Formula and processing technology of cold cake

A processing technology and cake technology, applied in the fields of refrigerated storage, baked goods, food science, etc., can solve the problems of unbalanced nutritional supplementation, tooth irritation, low taste temperature, etc., to reduce the greasy feeling, the poor taste, and the irritation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

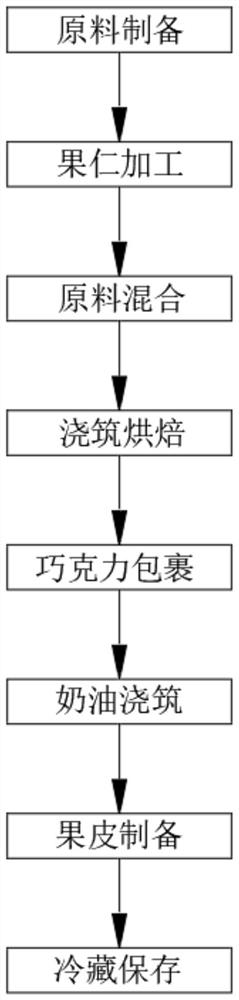

Image

Examples

Embodiment 1

[0029] Embodiment 1: A kind of cold food cake formula, formula is by weight 30 parts of eggs, 100 parts of flour, 1 part of edible oil, 5 parts of baking powder, 10 parts of honey, 20 parts of cream, 10 parts of chocolate, nut block 30. Composed of 20 parts of milk powder and water.

[0030] A processing technology for cold cake preparation, the processing technology comprises the following steps:

[0031] S1: Raw material preparation, separate the egg white and egg yolk, stir the egg yolk in one direction clockwise until smooth and even paste, add baking powder to the egg white and beat it quickly with an egg beater, add honey in three times during the beating process;

[0032] S2: Nut processing, the milk powder is stirred and dissolved with water at a ratio of 1:3, the nut pieces are soaked in milk for 20 minutes, then heated and boiled, fully broken and stirred by a crusher, and the milk juice is obtained after filtering through a filter;

[0033] S3: Mix the raw material...

Embodiment 2

[0040] Embodiment 2: a kind of cold food cake formula, formula is by weight 35 parts of eggs, 115 parts of flour, 2 parts of cooking oil, 7 parts of baking powder, 12 parts of honey, 25 parts of cream, 15 parts of chocolate, nut piece 35. Composed of 22 parts of milk powder and water.

[0041] A processing technology for cold cake preparation, the processing technology comprises the following steps:

[0042] S1: Raw material preparation, separate the egg white and egg yolk, stir the egg yolk in one direction clockwise until smooth and even paste, add baking powder to the egg white and beat it quickly with an egg beater, add honey in three times during the beating process;

[0043] S2: Nut processing, the milk powder is stirred and dissolved with water at a ratio of 1:5, the nut pieces are soaked in milk for 20 minutes, then heated and boiled, fully broken and stirred by a crusher, and the milk juice is obtained after filtering through a filter;

[0044] S3: Mix the raw materi...

Embodiment 3

[0051] Embodiment 3: a kind of cold food cake formula, formula is by weight 40 parts of eggs, 130 parts of flour, 3 parts of cooking oil, 10 parts of baking powder, 15 parts of honey, 30 parts of cream, 20 parts of chocolate, nut block 40. Composed of 25 parts of milk powder and water.

[0052] A processing technology for cold cake preparation, the processing technology comprises the following steps:

[0053] S1: Raw material preparation, separate the egg white and egg yolk, stir the egg yolk in one direction clockwise until smooth and even paste, add baking powder to the egg white and beat it quickly with an egg beater, add honey in three times during the beating process;

[0054] S2: Nut processing, the milk powder is mixed with water at a ratio of 1:6 to dissolve, the nut pieces are soaked in milk for 20 minutes, then heated and boiled, fully broken through the crusher and stirred, filtered through a filter to obtain milk juice;

[0055] S3: Mix the raw materials, add the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com