Hydrogen selenide preparation device and method

A preparation device, hydrogen selenide technology, applied in the direction of binary selenium/tellurium compounds, etc., can solve the problems of low reaction efficiency, low reaction efficiency, and affecting the stability of the reaction process, and achieve the effect of increasing the reaction temperature and reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

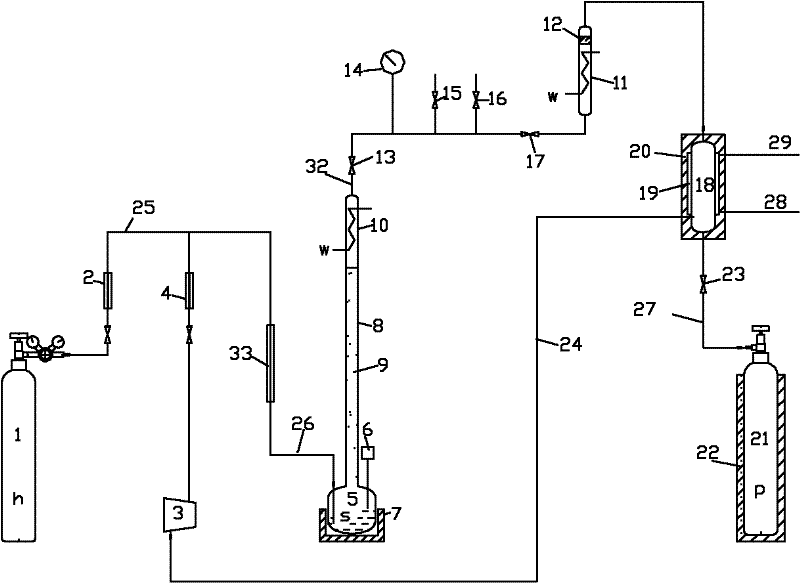

[0049] [Example 1] A kind of process of hydrogen selenide preparation device and method of the present invention, with figure 1 As an example to specify:

[0050] A hydrogen selenide preparation device and method is a preparation device and method for directly synthesizing hydrogen selenide from hydrogen and selenium, comprising a selenium liquefaction vaporizer, a synthesis reactor, a selenium condensation separator and a hydrogen selenide condensation separator. The selenium liquefaction vaporizer 5 is connected with a hydrogen gas inlet pipeline 26, and the outlet of the selenium liquefaction vaporizer is directly connected with the inlet of the synthesis reactor. The synthesis reactor is in the form of a packed tower reactor 8, and the filler 9 is stacked in the packed tower 8 to form a packed bed. , the outlet of the packed tower synthesis reactor is also directly connected with the entrance of the selenium condensation separator 10, and the selenium condensate reflux por...

Embodiment 2

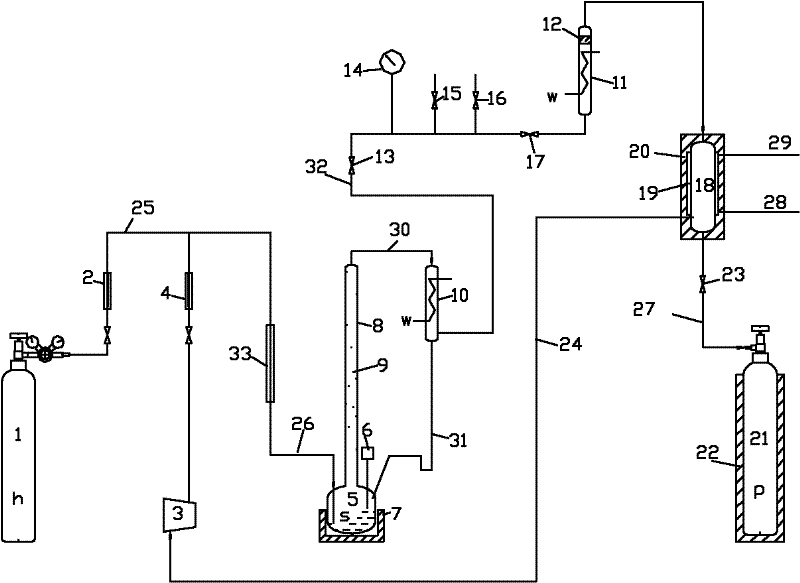

[0077] A kind of technological process of hydrogen selenide preparation device and method of the present invention, with figure 2 As an example to specify:

[0078] A hydrogen selenide preparation device for directly synthesizing hydrogen selenide from hydrogen and selenium, comprising a selenium liquefaction vaporizer 5 , a synthesis reactor 8 , a selenium condensation separator 10 and a hydrogen selenide condensation separator 18 . The selenium liquefaction vaporizer is connected with a hydrogen gas intake pipeline 25, and the hydrogen gas intake pipeline is attached with an external heater 33. The selenium liquefaction vaporizer is used as an initial synthesis reactor for hydrogen and selenium to synthesize hydrogen selenide, and the selenium liquefaction vaporizer 5 is connected to the synthesis reactor 8 , the synthesis reactor is in the form of a packed tower reactor, which contains a packed bed 9, the outlet of the selenium liquefaction vaporizer is directly connected ...

Embodiment 3

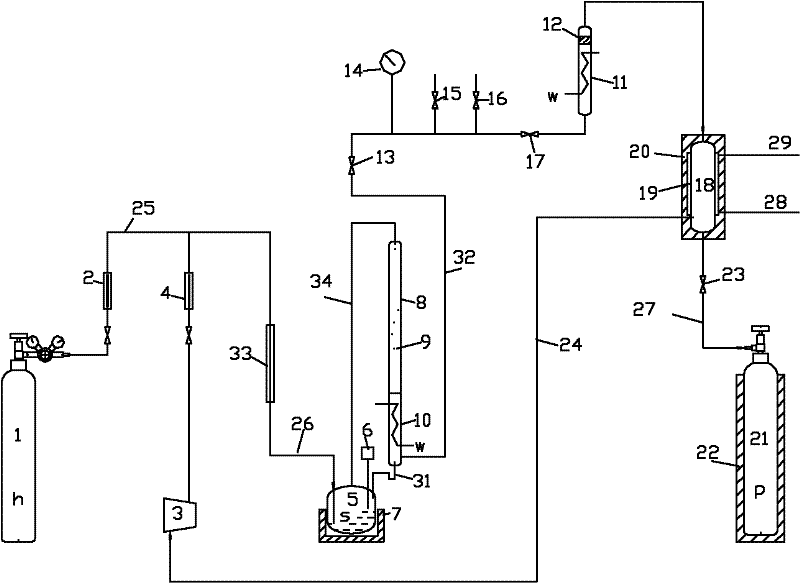

[0086] A hydrogen selenide preparation device and method for directly synthesizing hydrogen selenide from hydrogen and selenium, with image 3 Take as an example to specify.

[0087] It contains a selenium liquefaction vaporizer 5 , a synthesis reactor 8 , a selenium condensation separator 11 and a hydrogen selenide condensation separator 18 , and the selenium liquefaction vaporizer is connected with a hydrogen inlet pipeline 26 . The outlet of the selenium liquefaction vaporizer 5 is connected with the inlet of the synthesis reactor 8 through the pipeline 34, the synthesis reactor is a packed tower reactor, and the outlet of the packed tower synthesis reactor 8 is directly connected with the inlet of the selenium condensation separator 10. One outlet of the selenium condensation separator 10 is located at the lower end of the selenium condensation separator, and this outlet is the return channel 31 of the selenium condensate, and the pipeline 31 is communicated with the selen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com