circuit and an antenna according to the present invention are mounted is formed.

Owner:SEMICON ENERGY LAB CO LTD

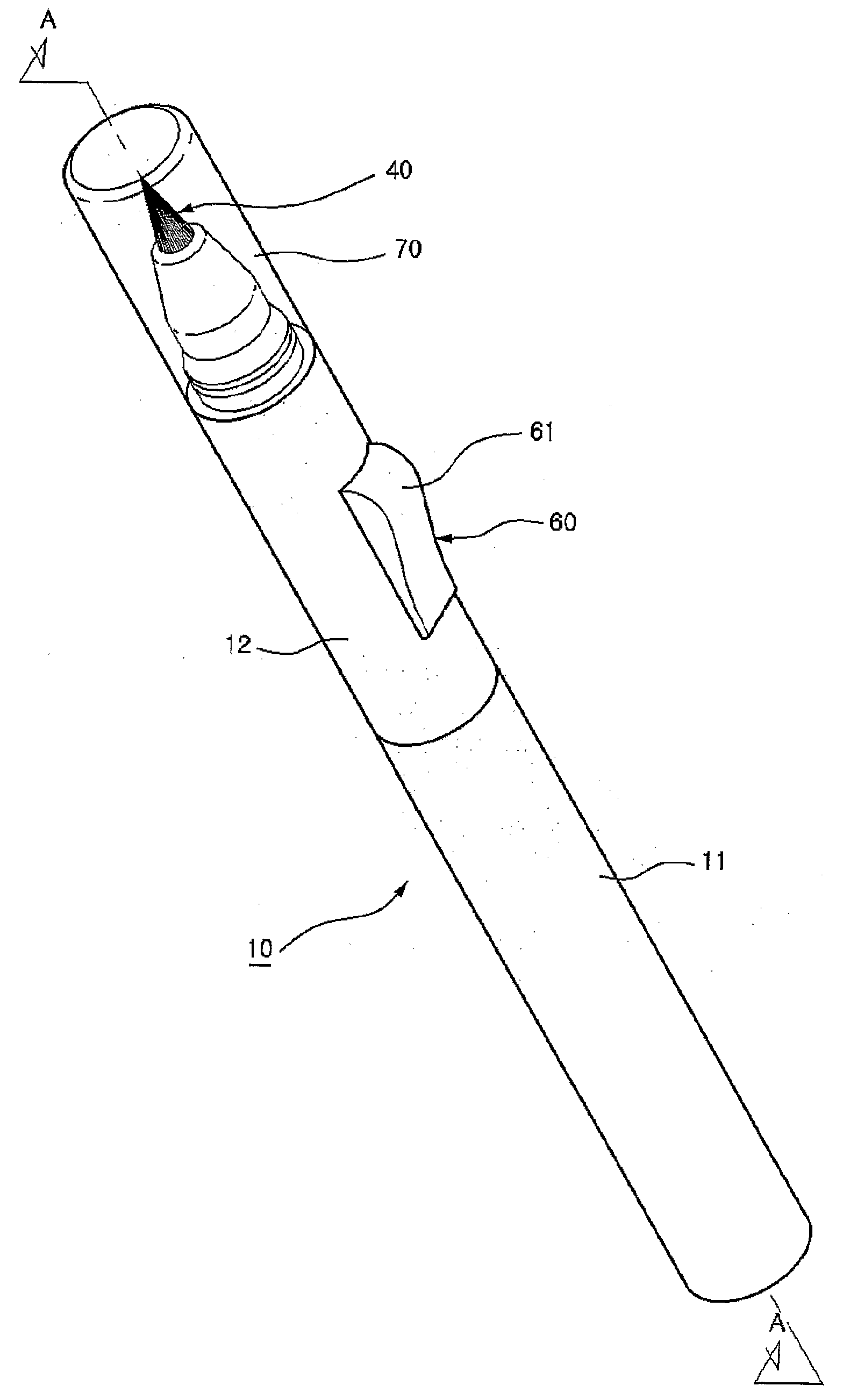

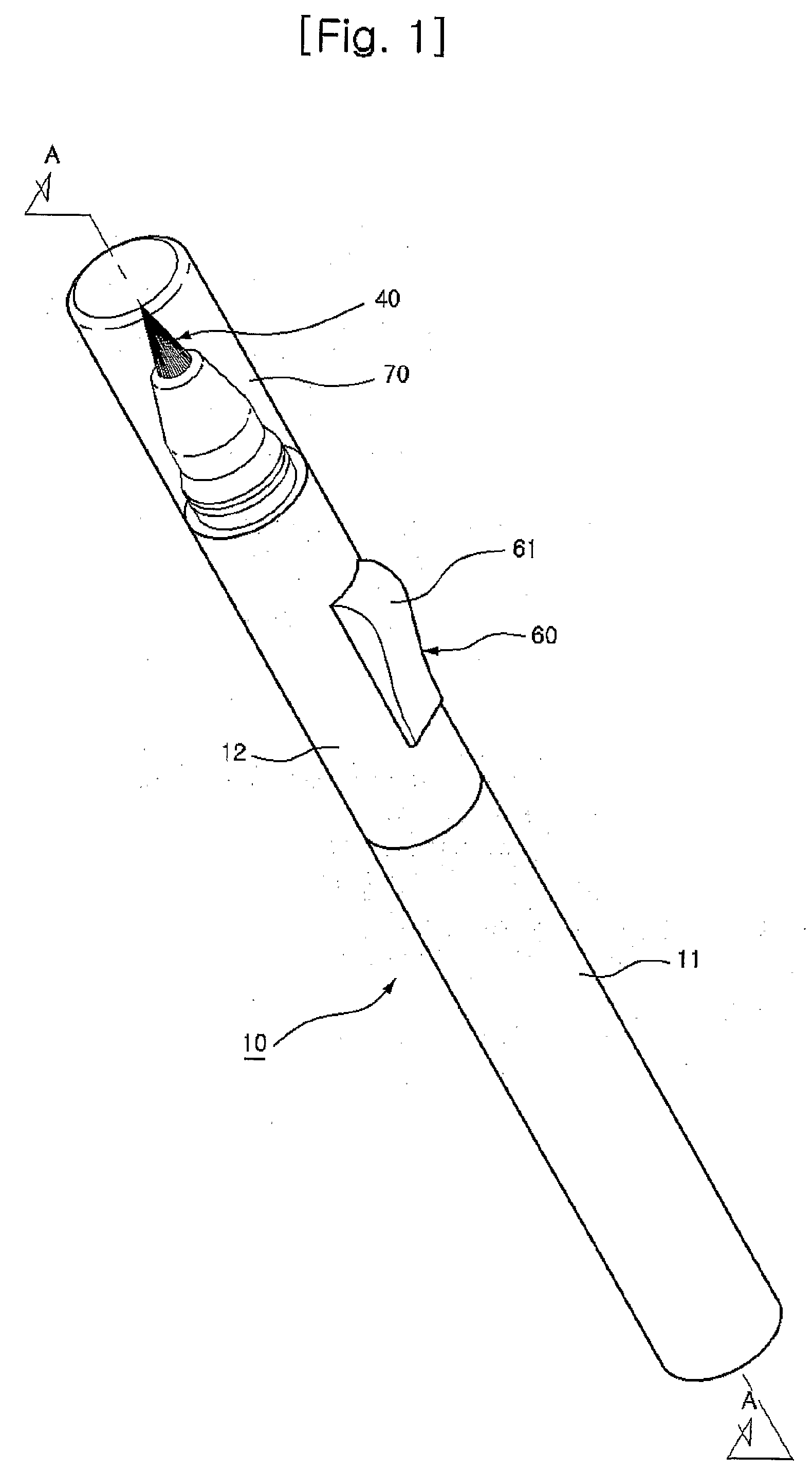

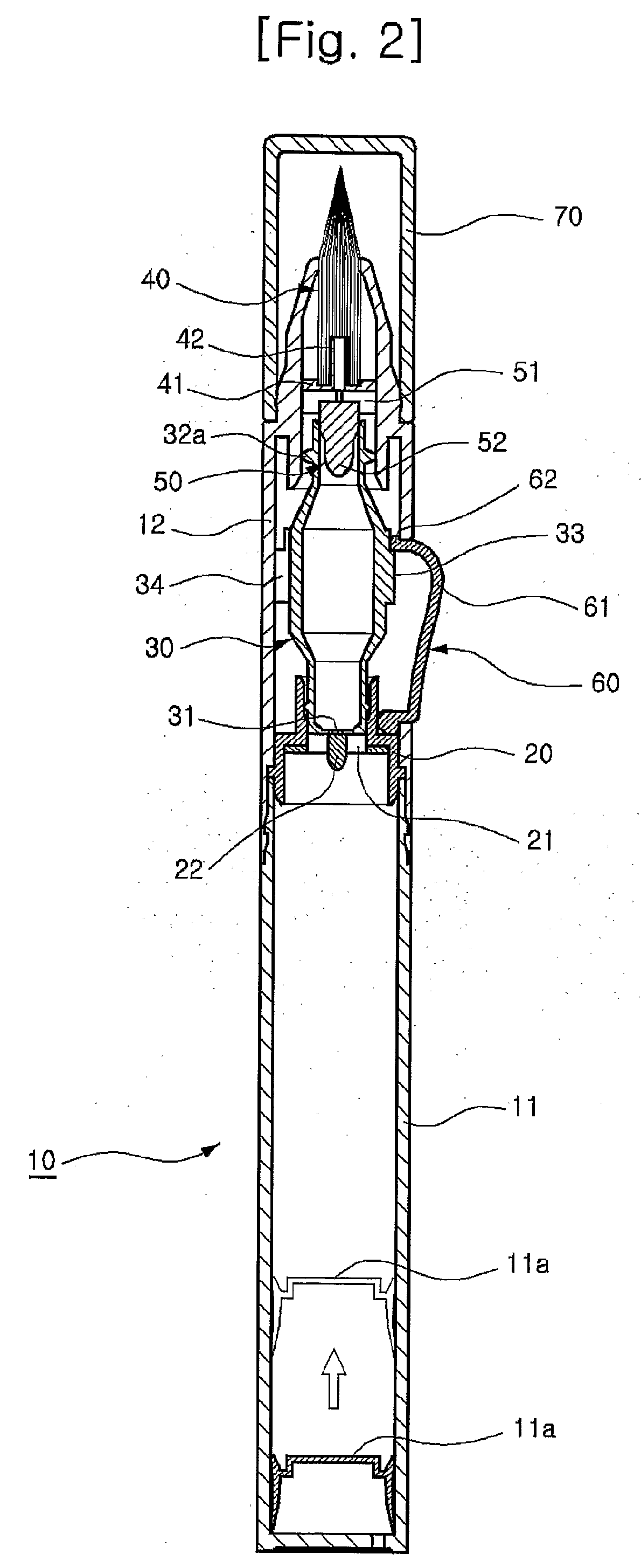

Standard Capacity Discharge Case of Liquid Content

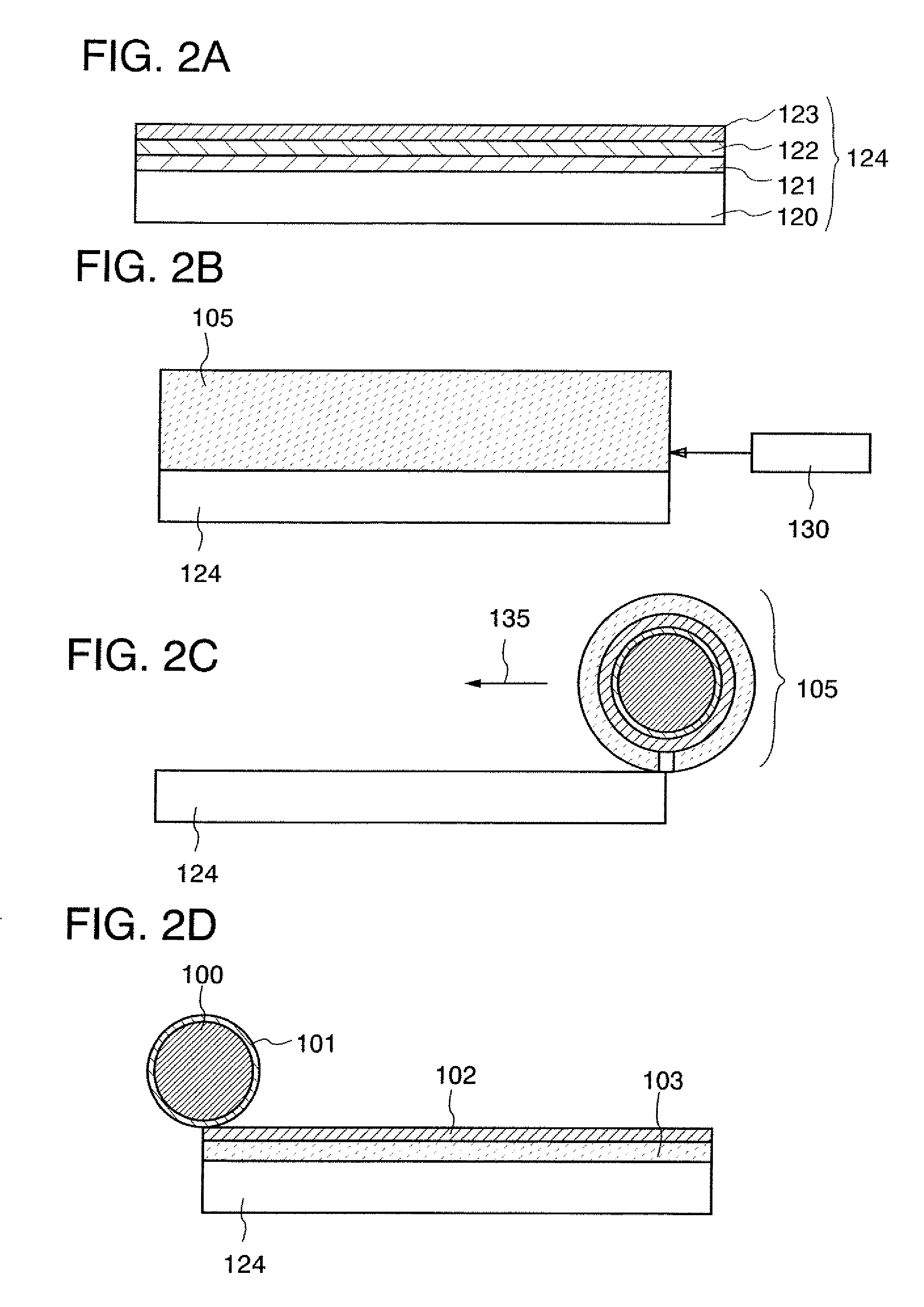

InactiveUS20080296320A1Simple structureEliminating ultra precision machiningDispensing apparatusSingle-unit apparatusManufacturing cost reductionProduction rate

The present design relates in general to an automatic pencil type case enabling a user to discharge a liquid cosmetic to a brush by pressing a release button, more specifically, to an improved structure of a dispensing unit dispensing a liquid cosmetic product to thereby enhance productivity in assembly process and reduce manufacturing cost at the same time. As such, a liquid foundation case capable of discharging liquid content reserved in a body to a makeup brush through a pressing down operation of a release button, includes: a body (10) formed of a first case (11) where the liquid content is reserved and a second case (12) in which a pump tube (30) is installed; a check valve (20) mounted in the first case (11); a pump tube (30) installed inside the second case (12); a valve (50) mounted on the front end of the pump tube (30); a release button (60) for pressing down the pump tube (30); and a makeup brush (40) installed on an exposed end of the second case (12).

Owner:KANG SUNGIL

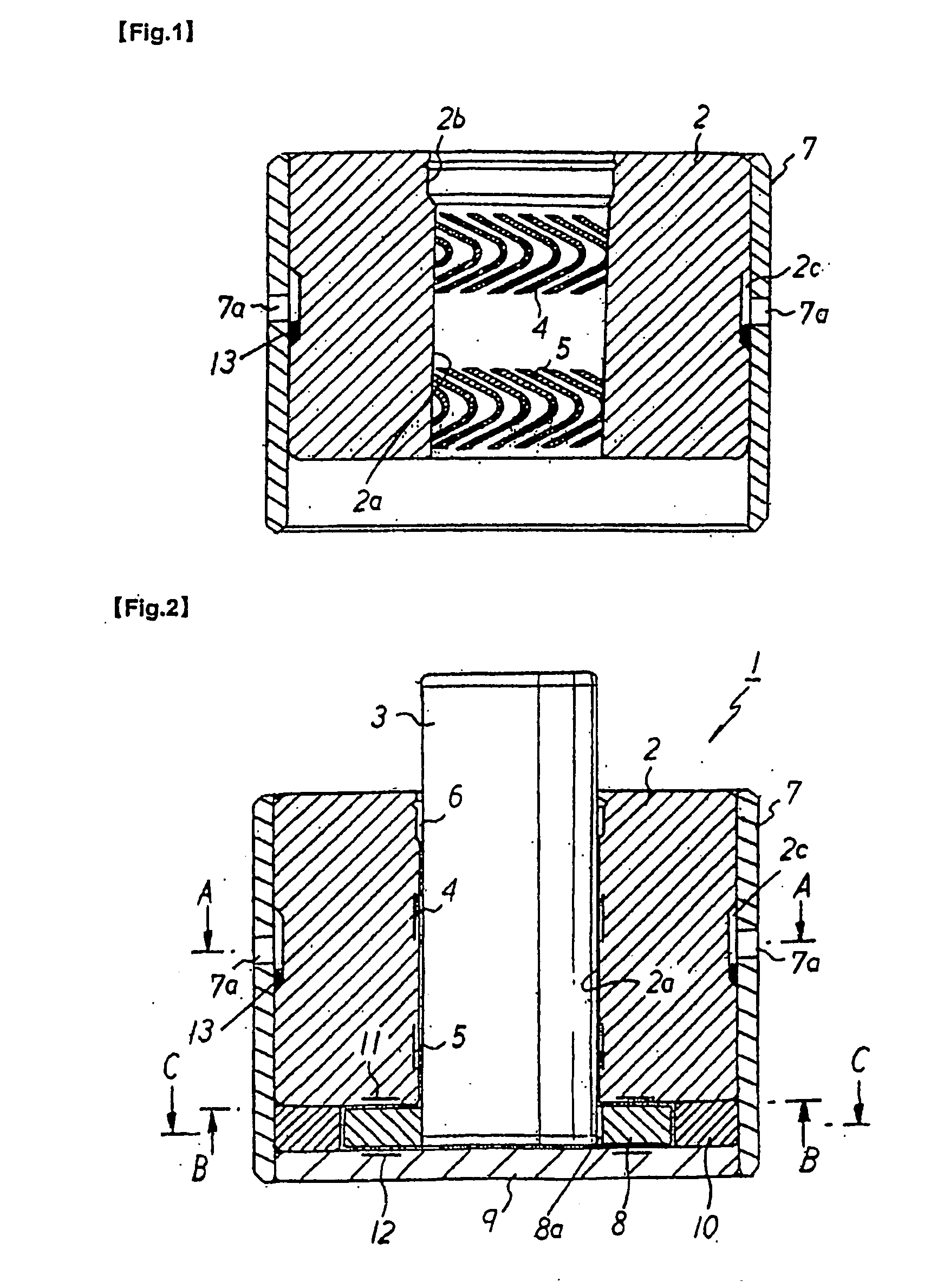

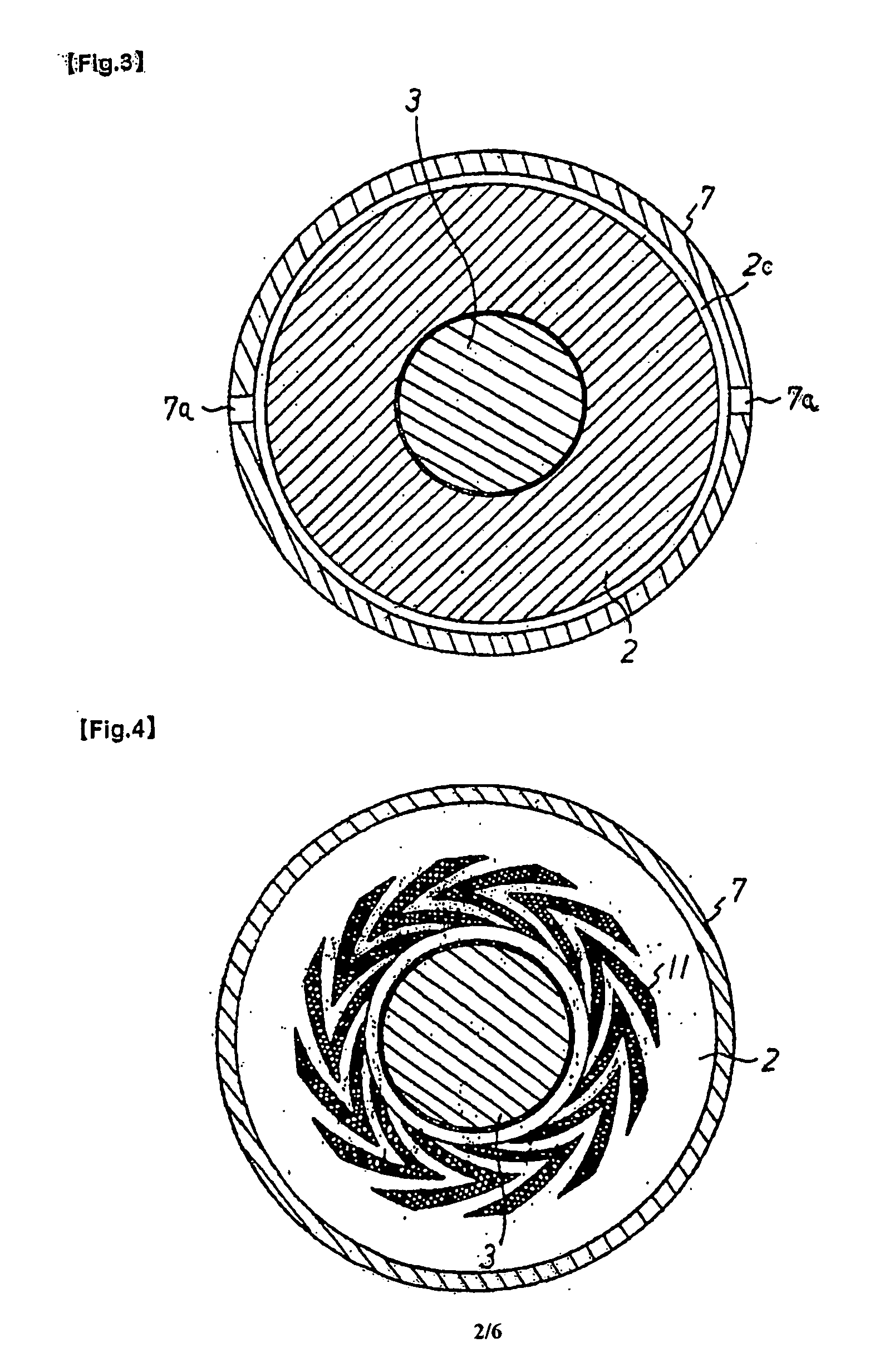

Fluid Dynamic Pressure Bearing

InactiveUS20090160277A1Maintain dimensional accuracyMaintain geometric accuracyShaftsBearing componentsAdhesiveEngineering

A fluid dynamic bearing (1) with a rotating shaft (3) inserted into a sleeve (2) fitted into a case (7) is disclosed. Tree rotating shaft (3) rotates freely without contact with the sleeve (2) by means of dynamic pressure force generated by the lubricant fluid that fills the gap formed around the rotating shaft (3). An adhesive groove (2c) is formed around the entire outer circumferential surface of the sleeve (2). At least one hole (7a) facing the adhesive groove (2c) is formed in case (7), and case (7) and sleeve (2) are; adhered by the injection of an adhesive (13) into adhesive groove (2c) from the hole (7a). The fluid dynamic pressure bearing, manufactured in this manner provides a high-quality bearing that is easy to construct, that can be adapted to low-cost manufacturing, and that can maintain dimensional and structural accuracy and in which the case (7) and sleeve (2) can be reliably adhered together with the adhesive (13). Such bearing will maintain long-term airtightness of the joint between the sleeve (2) and the case (7) and prevent leakage of lubricant fluid during manufacture. The bearing can be used for a spindle and other compact motors for driving memory devices for magnetic discs and optical discs (such as a CD or a DVD), motors for polygon mirrors used for scanning processes of laser beam printers, and for small motors for use such as in axial flow fans.

Owner:MINEBEA CO LTD

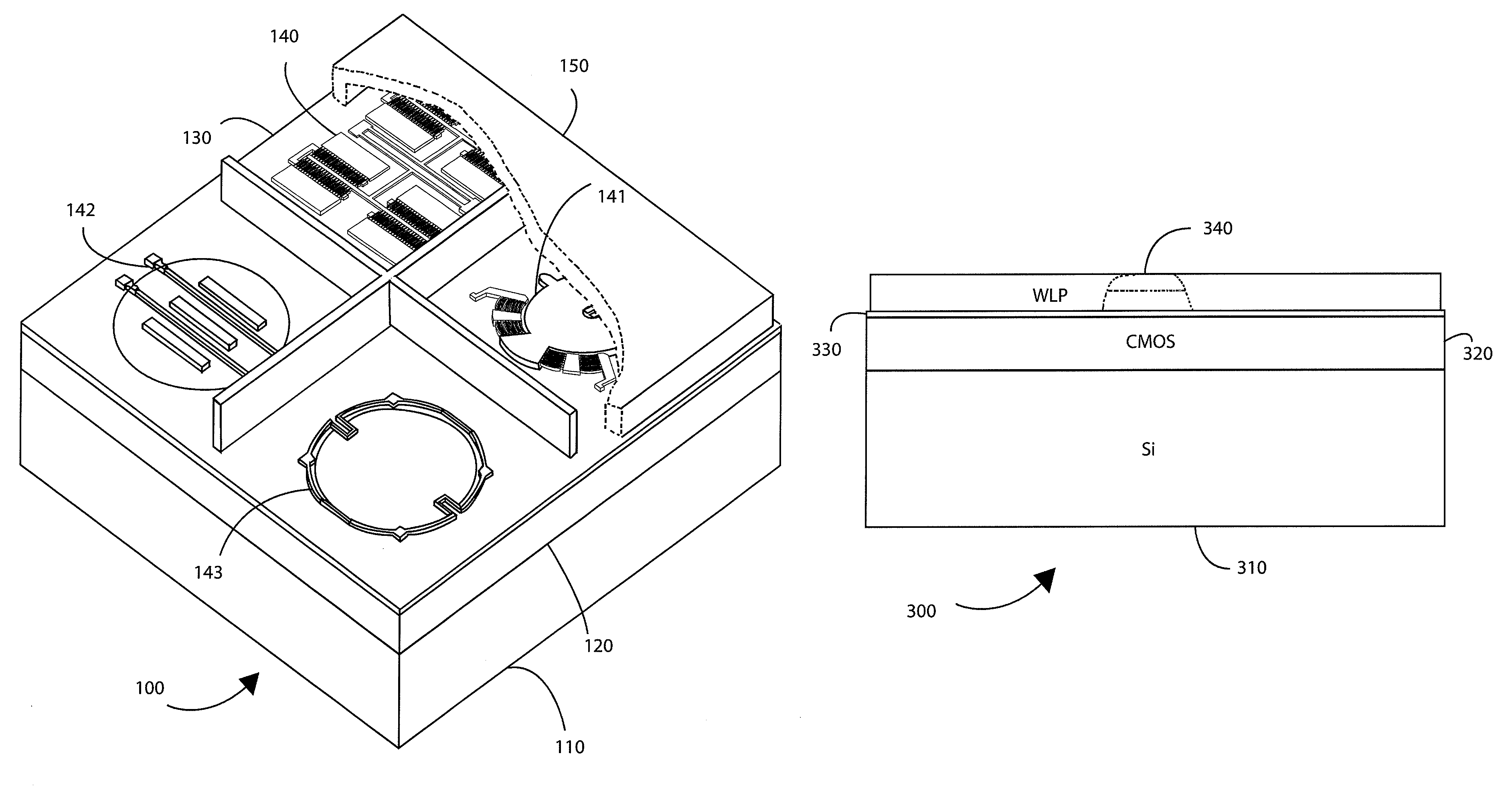

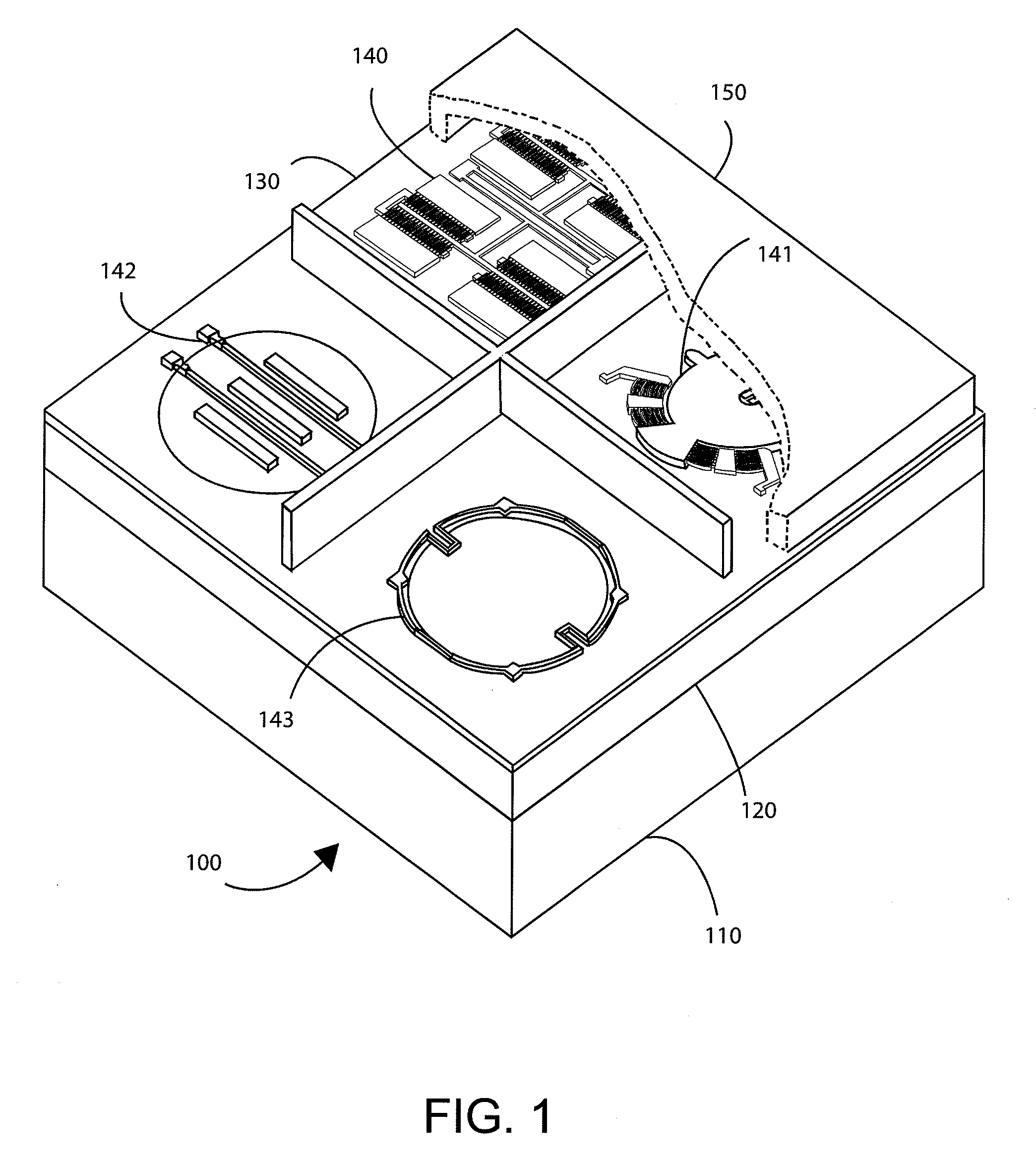

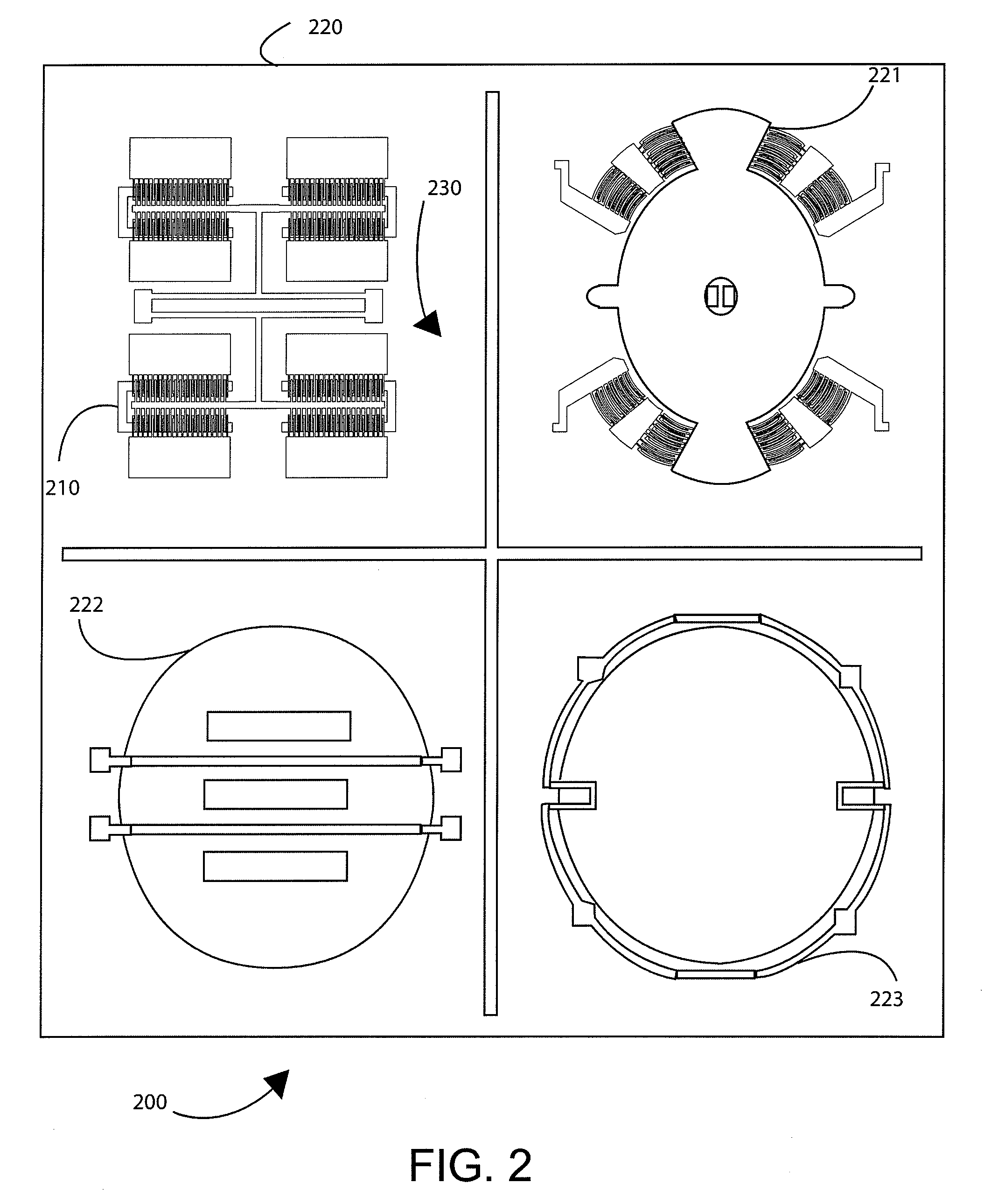

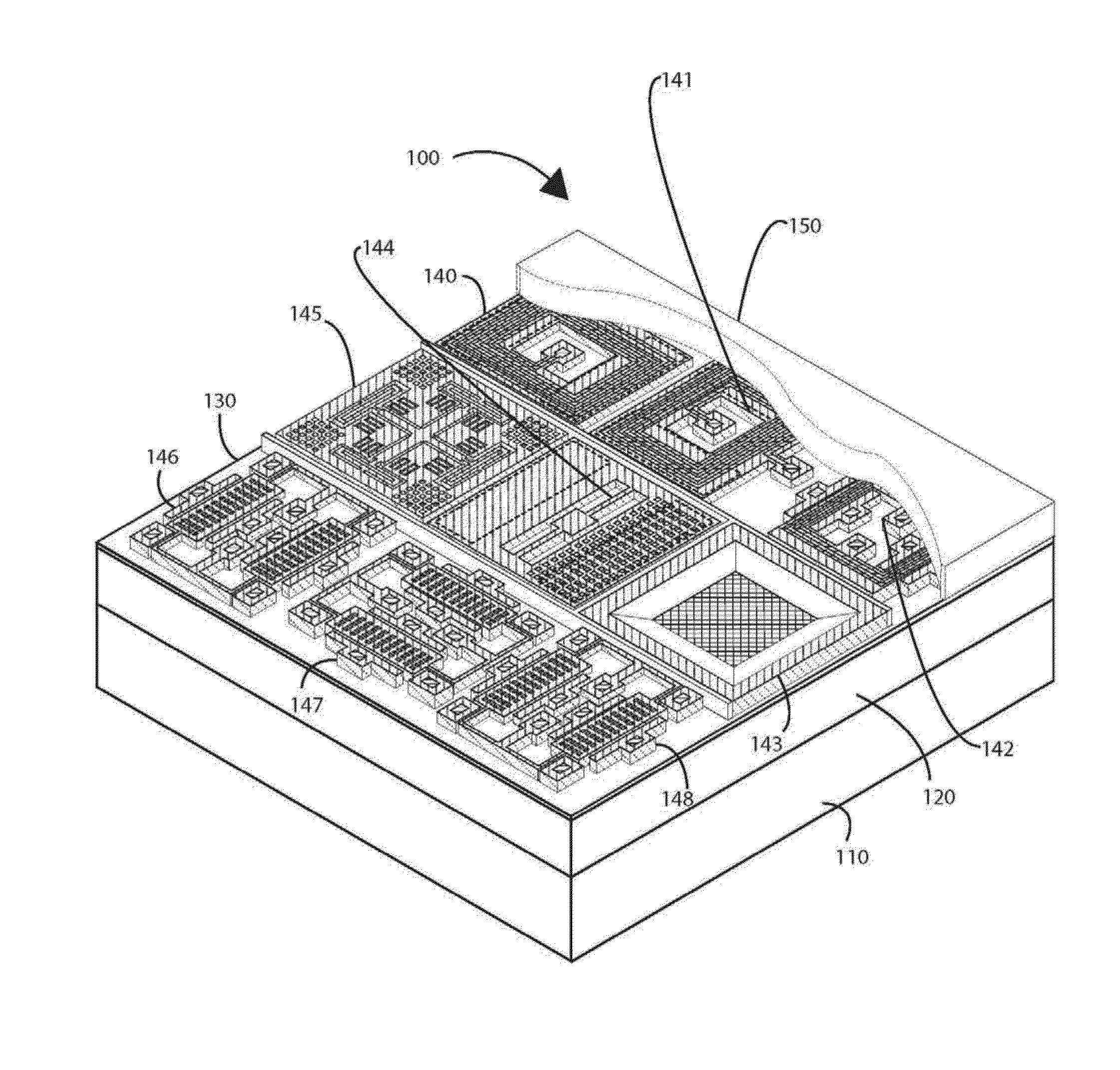

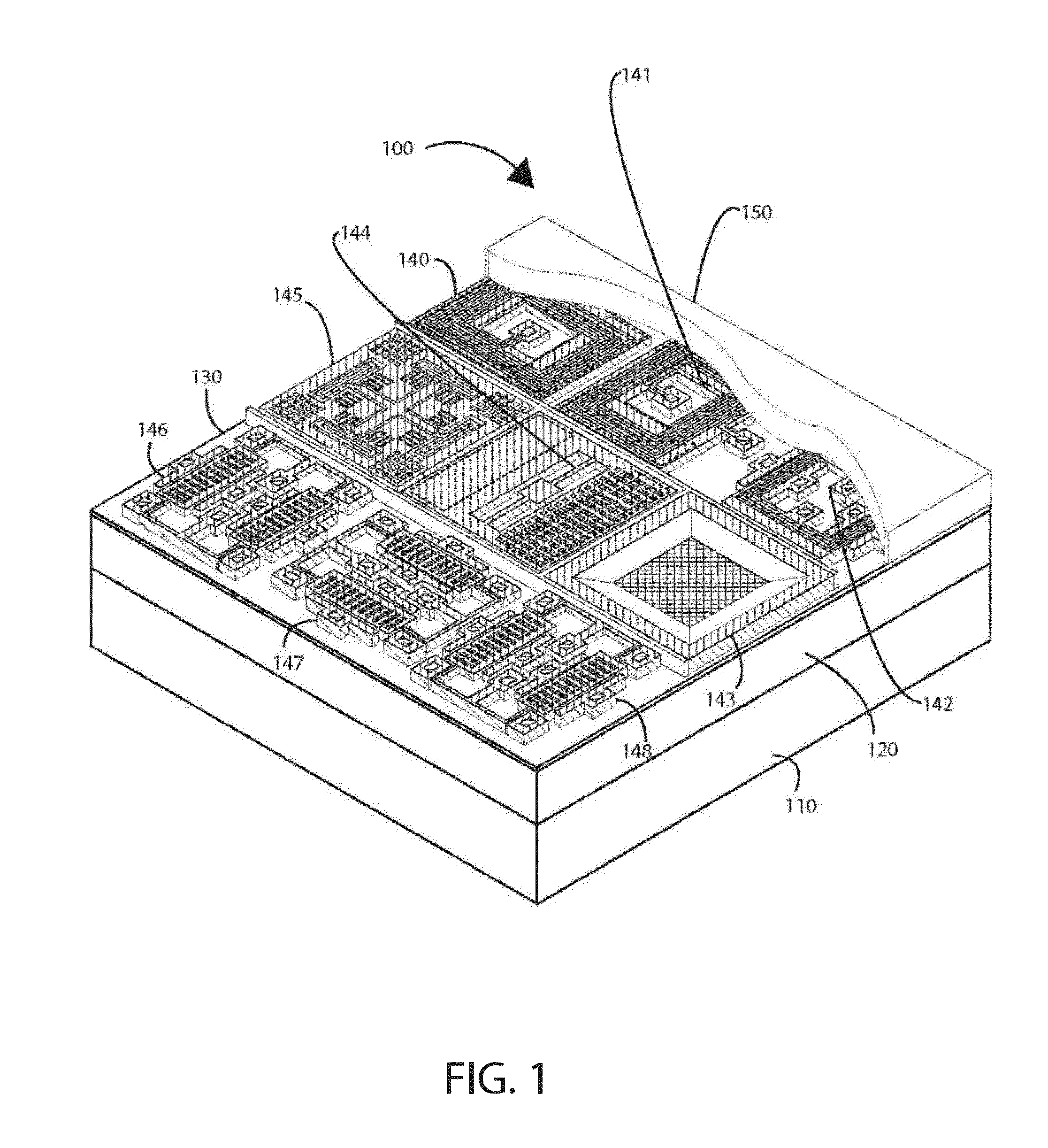

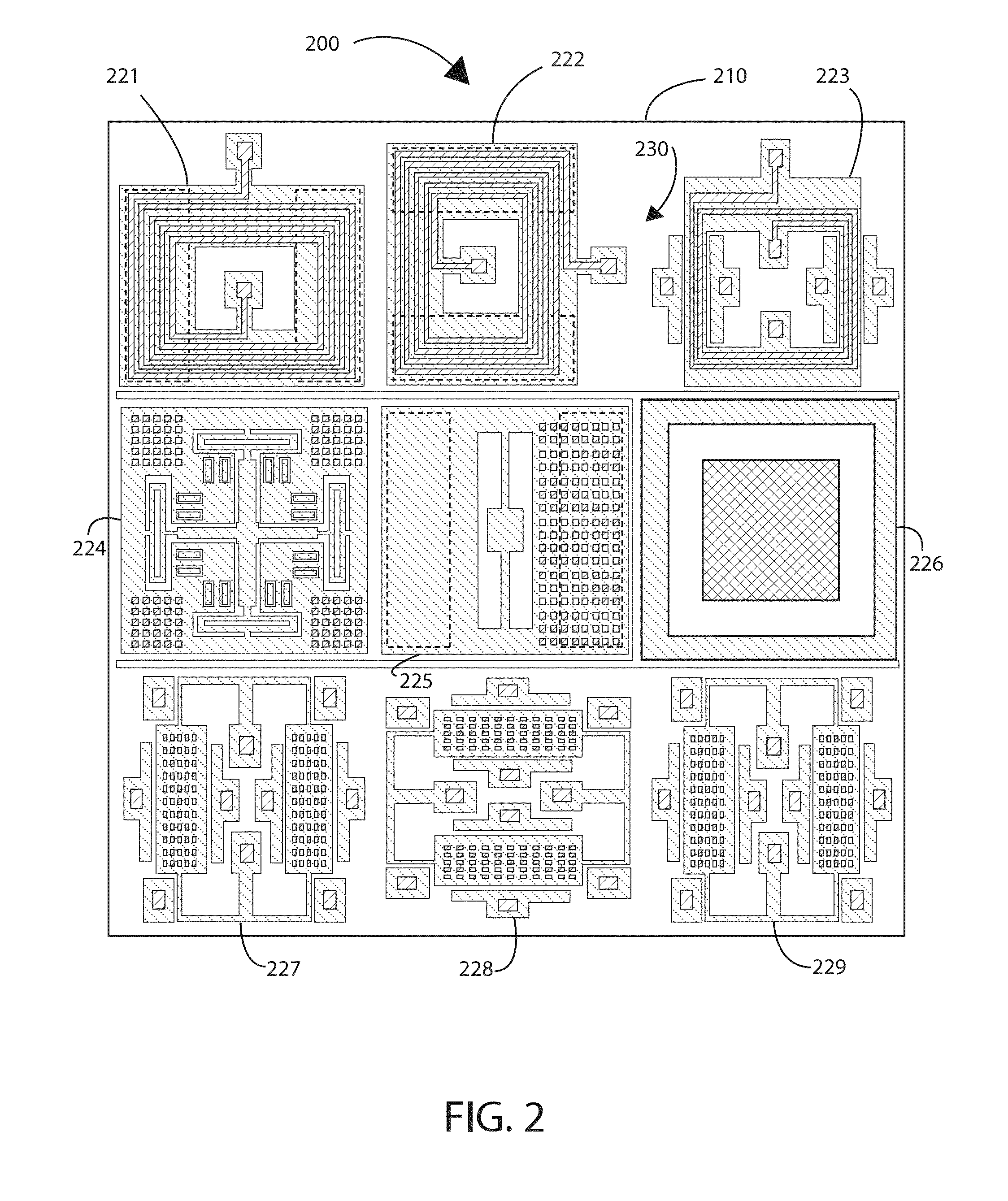

Integrated system on chip using multiple MEMS and CMOS devices

ActiveUS8823007B2Easy to useHigh device yieldVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringCmos mems

Owner:MOVELLA INC

Multi-axis integrated MEMS devices with CMOS circuits and method therefor

ActiveUS20140162393A1Easy to useHigh device yieldDecorative surface effectsSolid-state devicesCMOSEngineering

An integrated multi-axis mechanical device and integrated circuit system. The integrated system can include a silicon substrate layer, a CMOS device region, four or more mechanical devices, and a wafer level packaging (WLP) layer. The CMOS layer can form an interface region, on which any number of CMOS and mechanical devices can be configured. The mechanical devices can include MEMS devices configured for multiple axes or for at least a first direction. The CMOS layer can be deposited on the silicon substrate and can include any number of metal layers and can be provided on any type of design rule. The integrated MEMS devices can include, but not exclusively, any combination of the following types of sensors: magnetic, pressure, humidity, temperature, chemical, biological, or inertial. Furthermore, the overlying WLP layer can be configured to hermetically seal any number of these integrated devices.

Owner:MOVELLA INC

Consolidation and densification methods for fibrous monolith processing

InactiveUS20020140139A1Low production costImprove effectivenessCeramic shaping apparatusClaywaresEngineeringMechanical engineering

Owner:ADVANCED CERAMICS

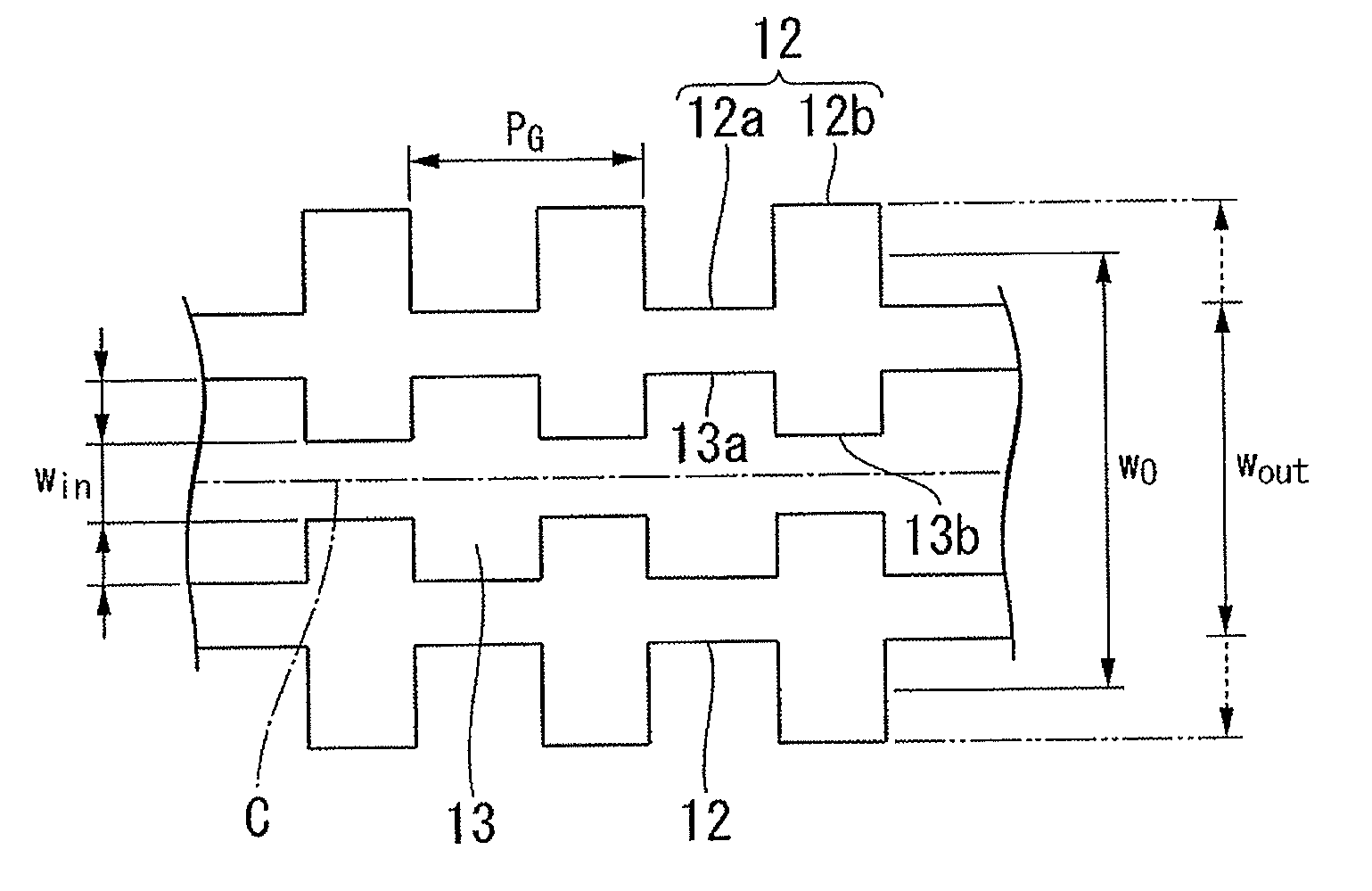

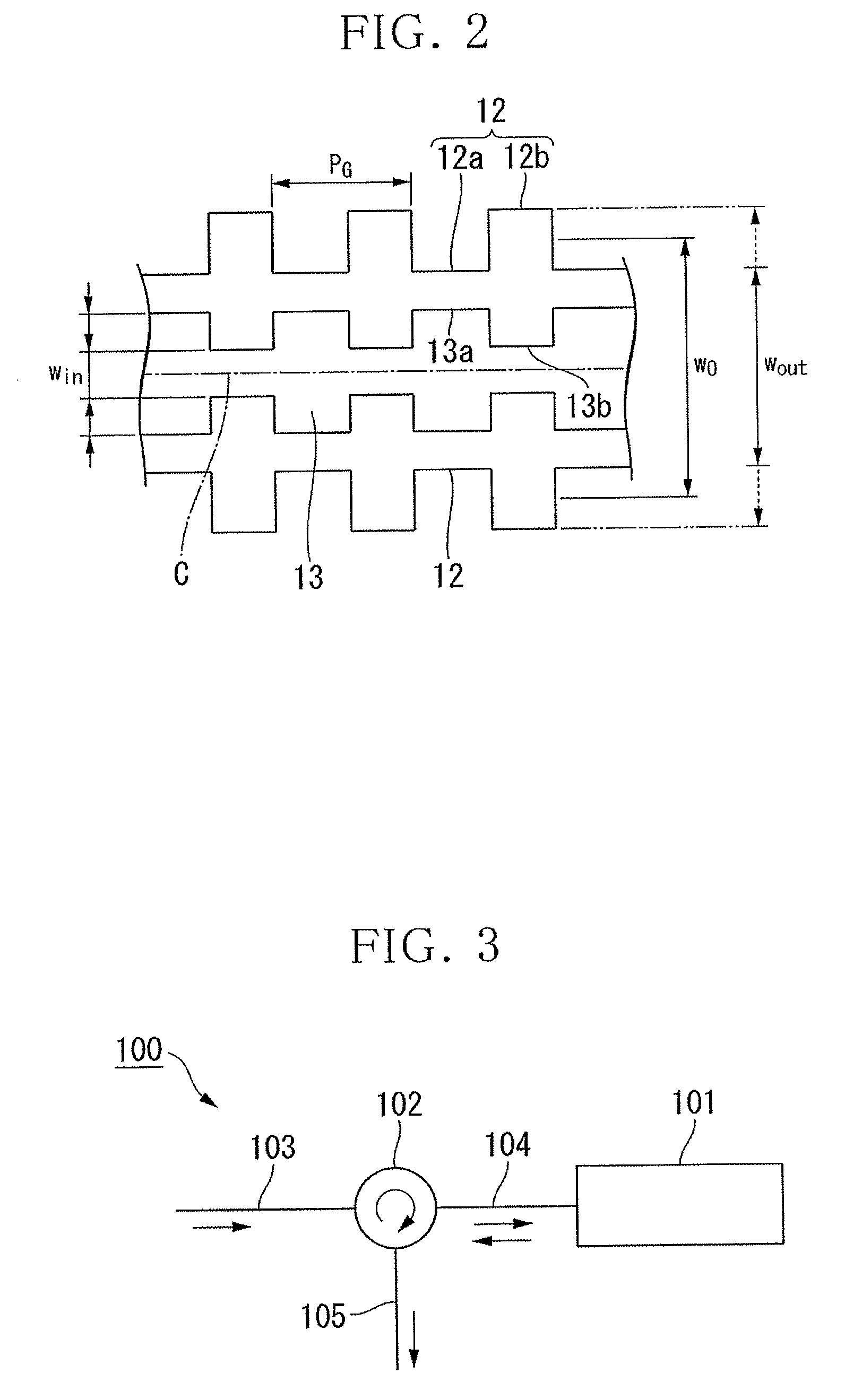

Manufacturing method of planar optical waveguide device with grating structure

ActiveUS20110053095A1Formed easily and preciselyFunction increaseOptical articlesPhotomechanical exposure apparatusGratingRefractive index

A method for manufacturing a planar optical waveguide device including a core of which a top face is provided with a groove section filled with a groove section filler made of a low refractive index material having a refractive index lower than that of the core, the method including; a first high refractive index material layer forming step of forming a high refractive index material layer; a low refractive index material layer forming step of forming a low refractive index material layer made of the low refractive index material on the high refractive index material layer; a groove section filler forming step of forming the groove section filler by trimming both lateral portions of the low refractive index material layer; and a second high refractive index material layer forming step of forming a high refractive index material layer so as to fill the both sides of the lateral portions of the groove section filler.

Owner:ADVANCED MICRO FOUNDRY PTE LTD

Consolidation and densification methods for fibrous monolith processing

InactiveUS6740286B2Low production costImprove effectivenessCeramic shaping apparatusClaywaresFiberPolymer science

Methods for consolidation and densification of fibrous monolith composite structures are provided. Consolidation and densification of two- and three-dimensional fibrous monolith components having complex geometries can be achieved by pressureless sintering. The fibrous monolith composites are formed from filaments having at least a first material composition generally surrounded by a second material composition. The composites are sintered in an inert gas or nitrogen gas at a pressure of no more than about 30 psi to provide consolidated and densified fibrous monolith composites.

Owner:ADVANCED CERAMICS

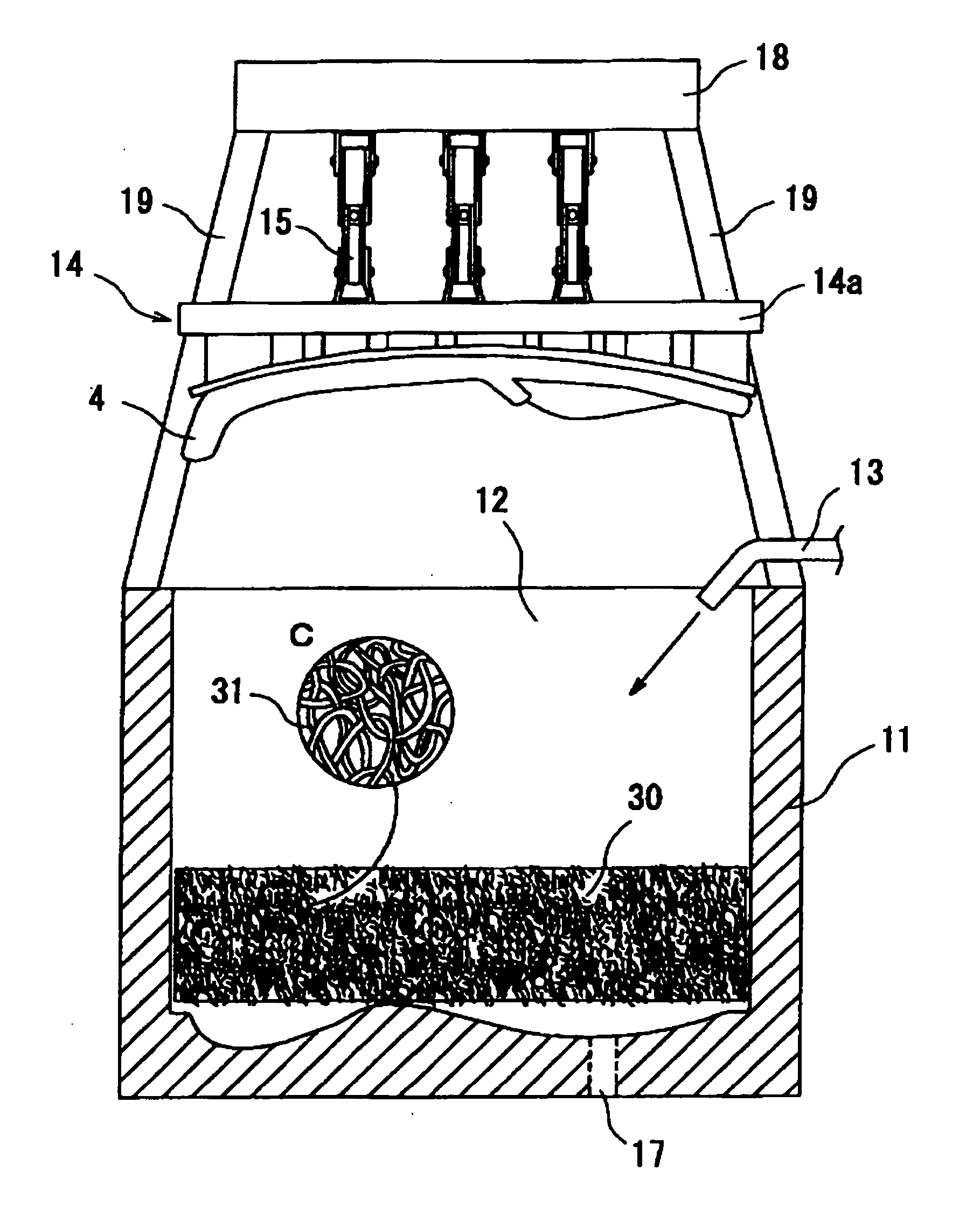

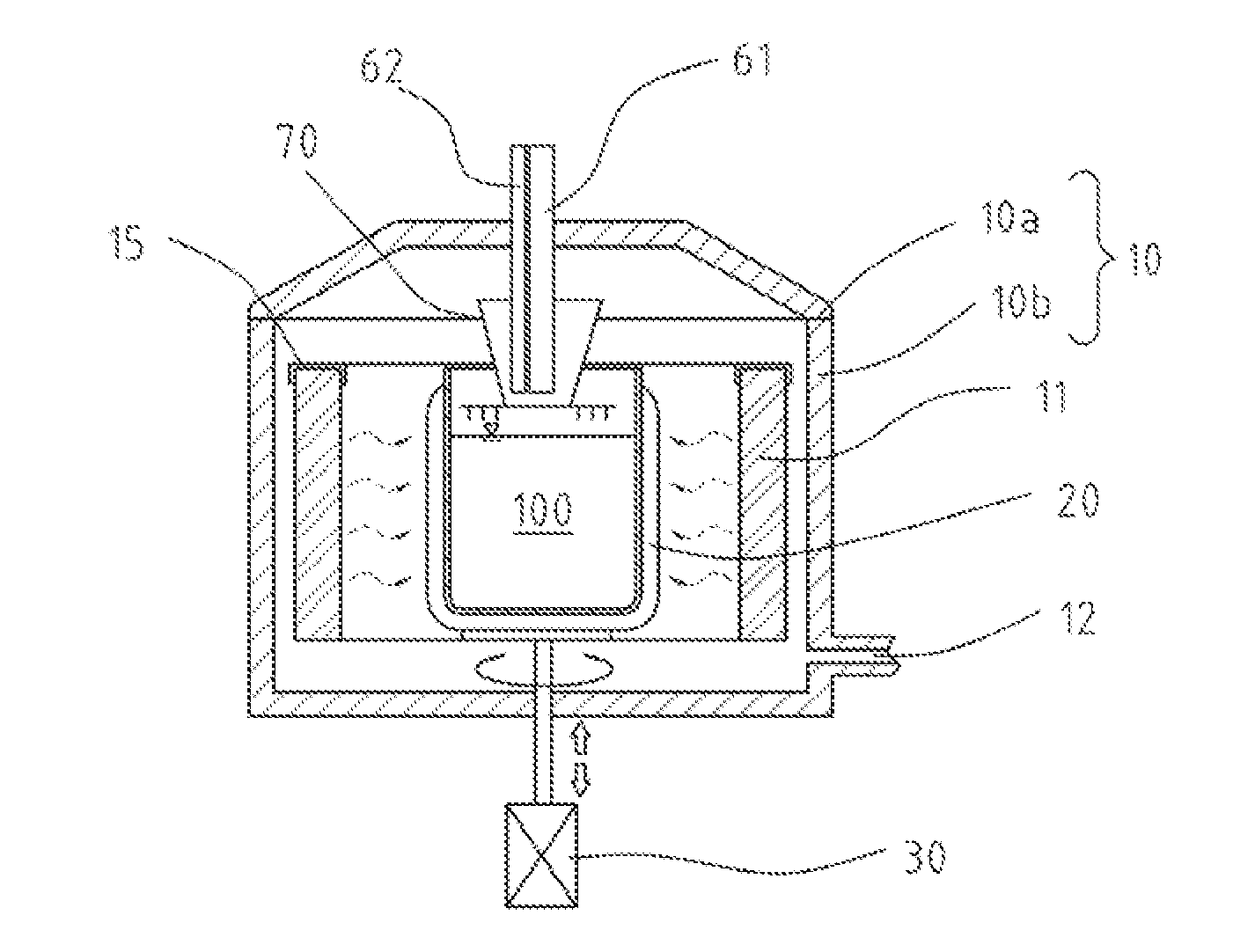

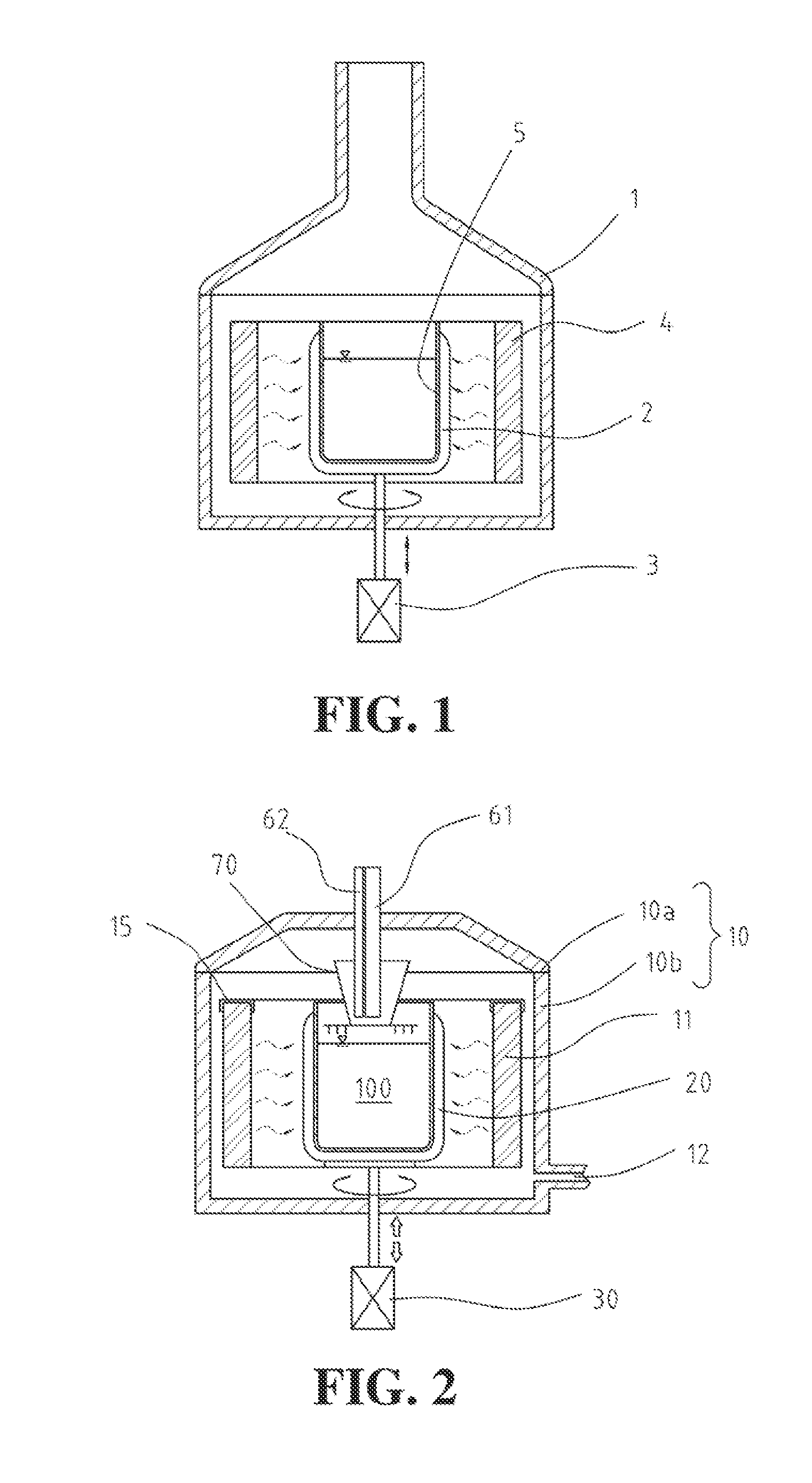

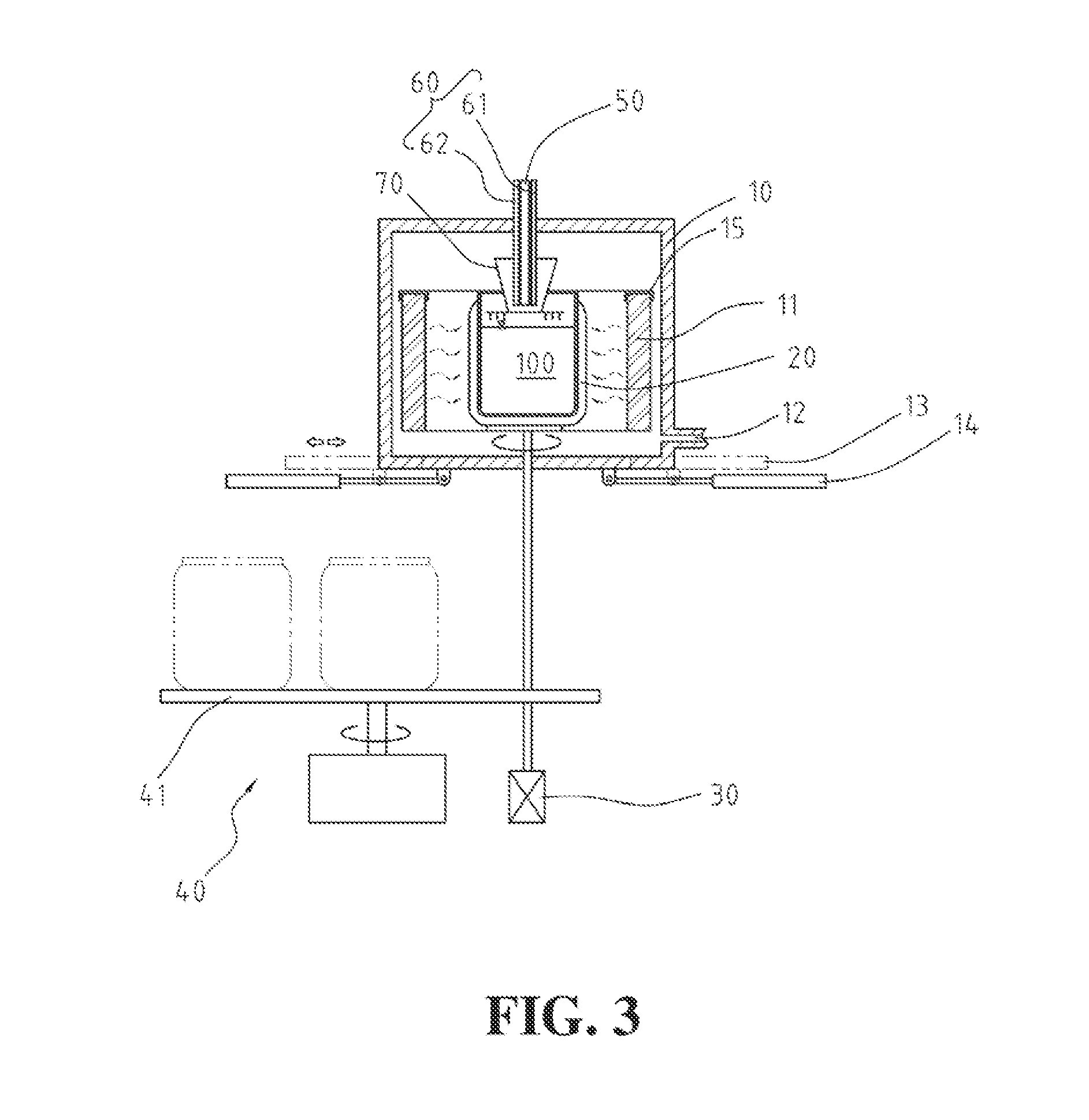

Apparatus for purifying metallurgical silicon for solar cells

InactiveUS20110198336A1Ensure safetyImprove purification efficiencyPolycrystalline material growthElectric discharge heatingCelsius DegreeCrucible

A system for forming high quality silicon material, e.g., polysilicon. In a specific embodiment, the melted material comprises a silicon material and an impurity, e.g., phosphorous species. The system includes a crucible having an interior region. In a specific embodiment, the crucible is made of a suitable material such as a quartz material or others. The quartz material is capable of withstanding a temperature of at least 1400 Degrees Celsius for processing silicon. In a specific embodiment, the crucible is configured in an upright position and has an open region to expose a melted material. In a specific embodiment, the present system has an energy source. Such energy source may be an arc heater or other suitable heating device, including multiple heating devices, which may be the same or different. The arc heater is configured above the open region and spaced by a gap between the exposed melted material and a muzzle region of the arc heater to cause formation of a determined temperature profile within a vicinity of a center region of the exposed melted material while maintaining outer regions of the melted material at a temperature below a melting point of the quartz material of the crucible. In a specific embodiment, the system produces a melted material comprising a resulting phosphorous species of 0.1 ppm and less, which is purified silicon.

Owner:HOSHINO MASAHIRO +1

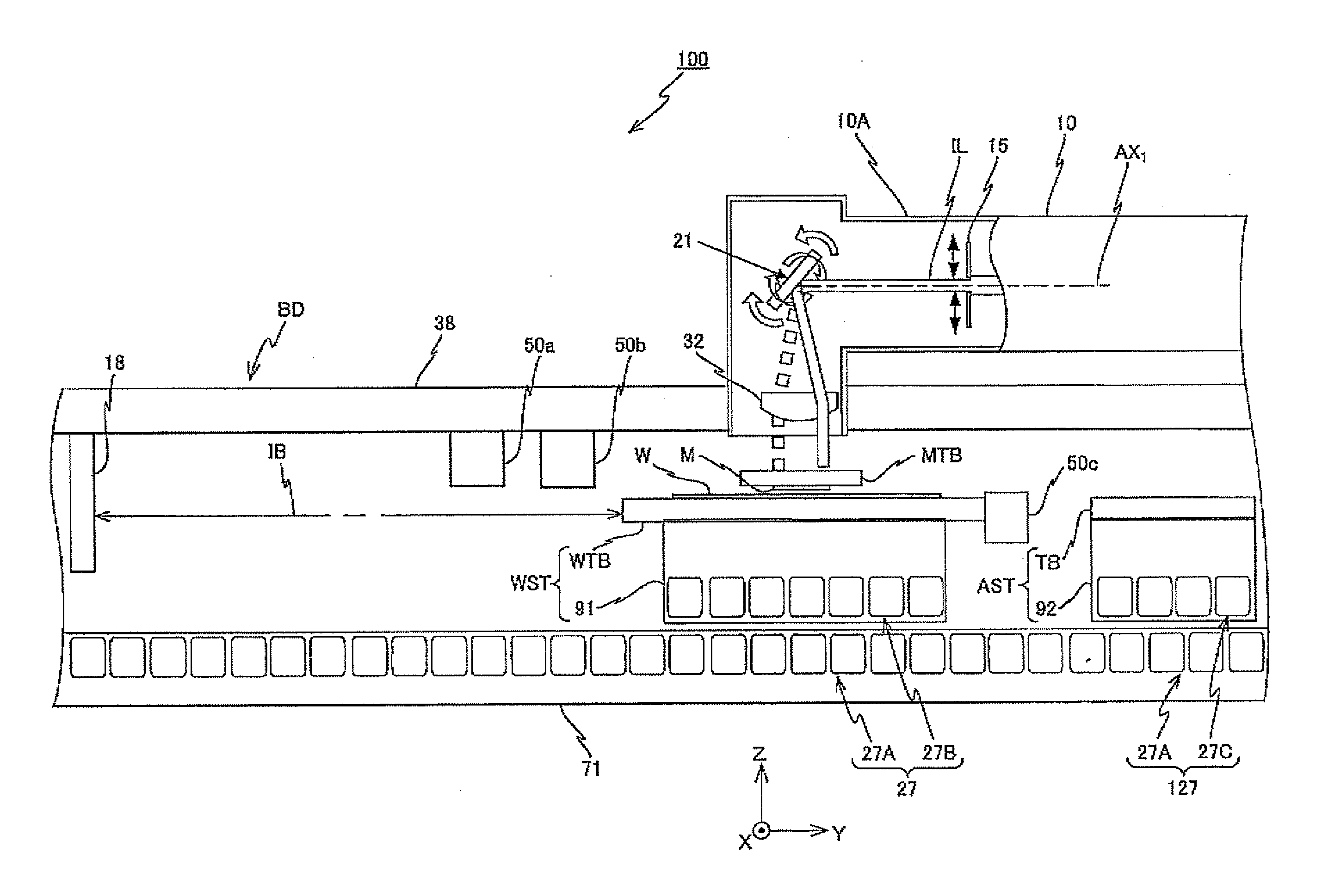

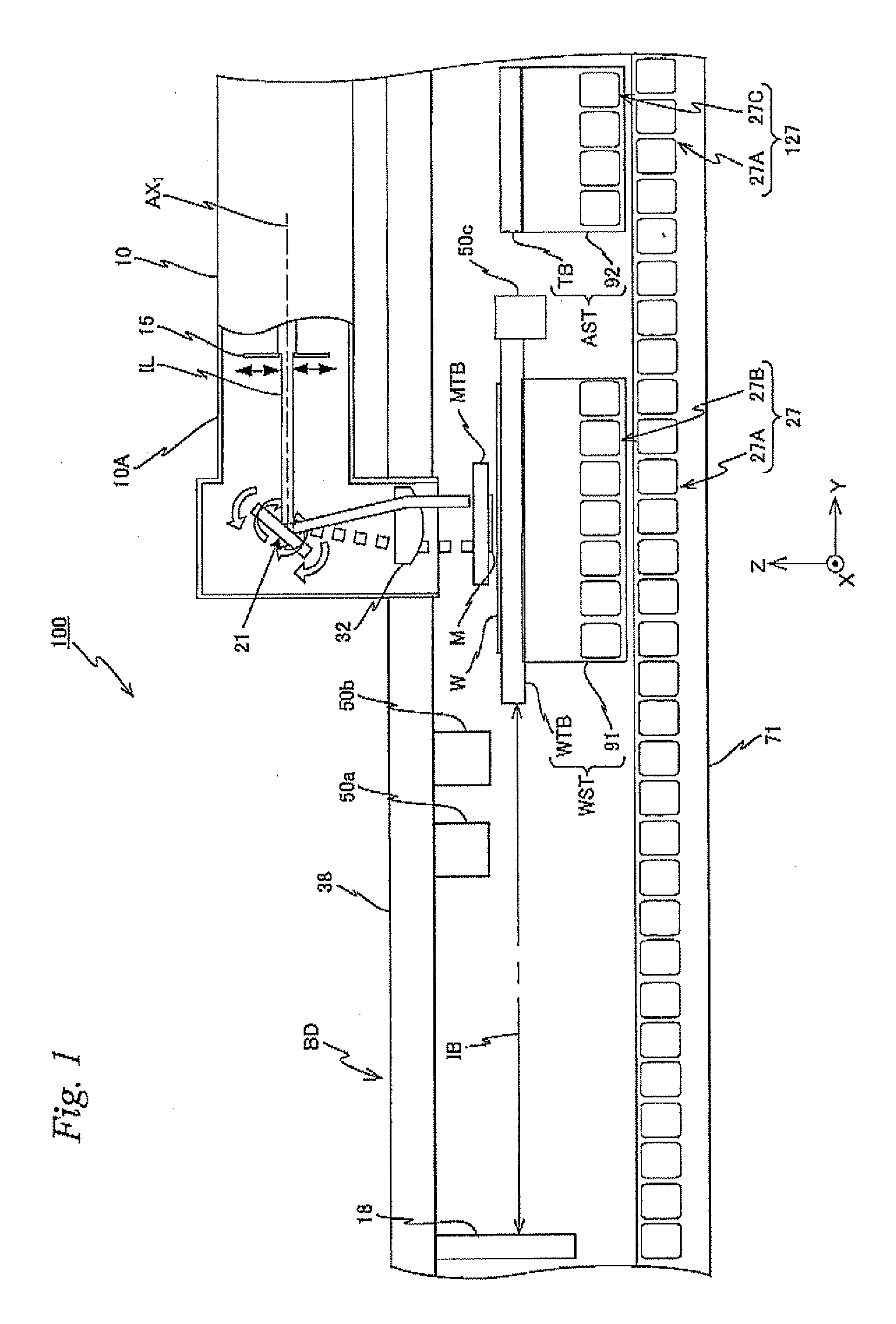

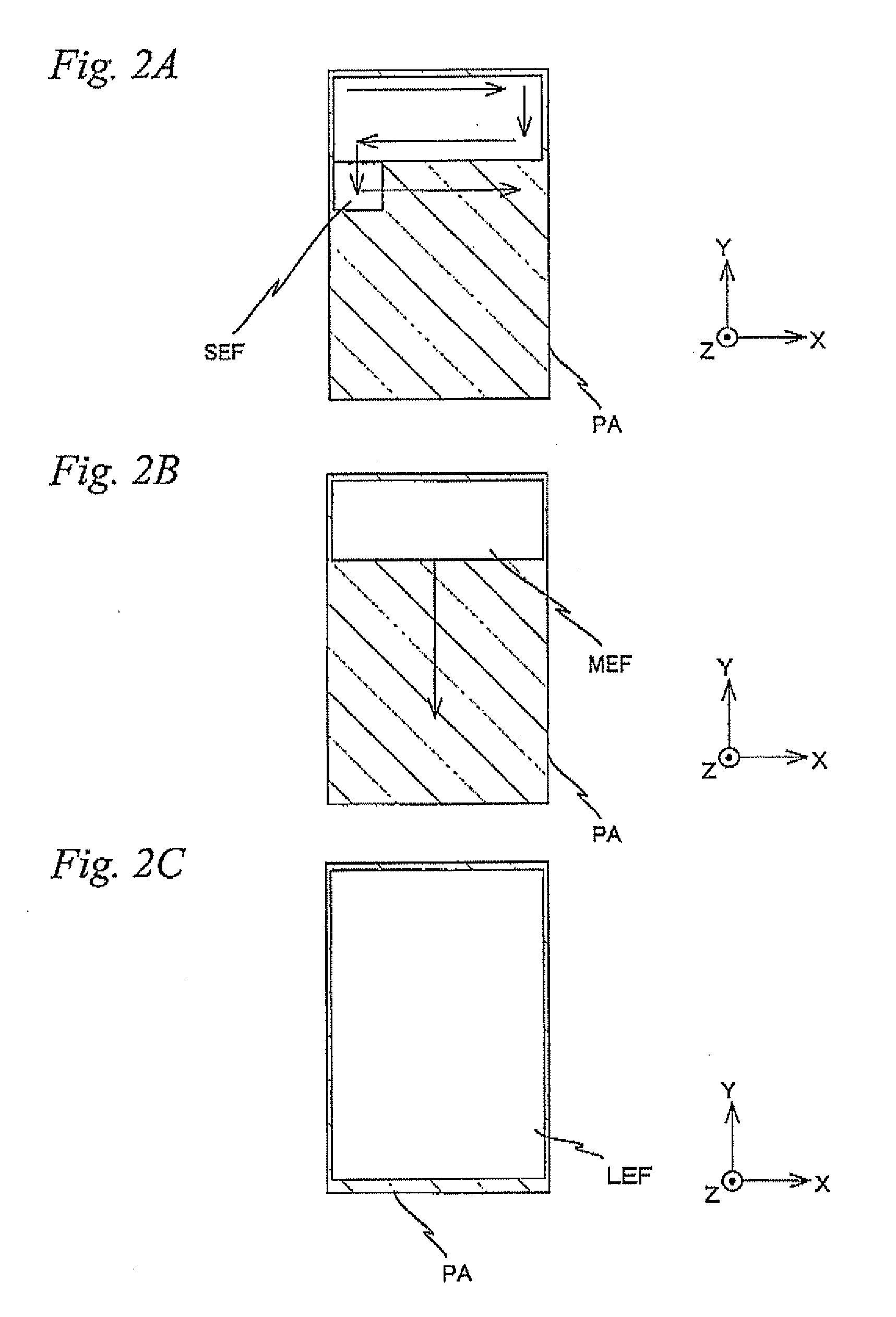

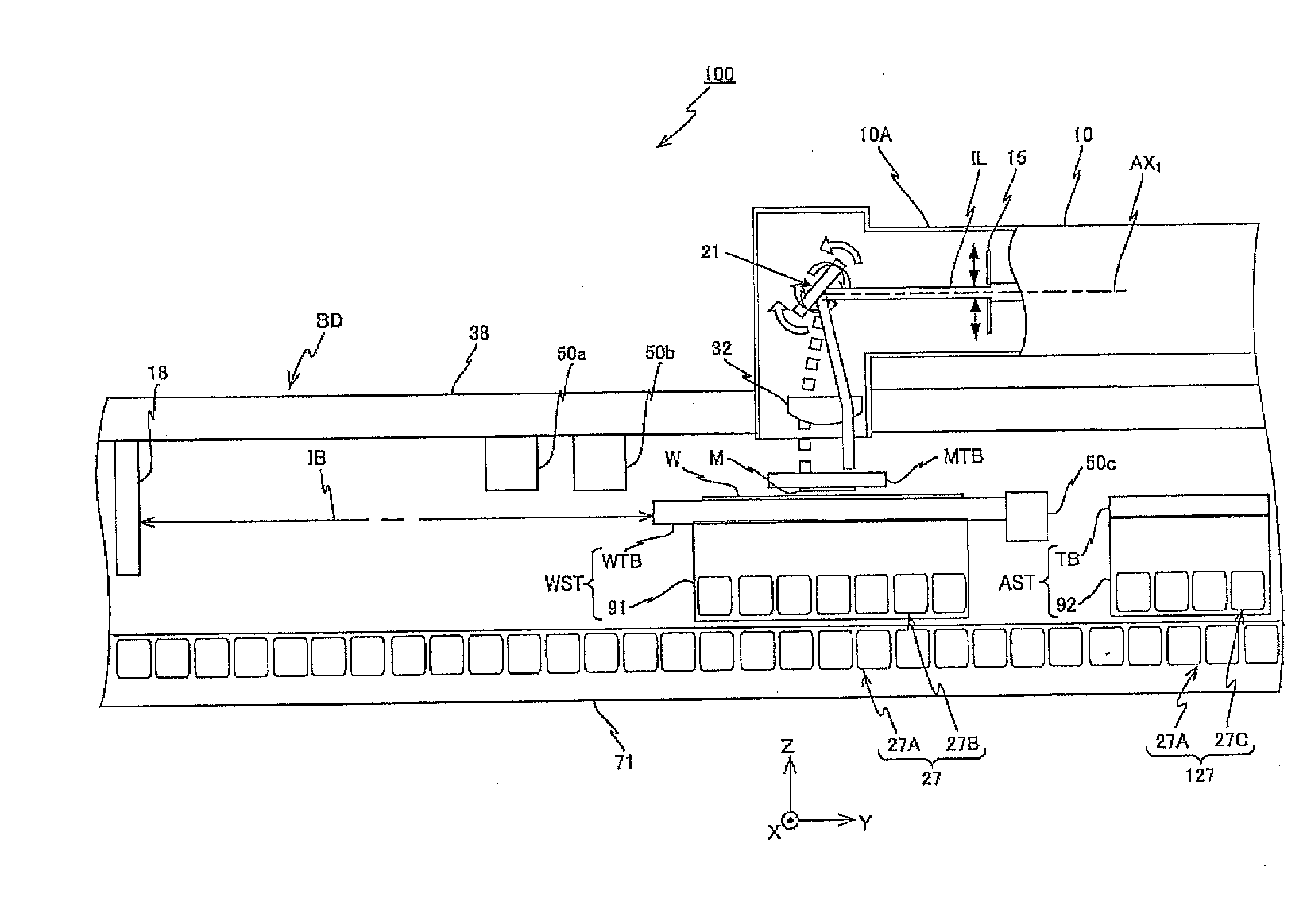

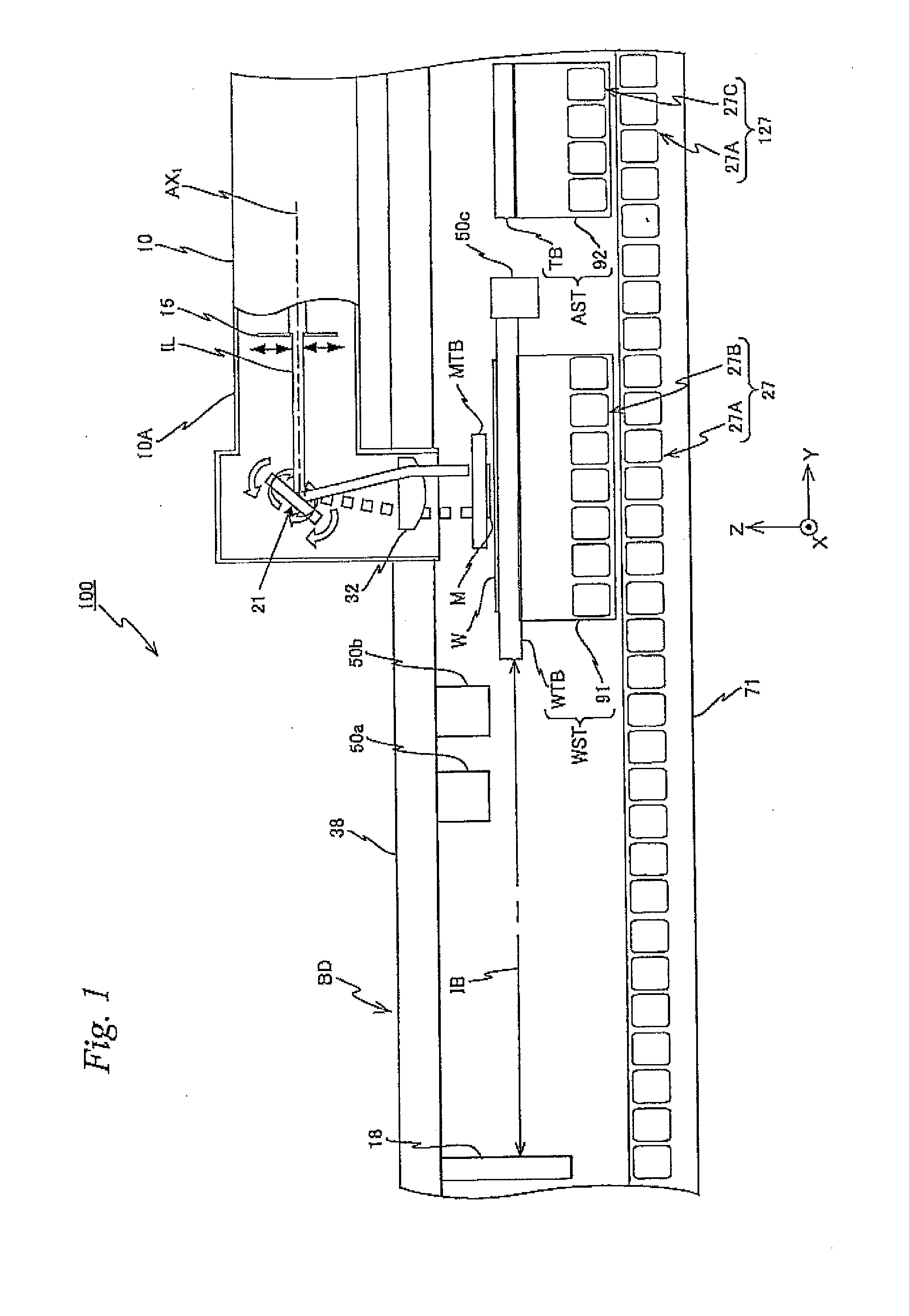

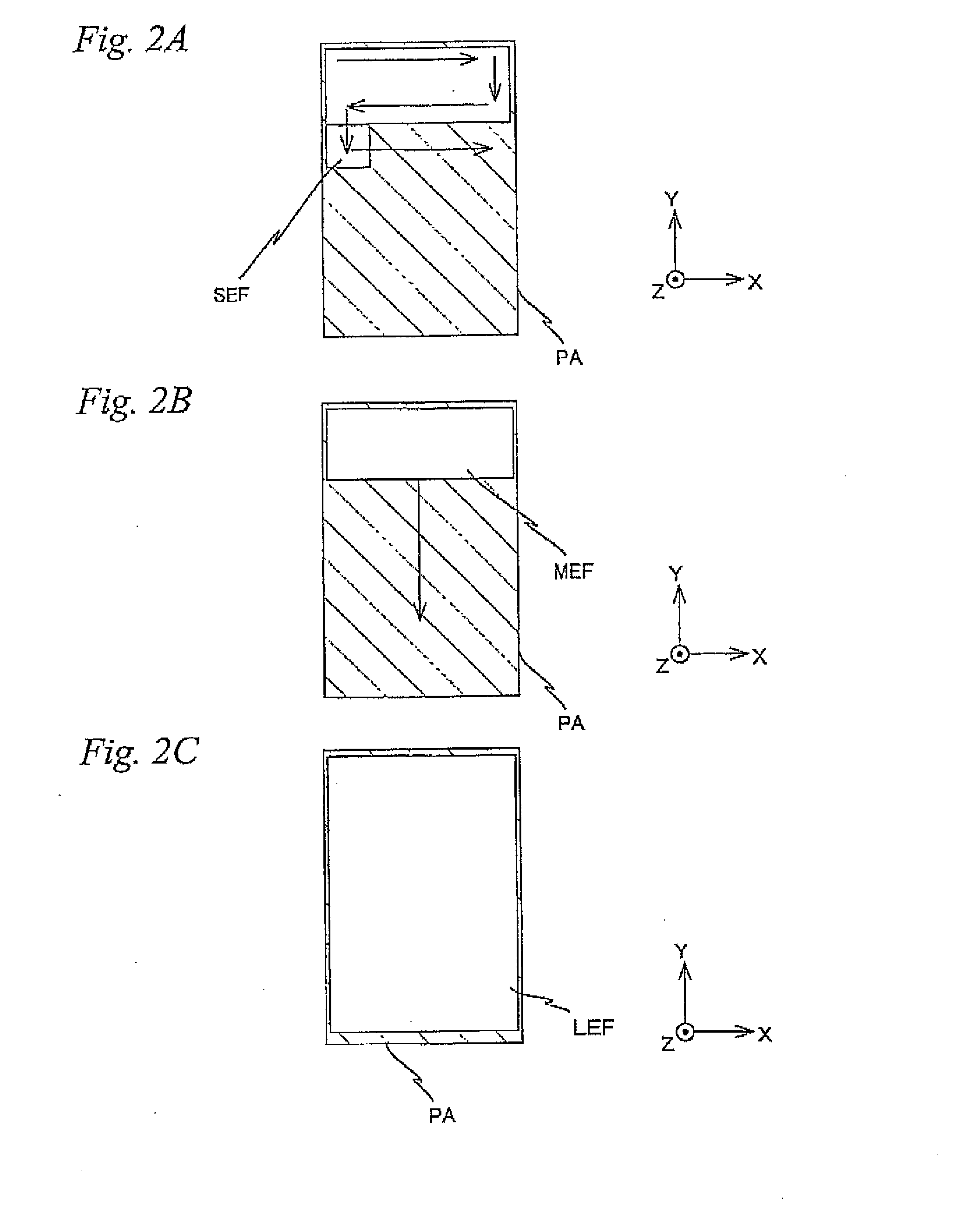

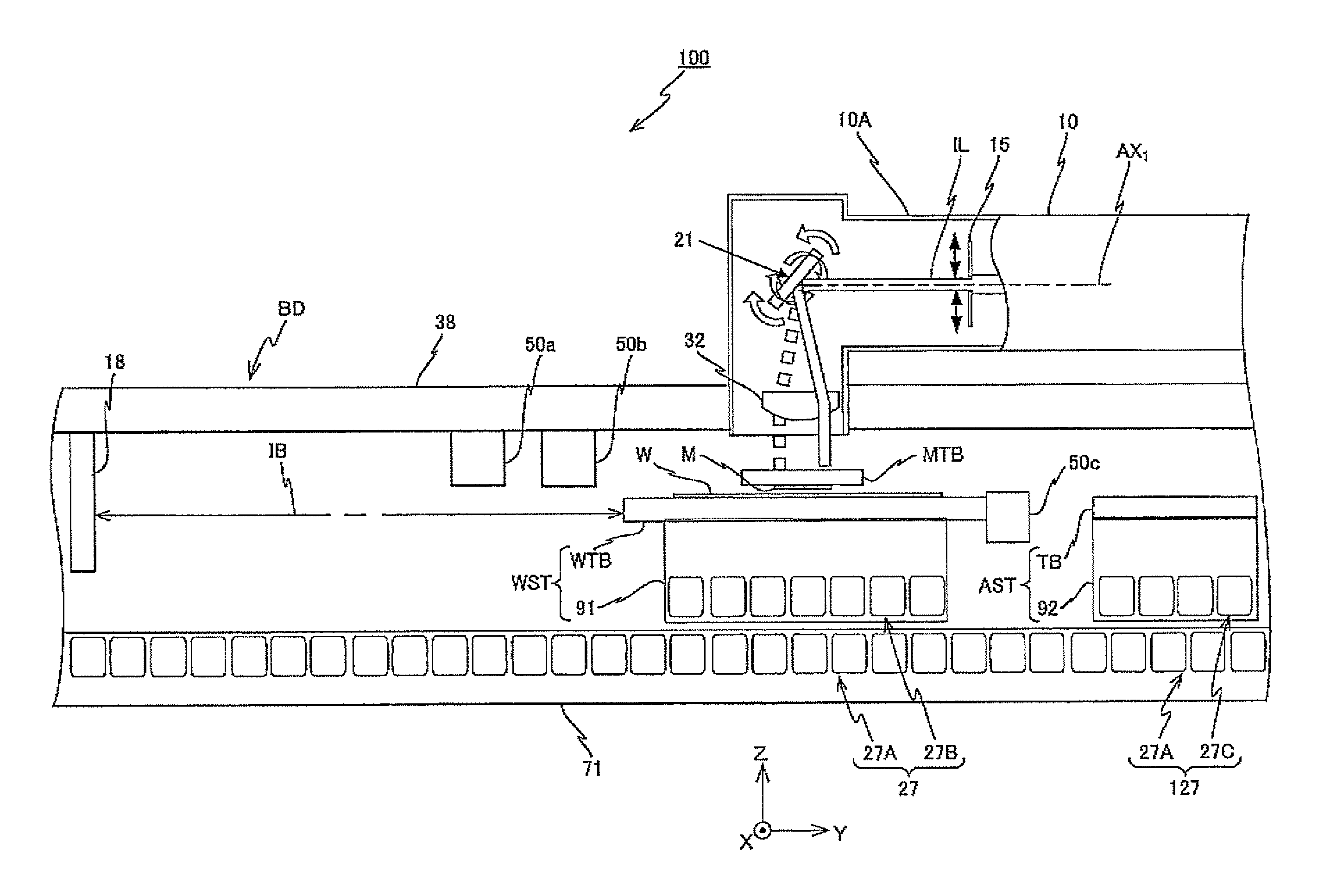

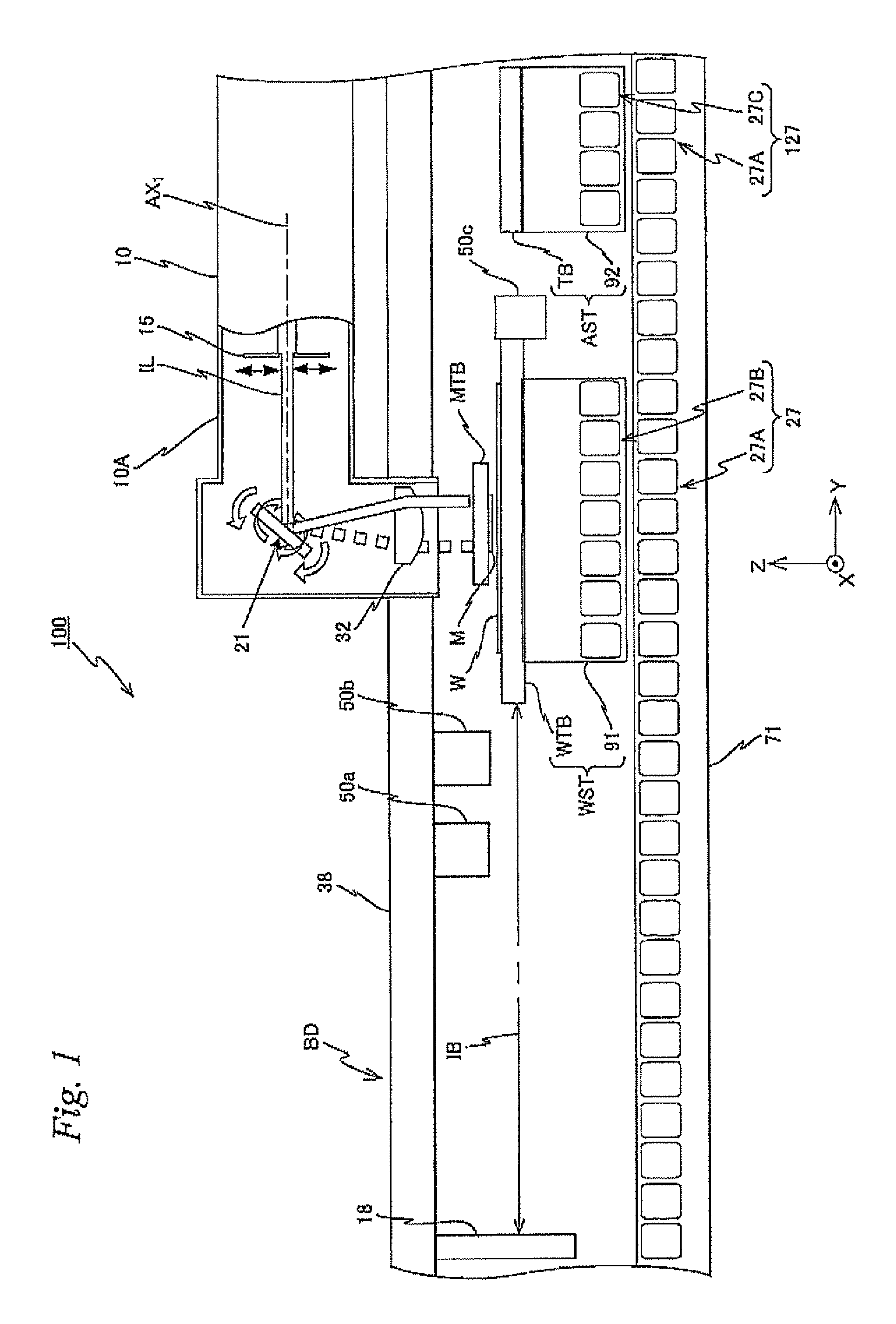

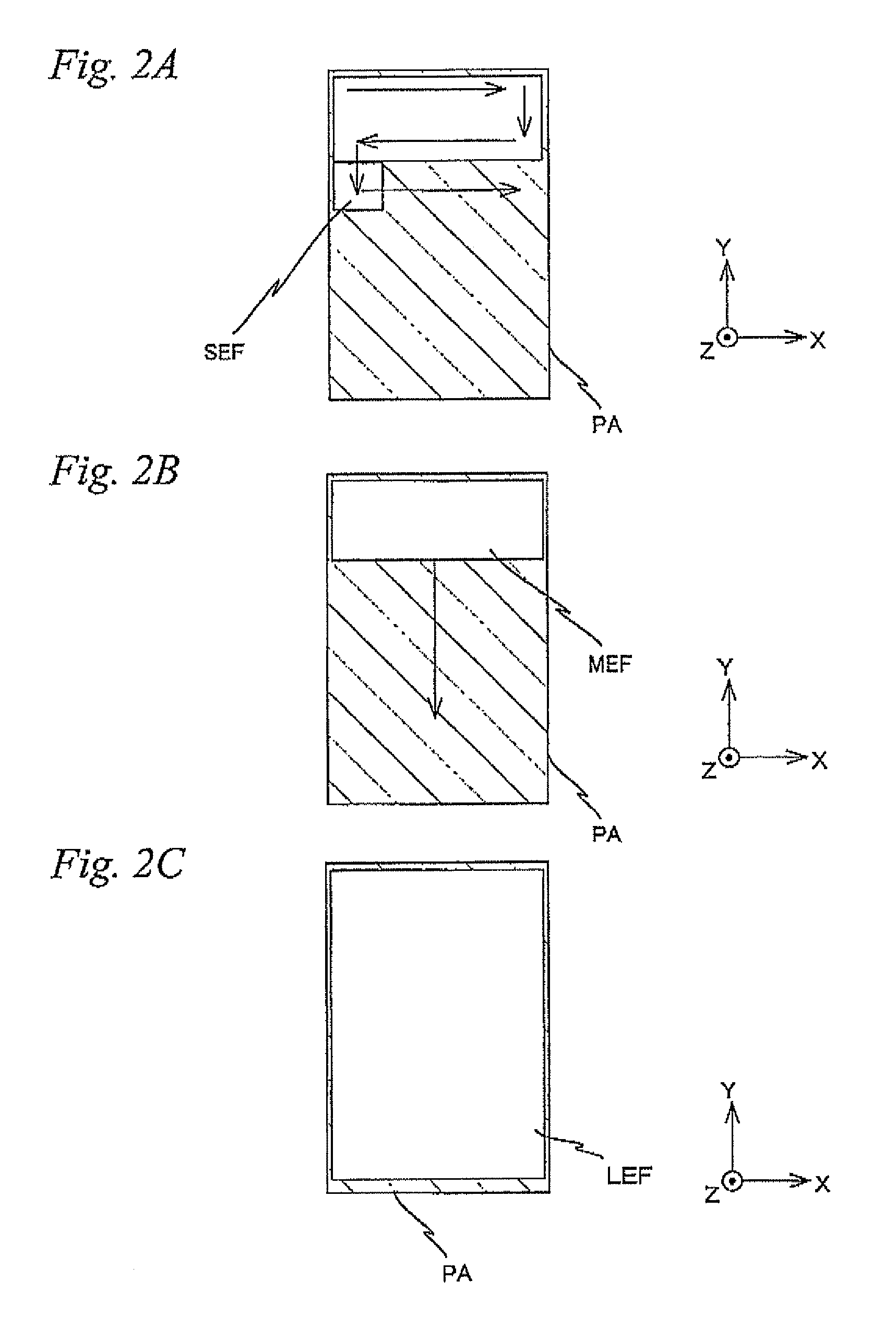

Exposure method and exposure apparatus, and device manufacturing method

ActiveUS20130183627A1Avoid interferencePrecise overlay of the patternSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusExposureProjection optics

Exposure apparatus is equipped with an illumination optical device which illuminates a mask with an exposure beam, a mask table which holds a periphery of a pattern area of the mask from above so that a pattern surface of the mask becomes substantially parallel to an XY plane and makes a force at least parallel to an XY plane and on the mask, and a wafer stage which moves along the XY plane, holding a wafer substantially parallel to the XY plane. Therefore, an overlay with high precision of a pattern of a mask and an underlying pattern on the substrate can be realized, even though the exposure apparatus employs a proximity method, that is, the exposure apparatus does not use a projection optical system.

Owner:NIKON CORP

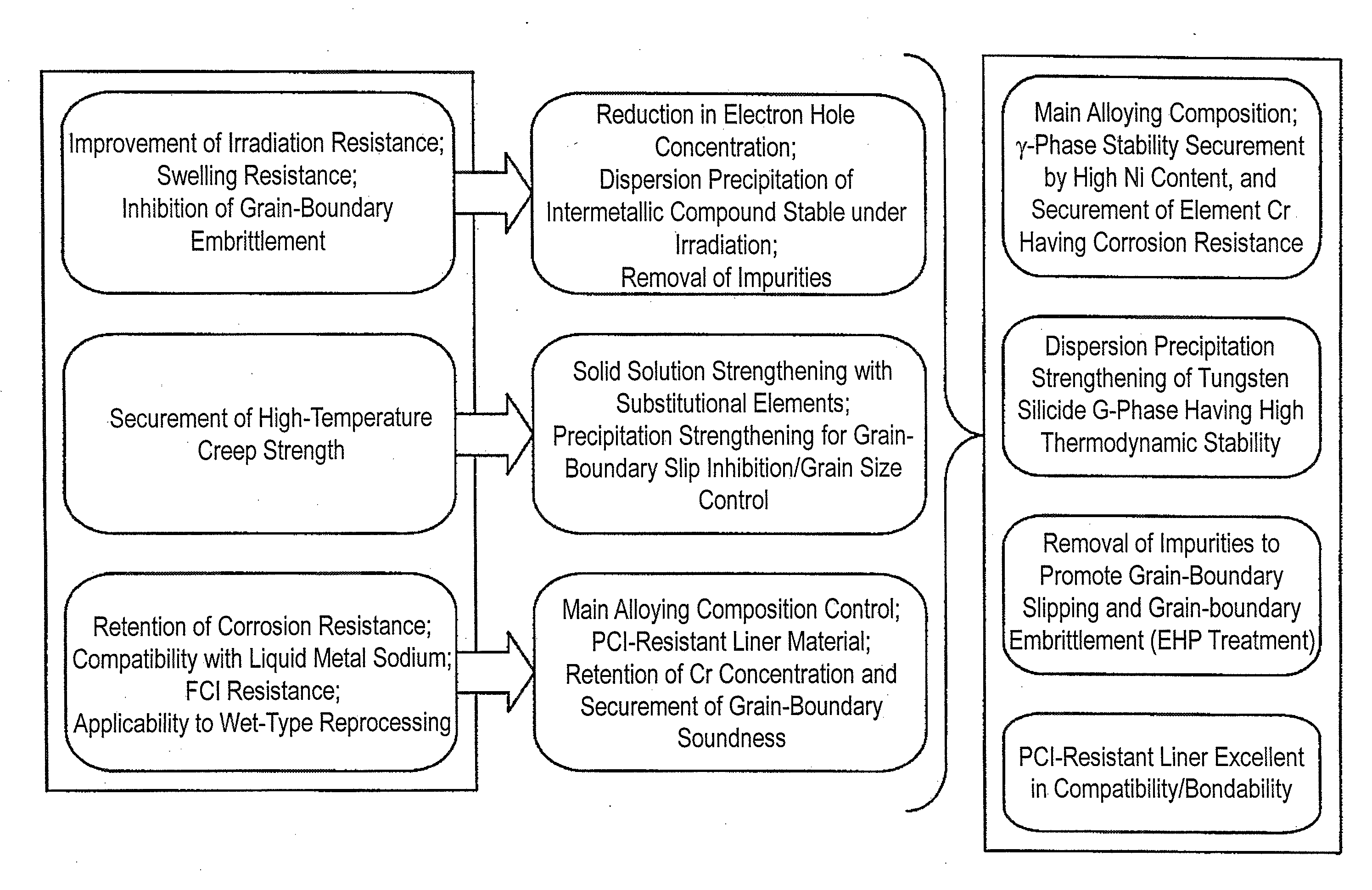

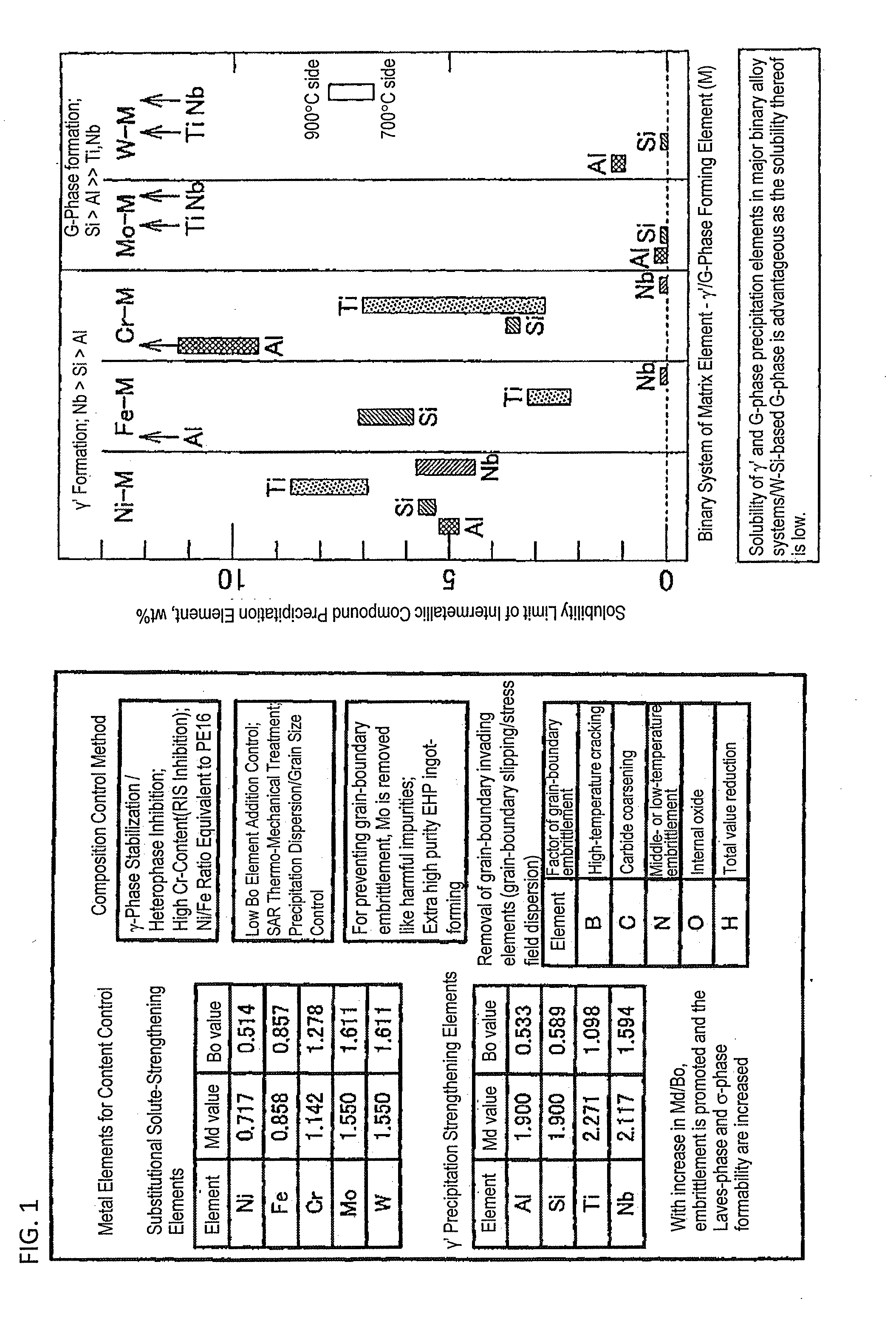

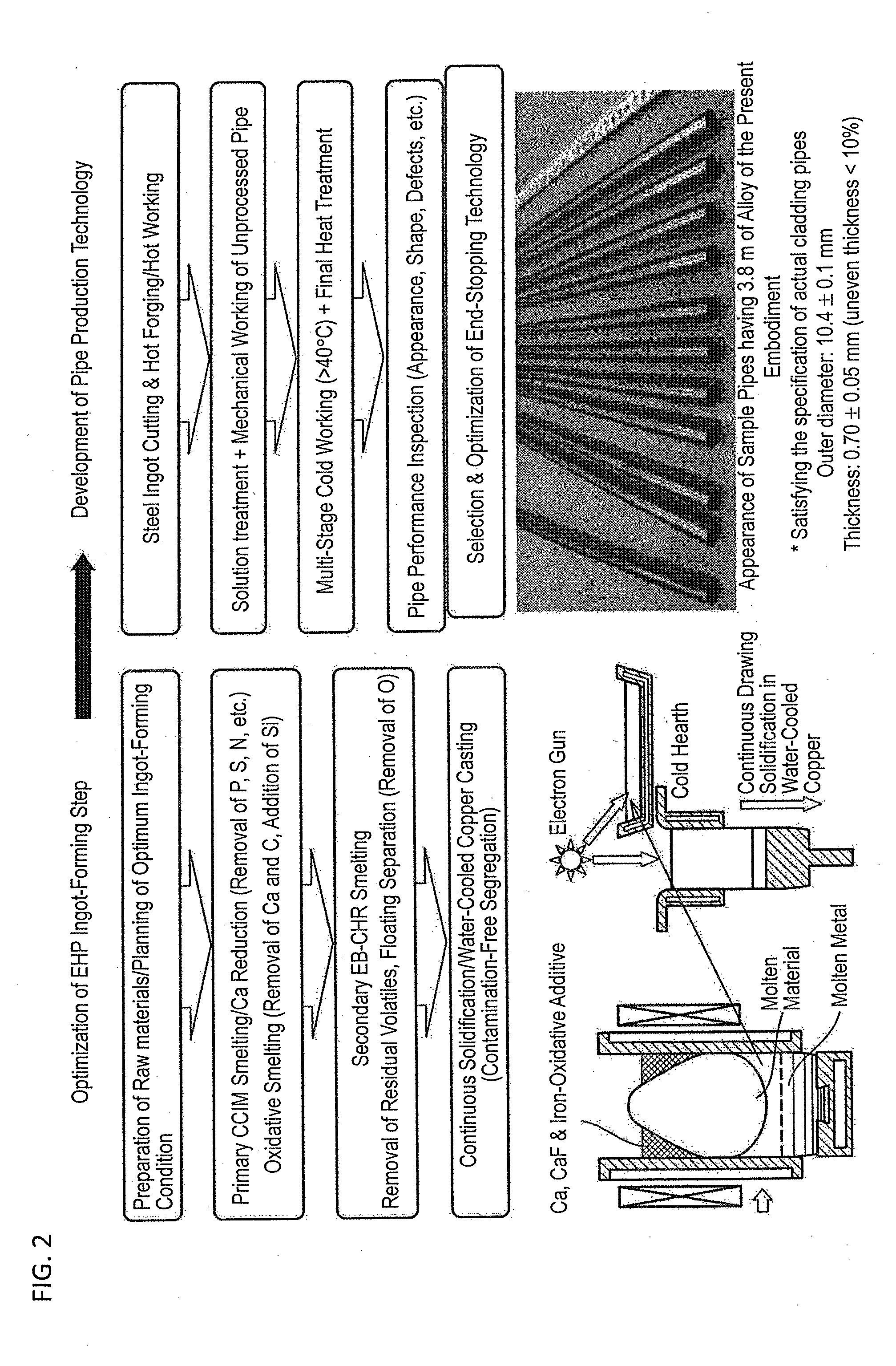

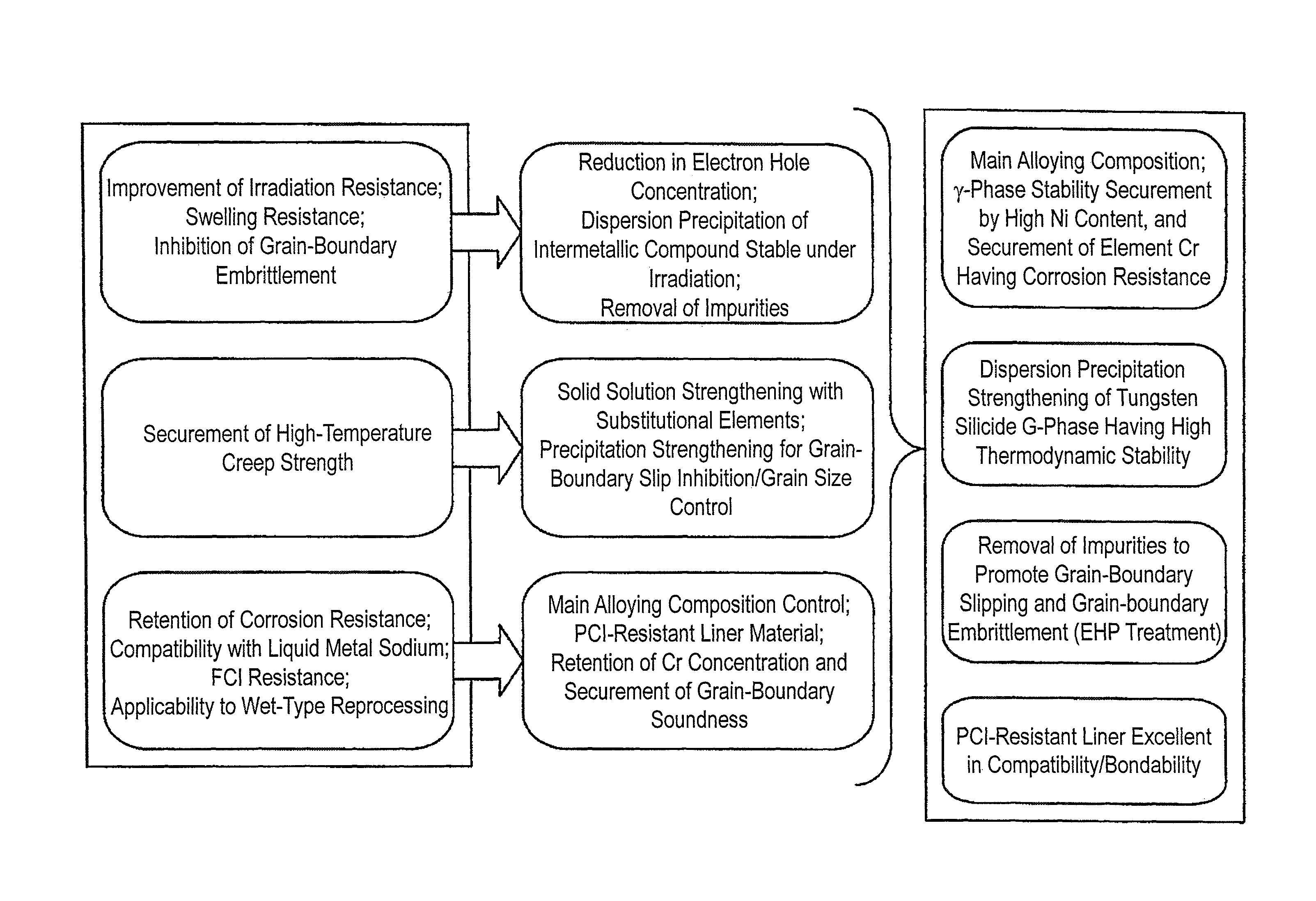

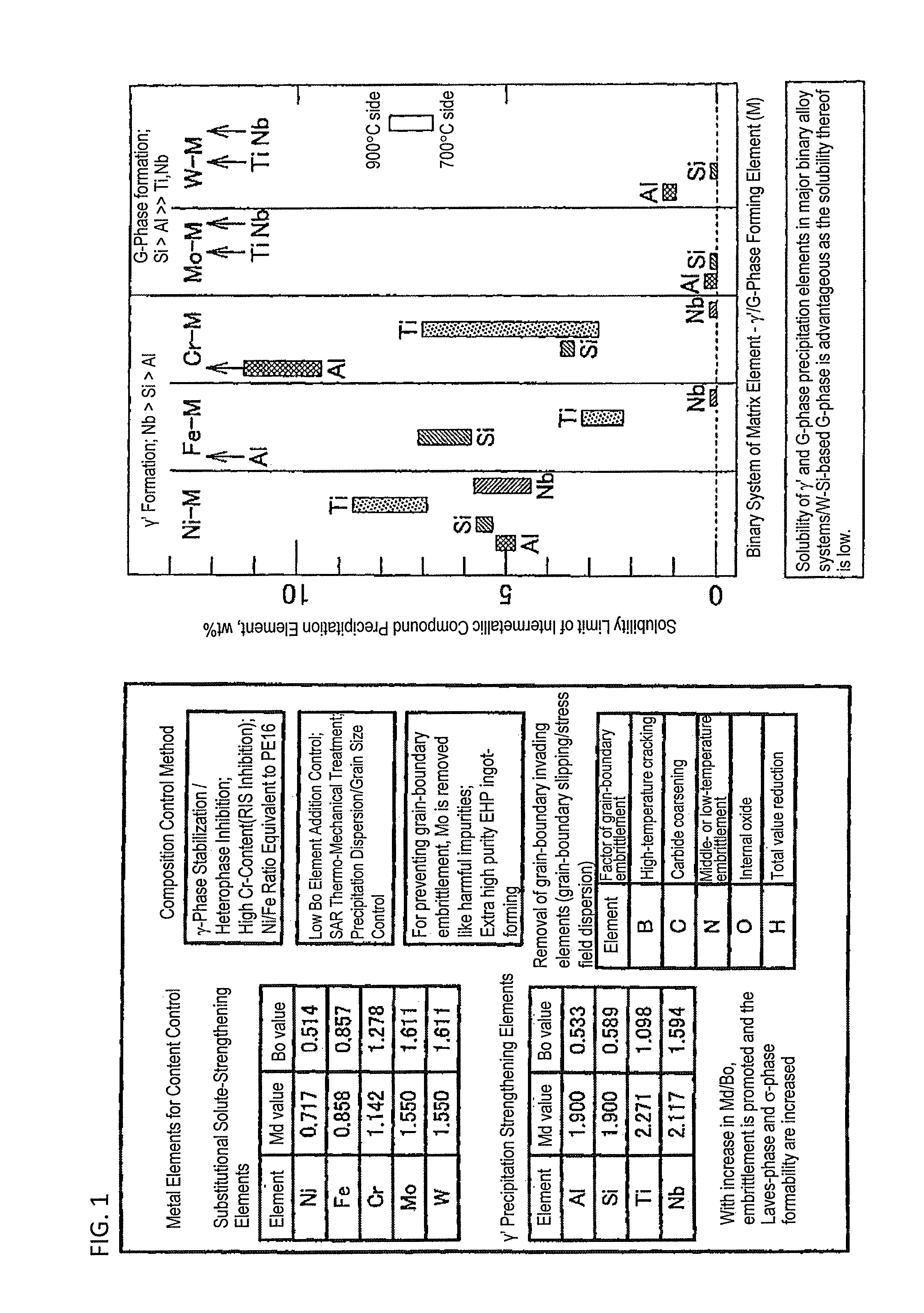

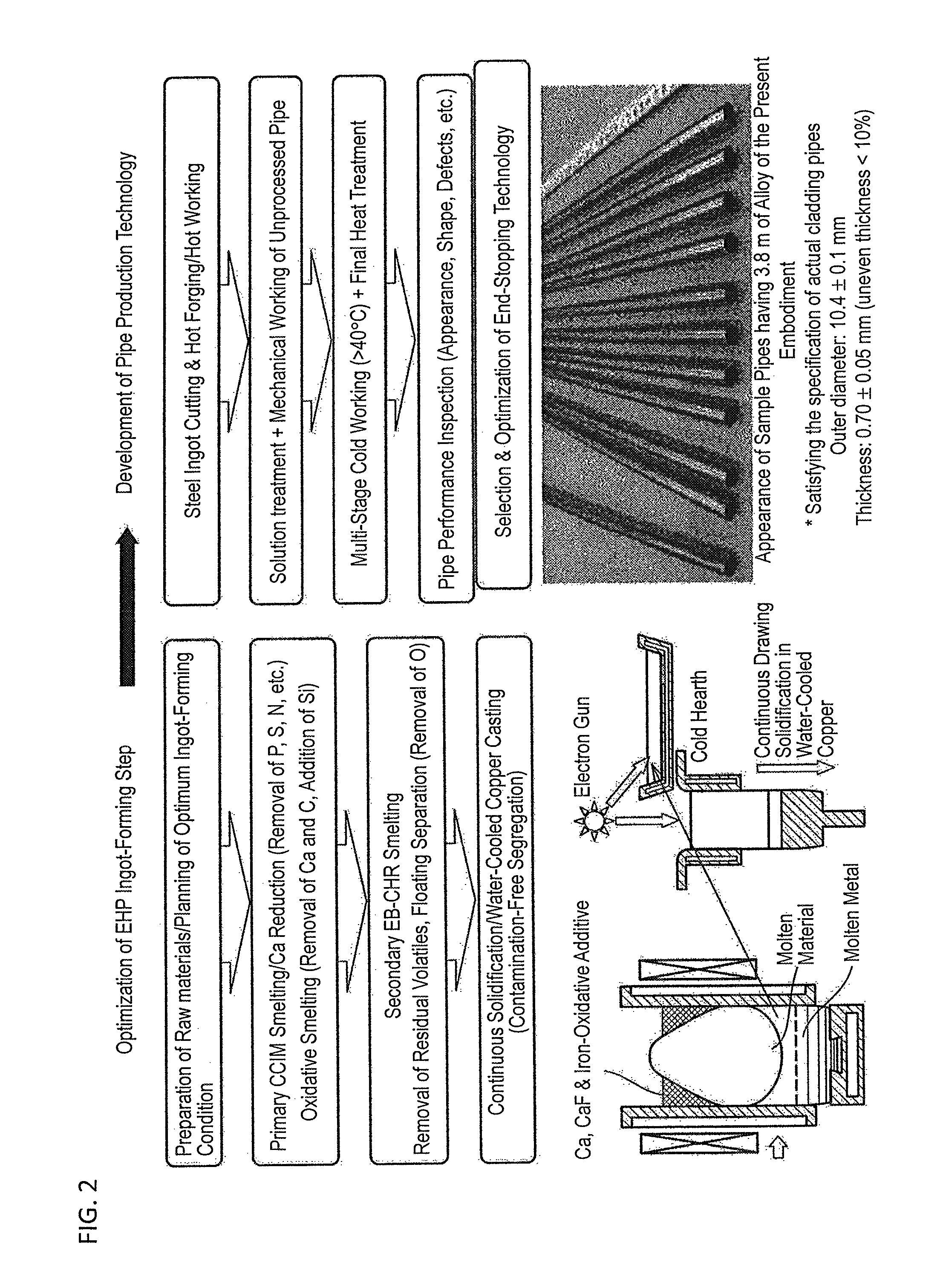

Precipitation-strengthened ni-based heat-resistant alloy and method for producing the same

A precipitation-strengthened Ni-based heat-resistant alloy of the present invention includes 0.03 wt % or less of C, 0.5 wt % or less of Mn, 0.01 wt % or less of P, 0.01 wt % or less of S, 2.0 to 3.0 wt % of Si, 23 to 30 wt % of Cr, 7.0 to 14.0 wt % of W, 10 to 20 wt % of Fe, and 40 to 60 wt % of Ni, wherein a total content of C, N, O, P and S is 0.01 wt % or less. A silicide is dispersed and precipitated and a grain size of a matrix austenite is controlled through a thermo-mechanical treatment. As a result, the precipitation-strengthened Ni-based heat-resistant alloy excellent in irradiation resistance, heat resistance and corrosion resistance can be obtained with a low cost.

Owner:KOBE STEEL LTD

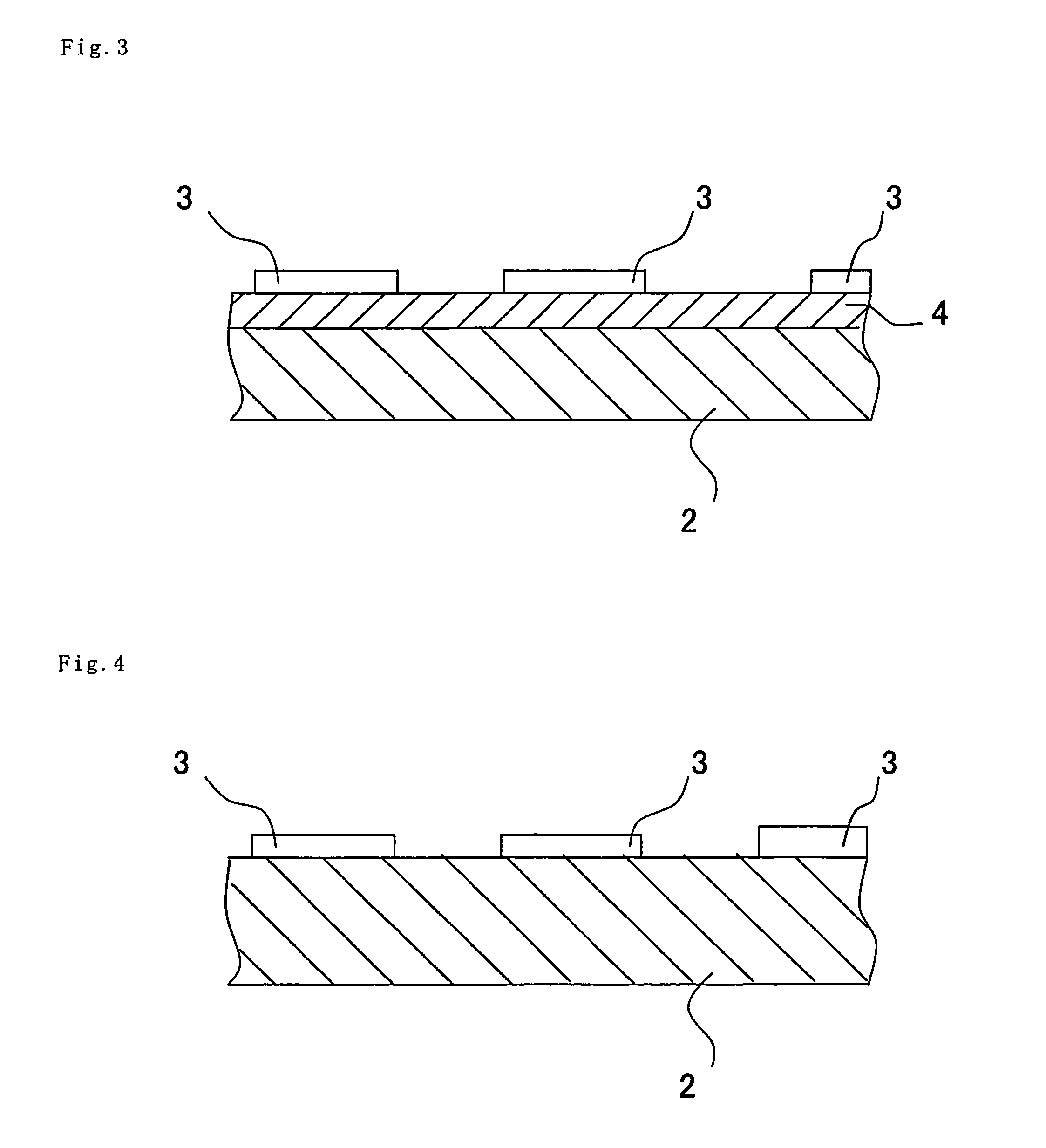

Semiconductor device

InactiveUS20070069382A1High strengthImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

The invention includes a layer having an integrated circuit, a first terminal which is formed over the layer having the integrated circuit and is electrically connected to the layer having the integrated circuit, a conductive layer which functions as an antenna, which is formed over the first terminal and is electrically connected to the first terminal, and a second terminal which is formed over the layer having the integrated circuit and is not electrically connected to the layer having the integrated circuit, the conductive layer which functions as the antenna, and the first terminal.

Owner:SEMICON ENERGY LAB CO LTD

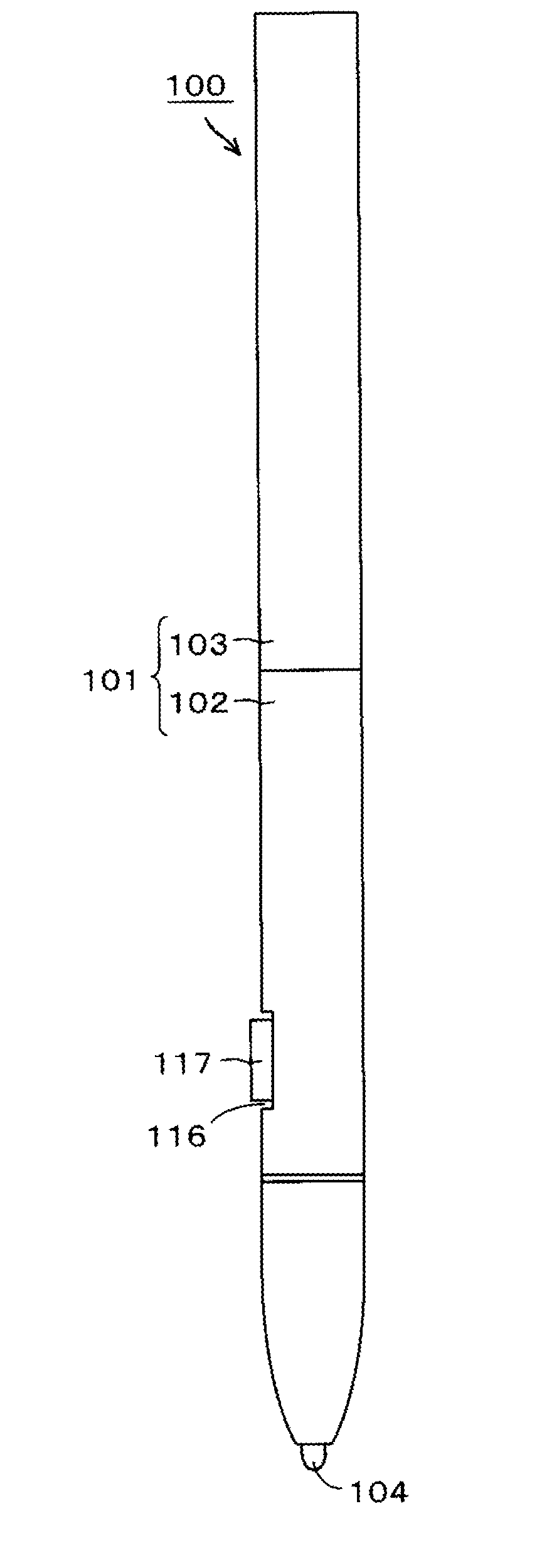

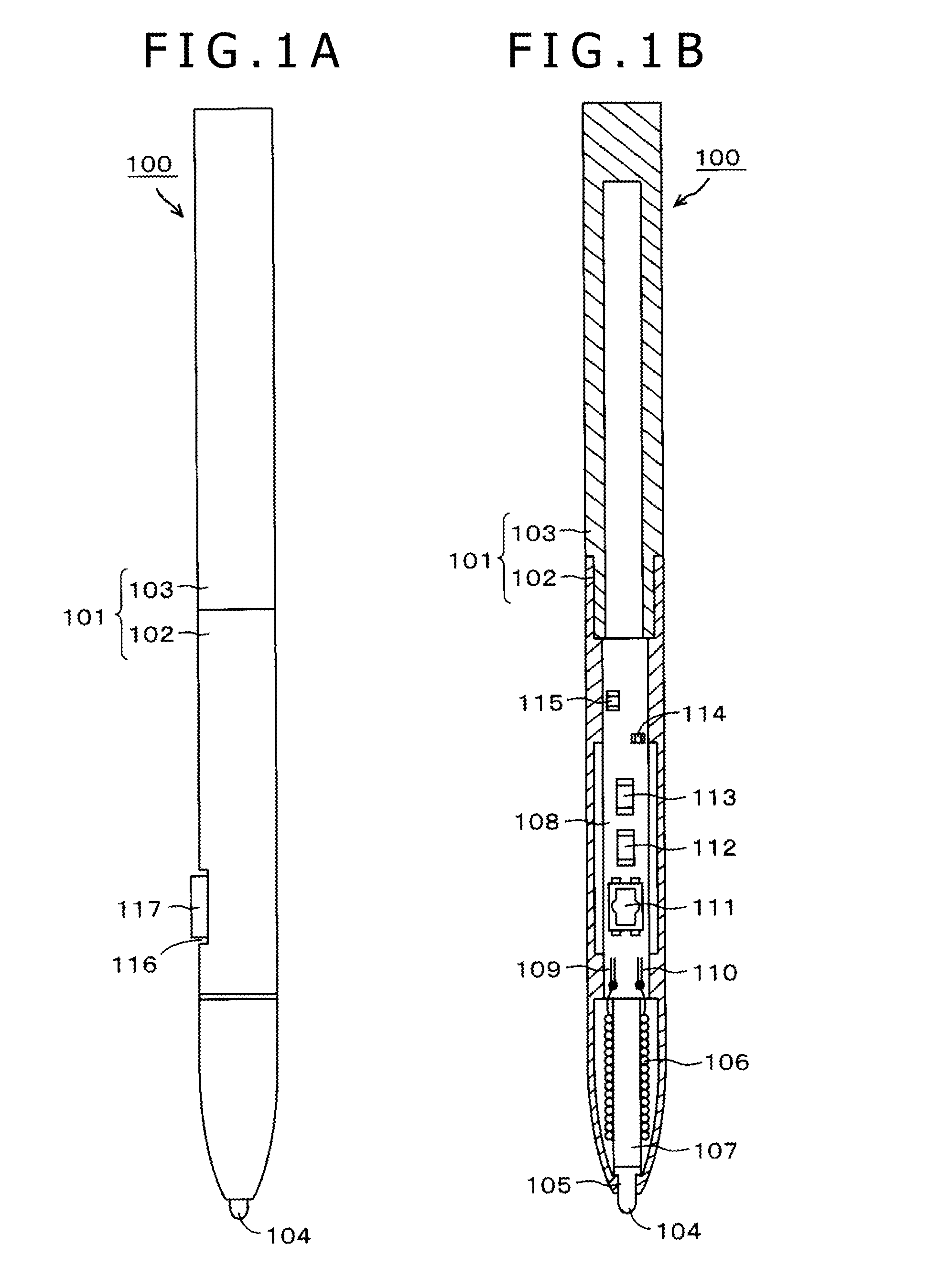

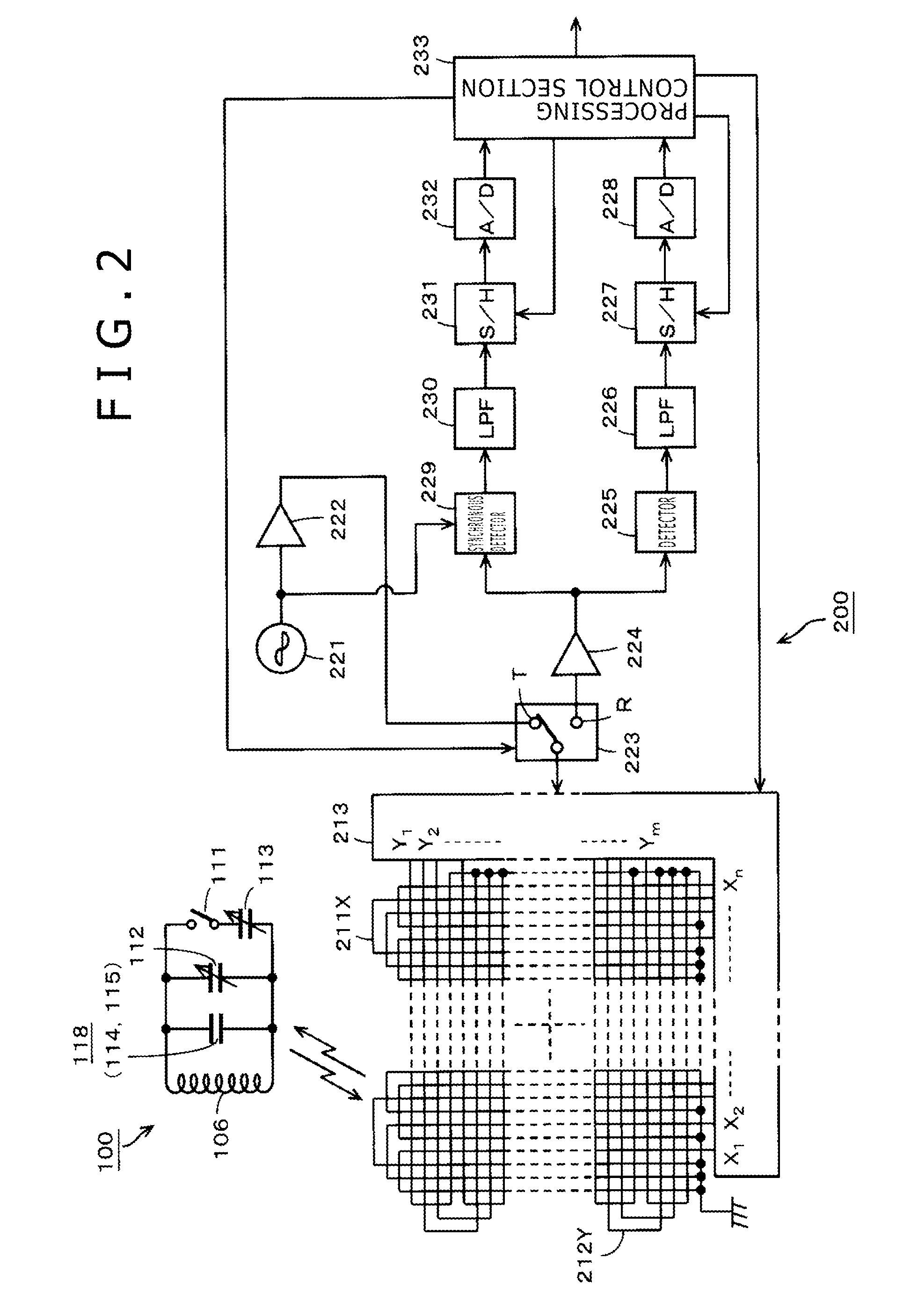

Position indicator and capacitor

ActiveUS20140184245A1Avoid problemsSmall sizeFixed capacitor electrodesResistance/reactance/impedenceDielectricCapacitance

A position indicator includes a resonance circuit housed in a casing and having an inductance element and a capacitor variable in capacitance, such that the resonance circuit resonates at a predetermined frequency. The position indicator is electromagnetically coupled to a position detecting device. The capacitor includes a dielectric, an electrode disposed on one side of the dielectric, and a trimming electrode disposed on another side of the dielectric such that at least one part of a region of the trimming electrode is opposed to the electrode with the dielectric interposed in between, to form the capacitance of the capacitor. The capacitor is housed in the casing such that the at least one part can be exposed from the casing. The area of the at least one part exposed from the casing to the outside is changed so as to correspond to a resonance frequency desired for the resonance circuit.

Owner:WACOM CO LTD

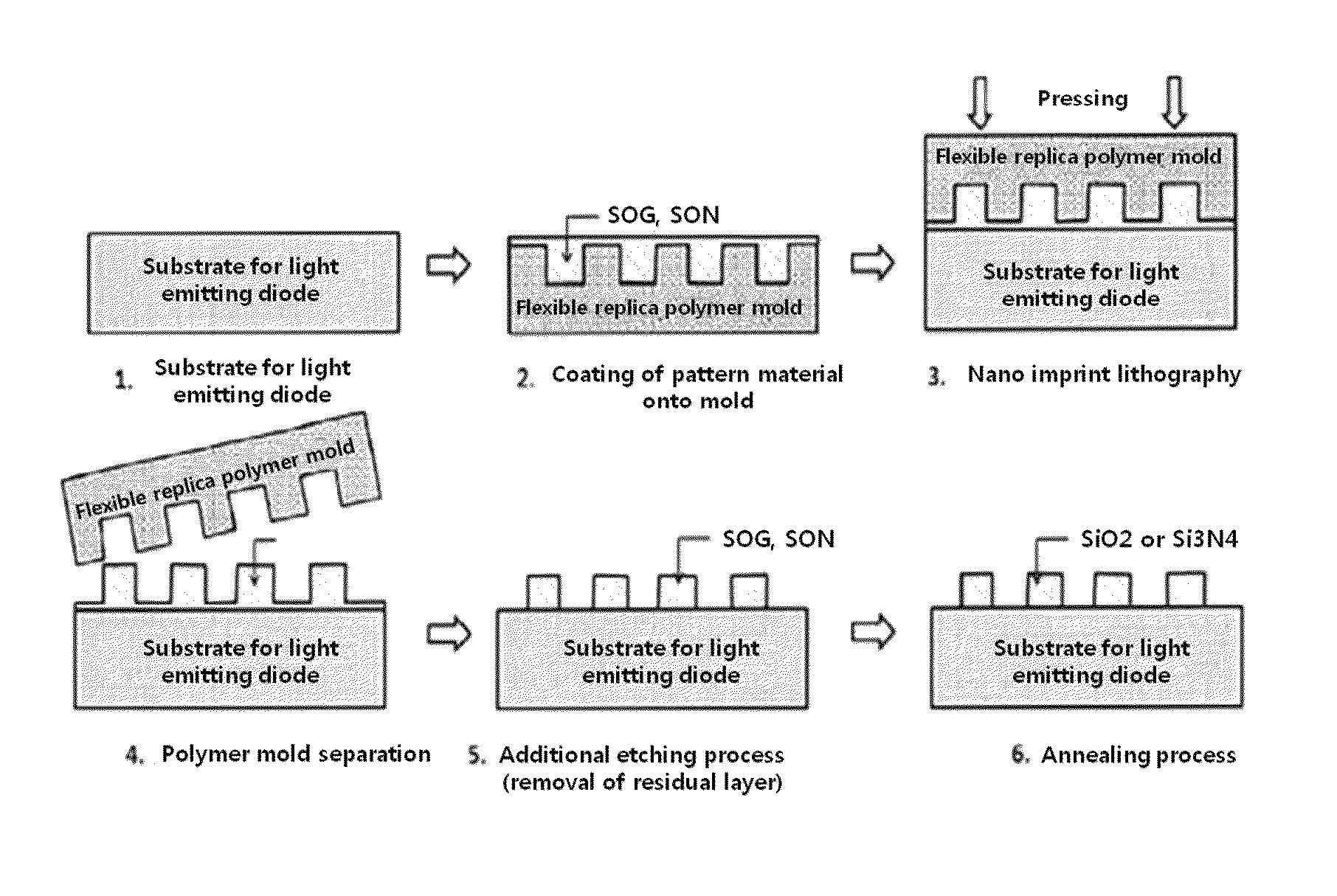

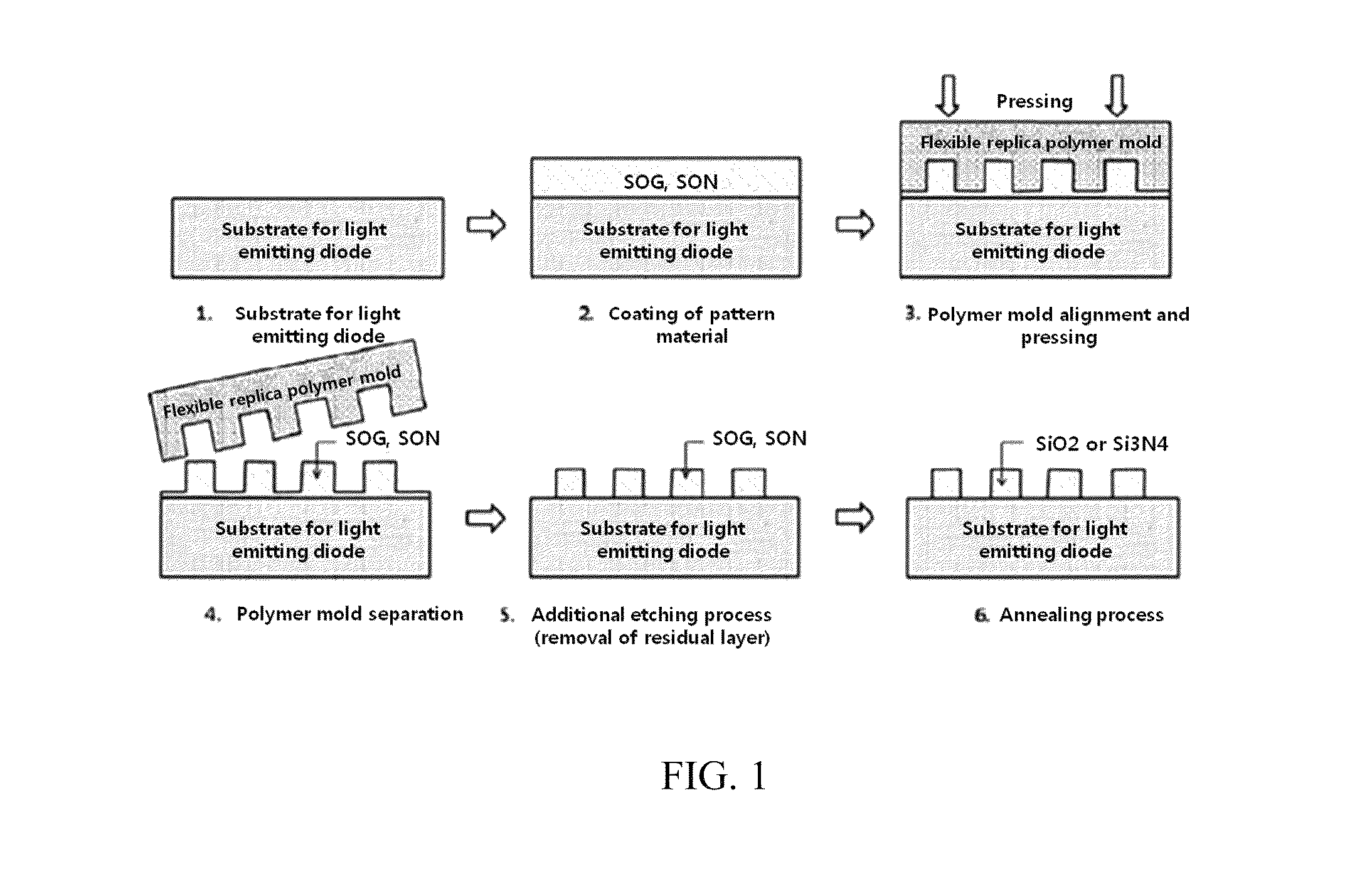

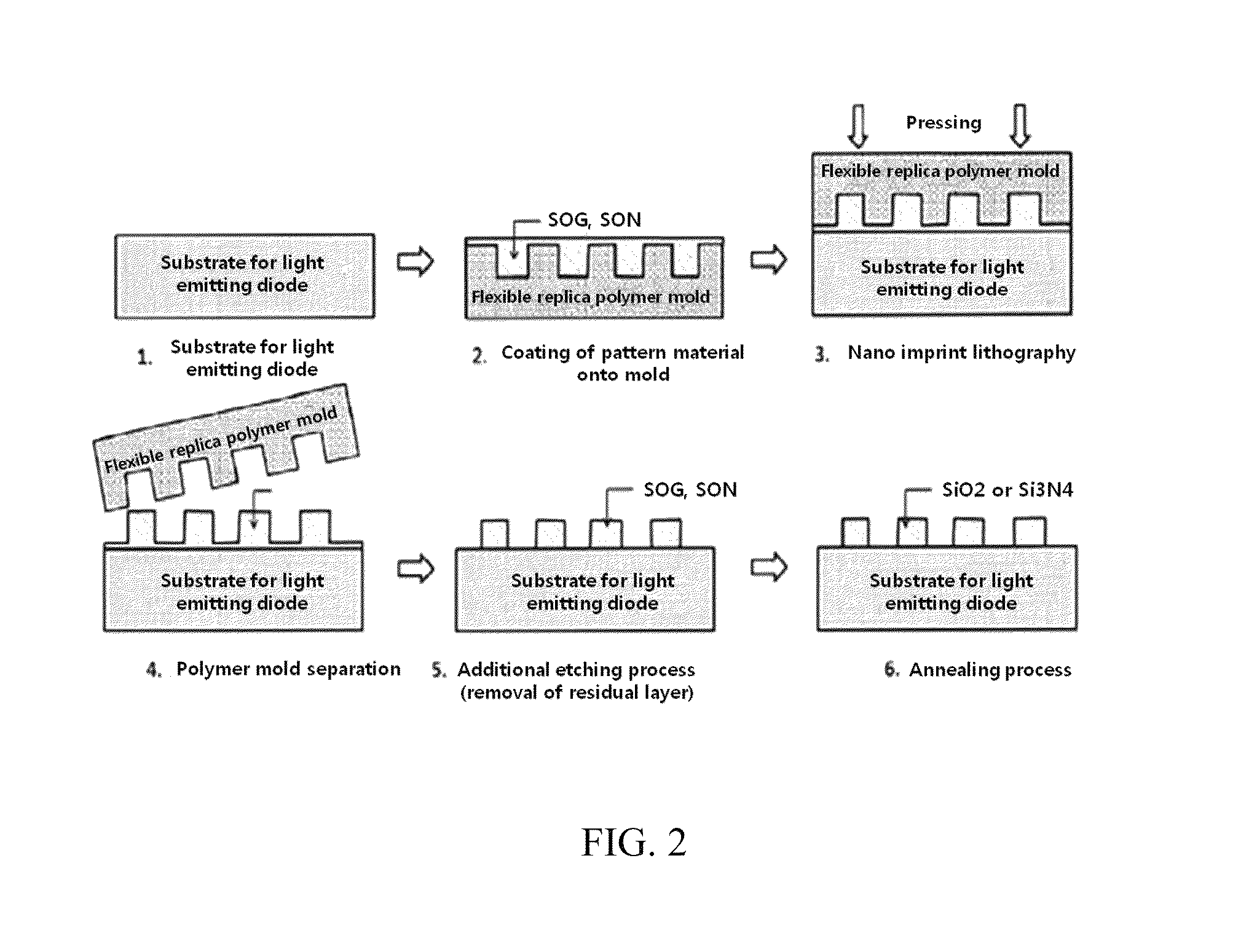

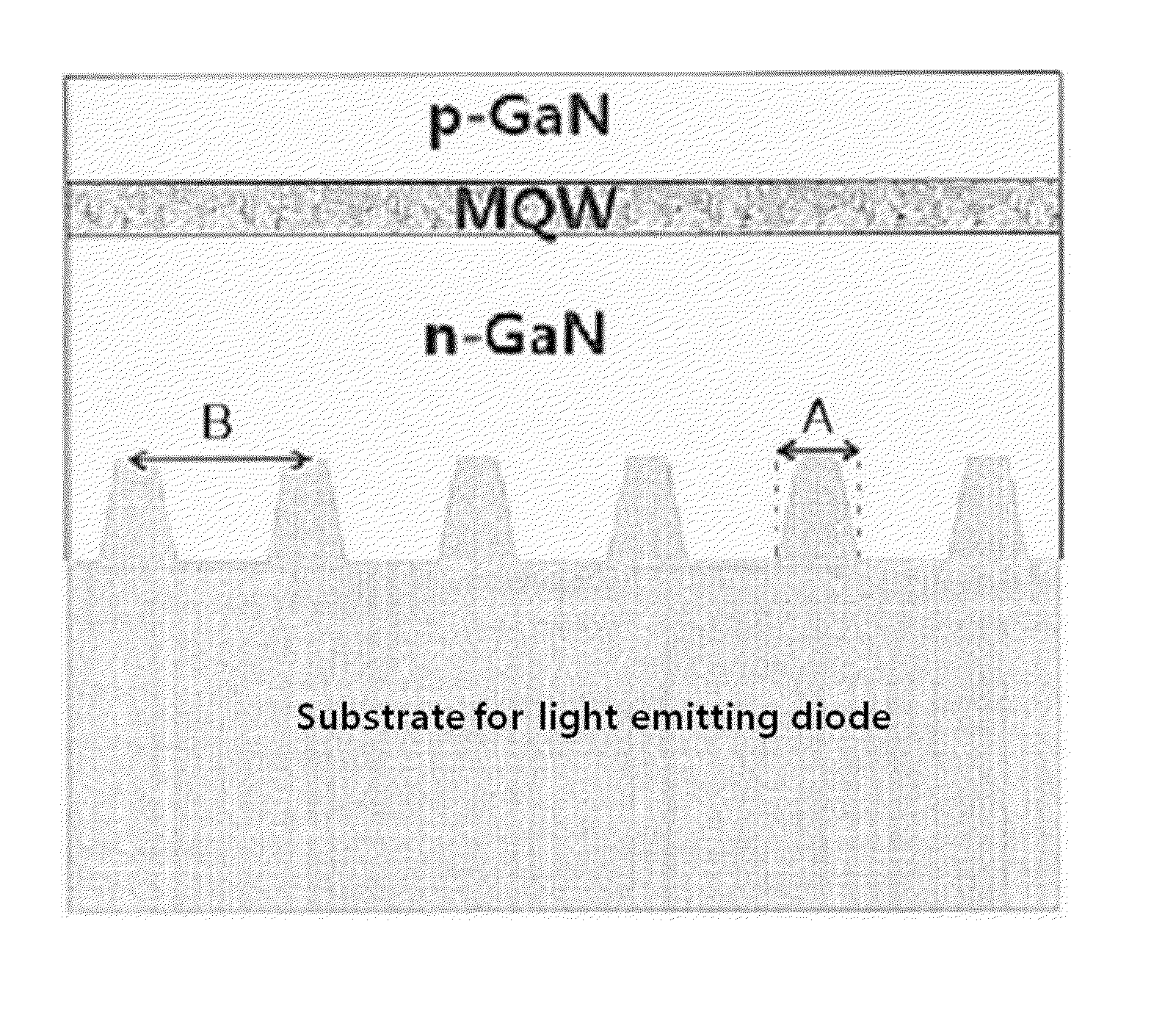

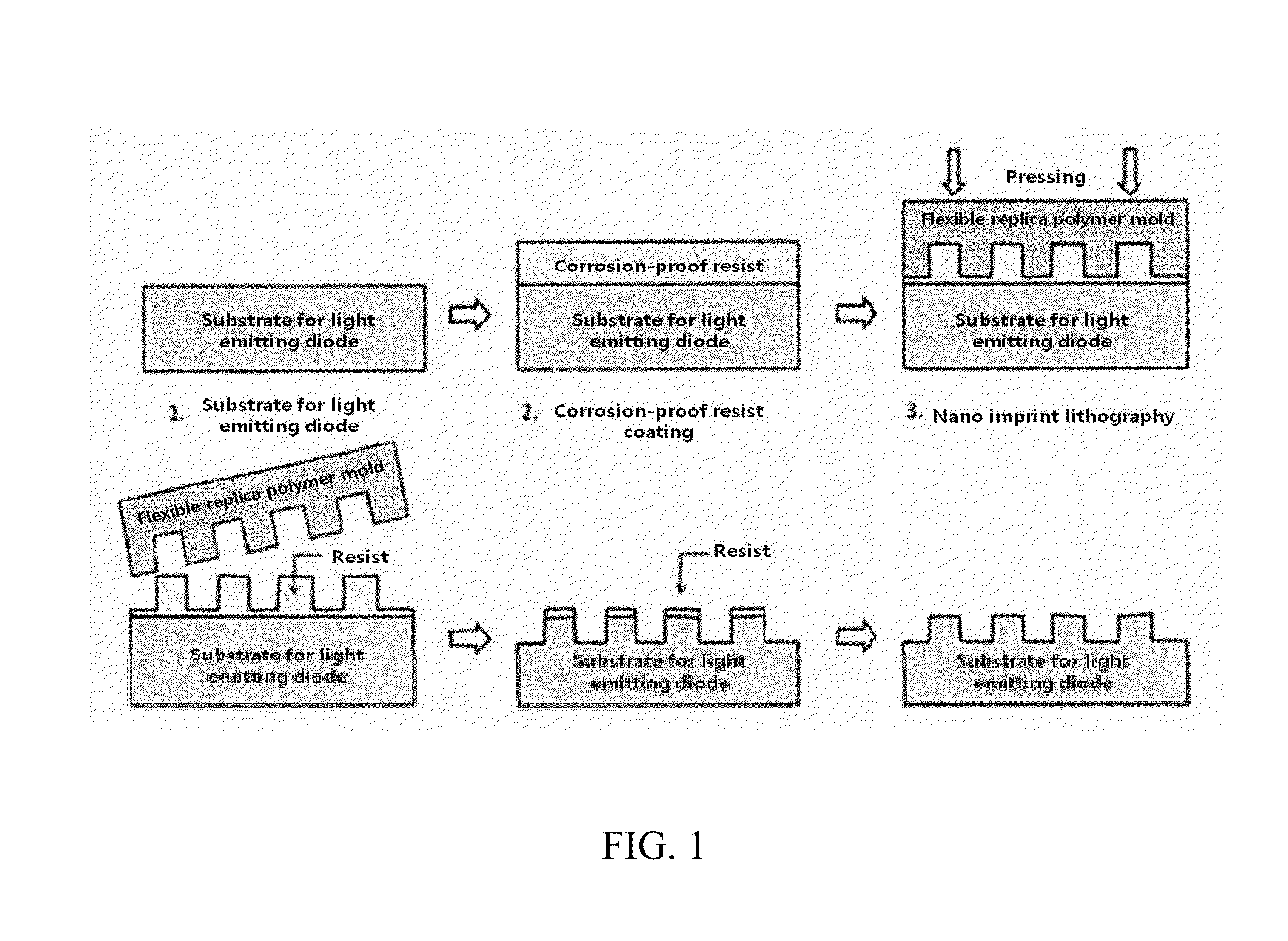

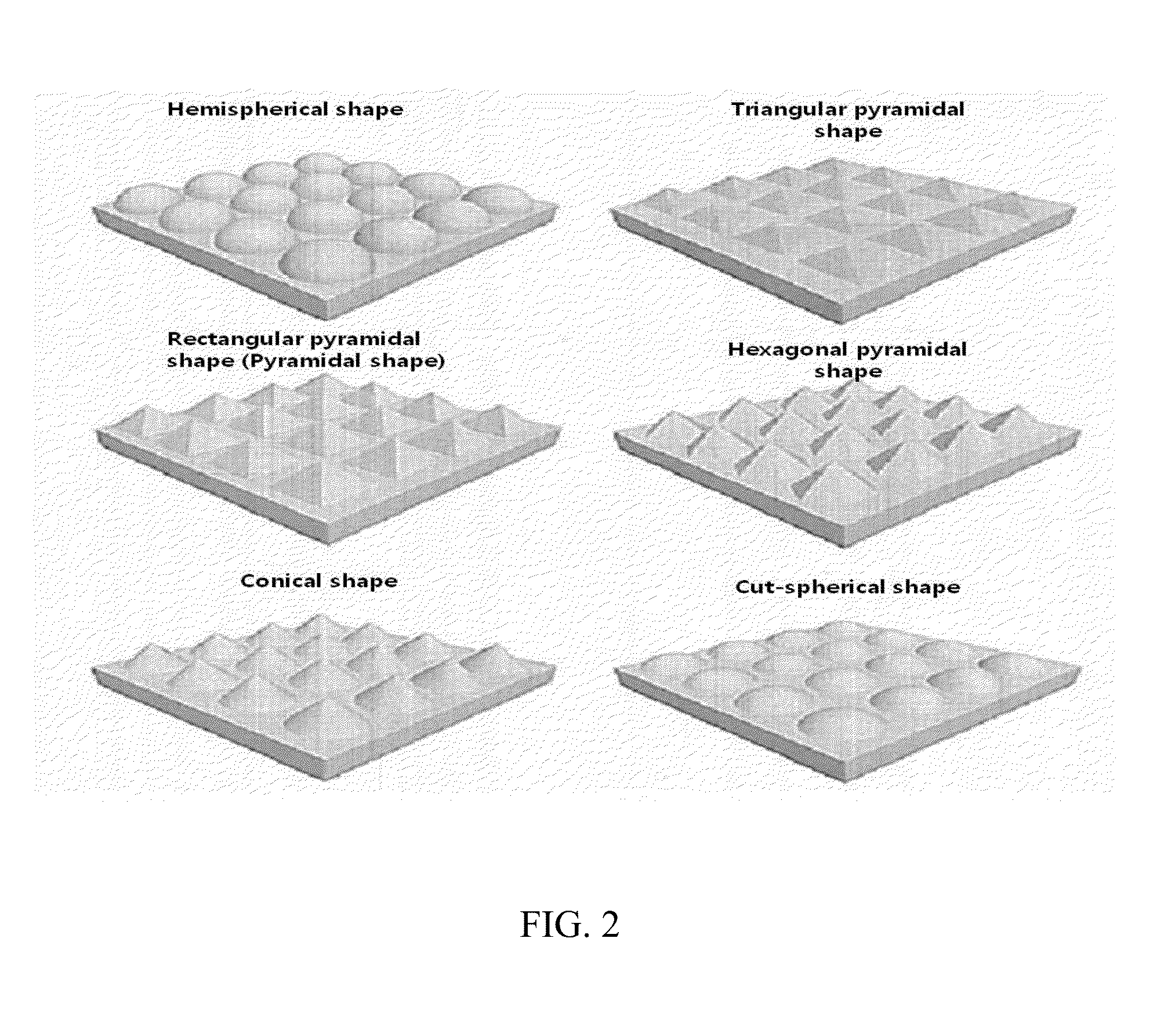

Method for fabricating nano-patterned substrate for high-efficiency nitride-based light-emitting diode

ActiveUS9246050B2Improve production yieldIncrease production capacitySolid-state devicesSemiconductor/solid-state device manufacturingPatterned substrateLight-emitting diode

Provided is a method of manufacturing a substrate for a light emitting diode including a convex section forming step and a crystallization / crystallizing step. According to the method and the substrate for the light emitting diode, light extraction is significantly improved and nano to micron sized pattern, economically formed.

Owner:HUNET PLUS

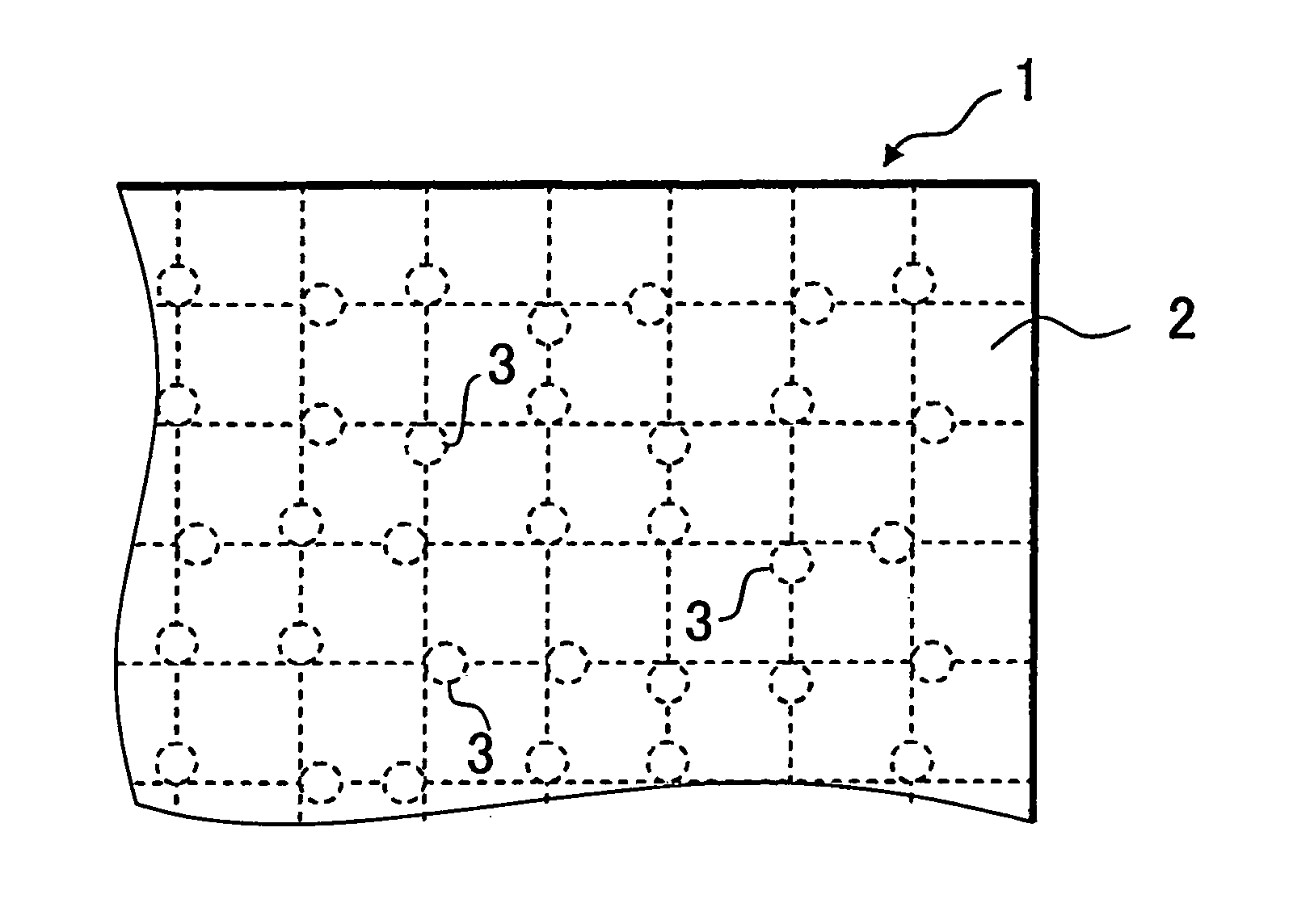

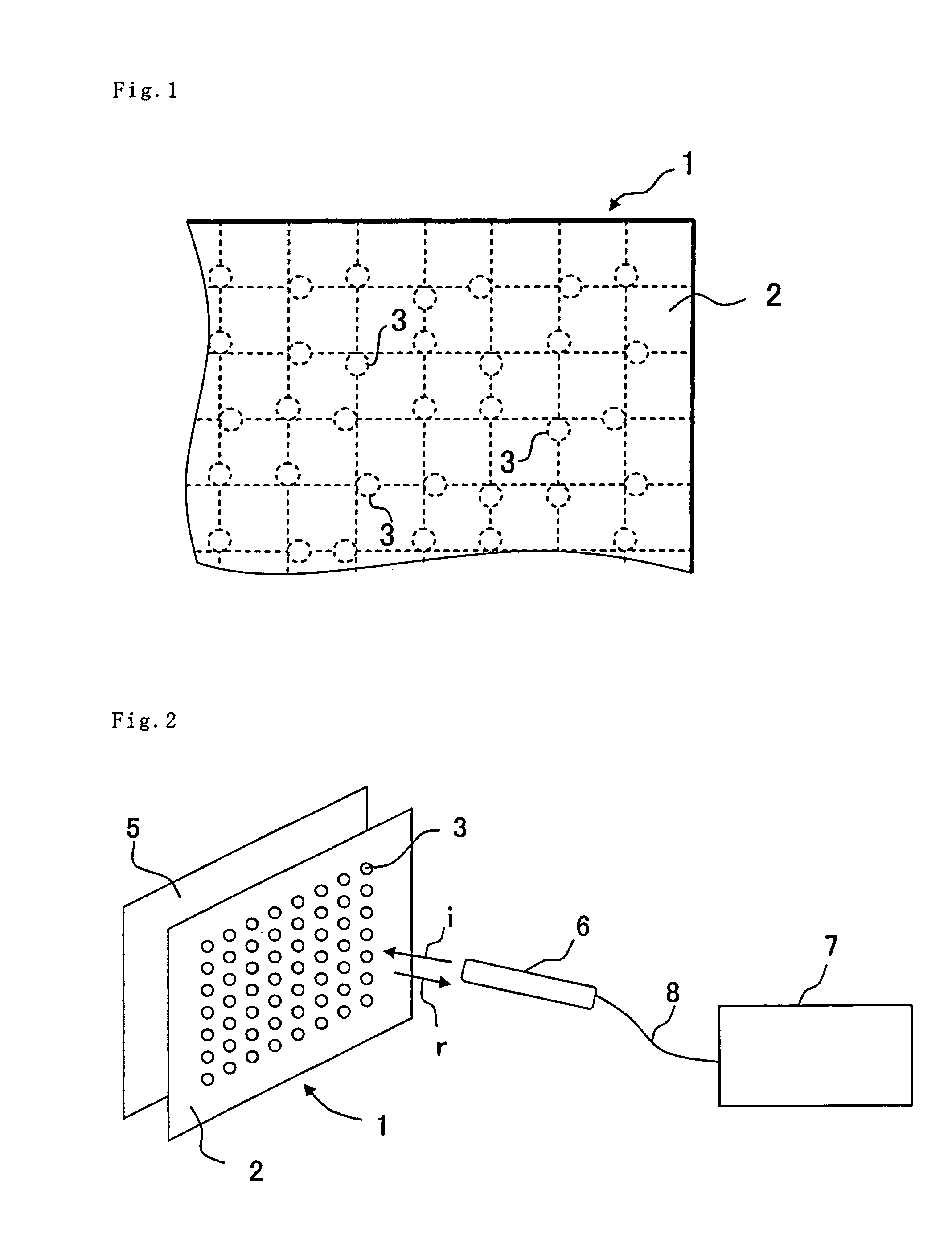

Transparent sheet having a pattern for infrared reflection

ActiveUS8993100B2Low costEasy to liftLamination ancillary operationsLayered product treatmentHandwritingDisplay device

An infrared ray reflection pattern-printed transparent sheet is provided which can be applied to a data input system of a type of handwriting directly on a screen of a display device and provides a coordinate detect means and which is lightweight, low in a cost, readily increased in an area, possible in mass production and excellent in a read performance. It is an infrared ray reflection pattern-printed transparent sheet in which infrared ray reflective transparent patterns are printed on a surface of a transparent substrate and which is disposed oppositely to a front face of a display device. A cross section obtained by cutting the infrared ray reflective transparent patterns printed on the above transparent substrate in a face orthogonal to the above transparent substrate is formed so that it assumes a multilayer structure comprising a fixed repeating cycle when observed under a scanning electron microscope.

Owner:DAI NIPPON PRINTING CO LTD

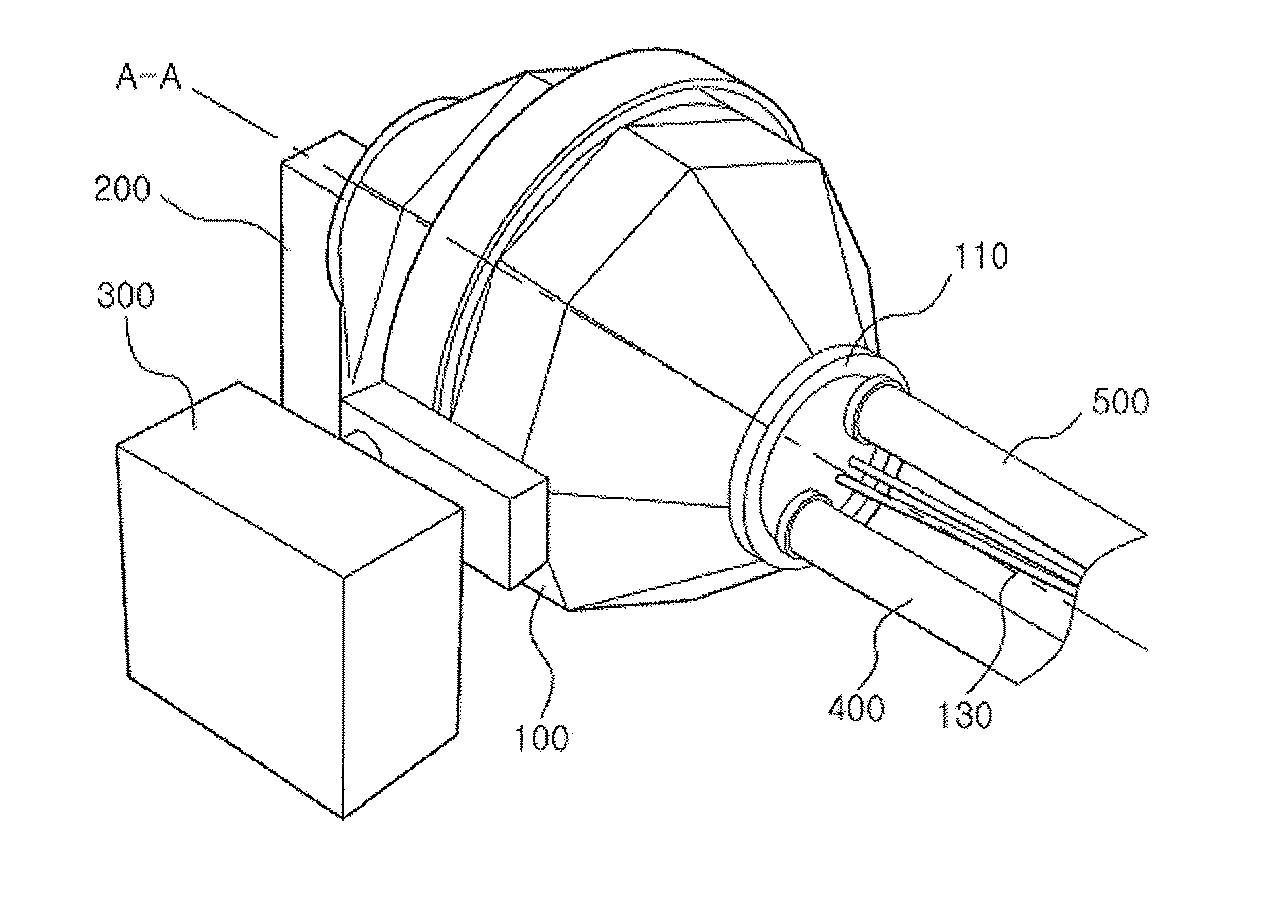

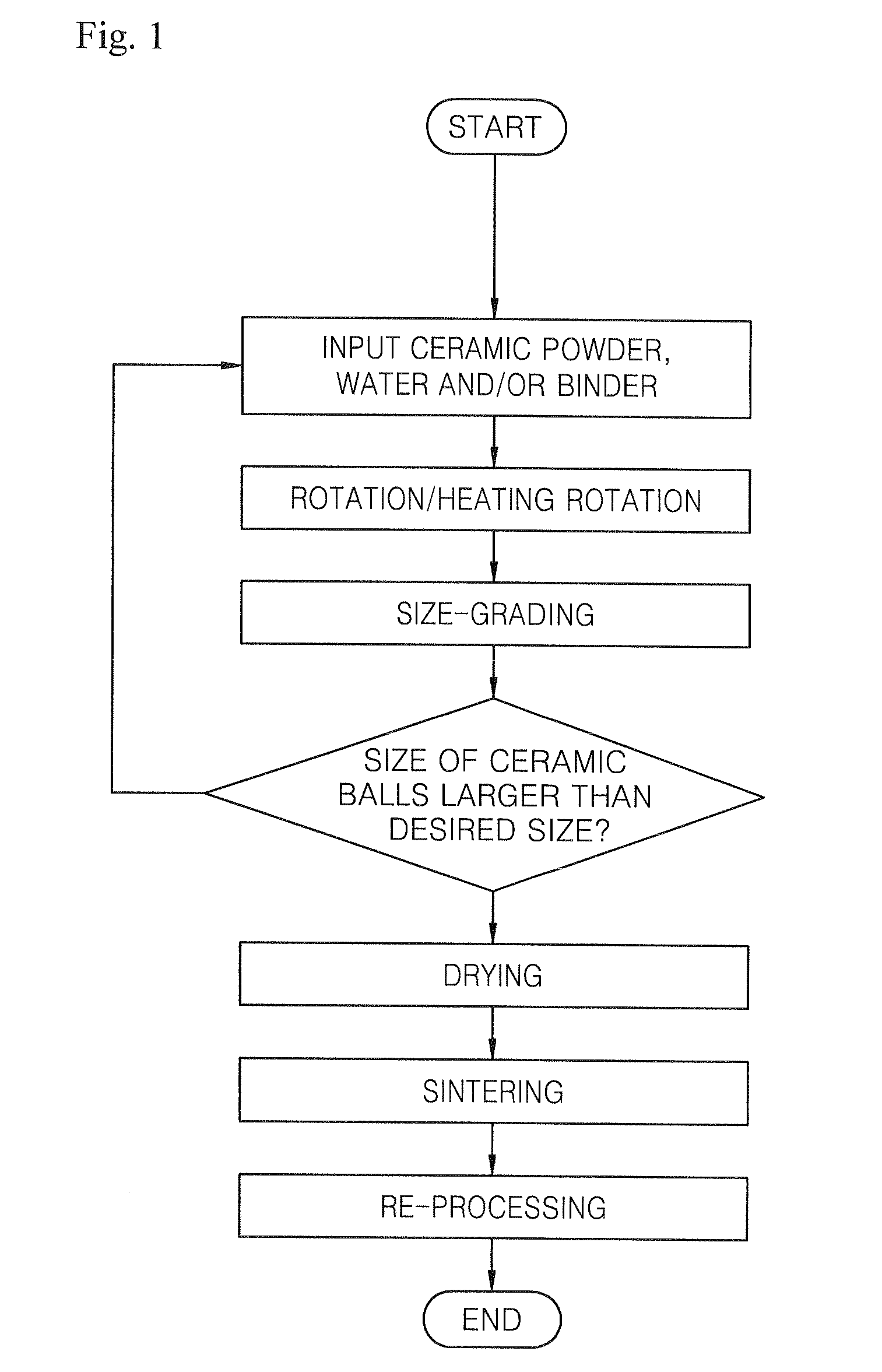

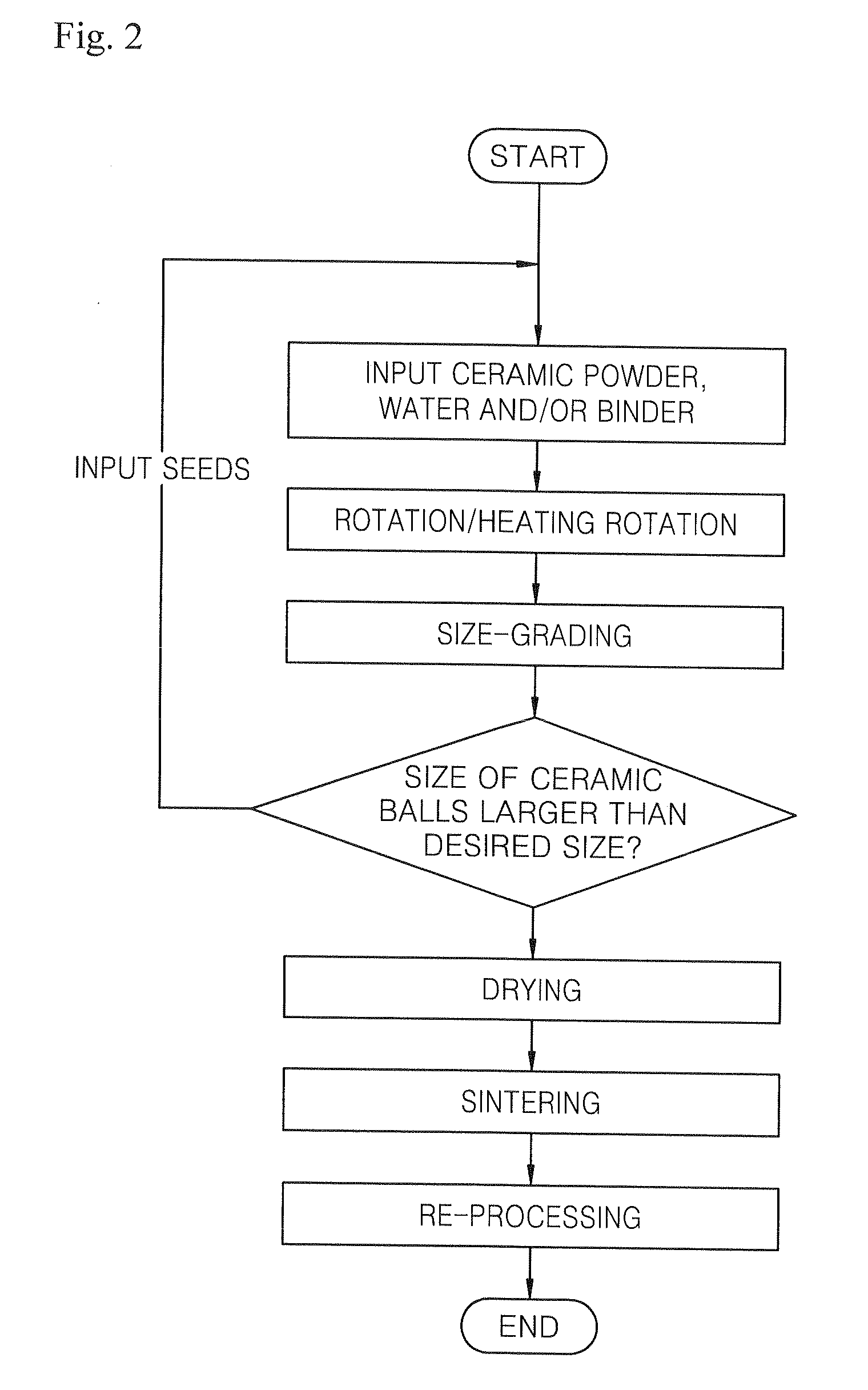

Production method for a truly spherical ceramic ball by means of a rotational method, and a device therefor

ActiveUS20120098170A1High strengthPromote formationDough homogenizationFrozen sweetsMetallurgyRotation method

The present invention relates to a production method for a truly spherical ceramic ball by means of a rotational method, and to a device therefor. More specifically, a method is disclosed which uses seeds to facilitate formation of ceramic balls into a spherical shape and repeats heating and cooling or grades ceramic balls according to size to form ceramic balls having a similar size during the formation process, thereby increasing strength of the ceramic balls while ensuring excellent particle size distribution. Also, an apparatus for producing ceramic balls using a rotation manner is disclosed.

Owner:BIOCERA

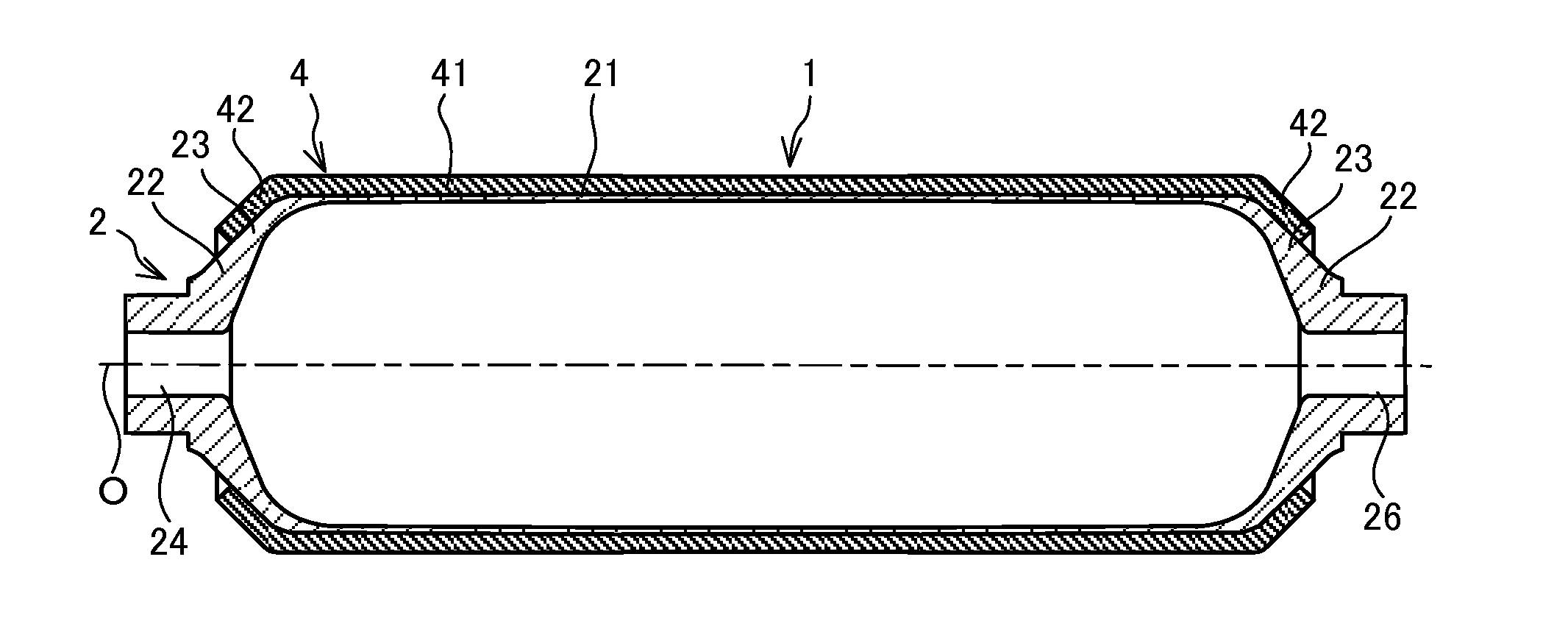

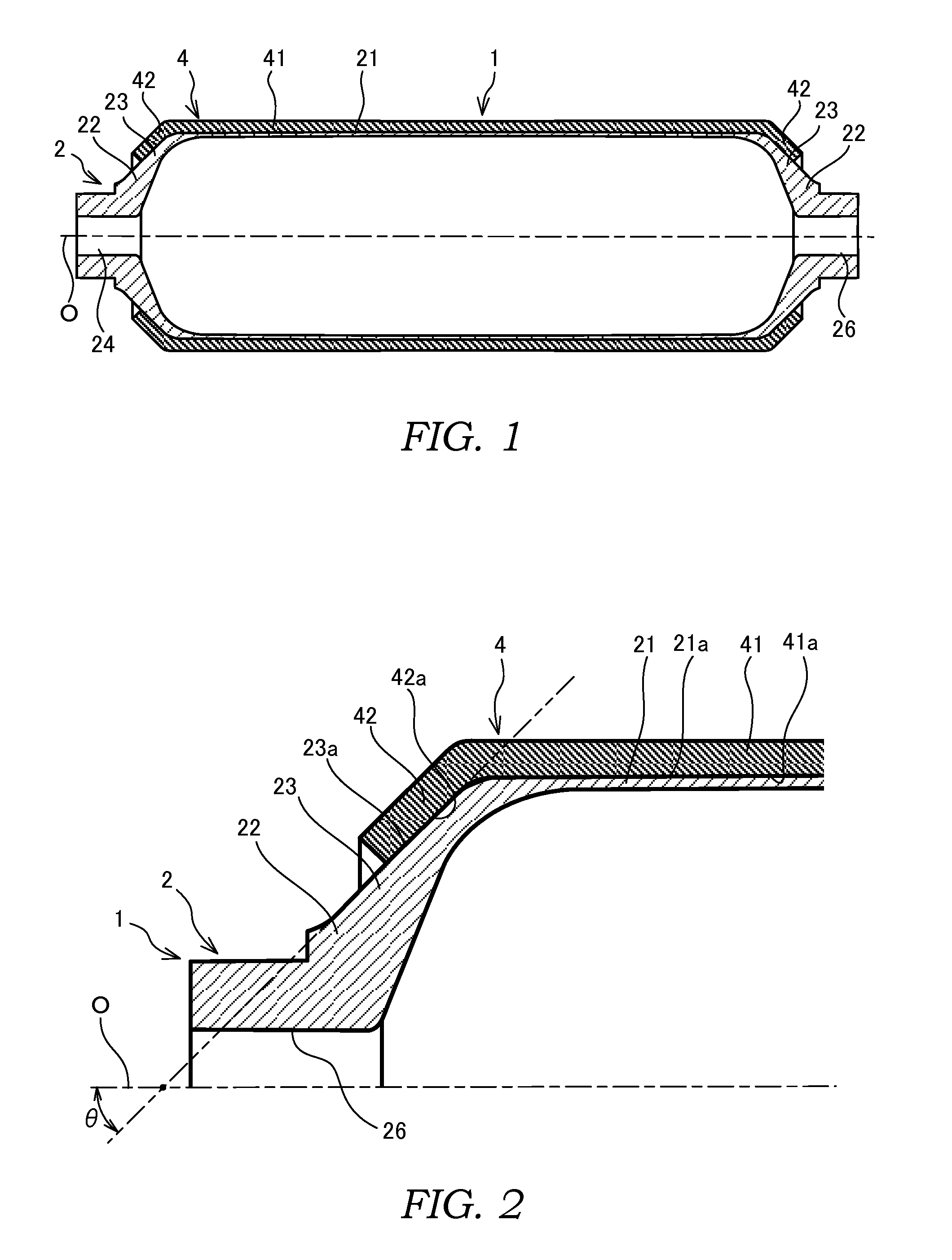

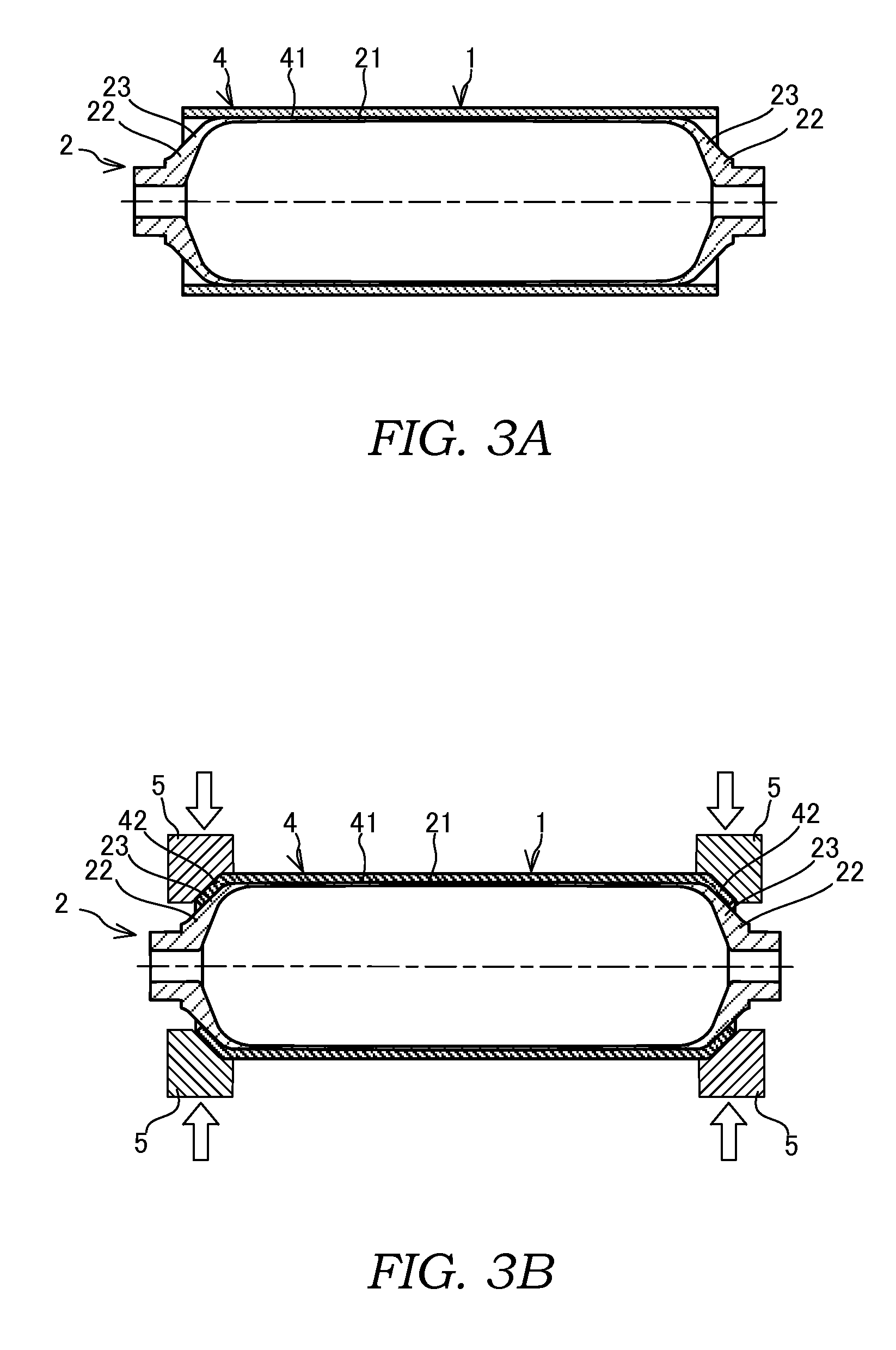

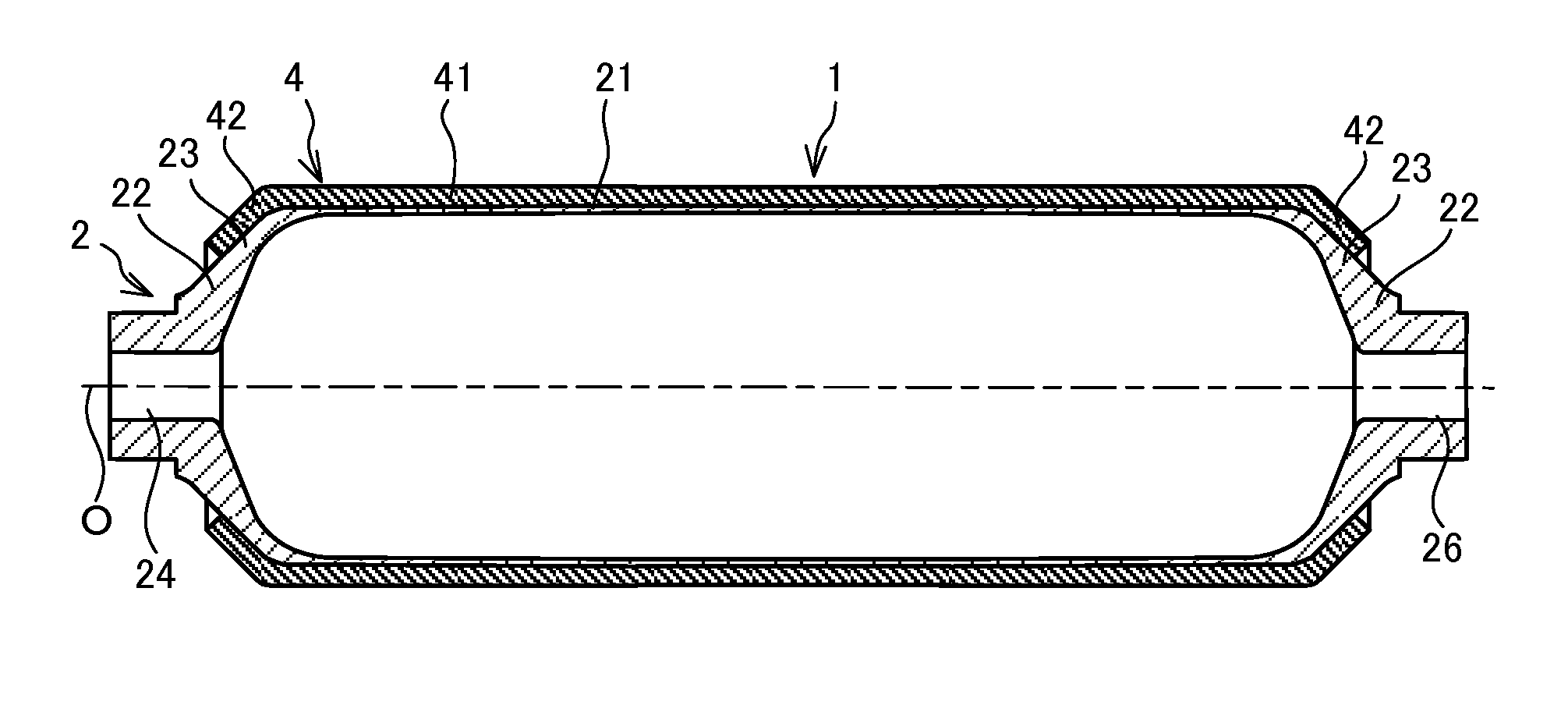

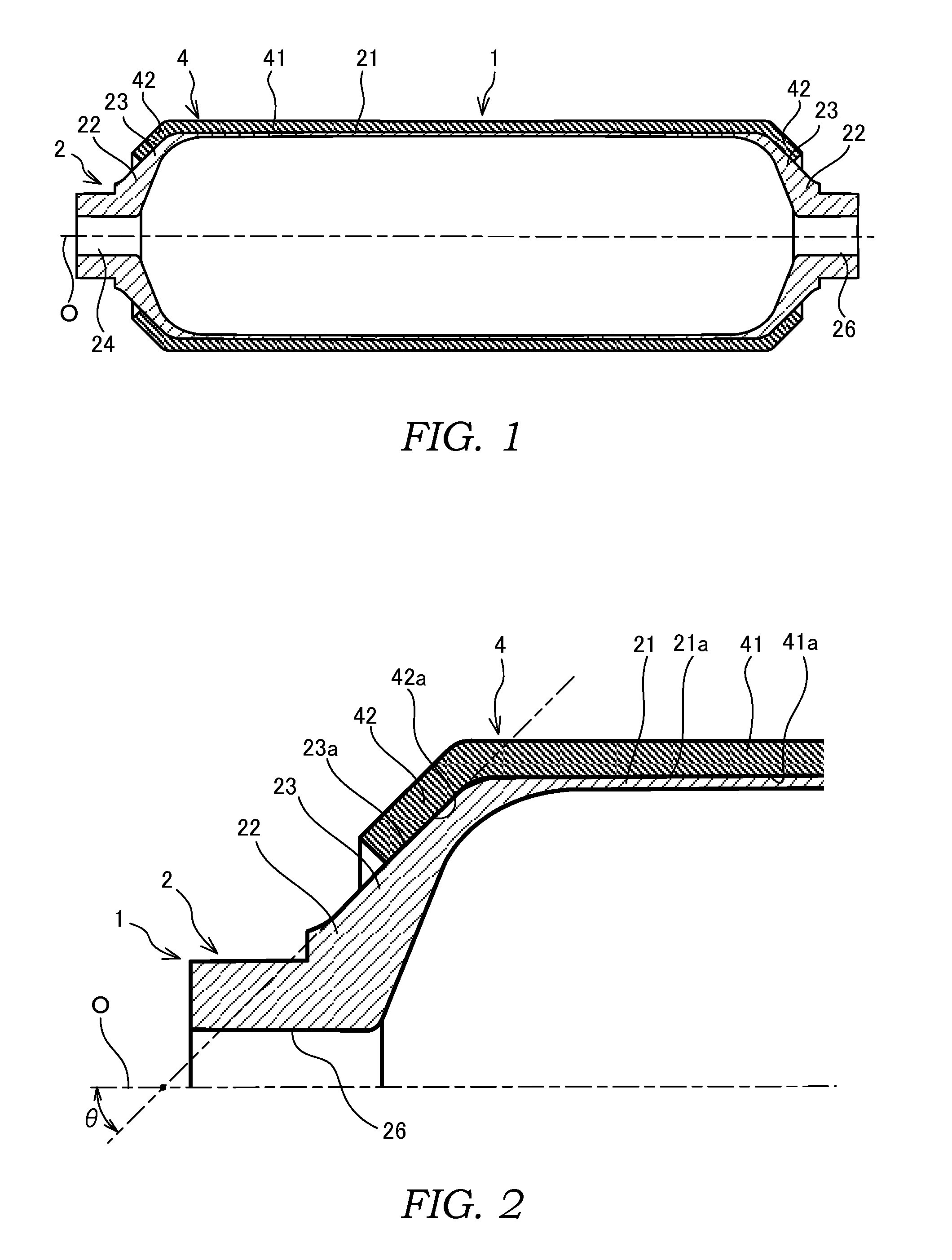

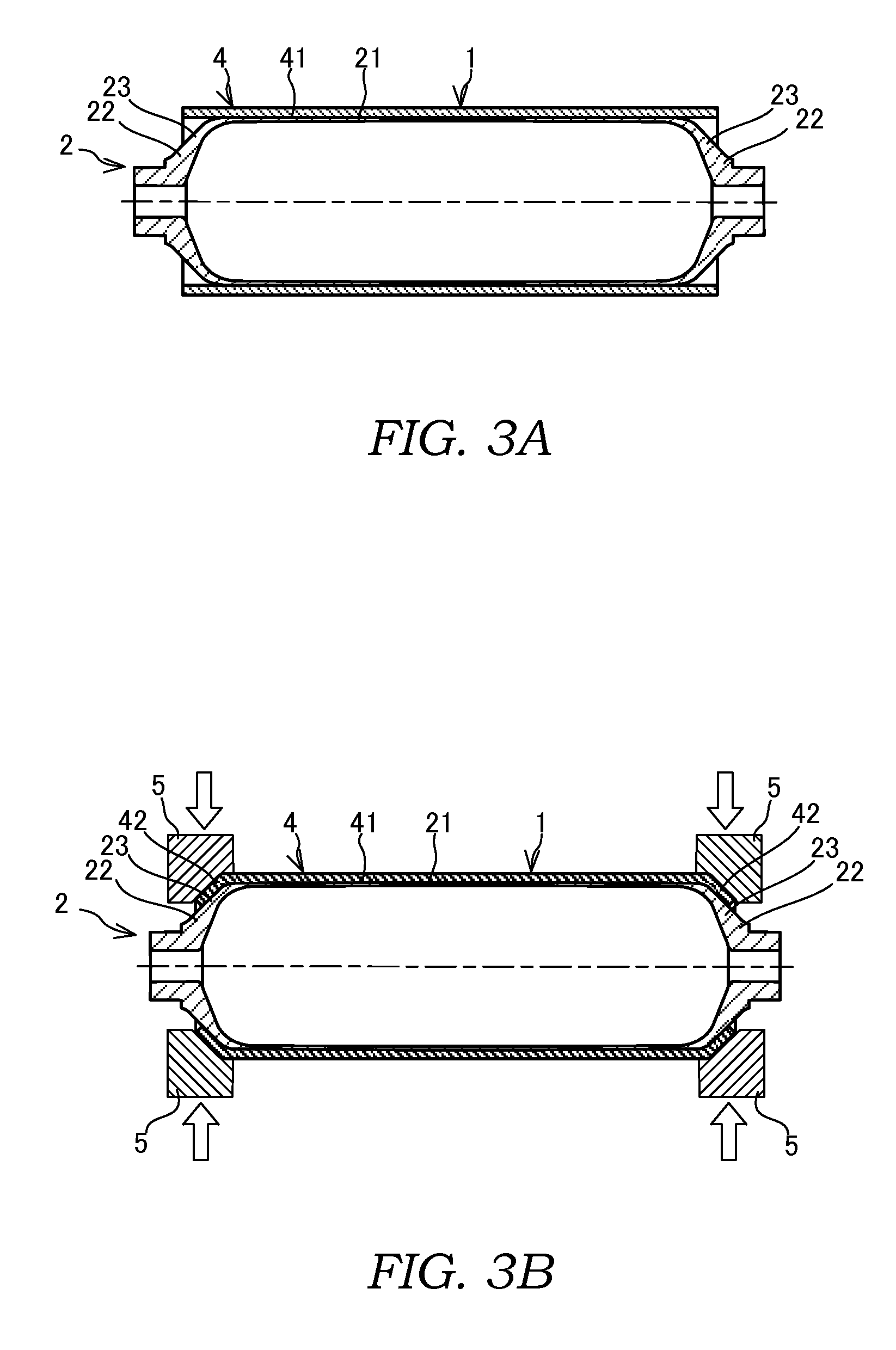

High pressure gas container and manufacturing method for high pressure gas container

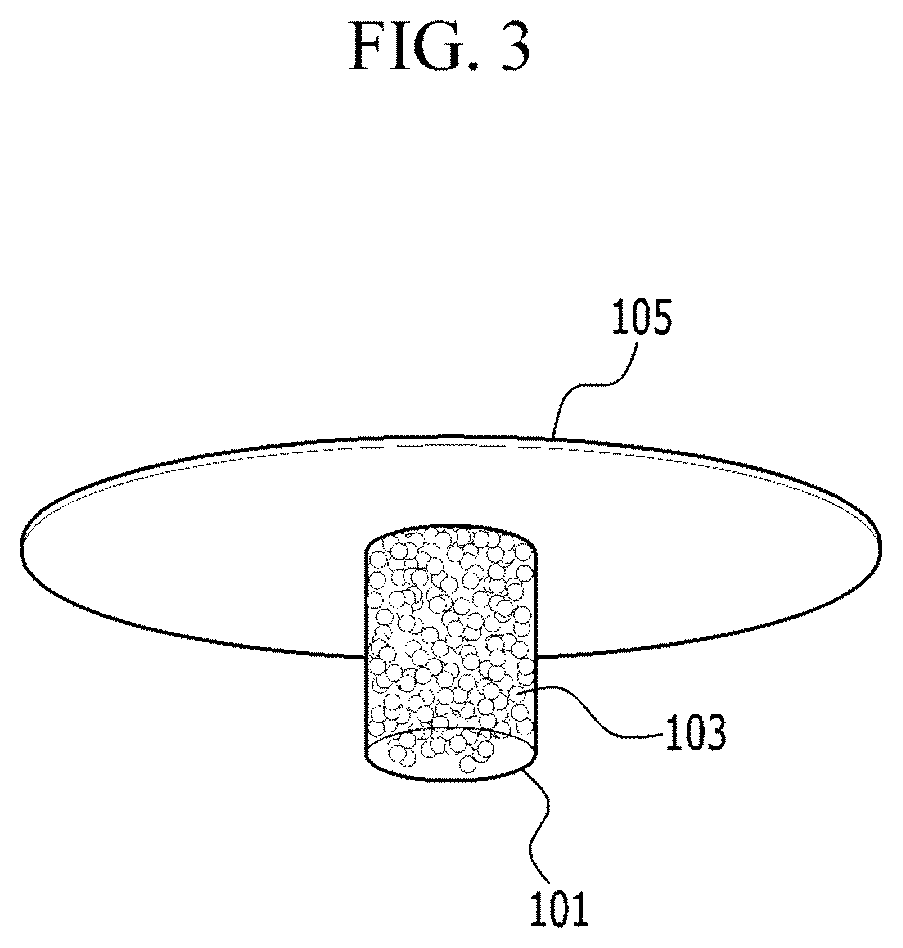

InactiveUS20140197179A1Mass production is possibleVessel geometry/arrangement/sizeVessel wallsEngineeringProduct gas

This invention is a high pressure gas container into which a high pressure gas is charged, includes: a liner into which the high pressure gas is charged; and a reinforcing sleeve that envelops an outer surface of the liner, wherein the liner includes: a cylindrical liner trunk portion; and a pair of liner shoulder portions formed by reducing a diameter of respective end portions of the liner trunk portion, and the reinforcing sleeve includes: a sleeve trunk portion fitted to the liner trunk portion; and a pair of sleeve shoulder portions that extend from the sleeve trunk portion so as to contact the respective liner shoulder portions.

Owner:KYB CORP

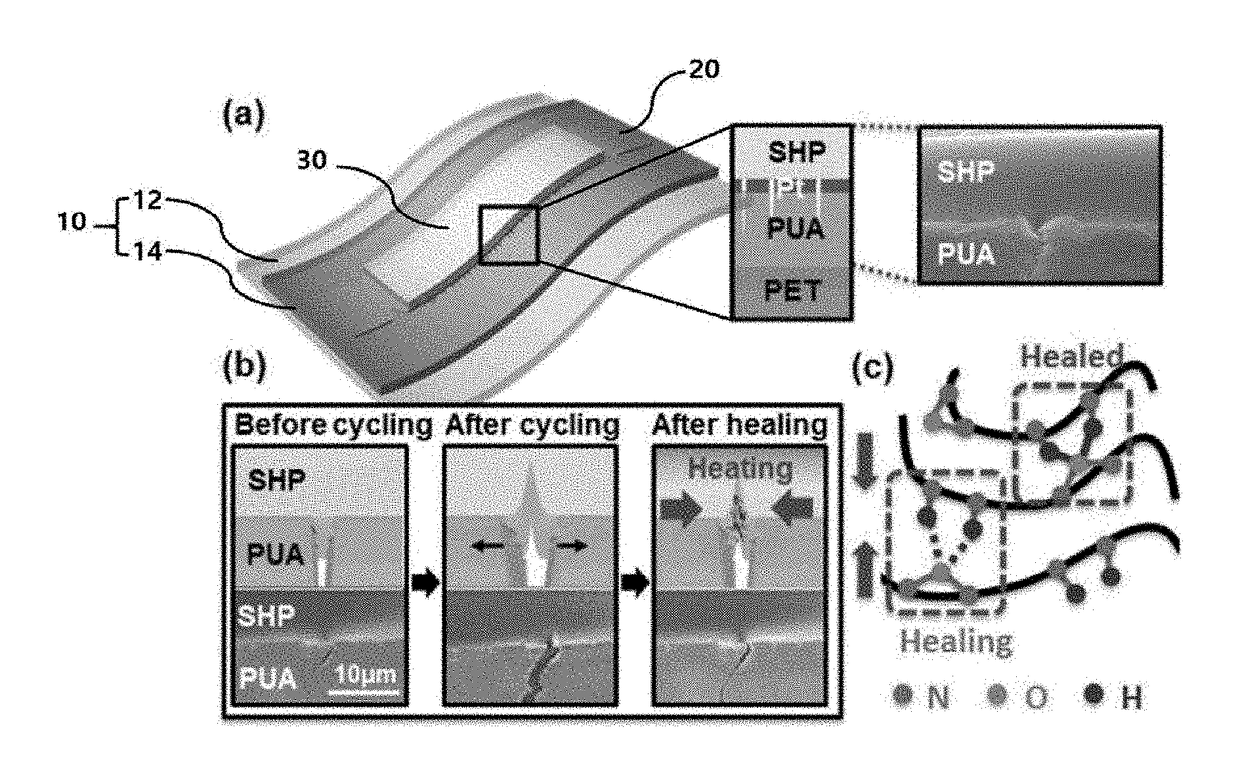

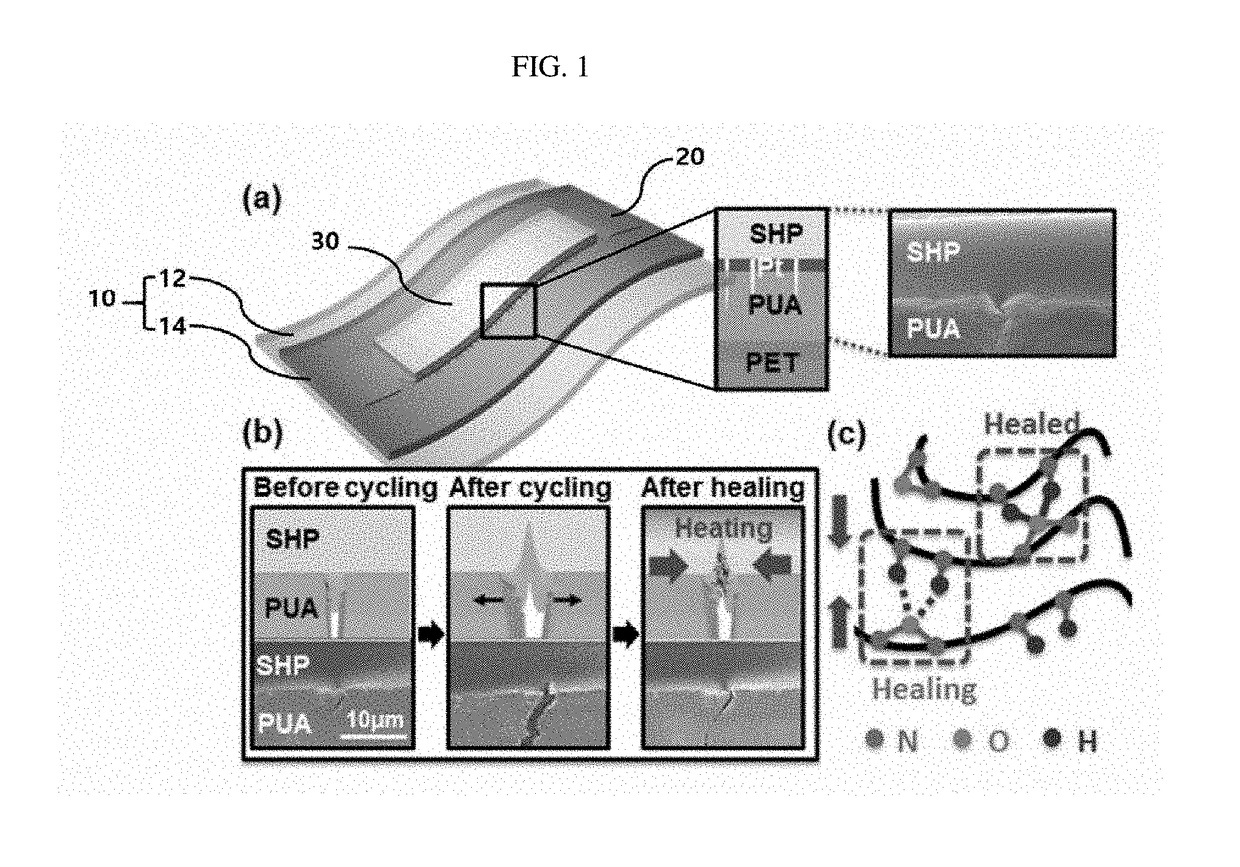

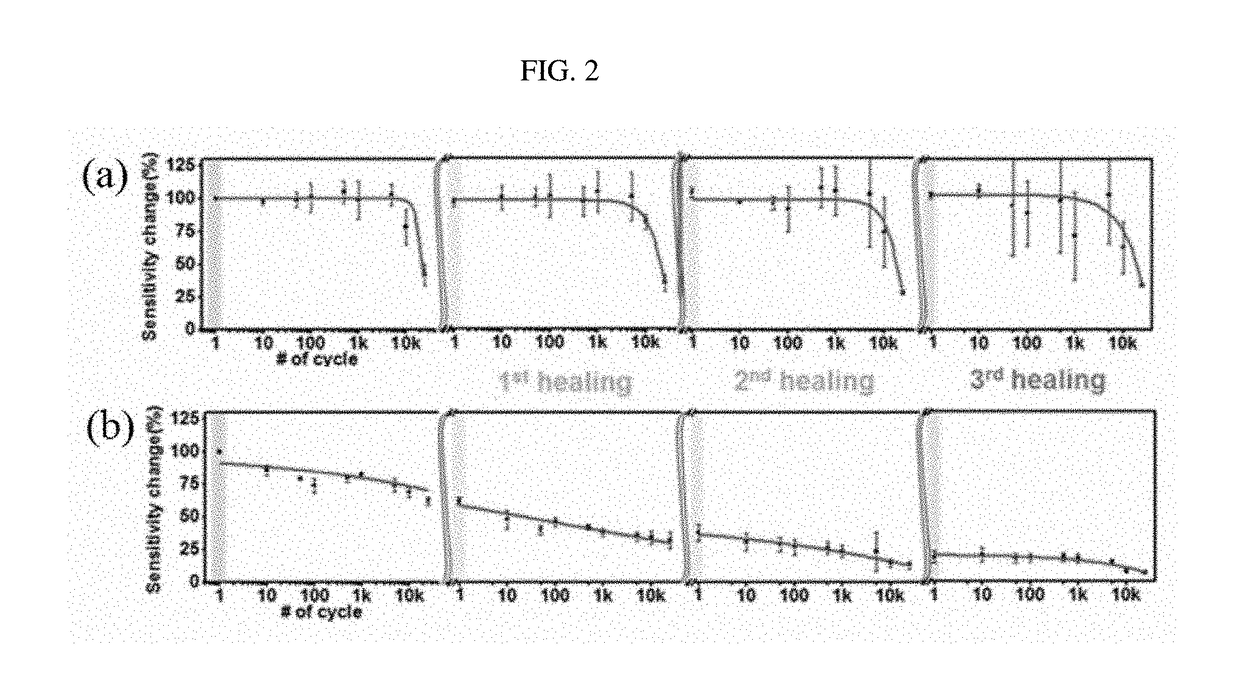

Crack sensor including polymer for healing cracks and electronic device including the same

ActiveUS20180246165A1Enhance resilienceMaintaining the durability of the crack sensorSemiconductor/solid-state device testing/measurementElectronic circuit testingOptoelectronicsElectron

A crack sensor with crack healing is provided. The sensor having: a substrate; a conductive layer disposed on the substrate, wherein the conductive layer contains cracks formed therein; and a polymer layer disposed between the substrate and the conductive layer, or disposed on the conductive layer and not between the substrate and the conductive layer; wherein a restoring force of the polymer layer suppresses further growth of the cracks or restores cracks.

Owner:IND ACADEMIC COOPERATION FOUND OF AJOU UNIV +1

High pressure gas container and manufacturing method for high pressure gas container

InactiveUS9512964B2Mass production is possibleVessel geometry/arrangement/sizeVessel wallsEngineeringProduct gas

This invention is a high pressure gas container into which a high pressure gas is charged, includes: a liner into which the high pressure gas is charged; and a reinforcing sleeve that envelops an outer surface of the liner, wherein the liner includes: a cylindrical liner trunk portion; and a pair of liner shoulder portions formed by reducing a diameter of respective end portions of the liner trunk portion, and the reinforcing sleeve includes: a sleeve trunk portion fitted to the liner trunk portion; and a pair of sleeve shoulder portions that extend from the sleeve trunk portion so as to contact the respective liner shoulder portions.

Owner:KYB CORP

Exposure method and exposure apparatus, and device manufacturing method

ActiveUS20140218707A1Precise overlay of the patternHighly precise overlaySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringExposure

An exposure apparatus which transfers a pattern formed on a mask onto a photosensitive substrate placed in proximity to the mask, the apparatus including an illumination optical device which illuminates the mask with an energy beam, a mask holding device which holds a periphery area of a pattern area of the mask from above, and makes a force at least within a plane parallel to a predetermined plane act on the mask and a substrate holding device which moves along the predetermined plane holding the substrate.

Owner:NIKON CORP

Exposure method and exposure apparatus, and device manufacturing method

ActiveUS8735051B2Precise overlay of the patternHighly precise overlayPhoto-taking processesSemiconductor/solid-state device manufacturingLight beamOptoelectronics

Exposure apparatus is equipped with an illumination optical device which illuminates a mask with an exposure beam, a mask table which holds a periphery of a pattern area of the mask from above so that a pattern surface of the mask becomes substantially parallel to an XY plane and makes a force at least parallel to an XY plane and on the mask, and a wafer stage which moves along the XY plane, holding a wafer substantially parallel to the XY plane. Therefore, an overlay with high precision of a pattern of a mask and an underlying pattern on the substrate can be realized, even though the exposure apparatus employs a proximity method, that is, the exposure apparatus does not use a projection optical system.

Owner:NIKON CORP

Method for fabricating nano-patterned substrate for high-efficiency nitride-based light-emitting diode

InactiveUS20150064821A1Improve production yieldIncrease production capacityPhotomechanical apparatusSemiconductor/solid-state device manufacturingPatterned substrateLength wave

Provided is a method of manufacturing a nitride-based light emitting diode. According to the method, a substrate having a nano to micron sized pattern including a bottom section and a convex section, wherein a lower end diameter of the convex section is 0.1 to 3 times a light emitting wavelength of the light emitting diode, and a buffer layer formed on the substrate and formed as a GaN layer are manufactured. According to the method of manufacturing the nitride-based light emitting diode, light extraction is significantly improved, and the nano to micron sized pattern, economically formed.

Owner:HUNET PLUS

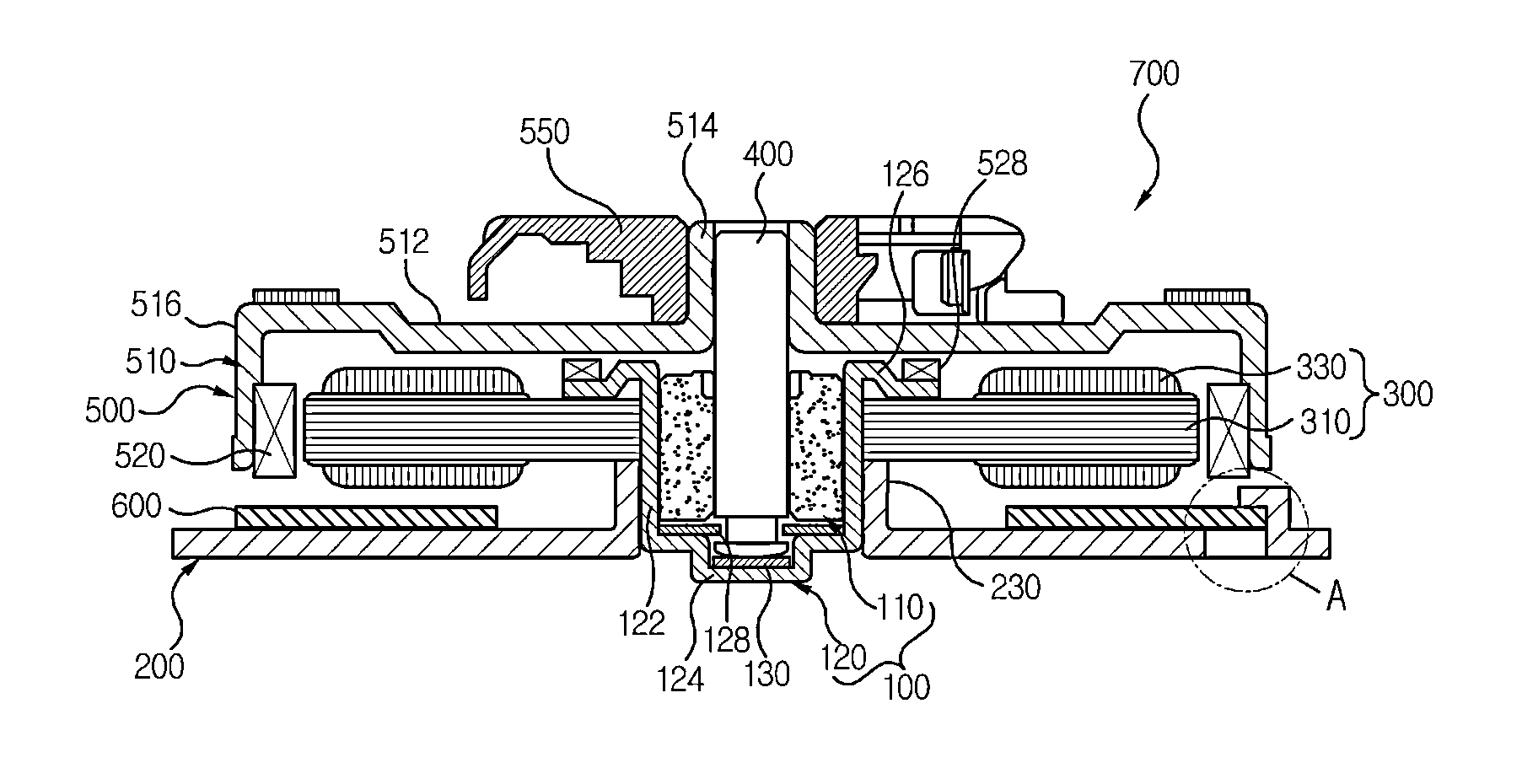

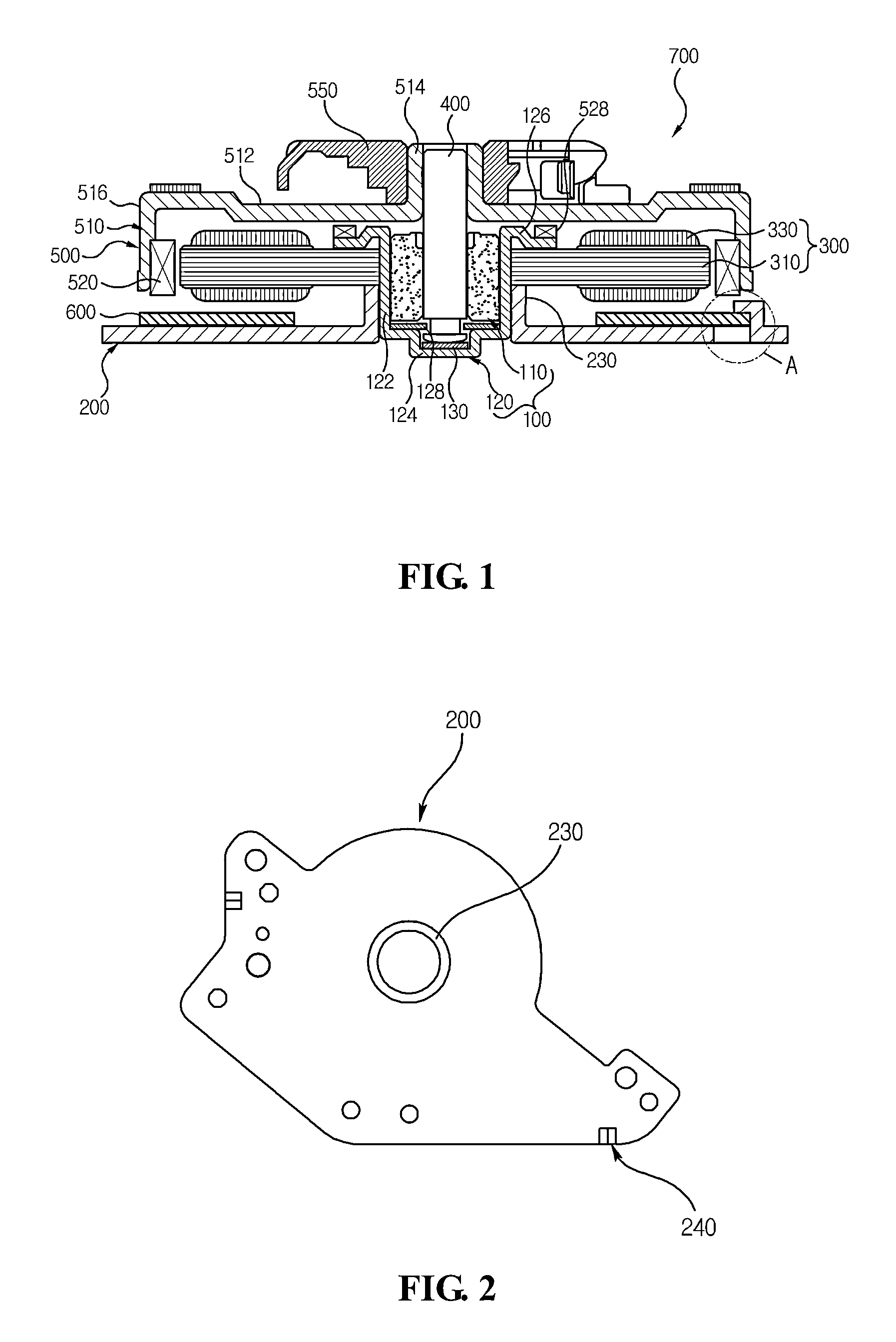

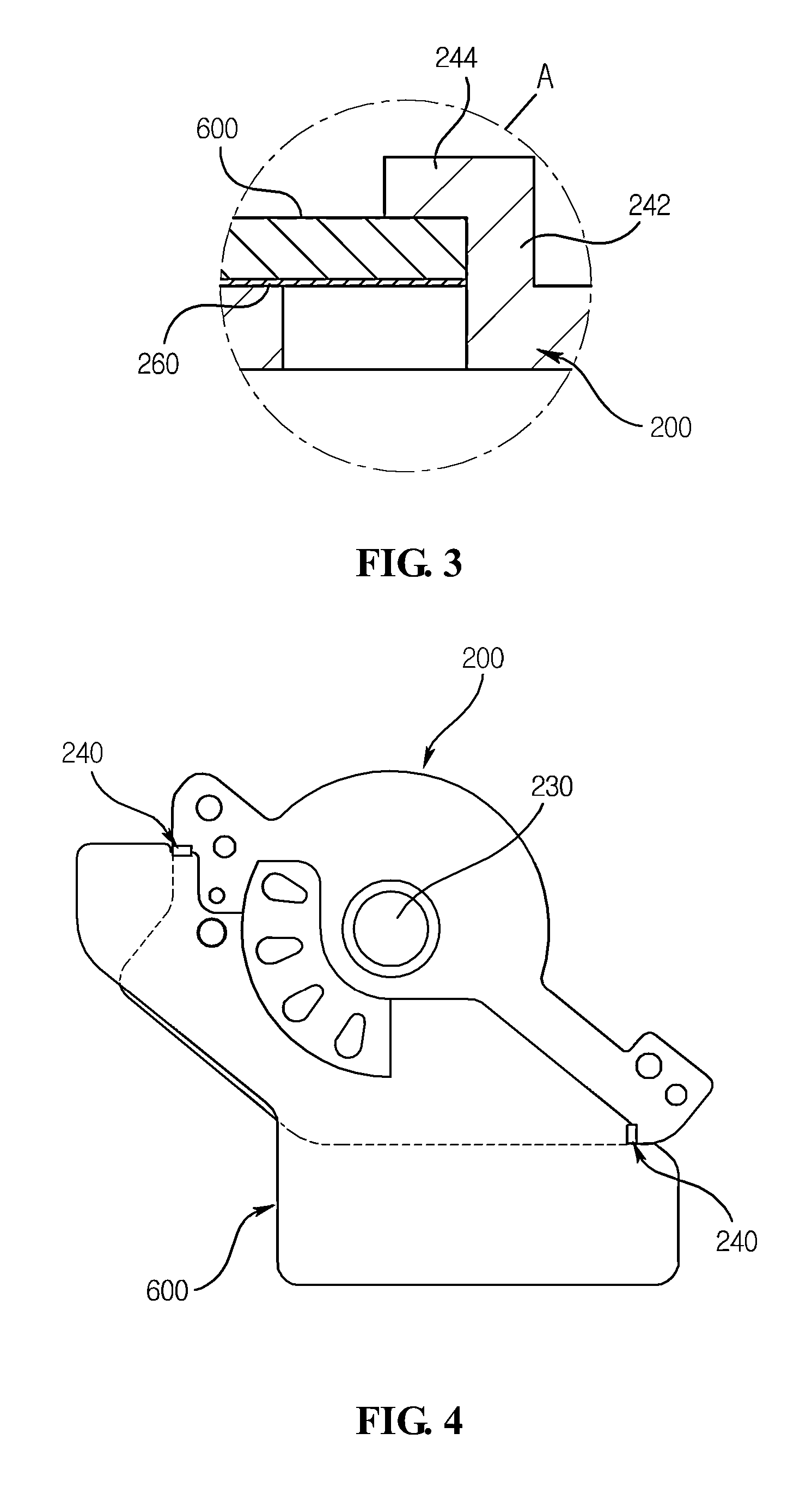

Spindle motor

InactiveUS20130147322A1Prevent alignment defectPrecise alignmentAssociation with control/drive circuitsMagnetic circuitEngineeringElectric motor

A spindle motor is provided, the motor including a bearing assembly including a bearing housing accommodating a bearing, a stator coupled to an ambience of the bearing housing, a rotation shaft rotatably accommodated into the bearing, a rotor coupled to the rotation shaft to rotate in association with the stator, a base plate coupled to the bearing housing, and a circuit board arranged at an upper surface of the base plate to be electrically connected to the stator.

Owner:HITACHI LG DATA STORAGE KOREA

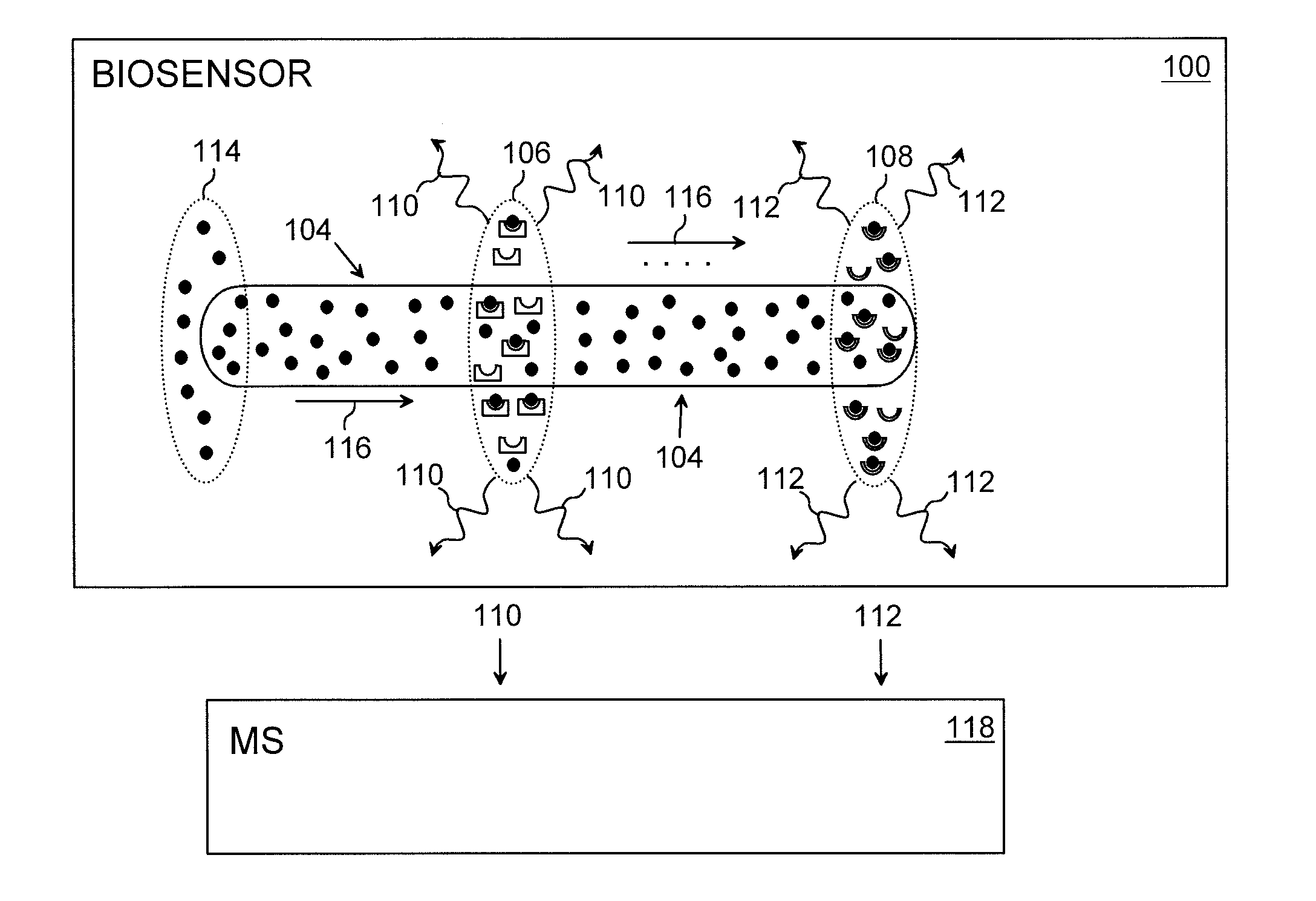

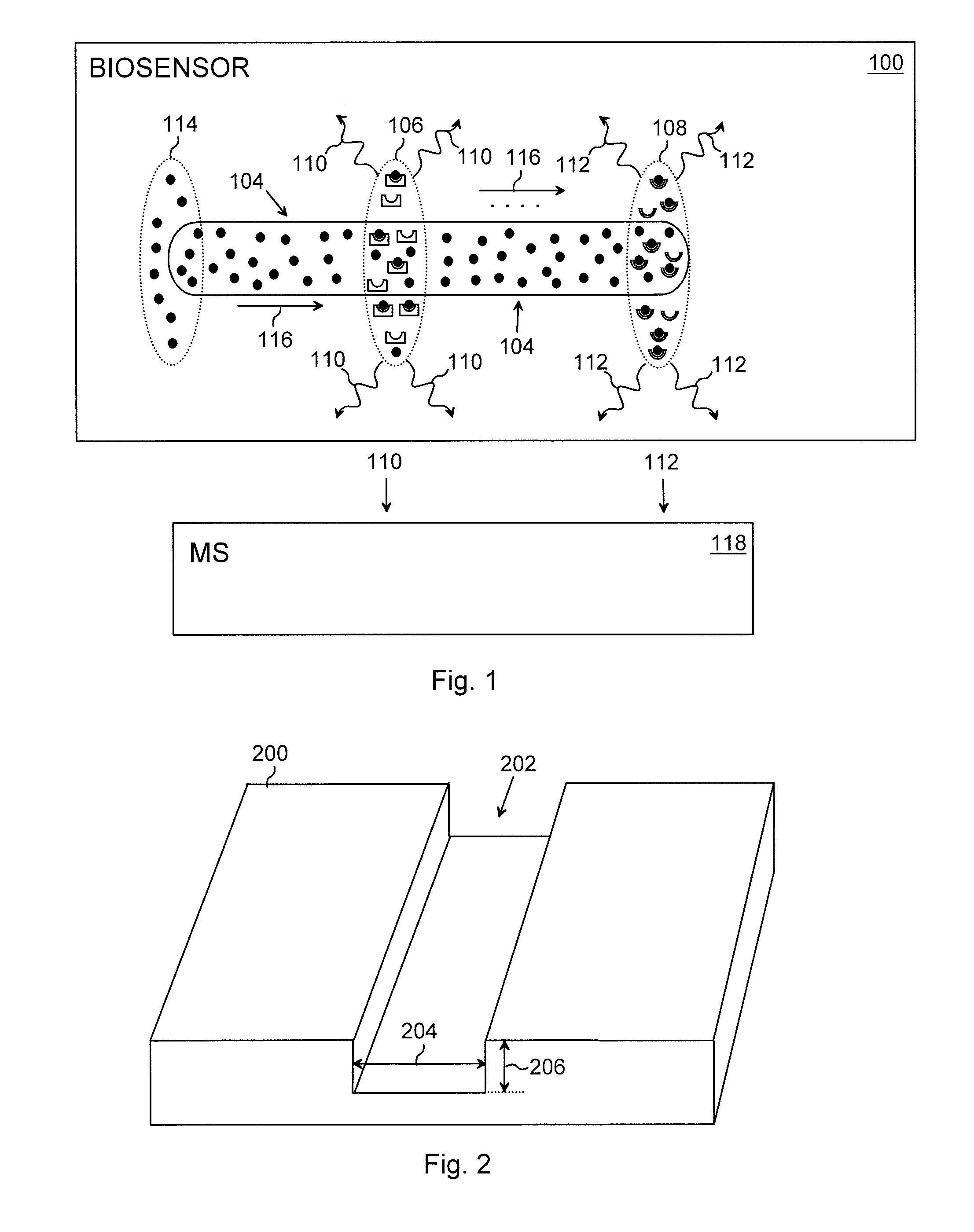

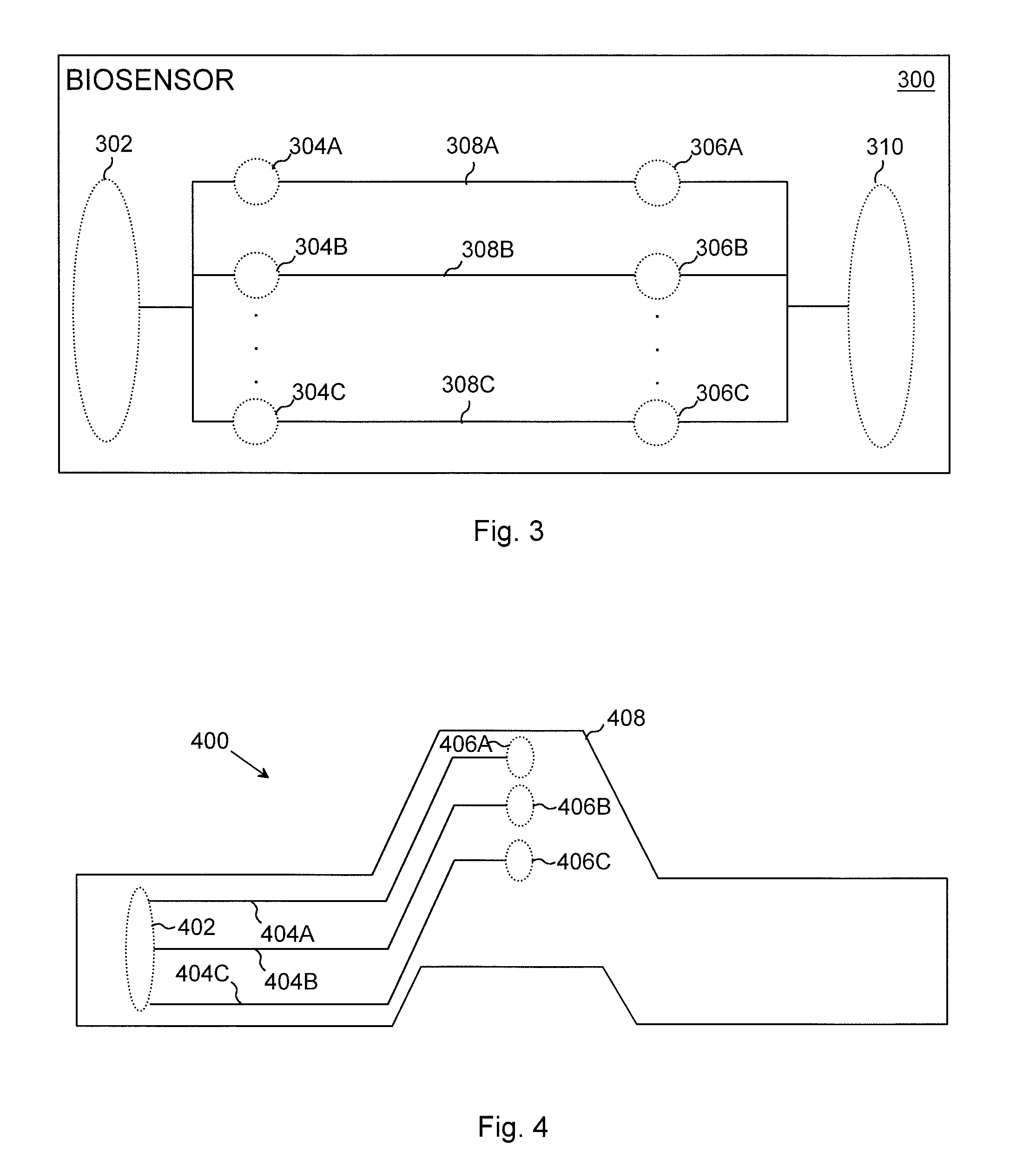

Biosensor

InactiveUS20110189388A1Easy to manufactureLittle processingMicrobiological testing/measurementPretreated surfacesSignature MoleculeBiosensor

The invention relates to a biosensor solution in which the biosensor comprises at least one sol-gel response region pattern doped with a biological signature molecule and printed on the biosensor, and at least one micro-channel for transporting material to said at least one sol-gel response region pattern.

Owner:VALTION TEKNILLINEN TUTKIMUSKESKUS

Precipitation-strengthened Ni-based heat-resistant alloy and method for producing the same

A precipitation-strengthened Ni-based heat-resistant alloy of the present invention includes 0.03 wt % or less of C, 0.5 wt % or less of Mn, 0.01 wt % or less of P, 0.01 wt % or less of S, 2.0 to 3.0 wt % of Si, 23 to 30 wt % of Cr, 7.0 to 14.0 wt % of W, 10 to 20 wt % of Fe, and 40 to 60 wt % of Ni, wherein a total content of C, N, O, P and S is 0.01 wt % or less. A silicide is dispersed and precipitated and a grain size of a matrix austenite is controlled through a thermo-mechanical treatment. As a result, the precipitation-strengthened Ni-based heat-resistant alloy excellent in irradiation resistance, heat resistance and corrosion resistance can be obtained with a low cost.

Owner:KOBE STEEL LTD

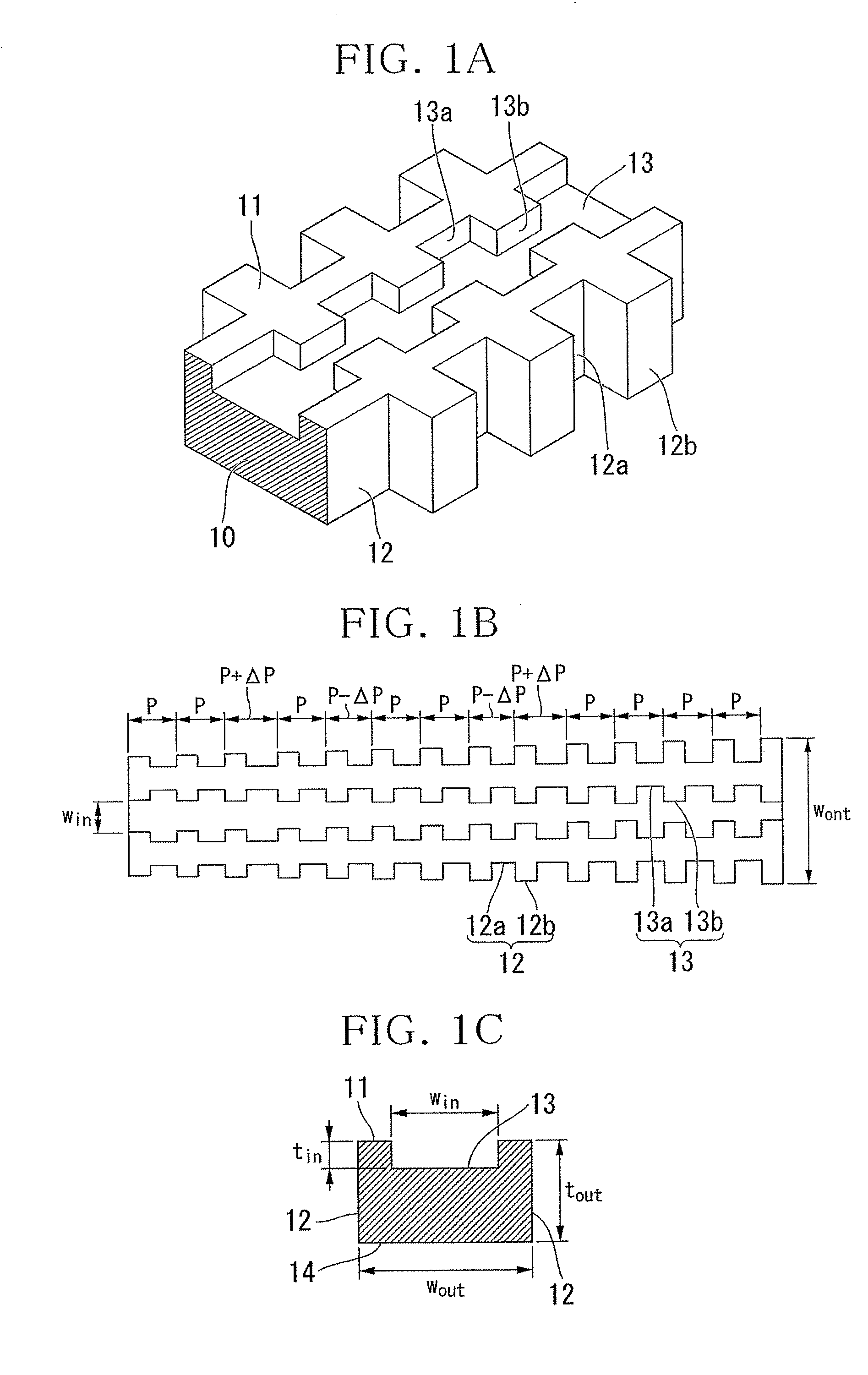

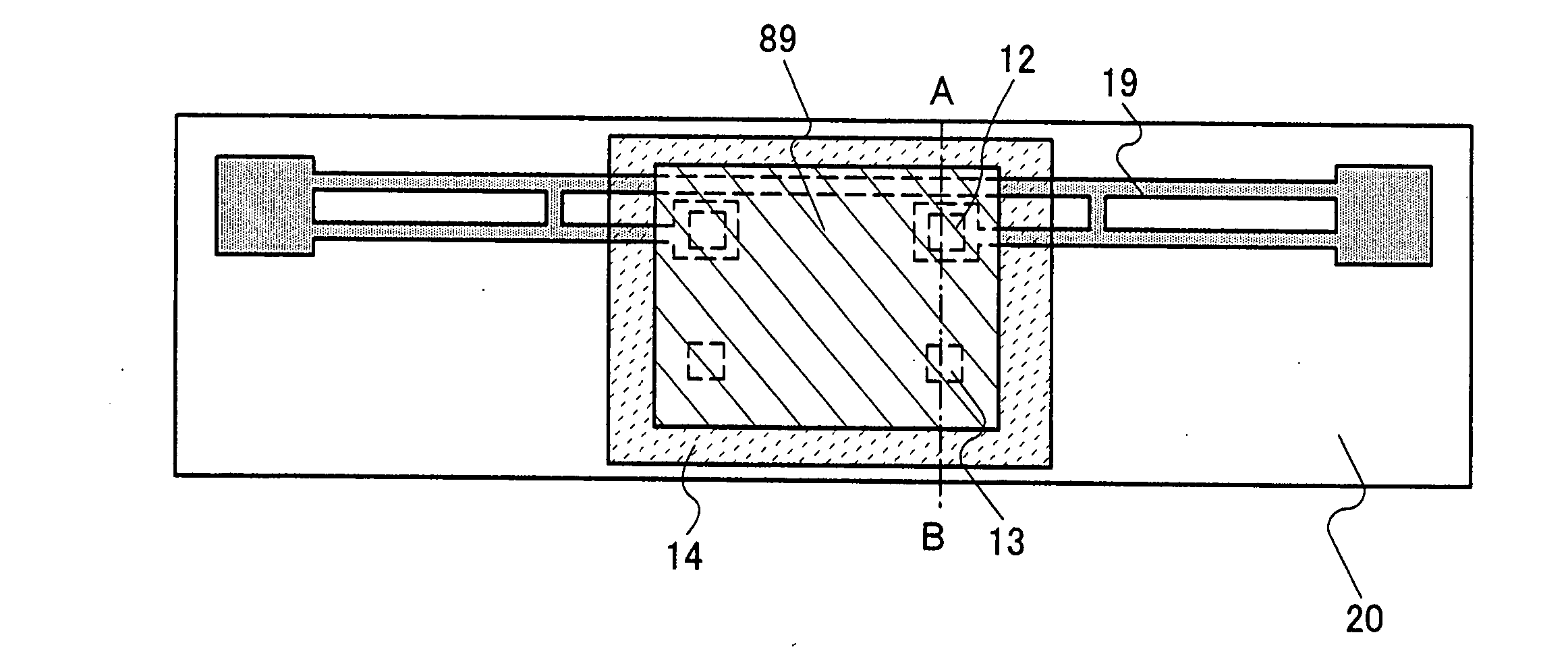

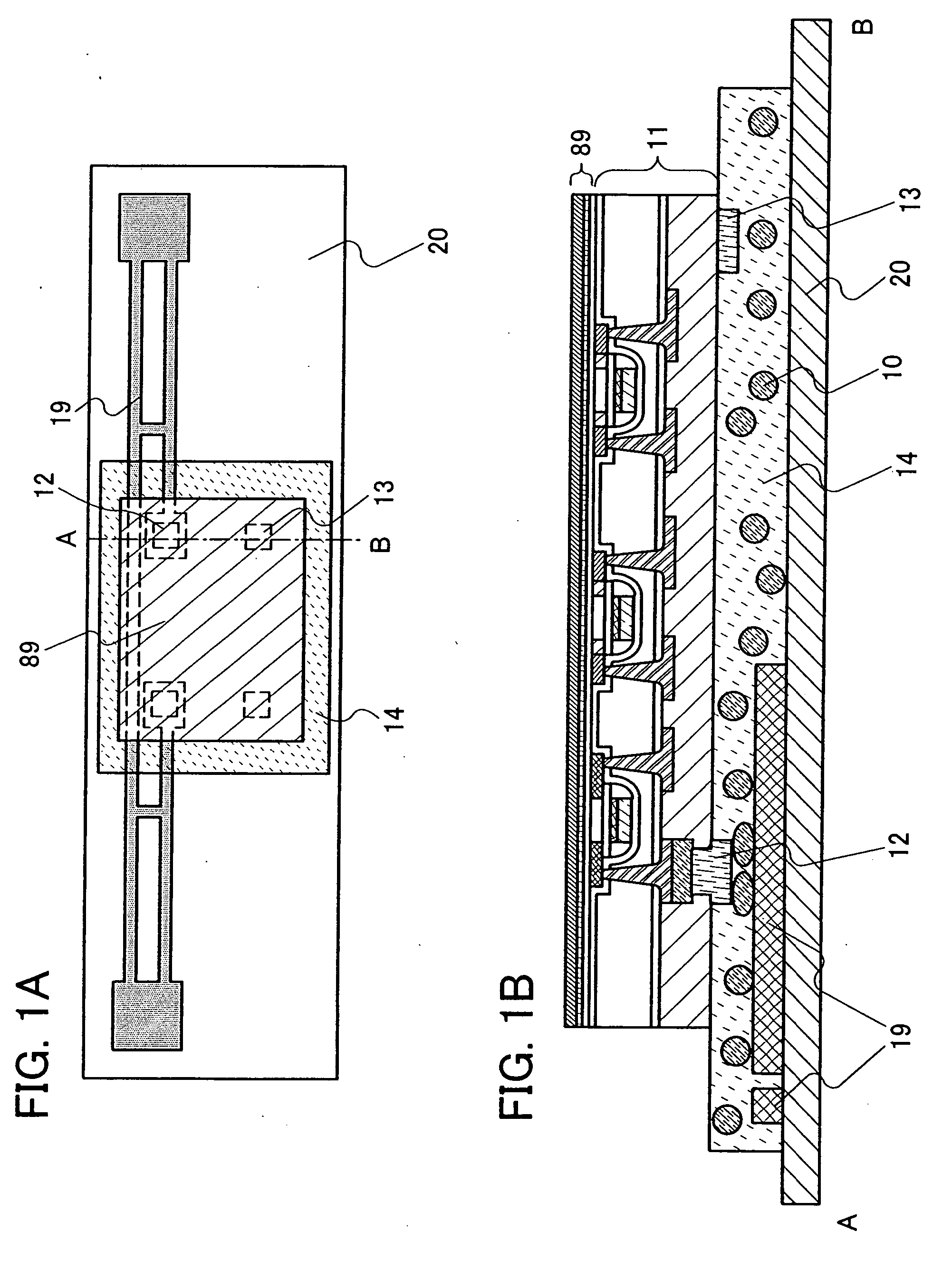

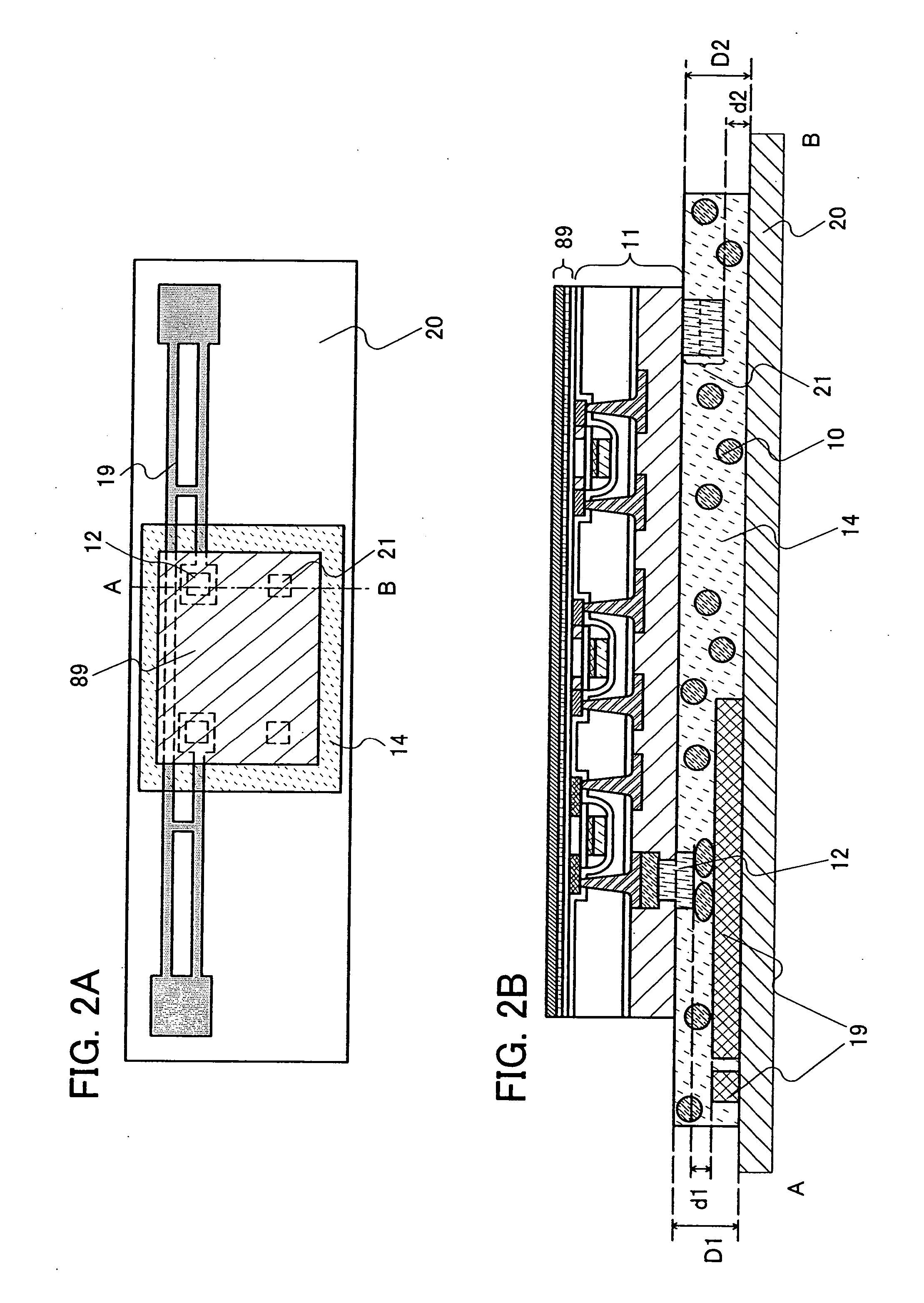

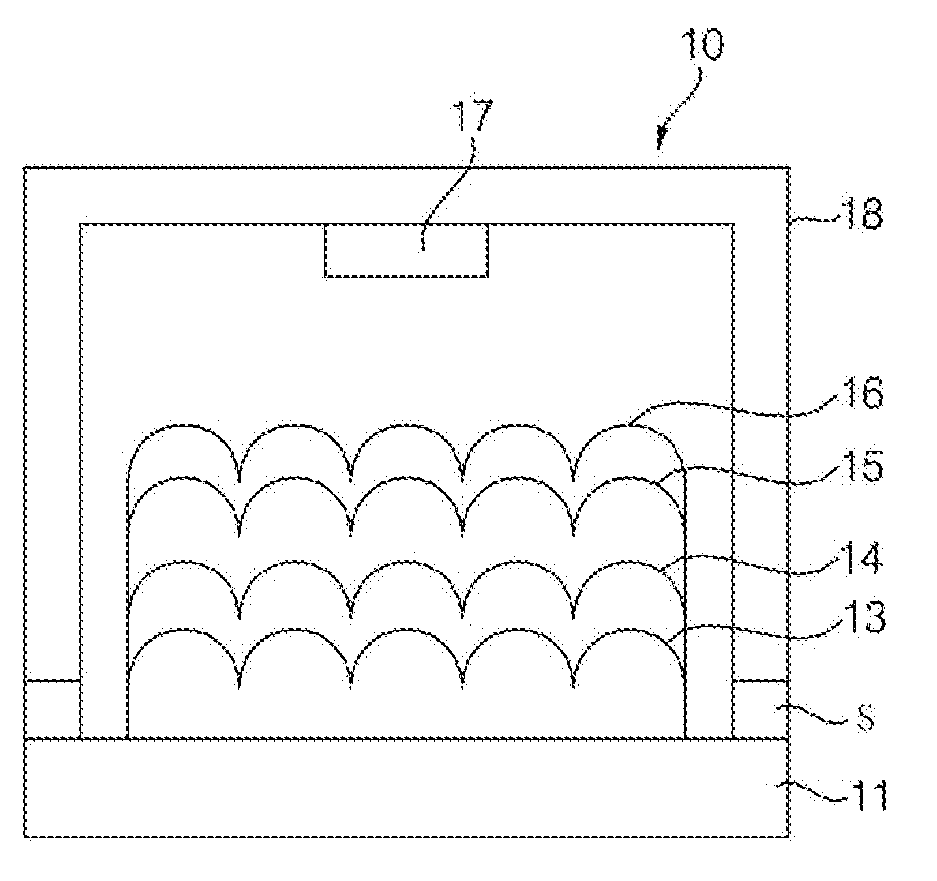

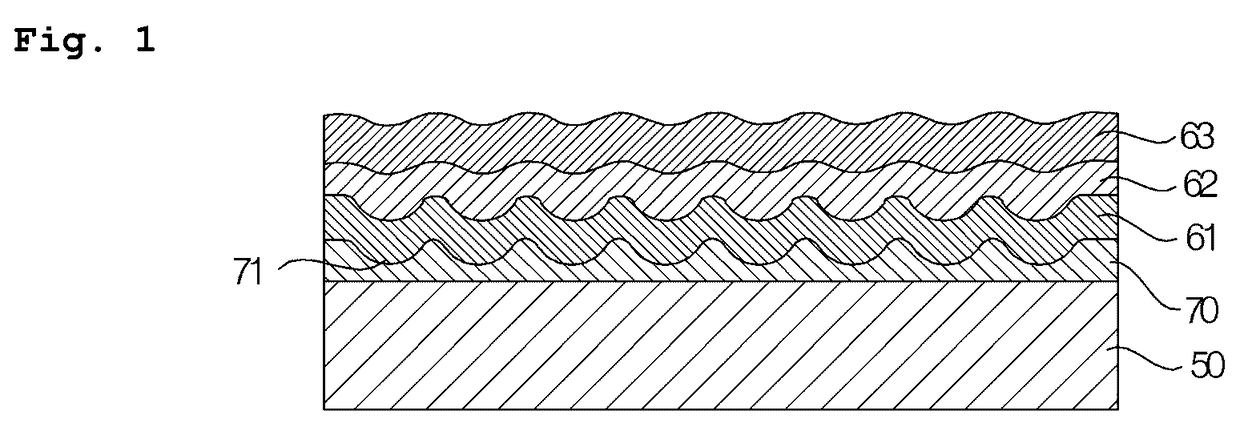

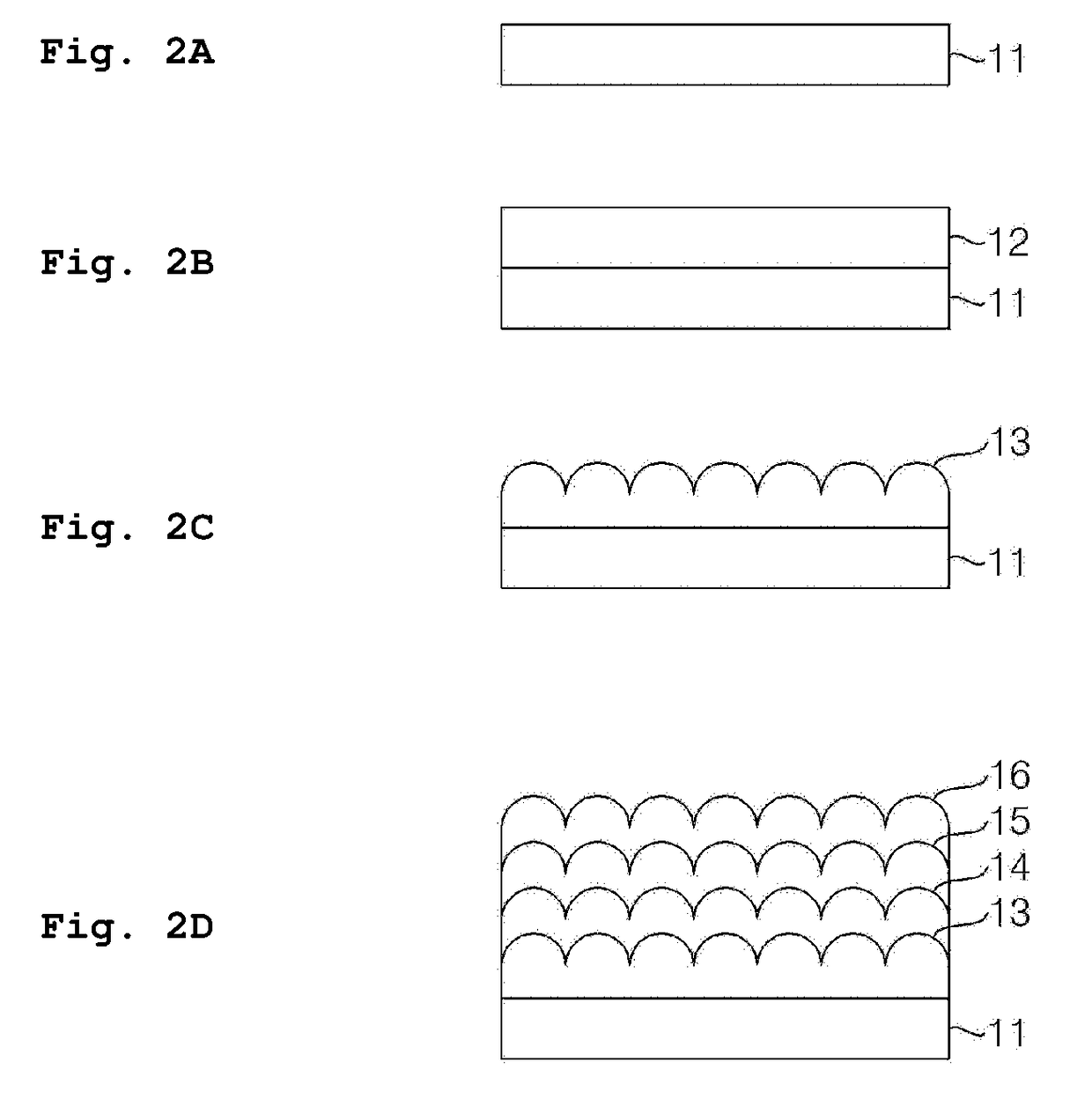

Method for manufacturing substrate, substrate, method for manufacturing organic electroluminescence device, and organic electroluminescence device

InactiveUS20170170434A1Reduce the amount requiredImprove extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingIon bombardmentOrganic electroluminescence

The purpose of the present invention is to reduce light, which is absorbed at an interface of an organic electroluminescence device and disappears, thereby improving the efficiency of extraction of light that is drawn to the outside. A substrate 11 is coated with polymer to form a polymer layer 12; ion bombardment stress resulting from plasma is applied to the polymer layer 12 to form a corrugated layer 13 having a plurality of corrugated parts; and a first electrode, an organic light-emitting layer, and a second electrode are successively formed on the substrate, on which the corrugated layer is formed, thereby manufacturing an organic electroluminescence device. In addition, a metal layer 23 may be additionally formed on the polymer layer, ion bombardment stress and thermal stress may be applied simultaneously to form corrugated parts, and the metal layer may then be removed.

Owner:NEOVIEWKOLON

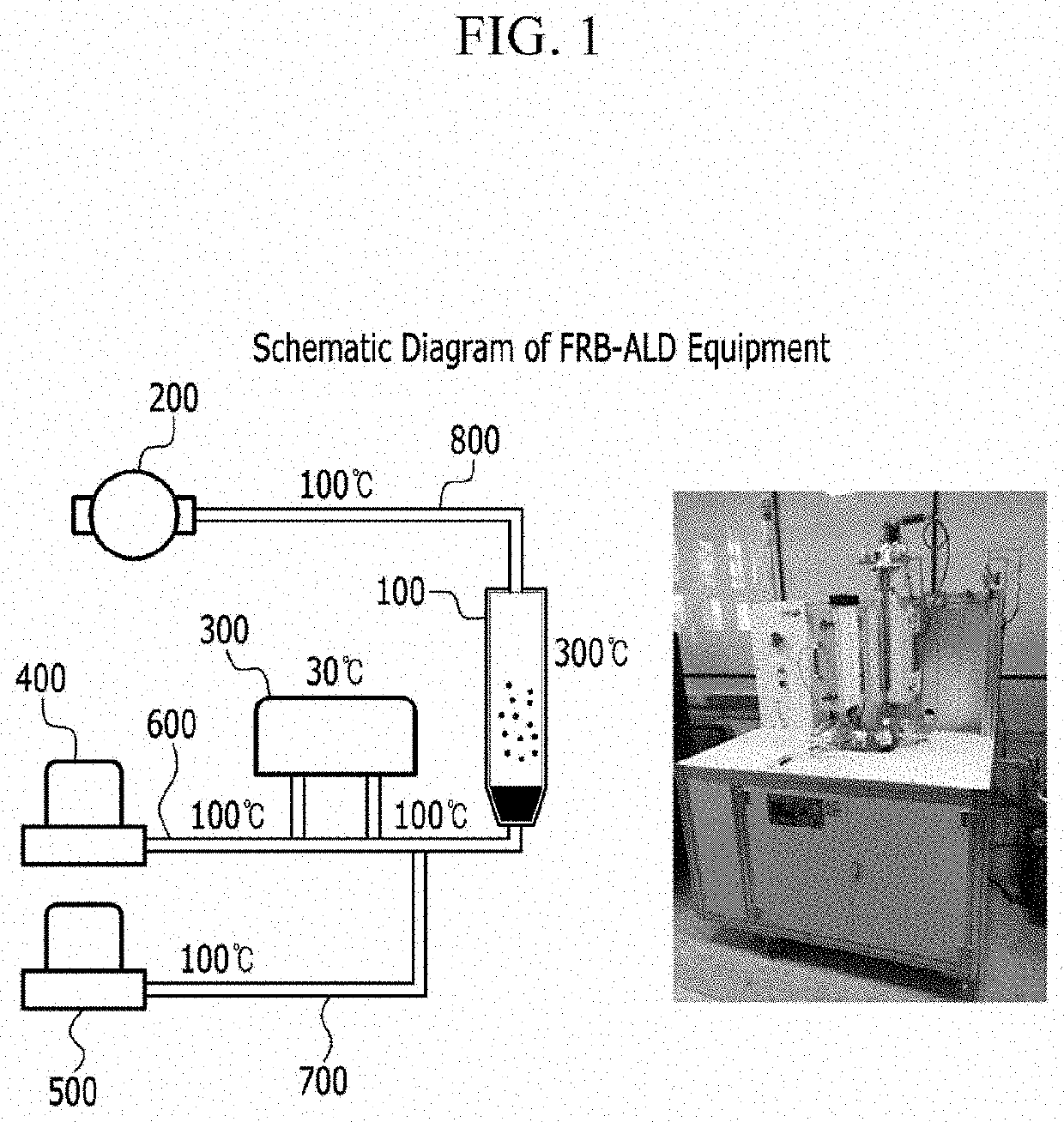

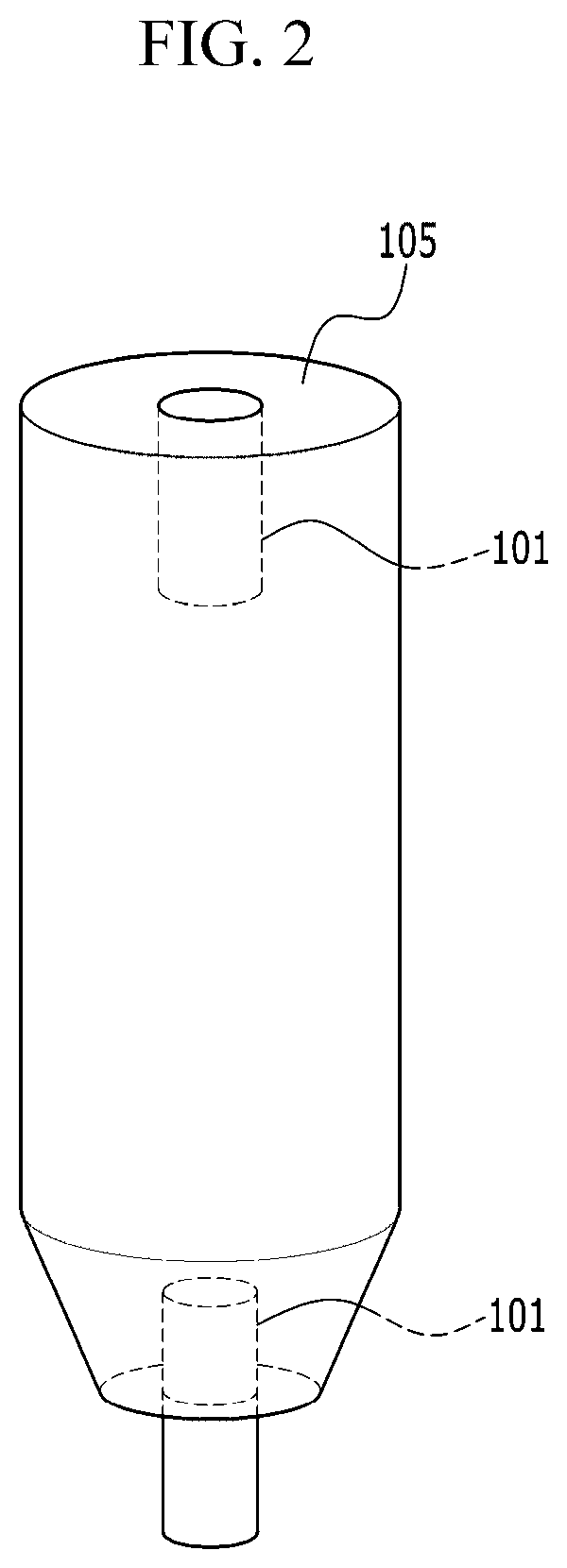

Method and apparatus of preparing catalyst for fuel cell

ActiveUS20200179893A1Large surface areaUniform and small sizeOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesCarbon particleFluidized bed

Owner:HYUNDAI MOTOR CO LTD +2

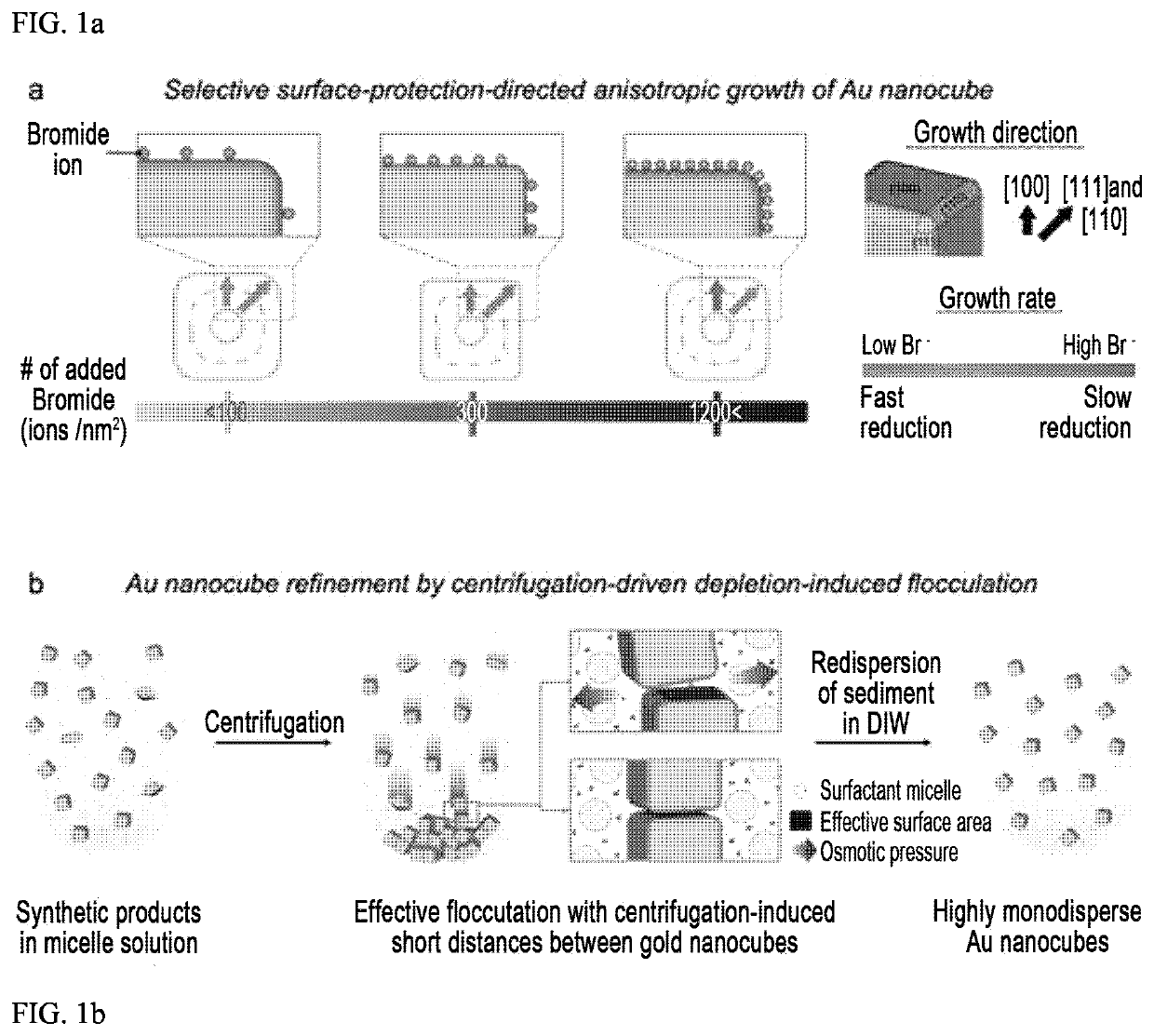

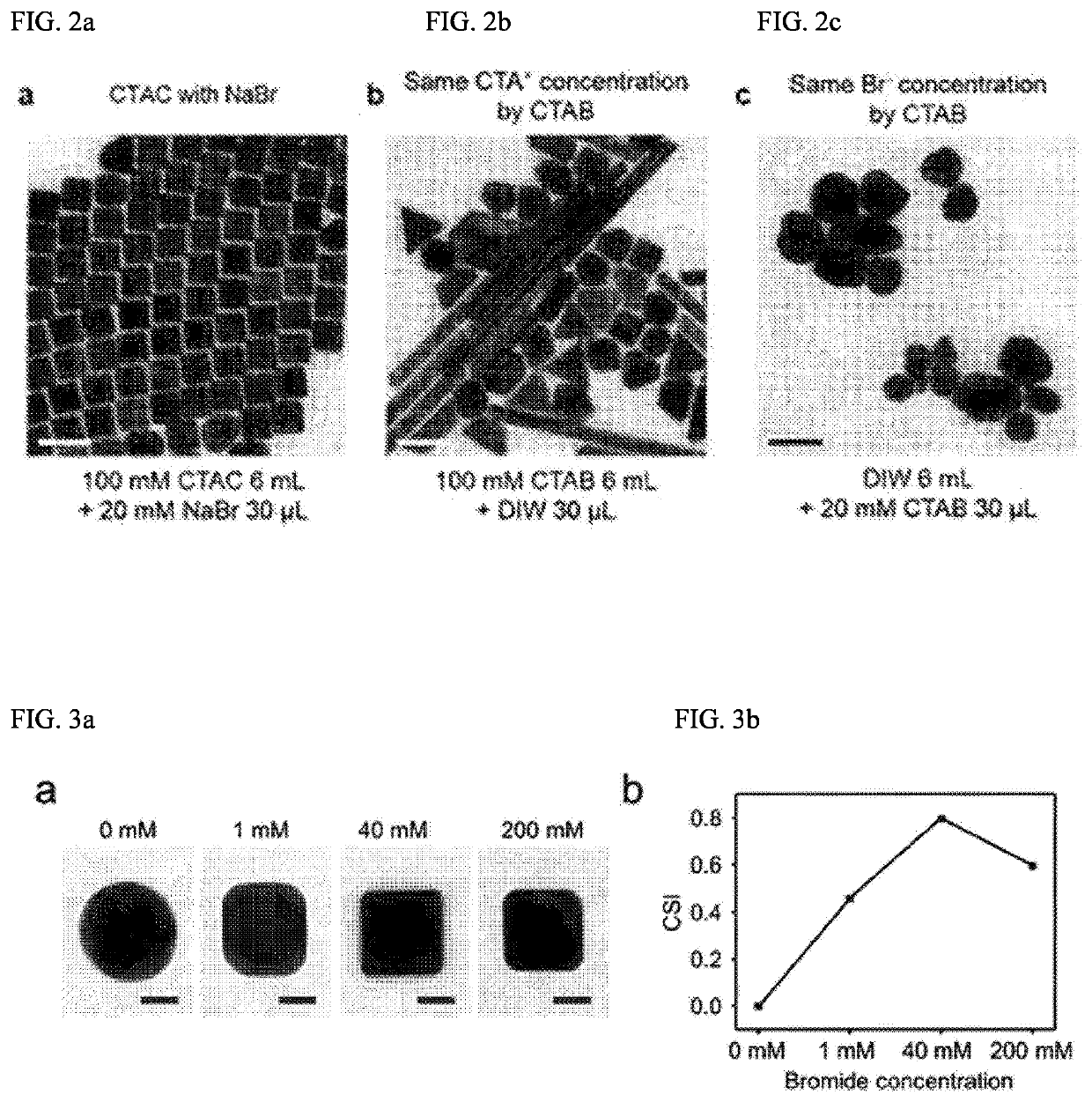

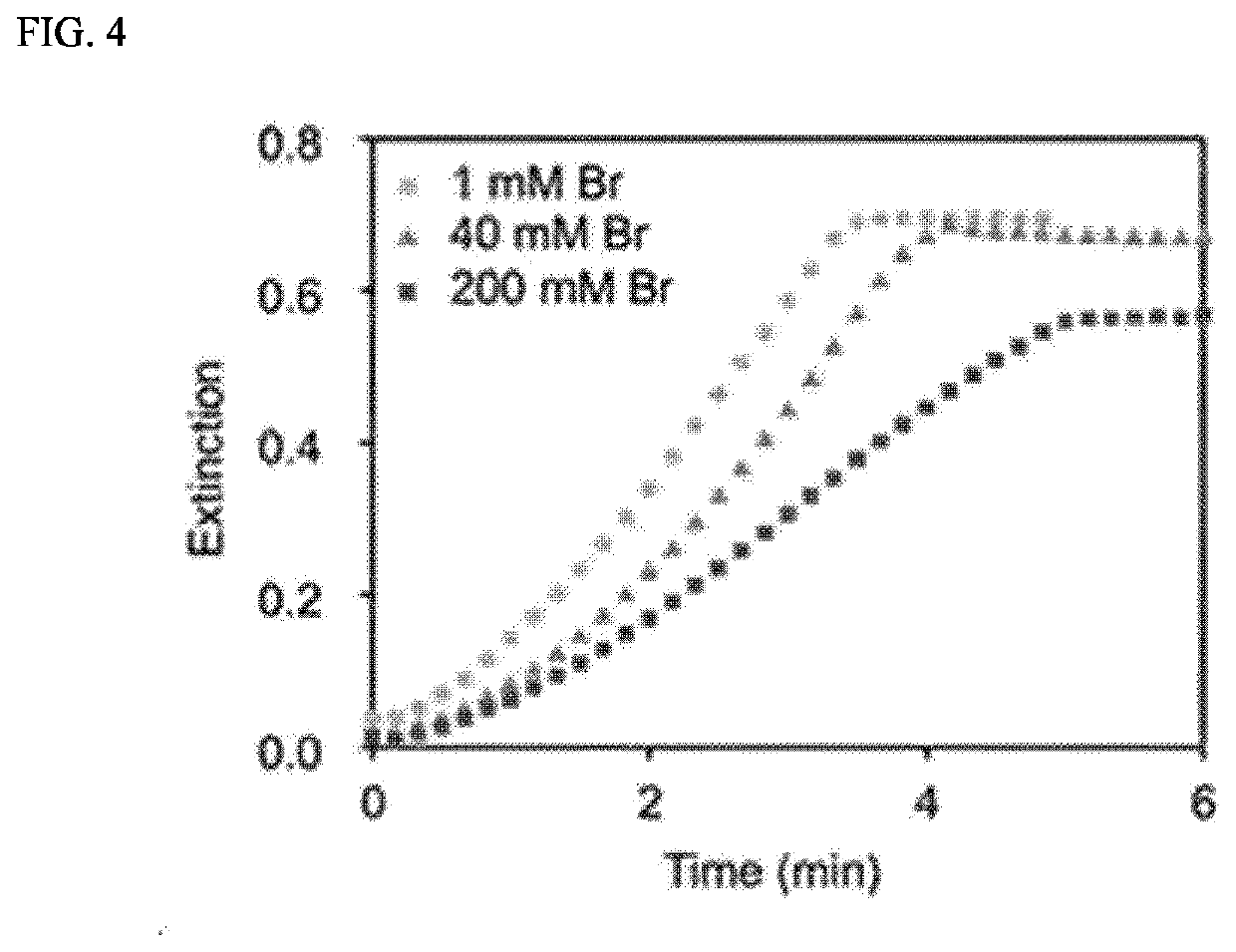

Method for Preparing Metal Nanocube with Controlled Corner Sharpness Index

PendingUS20210161952A1Mass production is possibleSimple control methodPowder deliveryInorganic active ingredientsActive agentSurface-active agents

The present invention relates to a method for preparing a metal nanocube with a controlled corner sharpness index, comprising a step of reacting with a first surfactant and a predetermined surface-protecting agent; a method for preparing a metal nanocube aggregate having a purity of 95% or more, comprising a step of centrifuging in the presence of a second surfactant; a probe composition comprising the metal nanocube or metal nanocube aggregate prepared by the method; and a gold (Au) nanocube having an average edge length of 20 nm or less.

Owner:SEOUL NAT UNIV R&DB FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com