Method and apparatus of preparing catalyst for fuel cell

Active Publication Date: 2020-06-11

HYUNDAI MOTOR CO LTD +2

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0046]By using a fluidized bed reactor, a catalyst metal spot having a small and uniform size; and distribution; is formed on the carbon particles, thereby producing a fuel cell catalyst having a large surface area of the catalyst metal.

[0047]In addition, using a fluidized bed reactor, mas

Problems solved by technology

Platinum is a very expensive metal and uses as little as possible but maximizes the surface area.

In conventional wet processes, the mass production process takes almost a week.

In addition, due to the use of chemicals, manufacturing costs are high due to environmental problems, post-treatment, and stabilizer input due to the disposal of chemicals.

At this time, large sized platinum spots are undesirable because they counteract the expansion

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Login to View More

Abstract

A method for producing a catalyst for a fuel cell comprising: a) injecting carbon particles into a fluidized bed reactor; b) evacuating the fluidized bed reactor to form a base pressure; c) introducing a catalytic metal precursor together with a carrier gas into the fluidized bed reactor to contact the catalytic metal precursor with the carbon particles; d d) purging a purge gas into the fluidized bed reactor; e) introducing a reaction gas into the fluidized bed reactor to attach the catalytic metal precursor to the carbon particles; and f) purging a purge gas into the fluidized bed reactor, wherein, the catalytic metal is attached to the carbon particles in a form of nano-sized spot.

Description

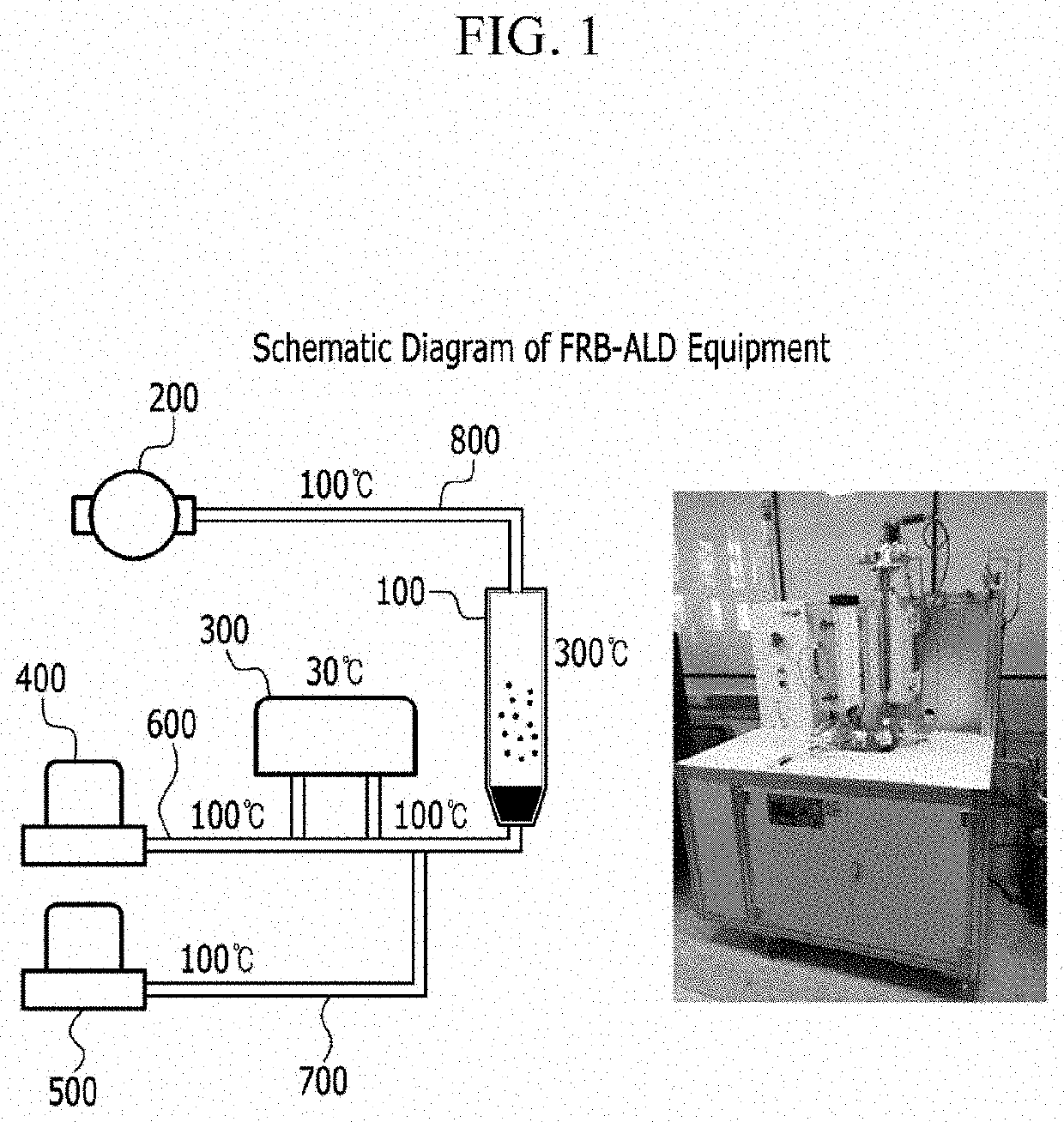

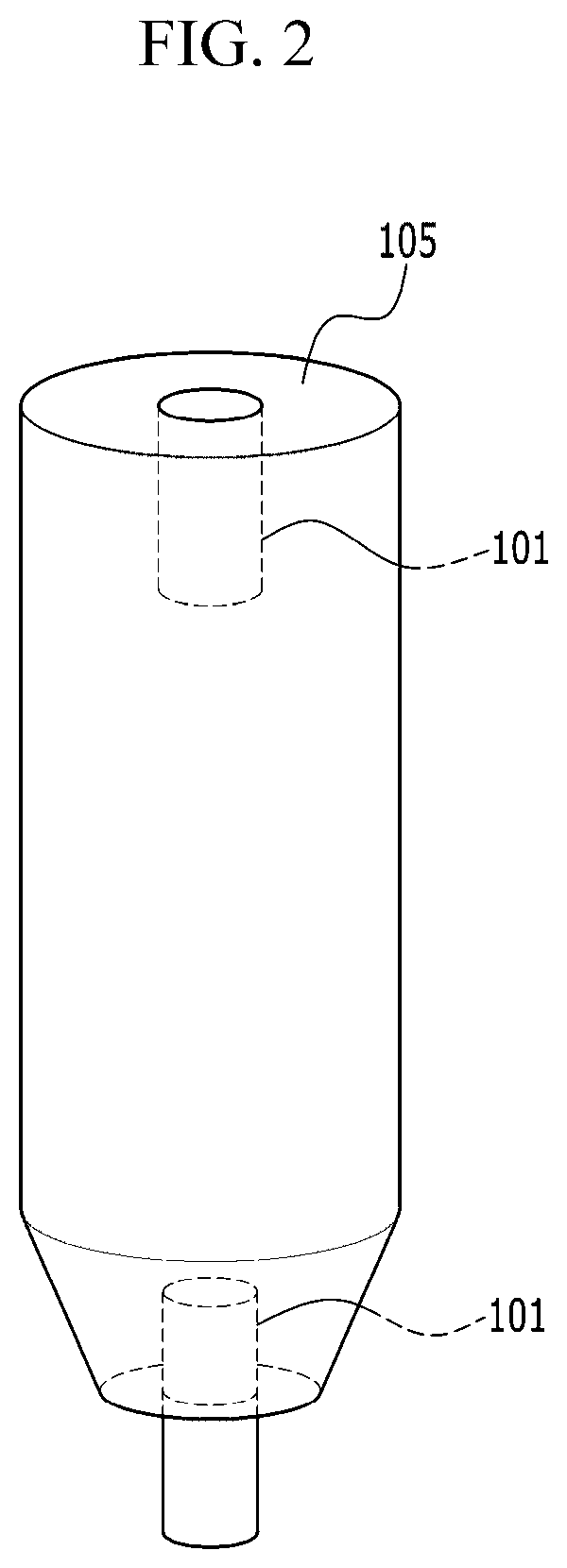

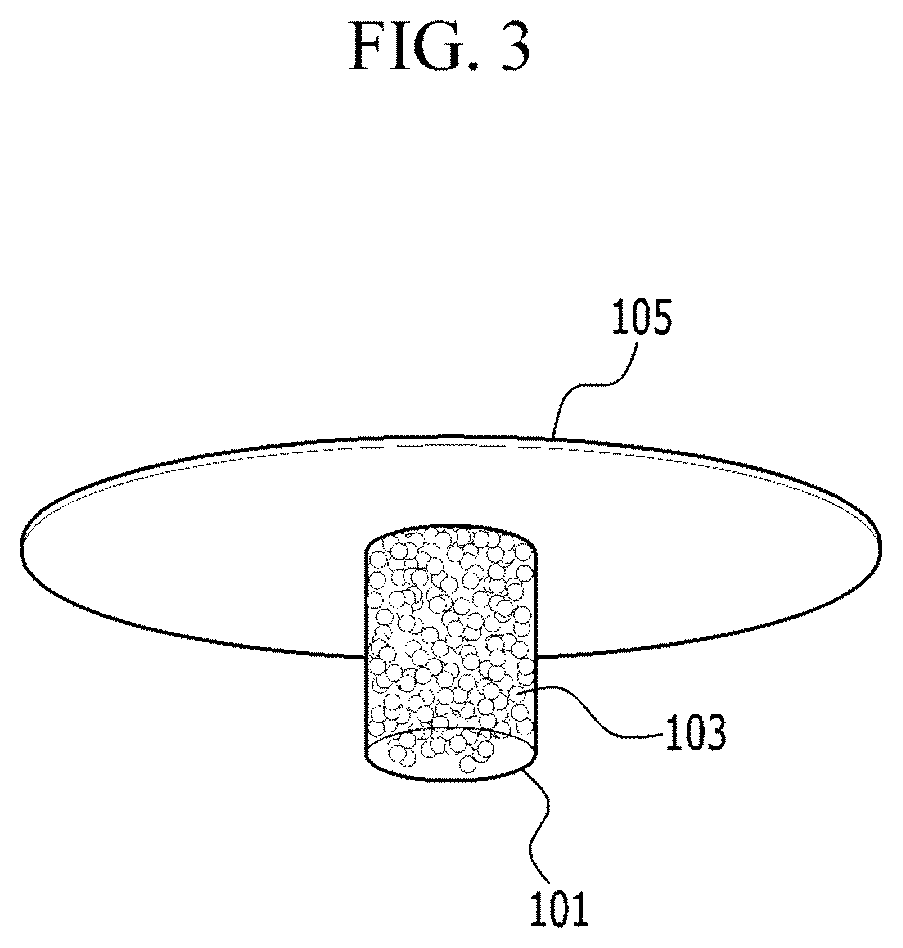

TECHNICAL FIELD[0001]The present disclosure relates to a catalyst production method and a production apparatus for a fuel cell. More specifically, the present disclosure relates to a method and apparatus for producing a catalyst for a fuel cell using a fluidized bed reactor.PRIOR ART[0002]In addition to the electrode material of the fuel cell, the catalyst is also continuously improving performance, and the proposed catalyst includes carbon black as a support and platinum spots are incorporated therein. Platinum is a very expensive metal and uses as little as possible but maximizes the surface area. Therefore, it is desirable to have a form where the platinum spot is small, uniform and active even with the same amount of platinum. Conventionally, such a catalyst is manufactured by a wet process as an example.[0003]In conventional wet processes, the mass production process takes almost a week. In addition, due to the use of chemicals, manufacturing costs are high due to environmental...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J8/38B01J23/42B01J31/12B01J8/40

CPCB01J21/18B01J2208/00539B01J8/40B01J23/42B01J8/388B01J31/122C23C16/18C23C16/08C23C16/4418C23C16/45525C23C16/455H01M4/921H01M4/926B01J8/32B01J2208/00752B01J2208/00548B01J2208/00017B01J2219/30207B01J2219/30433B01J2219/185B01J2219/1943B01J2219/1946B01J3/006B01J8/24H01M4/9083Y02E60/50C23C16/442C23C16/45534C23C16/45529C23C16/45555C23C16/45553C23C16/4408C23C16/4407C23C16/4417C23C16/14B01J37/02B01J23/40B01J23/48B01J23/74B01J23/72B01J37/086B01J37/349H01M4/94

Inventor HONG, WOONG PYOKWON, SE HUNLEE, WOO JAE

Owner HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com