Coated chewing gum comprising an active substance having local activity

a technology of active substances and chewing gum, which is applied in the direction of chewing gum, sweetmeats, confectionery, etc., can solve the problems of chewing gum losing active substances to the surroundings, chewing gum losing moisture and getting harder, and gradually losing flavour, etc., to achieve fast onset of effect, reduce undesirable taste, and be more resistant to decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

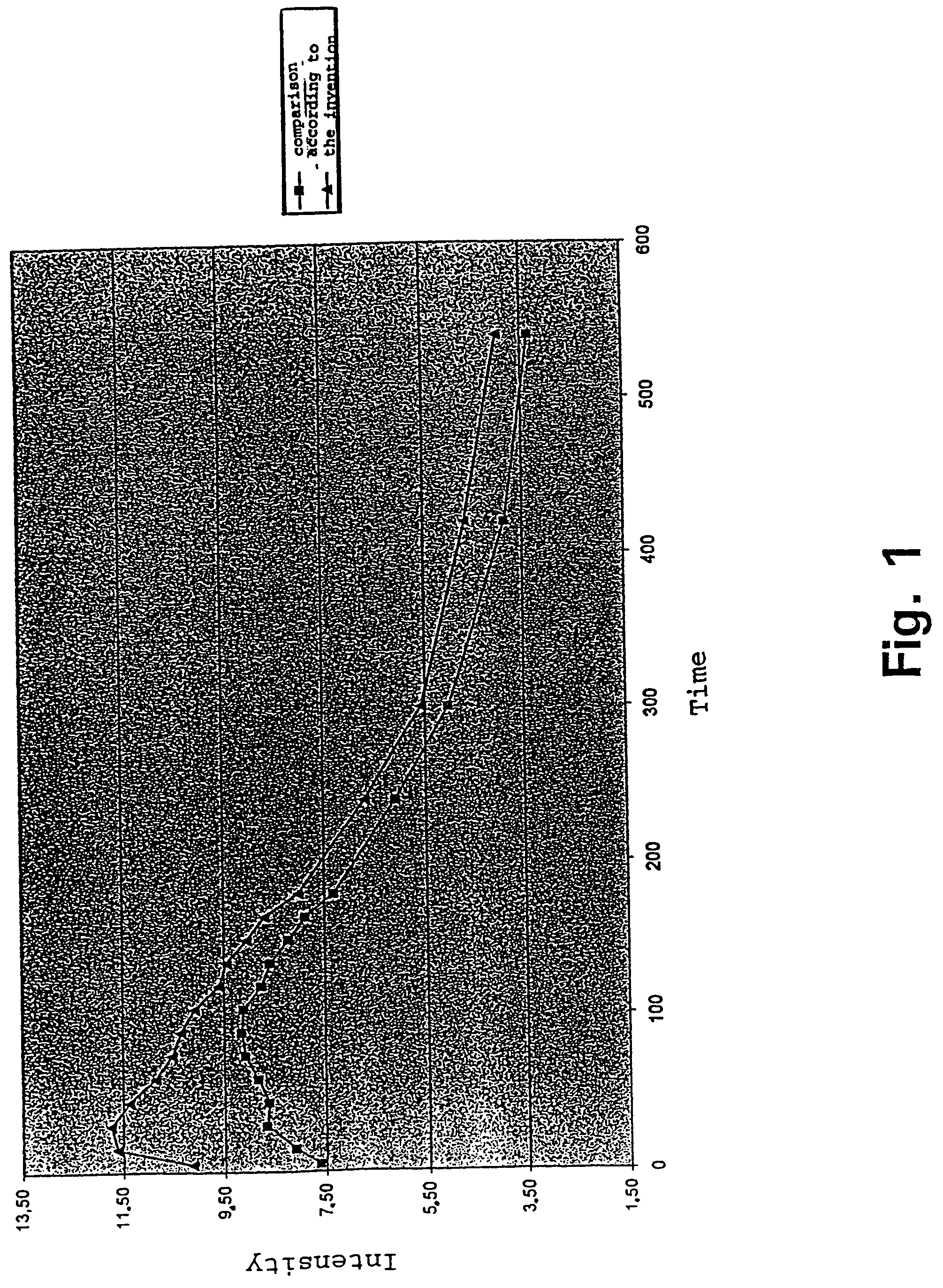

Image

Examples

example 1

[0106] Coating in DRIA 1200 equipment of 50 kg of sugar-containing chewing gum cores with peppermint taste.

SaccharoseAmount ofSmoothingDryingsuspensiondosageout timetimeDrumDosage No.gsec.sec.rpm 1-25004530011 3-12900454001113600 + 222*604001114-1570003801116-21100003801122-341000304101135-38600260280113950015002901140wax powder 50 g3003008

*A 600 g saccharose suspension + 222 g peppermint oil.

example 2

[0107] Coating in DRIA 1200 equipment of 50 kg of sugar-free chewing gum cores with peppermint taste.

SorbitolAmount ofSmoothingDryingsuspensiondosageout timetimeDrumDosage No.gsec.sec.rpm 1-2400025011 3-57001530011 6700 + 200*6030011 7-16700453001117-241000453501125-267002402401127wax powder 50 g3603608

*A 700 g sorbitol suspension + 200 g peppermint oil.

example 3

[0108] Coating in tilted kettles of 2 kg sugar-free chewing gum cores with a mixture of liquid eucalyptus, menthol, and anethol.

SorbitolAmount ofSmoothingDryingNumber ofsuspensiondosageout timetimerevolutionsDosage No.gsec.sec.rpm 12012012050 2209012050 320606050 4-93030905010-1130301205012 20*6012050139.9 liquid10050flavour14204005015-162051205017-2230601205023-2640301205027-3330601205034-35201202405036wax powder 2 g30030050

*A sorbitol suspension with 3.5% aspartame and 7.5% acesulfame K.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com