Standard Capacity Discharge Case of Liquid Content

a liquid content and discharge case technology, applied in the field of automatic pencil type cases, can solve the problems of reducing the production cost involved in the manufacturing process, affecting the quality of cosmetic containers, etc., and achieves the effects of eliminating ultra-precision machining, simplifying the structure of cosmetic containers, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The above-mentioned objectives, features, and advantages will be more apparent by the following detailed description in association with the accompanying drawings.

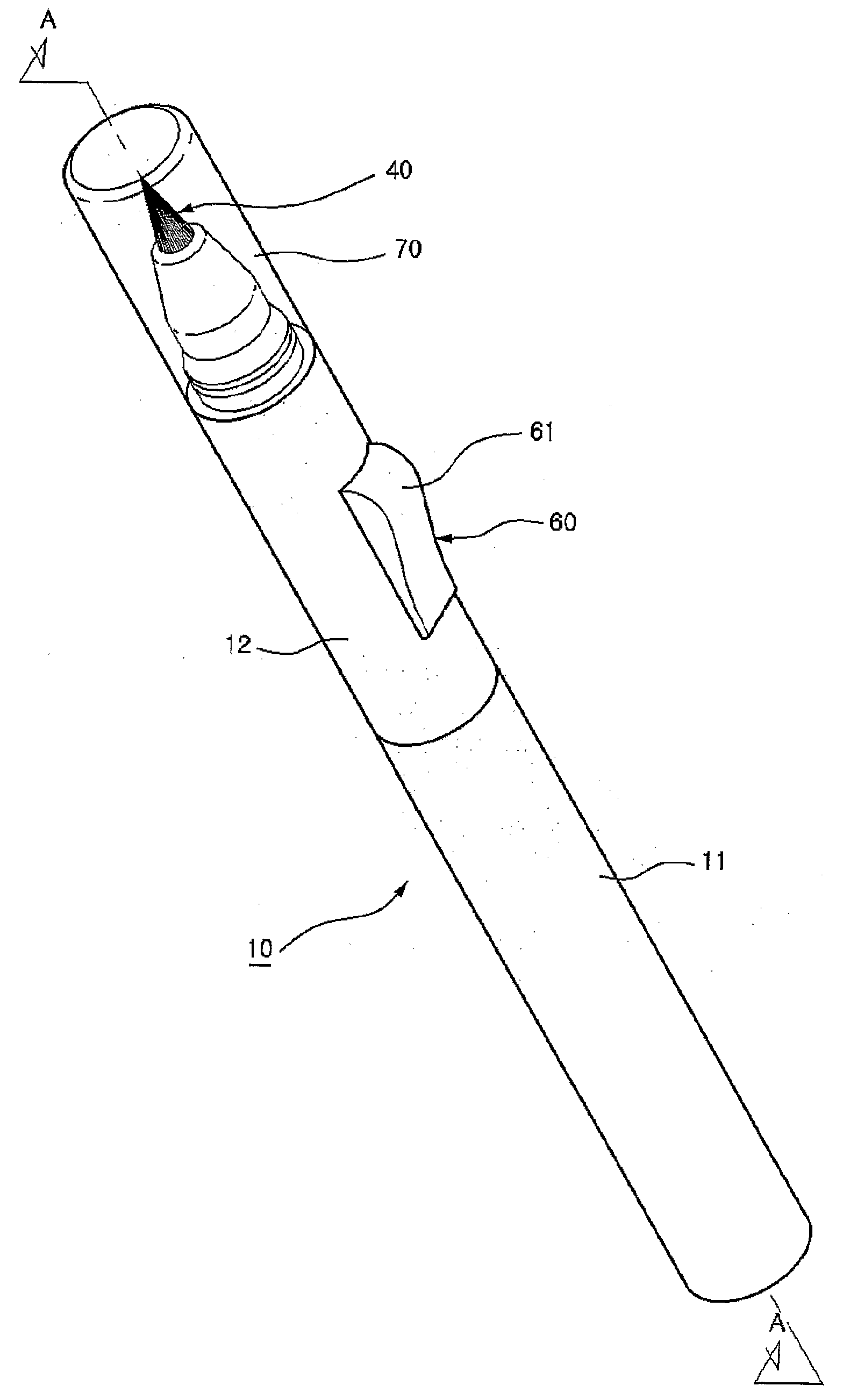

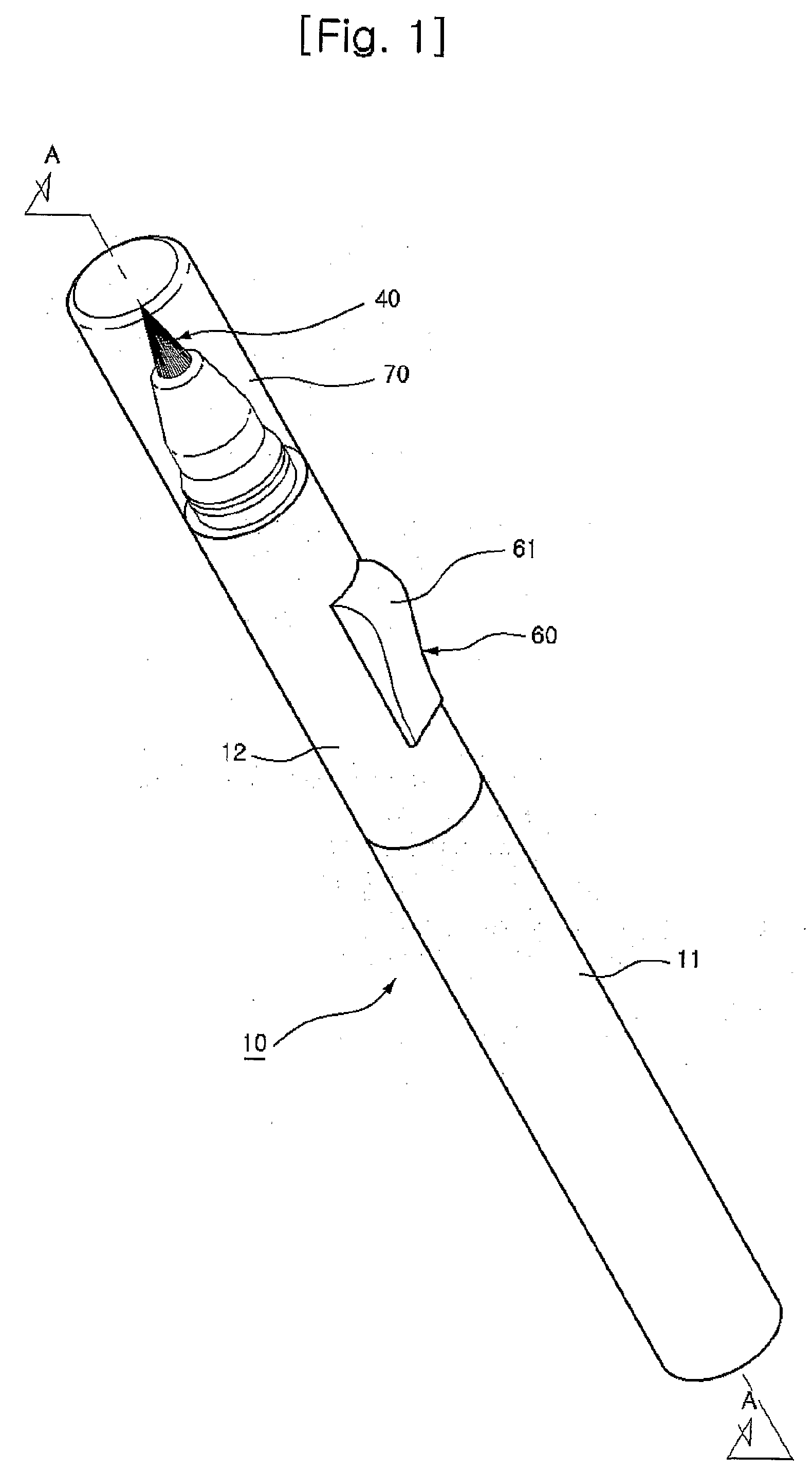

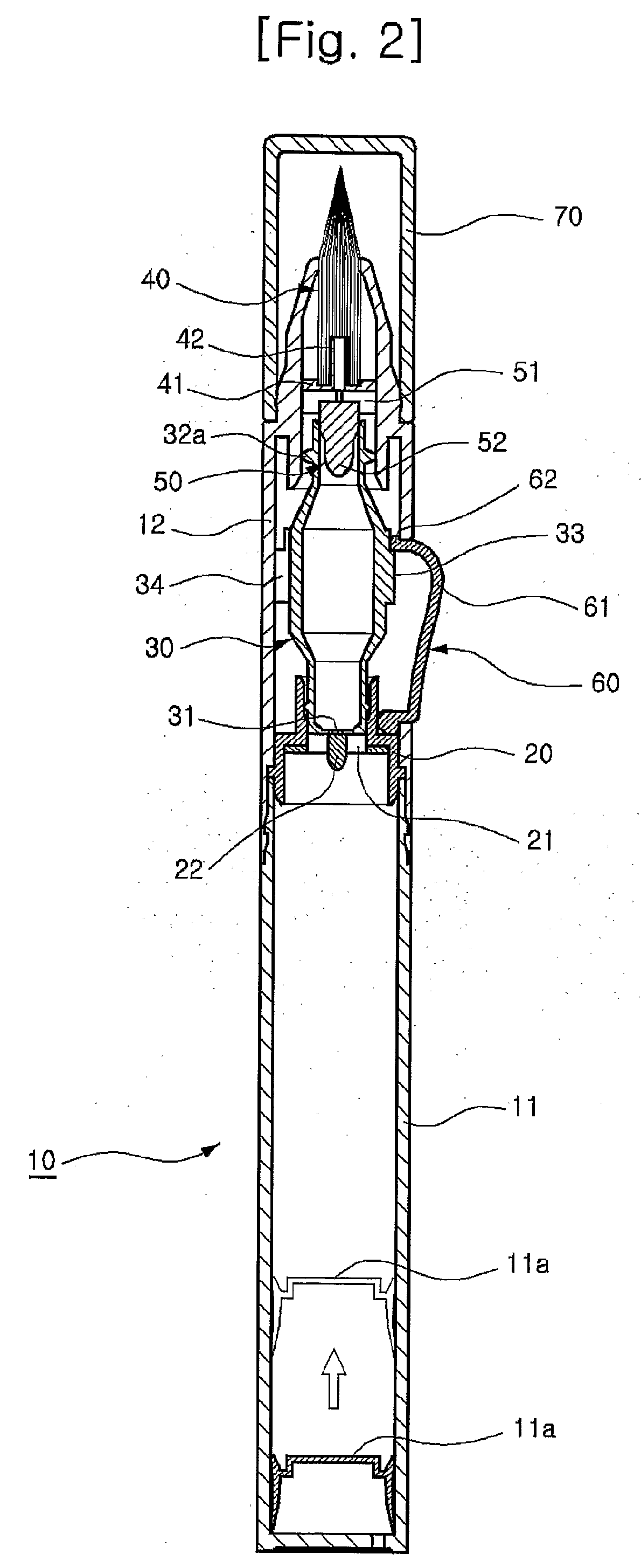

[0021]As shown in FIGS. 1 to 4, a standard capacity (e.g., a fixed quantity) discharge case of liquid content according to the present design is constituted by a body 10 formed of a first case 11 for reserving liquid content and a second case 12 undercut connected to the first case 11; a check valve 20 installed on the front end of the first case 11; a pump tube 30 installed inside the second case 12; a valve 50 mounted on the front end of the pump tube 30; and a makeup brush 40 installed on the front end of the second case 12.

[0022]The first case 11 of the body 10 has an opened top, and encloses a piston 11a pushing up the reserved liquid content.

[0023]The check valve 20 installed on the top of the first case 11 is provided with a content transfer passage in form of rib frame 21, to allow the liquid content to flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com